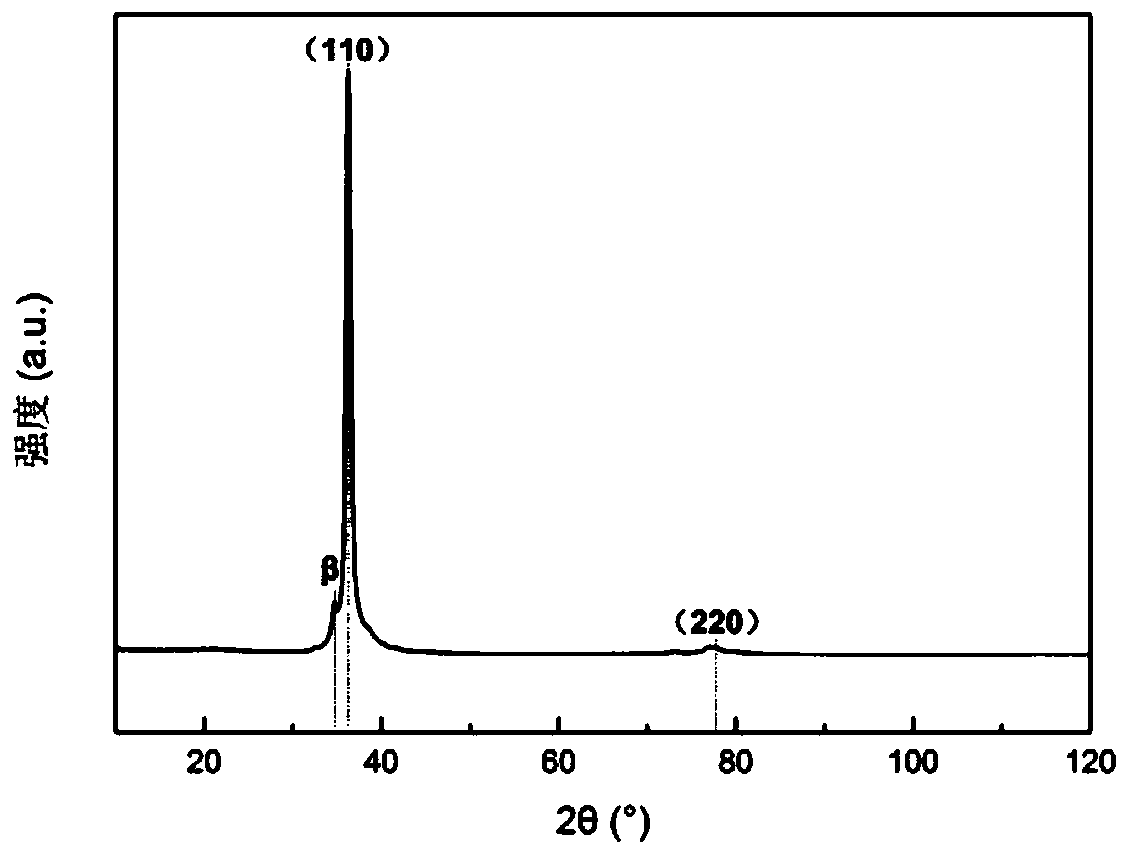

Preparation method of high-hardness quaternary infusible high-entropy alloy film

A high-entropy alloy, high-hardness technology, applied in metal material coating process, ion implantation plating, coating and other directions, to achieve the effect of precise control of thin thickness, good density and uniformity, and wide applicability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a high-hardness quaternary refractory high-entropy alloy film provided by the invention comprises the following steps:

[0035] The single-sided polished (100) crystal-oriented P-type Si sheet substrate was ultrasonically cleaned in acetone, alcohol, and deionized water at a frequency of 60 Hz for 15 minutes to remove pollutants on the surface; the cleaned Si sheet substrate was cleaned with Dry it with a hair dryer along the direction of the polished surface so that no deionized water stains are left on the surface; pass the Si wafer clamped on the sample plate into the sample chamber for backsplash for 15 minutes, and use a radio frequency power supply during backsplash. Vacuum the sampling chamber to 1×10 -3 Pa, the Ar flow rate is 30sccm, the power is 70W, the backsplash pressure is 2.0Pa, and the backsplash time is 15min. The purpose is to further clean the Si sheet substrate and improve its surface quality during sputtering; transfer the sa...

Embodiment 2

[0037] A method for preparing a high-hardness quaternary refractory high-entropy alloy film provided by the invention comprises the following steps:

[0038] The single-sided polished (100) crystal-oriented P-type Si sheet substrate was ultrasonically cleaned in acetone, alcohol, and deionized water at a frequency of 60 Hz for 15 minutes to remove pollutants on the surface; the cleaned Si sheet substrate was cleaned with Dry it with a hair dryer along the direction of the polished surface so that no deionized water stains are left on the surface; pass the Si wafer clamped on the sample plate into the sample chamber for backsplash for 15 minutes, and use a radio frequency power supply during backsplash. Vacuum the sampling chamber to 2.0×10 -3Pa, the Ar flow rate is 30sccm, the power is 80W, the backsplash pressure is 2.0Pa, and the backsplash time is 10min. The purpose is to further clean the Si sheet substrate and improve its surface quality during sputtering; transfer the s...

Embodiment 3

[0040] A method for preparing a high-hardness quaternary refractory high-entropy alloy film provided by the invention comprises the following steps:

[0041] The single-sided polished (100) crystal-oriented P-type Si sheet substrate was ultrasonically cleaned in acetone, alcohol, and deionized water at a frequency of 70 Hz for 20 minutes to remove pollutants on the surface; the cleaned Si sheet substrate was cleaned with Dry it with a hair dryer along the direction of the polished surface so that no deionized water stains are left on the surface; pass the Si wafer clamped on the sample plate into the sample chamber for backsplash for 15 minutes, and use a radio frequency power supply during backsplash. Vacuum the sampling chamber to 4.0×10 -3 Pa, the Ar flow rate is 30sccm, the power is 70W, the backsplash pressure is 2.0Pa, and the backsplash time is 15min. The purpose is to further clean the Si sheet substrate and improve its surface quality during sputtering; transfer the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com