Multi-passage fast in-situ annealing method for biaxial textured nickel-tungsten metal base band

A metal-based tape and multi-channel technology, applied in the field of high-temperature superconducting tape preparation, can solve the problem that the speed of the tape is difficult to reach the kilometer-level long tape, and achieve the effects of accelerated annealing speed, high stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

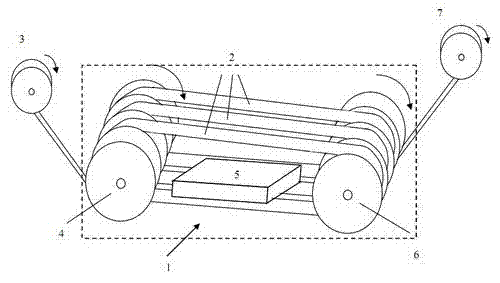

[0042] This embodiment provides a multi-channel rapid in-situ annealing method for a biaxially textured nickel-tungsten metal substrate, which includes the following steps:

[0043] Step 1, winding one end of the biaxially textured nickel-tungsten metal base tape on the first reel;

[0044] Step 2, pulling the biaxial textured nickel-tungsten metal base tape to wind through the two rollers of the multi-channel transmission device;

[0045] Step 3, fixing the other end of the biaxially textured nickel-tungsten metal substrate on the second reel;

[0046] Step 4. Close the vacuum door of the coating system and evacuate to 1×10 -7 Torr;

[0047] Step 5, start the heater, and heat up to the required annealing temperature of 700 o C;

[0048] Step 6. Pass the argon-hydrogen mixed gas into the coating system, and control the total pressure at the desired pressure value; in the argon-hydrogen mixed gas, the volume ratio of Ar is 85%, and the H 2 The volume ratio of hydrogen is 1...

Embodiment 2

[0052] This embodiment provides a multi-channel rapid in-situ annealing method for a biaxially textured nickel-tungsten metal substrate, which includes the following steps:

[0053] Step 1, winding one end of the biaxially textured nickel-tungsten metal base tape on the first reel;

[0054] Step 2, pulling the biaxial textured nickel-tungsten metal base tape to wind through the two rollers of the multi-channel transmission device;

[0055] Step 3, fixing the other end of the biaxially textured nickel-tungsten metal substrate on the second reel;

[0056] Step 4. Close the vacuum door of the coating system and evacuate to 1×10 -6 Torr;

[0057] Step 5, start the heater, and heat up to the required annealing temperature of 900 o C;

[0058] Step 6. Pass the argon-hydrogen mixed gas into the coating system, and control the total pressure at the desired pressure value; in the argon-hydrogen mixed gas, the volume ratio of Ar is 97%, and the H 2 The volume ratio of hydrogen is ...

Embodiment 3

[0062] This embodiment provides a multi-channel rapid in-situ annealing method for a biaxially textured nickel-tungsten metal substrate, which includes the following steps:

[0063] Step 1, winding one end of the biaxially textured nickel-tungsten metal base tape on the first reel;

[0064] Step 2, pulling the biaxial textured nickel-tungsten metal base tape to wind through the two rollers of the multi-channel transmission device;

[0065] Step 3, fixing the other end of the biaxially textured nickel-tungsten metal substrate on the second reel;

[0066] Step 4. Close the vacuum door of the coating system and evacuate to 5×10 -7 Torr;

[0067] Step 5, start the heater, and heat up to the required annealing temperature of 800 o C;

[0068] Step 6. Pass the argon-hydrogen mixed gas into the coating system, and control the total pressure at the desired pressure value; in the argon-hydrogen mixed gas, the volume ratio of Ar is 90%, and the H 2 The volume ratio of hydrogen is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com