Method of forming highly conformal amorphous carbon layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

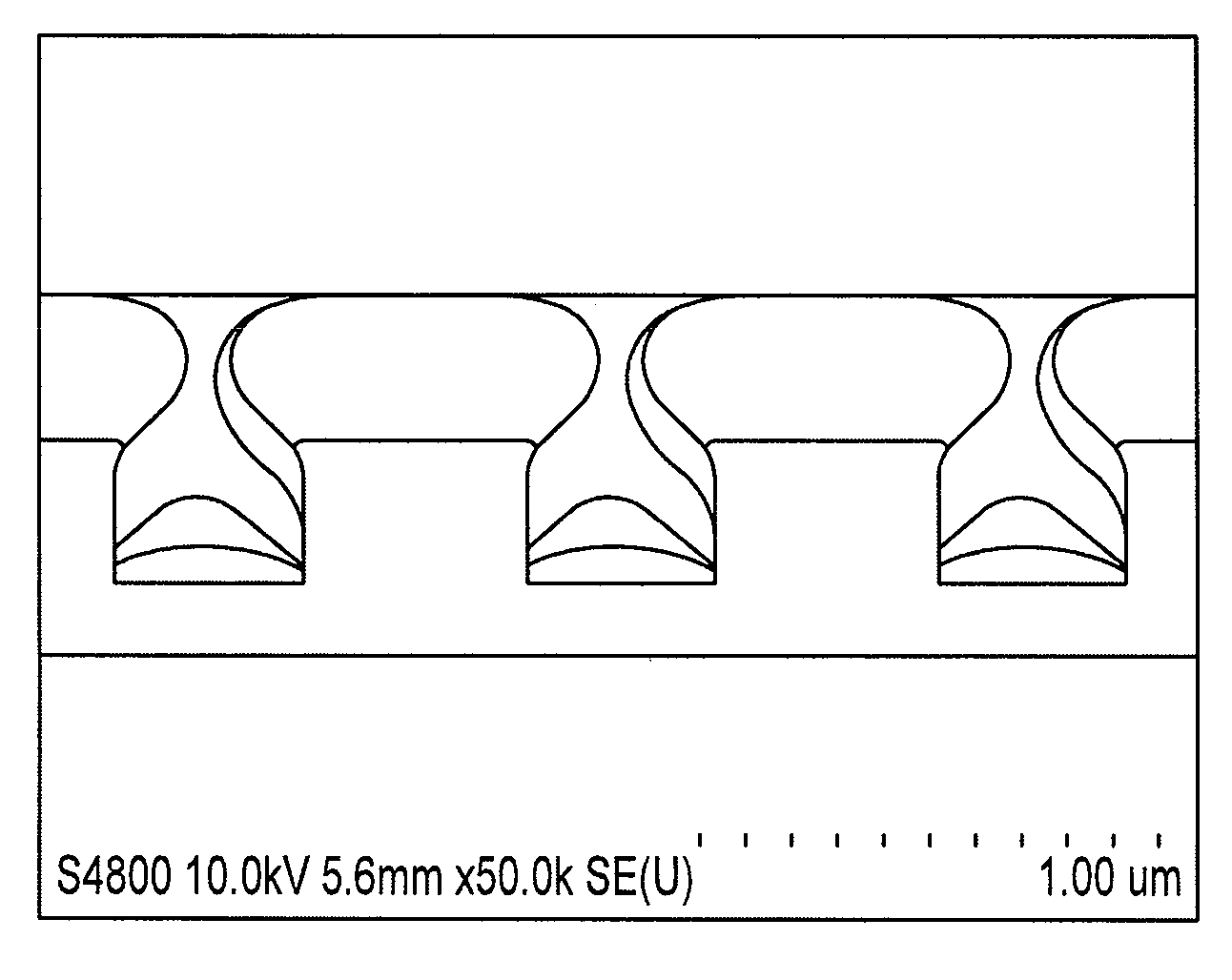

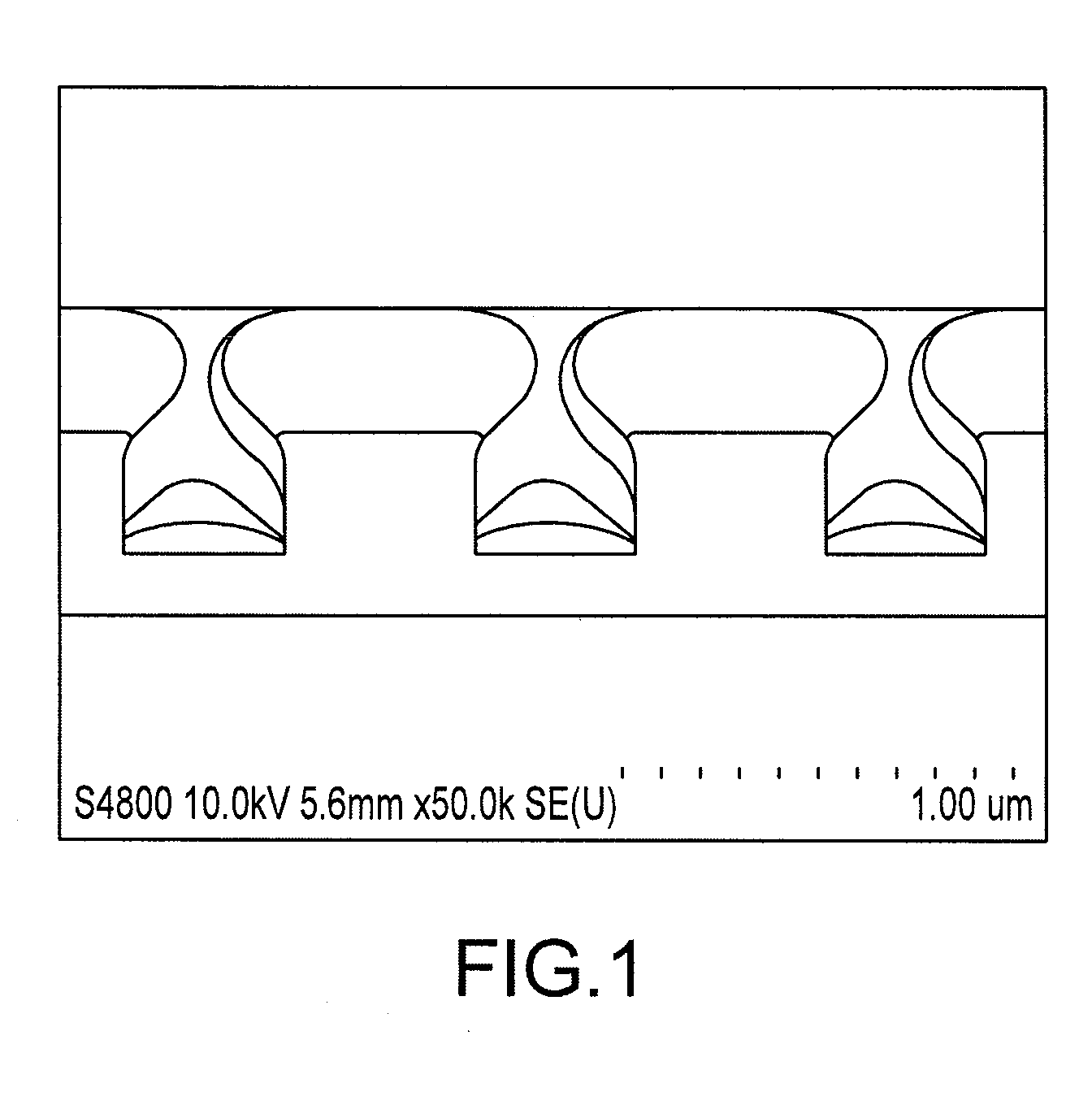

Resist Pattern for Double Patterning

[0118]Another advantage of an conformal amorphous carbon deposition process is that a lower temperature process may be used as sacrificial layer on a resist pattern for double patterning technology.

[0119]For forming conformal amorphous carbon layer on a resist pattern, deposition conditions in embodiments may be as follows:

[0120]Isoprene: 10˜300 sccm (preferably 100˜120 sccm)

[0121]Argon: 0˜3000 sccm (preferably 400˜600 sccm)

[0122]Nitrogen: 0˜1000 sccm (preferably 400˜600 sccm)

[0123]Process helium: 3000 sccm

[0124]Sealed helium: 50 sccm

[0125]Carrier helium: 300 sccm

[0126]Substrate temperature: 0˜150° C. (preferably 0˜50° C.)

[0127]RF power: 0.02 W / cm2˜7 W / cm2 (including a range of 0.05˜5 W / cm2, and a range of 0.5˜3 W / cm2 in embodiments).

[0128]Pressure: 0.1˜10 Torr (preferably 5˜6 Torr)

[0129]Deposition time: 30 sec.

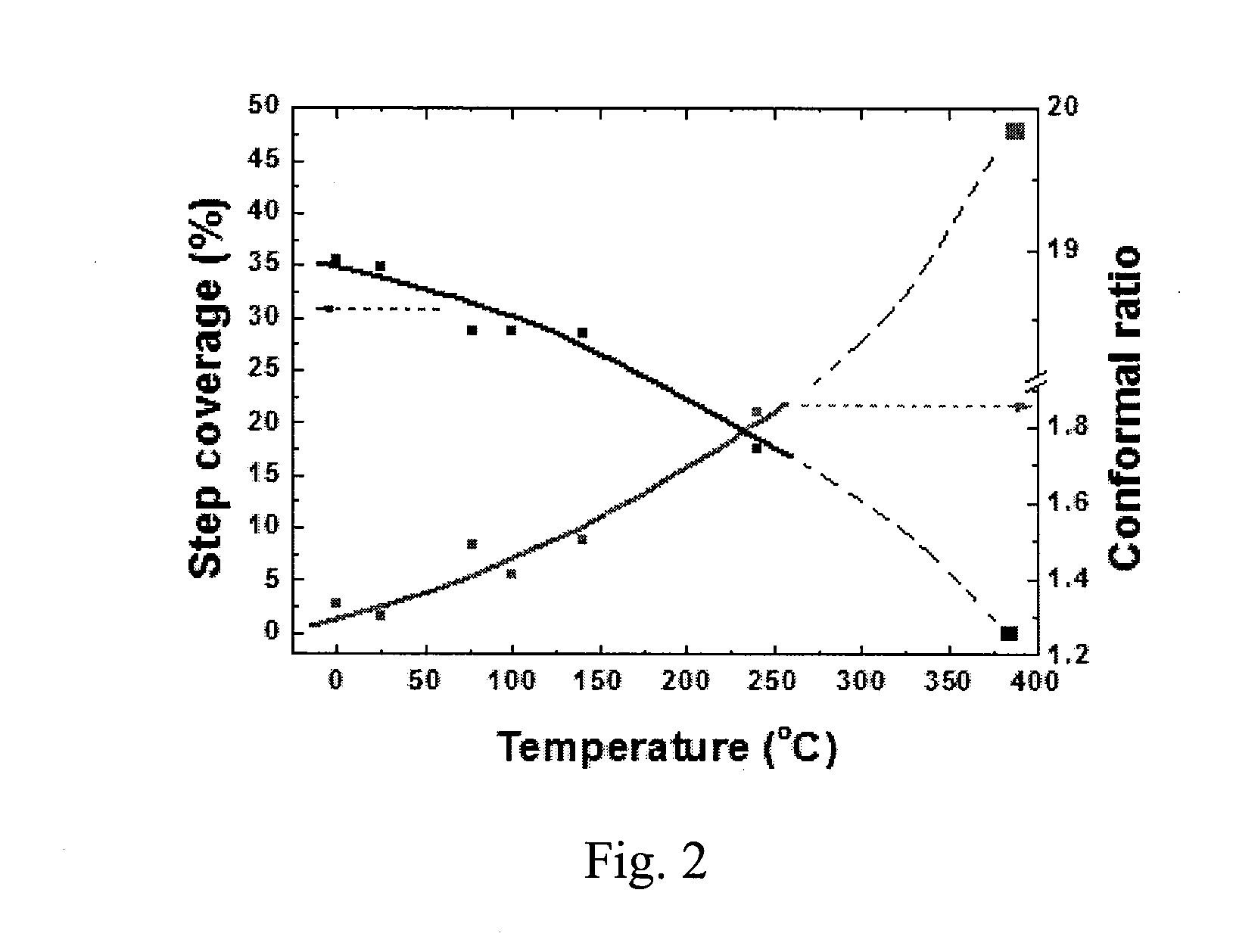

[0130]The obtained amorphous carbon film differ, depending on the process conditions, in an embodiments, shows a step coverage of more tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com