Method for manufacturing low layer number graphene film on silicon carbide substrate

A silicon carbide substrate, graphene film technology, applied in the direction of graphene, nano-carbon, etc., to achieve the effect of inhibiting sublimation and stable and controllable effective carbonization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

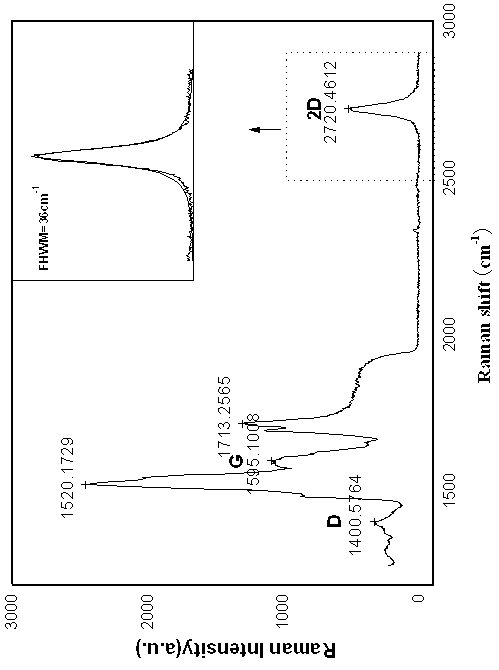

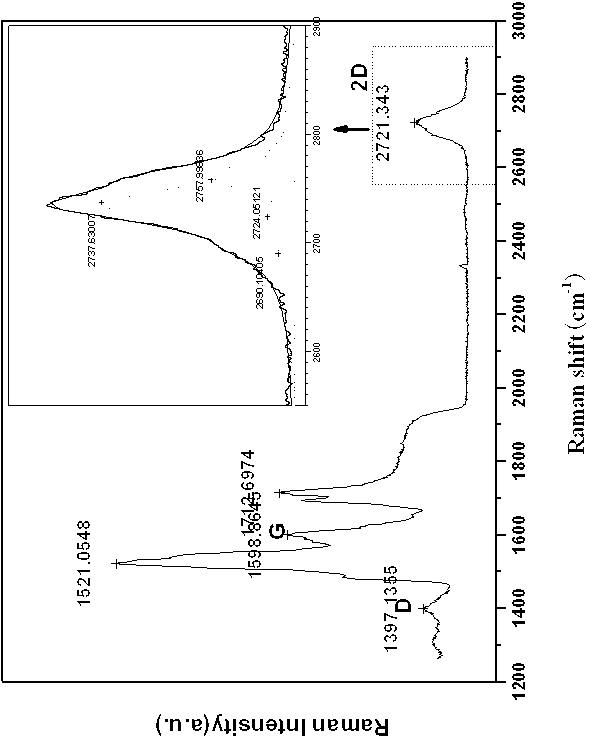

[0025] The provided method for growing a low-layer graphene film on a high-purity semi-insulating silicon carbide substrate with a positive crystal orientation (0001) silicon surface comprises the following steps:

[0026] 1) Select a high-purity semi-insulating silicon carbide substrate with a positive crystal orientation (0001) silicon surface, and place the substrate on a graphite base coated with tantalum carbide;

[0027] 2) The temperature of the system is raised to 1570°C, the pressure of the reaction chamber is set to 100mbar, and the surface of the substrate is treated online under the atmosphere of hydrogen flow rate of 80L / min and argon flow rate of 3L / min to remove surface damage and form micro steps, the processing time is 30 minutes;

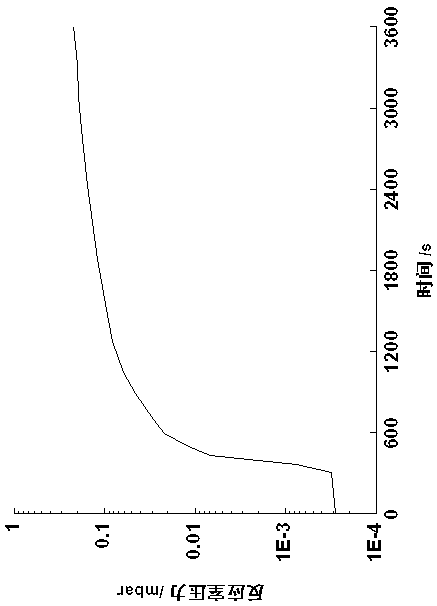

[0028] 3) Reduce the temperature of the reaction chamber to 1200°C, and gradually reduce the flow of hydrogen from 80L / min to 0L / min, keep the flow of argon at 3L / min, set the pressure of the reaction chamber to 100mbar, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com