TIG welding wire manufacturing method capable of improving surface cleanliness

A technology for surface cleaning and manufacturing methods, applied in cleaning methods and tools, cleaning methods using liquids, manufacturing tools, etc., can solve problems such as weld slag inclusions, pores, unclean welding wire surface, nickel-based alloy defects, etc., to achieve Ease of quality, good consistency of welding wire quality, and uniform cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Processing and manufacturing ER308L stainless steel straight TIGφ2.4mm welding wire, the specific steps are as follows:

[0034] (1) Incoming material, cold-drawn hard state, incoming material specification φ2.5mm;

[0035] (2) Bright annealing, the incoming material is annealed on-line through the protective atmosphere of ammonia decomposition gas, the annealing temperature is 1050°C, and the annealing line speed is 10m / min;

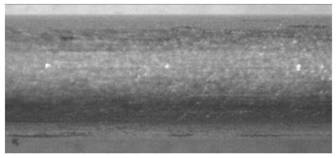

[0036] (3) Electrolytic cleaning, after annealing, the wire is electrolytically cleaned, the medium used for electrolytic cleaning is 10% dilute sulfuric acid, and the electrolytic cleaning speed is 80 m / min; after electrolysis, it is rinsed with online water and dried with a wind brush;

[0037] (4) Ultrasonic cleaning, the silk after electrolytic cleaning is ultrasonically cleaned, the medium used is tap water, the ultrasonic frequency is 60KHZ, and the ultrasonic time is 5s;

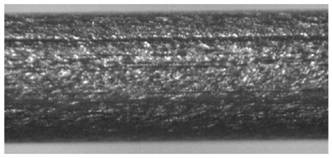

[0038] (5) Eye mold polishing: Pass the cleaned semi-finished wire...

Embodiment 2

[0041] Processing and manufacturing ERNiCr-3 nickel-based alloy coiled TIGφ2.0mm welding wire, the specific steps are as follows:

[0042] (1) Incoming material, cold-drawn hard state, incoming material specification φ2.1mm;

[0043] (2) Bright annealing, the incoming material is subjected to online solution annealing in the protective atmosphere of ammonia decomposition gas, the annealing temperature is 1080°C, and the annealing line speed is 10m / min;

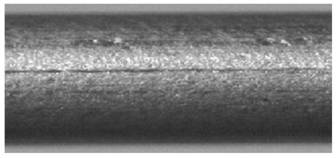

[0044] (3) Electrolytic cleaning, after annealing, the wire is electrolytically cleaned, the medium used for electrolytic cleaning is 10% dilute sulfuric acid, and the electrolytic cleaning speed is 80 m / min; after electrolysis, it is rinsed with online water and dried with a wind brush;

[0045] (4) Ultrasonic cleaning, the silk after electrolytic cleaning is ultrasonically cleaned, the medium used is tap water, the ultrasonic frequency is 60KHZ, and the ultrasonic time is 5s;

[0046] (5) Eye mold polishing: pass the cleane...

Embodiment 3

[0053] For ER308L stainless steel straight strips with incoming specifications of φ2.5mm, the annealing temperature is 1050°C and the relationship between the annealing wire and the welding wire strength is studied. The results are as follows Figure 5 shown by Figure 5 It can be seen that when the annealing speed is 10-12m / min, the strength of the welding wire after annealing is 900MPa-1000MPa

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com