Metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer and preparation method and application thereof

A metal bipolar plate, protective coating technology, applied in the direction of metal material coating process, coating, circuit, etc., can solve the problems of application limitation, poor corrosion resistance, poor corrosion resistance and electrical conductivity, etc., to improve the film The effect of base bond strength, excellent corrosion resistance and protection performance, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] One aspect of the embodiments of the present invention provides a method for preparing a highly conductive and corrosion-resistant protective coating of a metal bipolar plate, which is characterized in that it includes:

[0026] Provide metal bipolar plates;

[0027] Using a chromium target as a target material, using high-power pulsed magnetron sputtering technology to deposit a chromium transition layer on the surface of the metal bipolar plate;

[0028] And, using a graphite target as a target material, using DC magnetron sputtering technology to deposit an amorphous carbon layer on the surface of the chromium transition layer to obtain a metal bipolar plate highly conductive and corrosion-resistant protective coating;

[0029] Wherein, the process conditions adopted by the DC magnetron sputtering technology include: the central magnetic field intensity of the sputtering source is 40-60 mT, the fringe magnetic field intensity is 10-20 mT, and the power supply power is 0.8-1.0...

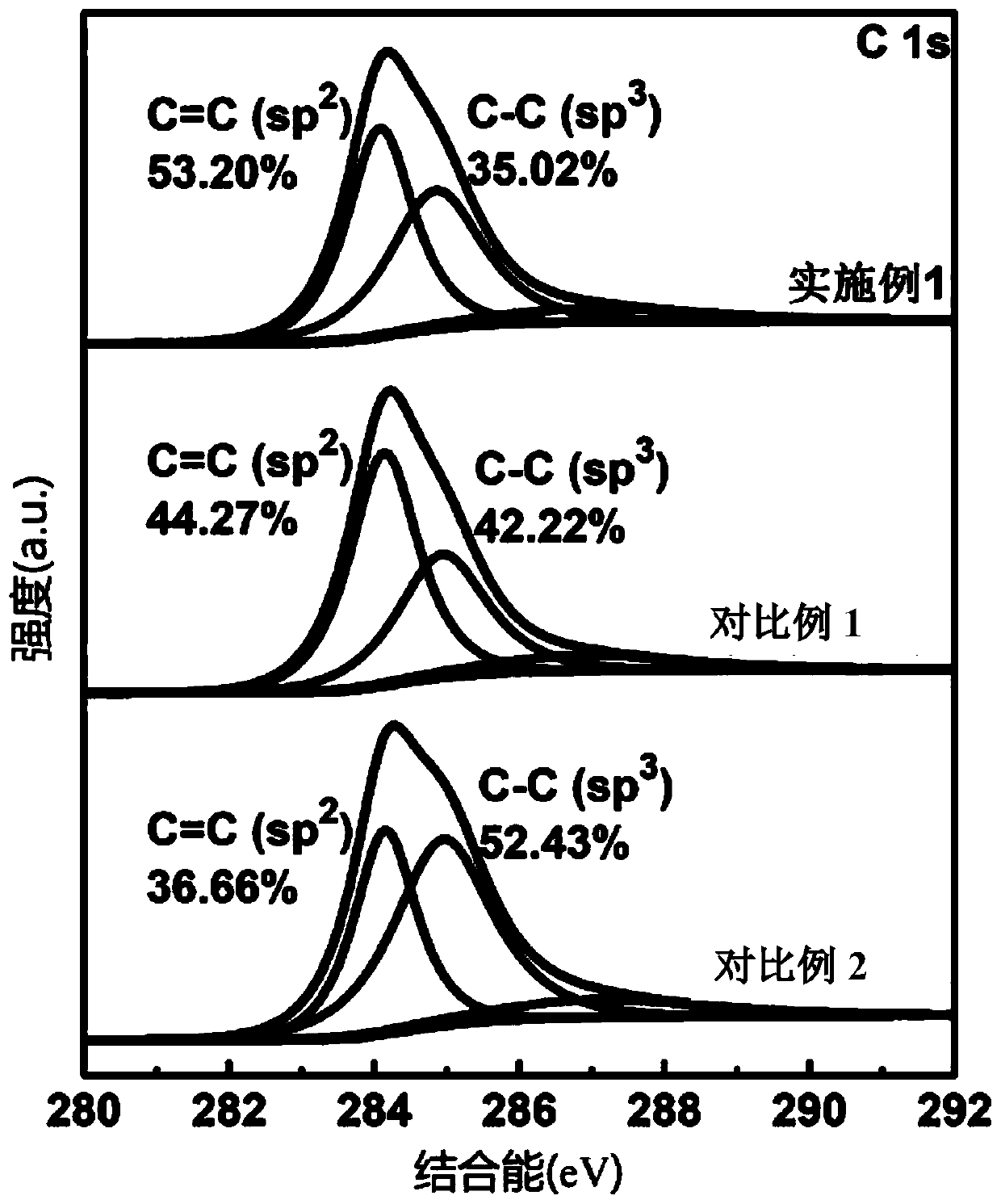

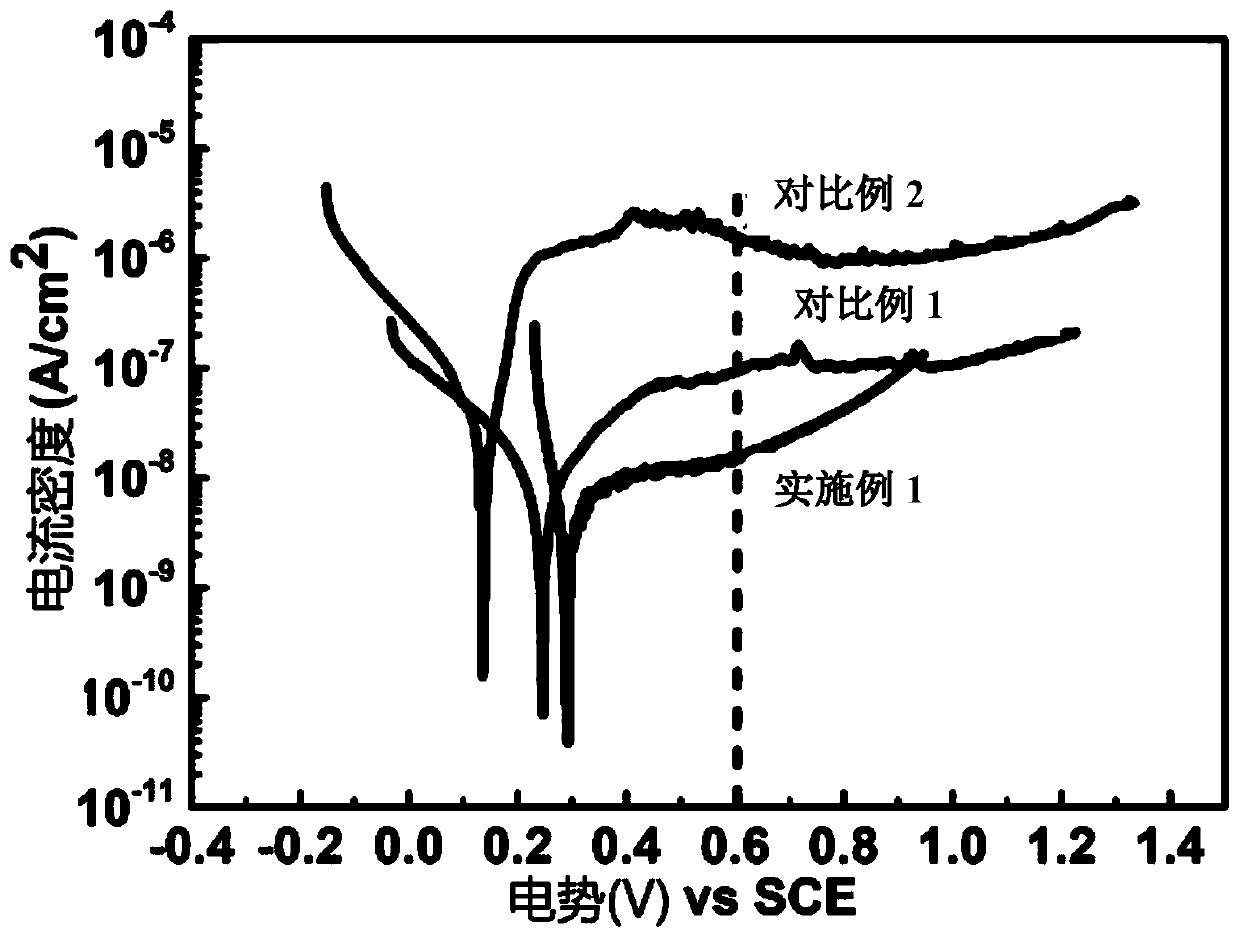

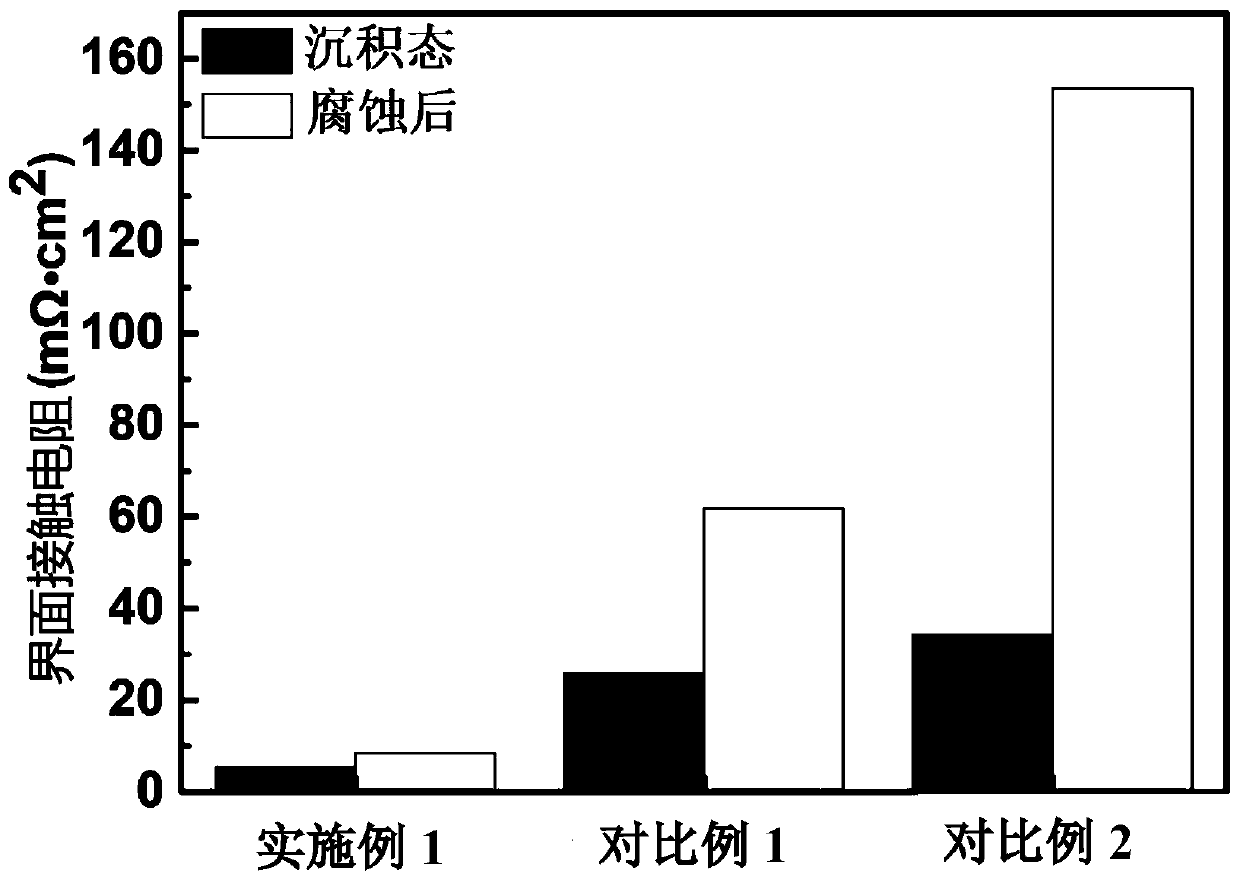

Embodiment 1

[0045] In this embodiment, the preparation method of the highly conductive and corrosion-resistant protective coating of the metal bipolar plate is as follows:

[0046] S1. The base material is made of 316L stainless steel, the stainless steel bipolar plate is ultrasonically cleaned, and it is dried and placed in the vacuum chamber, fixed on the workpiece holder, and vacuumed to 2.0×10 -5 Below Torr, then under the condition of argon flow rate of 100sccm and bias voltage of -450V, turn on the ion source, adjust the output voltage to 1200V, and use argon plasma to etch the surface of the stainless steel bipolar plate for 60min;

[0047] S2. Pour Ar gas into the cavity, maintain the cavity pressure at 1.7mTorr, turn on the high-power pulse power supply connected to the chromium sputtering target, set the power supply frequency to 500Hz, pulse width to 100μs, pulse voltage to 1000V, and power to 3KW, substrate bias voltage is -50V, chromium transition layer is deposited, thickness is 1...

Embodiment 2

[0050] In this embodiment, the preparation method of the highly conductive and corrosion-resistant protective coating of the metal bipolar plate is as follows:

[0051] S1. The base material is made of 316L stainless steel, the stainless steel bipolar plate is ultrasonically cleaned, and it is dried and placed in the vacuum chamber, fixed on the workpiece holder, and vacuumed to 2.0×10 -5 Below Torr, then under the condition of argon flow rate of 40sccm and bias voltage of -150V, turn on the ion source, adjust the output voltage to 1200V, and use argon plasma to etch the surface of the stainless steel bipolar plate for 30min;

[0052] S2. Pour Ar gas into the cavity, maintain the cavity pressure at 2mTorr, turn on the high-power pulse power supply connected to the chromium sputtering target, set the power supply frequency to 600Hz, pulse width to 100μs, pulse voltage to 800V, and power to 4KW , The substrate bias voltage is -80V, and the chromium transition layer is deposited with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com