Method for reinforcing zinc oxide thin membrane luminescence

A technology of zinc oxide film and reaction chamber, which is applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve the problems of unrealized and light quenching of enhanced zinc oxide film, and achieve the realization of defects Effects of luminous quenching, enhanced luminous intensity, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take the following steps: put the quartz substrate with zinc oxide film grown in the reaction chamber of the DC magnetron sputtering device, and the vacuum degree of the reaction chamber is evacuated to 5×10 -3 Pa, heat the substrate so that the temperature of the substrate is 200°C, then pass in argon as a protective gas, control the gas flow at 30sccm, adjust the pressure in the reaction chamber to 10Pa, and use silver with a purity of 99.99% as the target for sputtering deposition. The sputtering current and power were controlled at 0.2A and 60W, respectively, and the sputtering time was 20s.

Embodiment 2

[0019] The steps are the same as in Example 1, except that the sputtering time is 60s.

Embodiment 3

[0021] The steps are the same as in Example 1, except that the sputtering time is 85s.

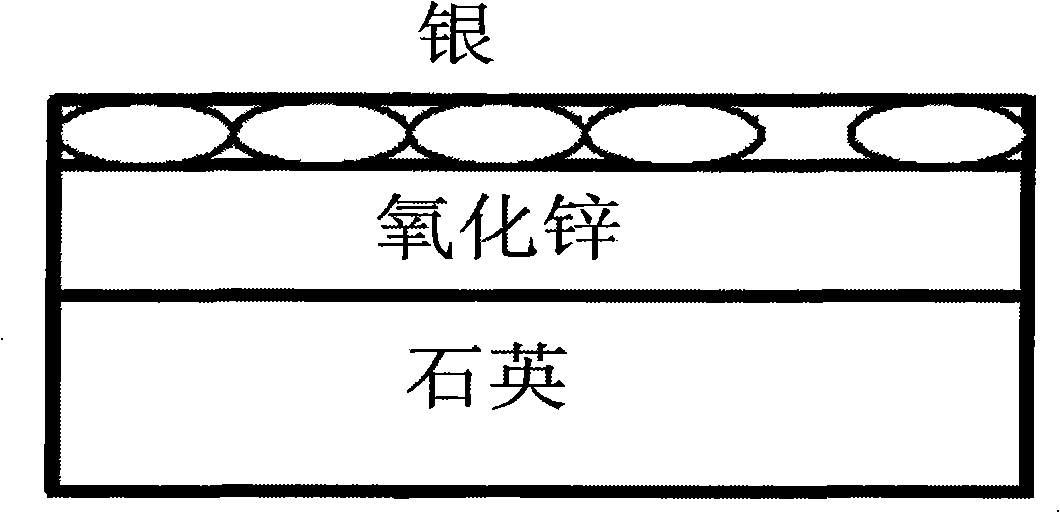

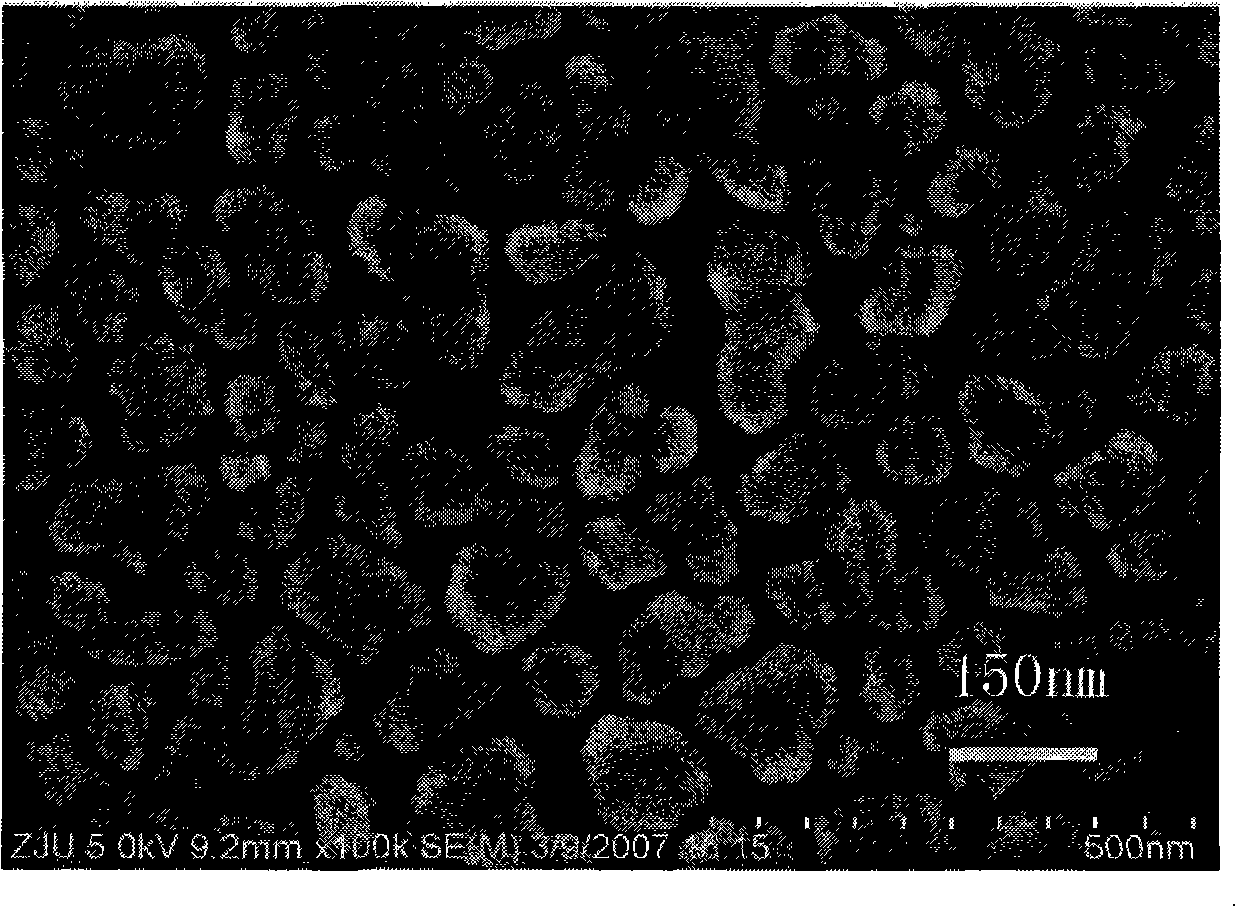

[0022] The silver nanoparticles deposited on the surface of the zinc oxide film in the present invention are oblate (such as figure 2 shown).

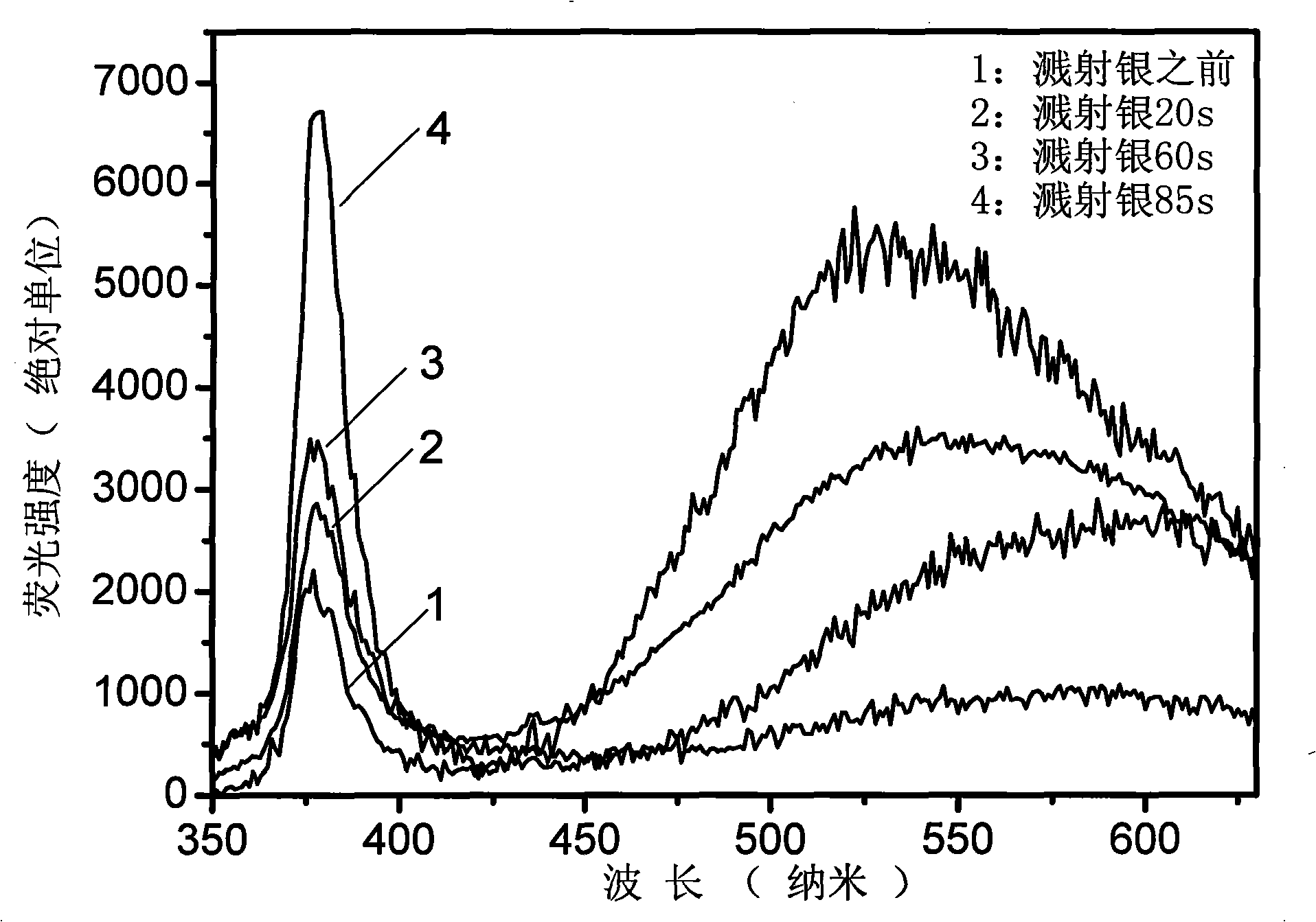

[0023] image 3 The fluorescence spectra of ZnO thin films before and after sputtering silver nanoparticles for different times are given. It can be seen from the figure that when the sputtering time is in the range of 20s-85s, the interband luminescence of the zinc oxide thin film can be enhanced by up to 3 times, while the defect luminescence has been quenched to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com