Process for annealing cold rolled pure titanium and titanium alloy roll by continuous bright annealing furnace

A titanium alloy coil and annealing furnace technology, applied in furnaces, heat treatment furnaces, manufacturing tools, etc., can solve the problem of high annealing temperature, and achieve the effects of fast annealing speed, accurate temperature control and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

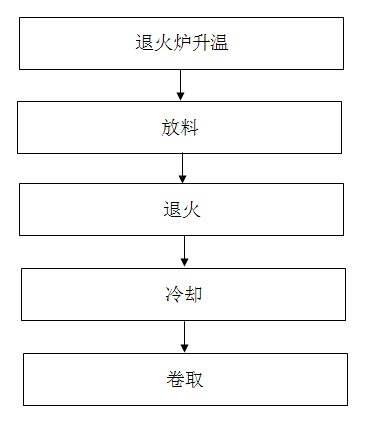

[0014] Depend on figure 1 It is known that a process for annealing cold-rolled pure titanium and titanium alloy coils in a continuous bright annealing furnace includes the following steps: 1) raising the temperature of the annealing furnace to 600°C, and heating the annealing furnace at 35m 3 The flow rate of / h is fed into argon to replace the air in the furnace.

[0015] 2) Put the cold-rolled TA1 titanium coil on the uncoiler of the annealing furnace, and weld the coil head of the pure titanium or titanium alloy coil and the tail of the leader.

[0016] 3) Pure titanium and titanium alloy coils first pass through the cleaning unit, and after drying, pass through the continuous bright annealing furnace at a speed of 4m / min.

[0017] 4) After the annealed pure titanium and titanium alloy coils are cooled, they are recoiled into coils on the coiler at the exit.

Embodiment 2

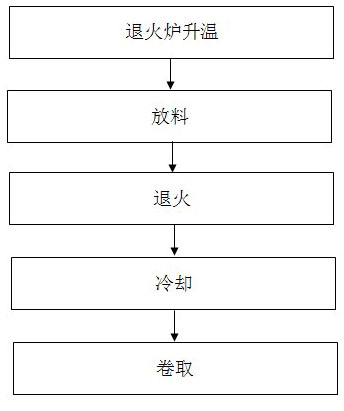

[0019] A process for annealing cold-rolled pure titanium and titanium alloy coils in a continuous bright annealing furnace, comprising the following steps:

[0020] 1) Raise the temperature of the annealing furnace to 850°C, and 3 The flow rate of / h is fed into argon to replace the air in the furnace.

[0021] 2) Put the cold-rolled TA15 titanium coil on the uncoiler of the annealing furnace, and weld the head of the titanium coil and the tail of the leader.

[0022] 3) The titanium coil first passes through the cleaning unit, and after drying, passes through the continuous bright annealing furnace at a speed of 3m / min.

[0023] 4) After the annealed titanium coil is cooled, it is recoiled into a coil on the coiler at the exit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com