Fluorine removal device and process for fluorine-containing wastewater

A waste water and waste water pump technology, which can be used in water pollutants, multi-stage water treatment, water/sewage treatment, etc., and can solve the problems of other ions exceeding the standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

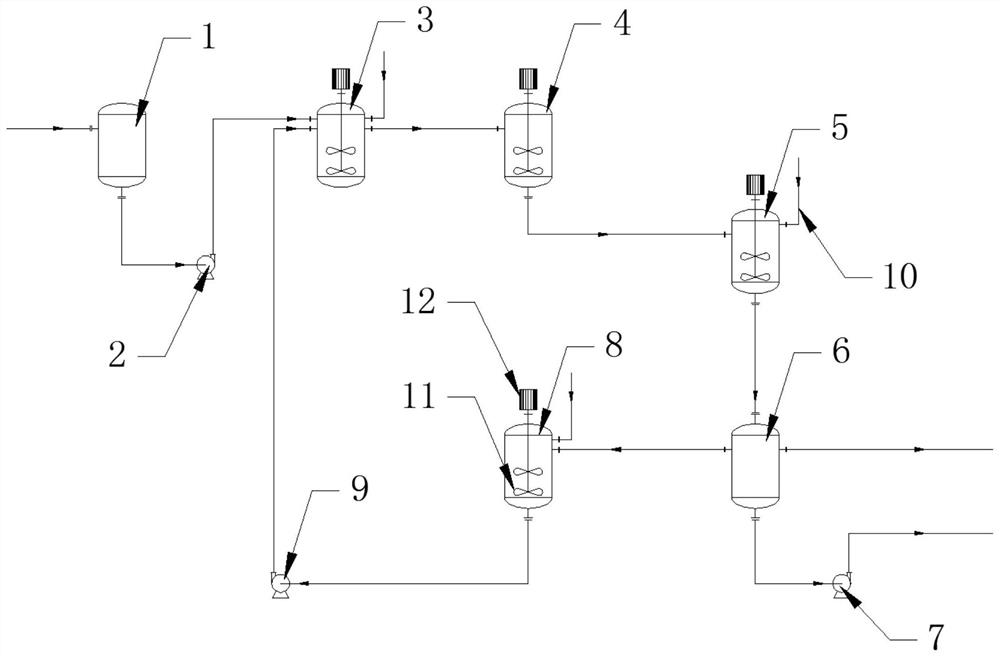

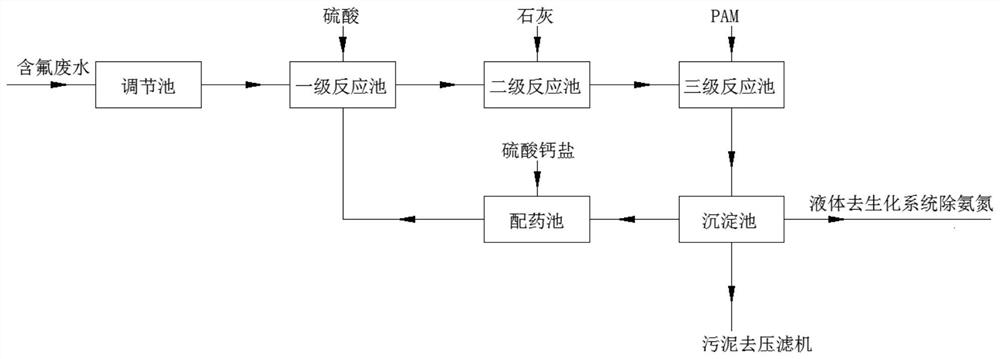

[0041] A process for removing fluoride from fluorine-containing wastewater, comprising the steps of:

[0042] 1) Adjustment: Discharge the wastewater containing high concentration of fluorine together with dilute fluorine wastewater, alkaline wastewater, comprehensive washing water, etc. into the buffer tank 1 for homogeneous and even quantity adjustment, and the adjustment time is 12 hours;

[0043] 2) Primary reaction: continuously pump the fluorine-containing wastewater from the buffer tank 1 into the primary reaction tank 3, add a small amount of sulfuric acid at the same time to keep the pH of the primary reaction tank 3 at 1.5, and add the calcium sulfate salt slurry prepared by the dispensing tank 8, Ca : F=2.0:1 (mol), the primary reaction time is 20 minutes;

[0044] 3) secondary reaction: the waste water after the primary reaction enters the secondary reaction tank 4, and the secondary reaction tank 4 adds a small amount of lime slurry to adjust the pH to 7, and the ...

Embodiment 2

[0049] A process for removing fluoride from fluorine-containing wastewater, comprising the steps of:

[0050] 1) Adjustment: Discharge the wastewater containing high concentration of fluorine, the wastewater containing dilute fluorine, alkaline wastewater, and comprehensive washing water into the buffer tank 1 for homogeneous and even quantity adjustment, and the adjustment time is 24 hours;

[0051] 2) Primary reaction: continuously pump the fluorine-containing waste water from the buffer tank 1 into the primary reaction tank 3, add sulfuric acid to keep the pH of the primary reaction tank 3 at 3.0, and add the calcium sulfate salt slurry prepared by the dispensing tank 8, Ca:F =2.5:1mol, the primary reaction time is controlled at 30 minutes;

[0052]3) secondary reaction: the waste water after the primary reaction enters the secondary reaction tank 4, and the secondary reaction tank 4 adds lime slurry to adjust the pH to 8, and the secondary reaction time is controlled at 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com