Wind-crushing water-cooling granulating method and device for high-temperature liquid-state steel slag, granulating steel slag and use thereof

A liquid steel slag, granulation technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of uncontrolled flow performance of steel slag, low blowing rate of steel slag, influence of steel slag use, etc., to achieve liquid state The effect of improving the fluidity of steel slag, eliminating unstable phases, and increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

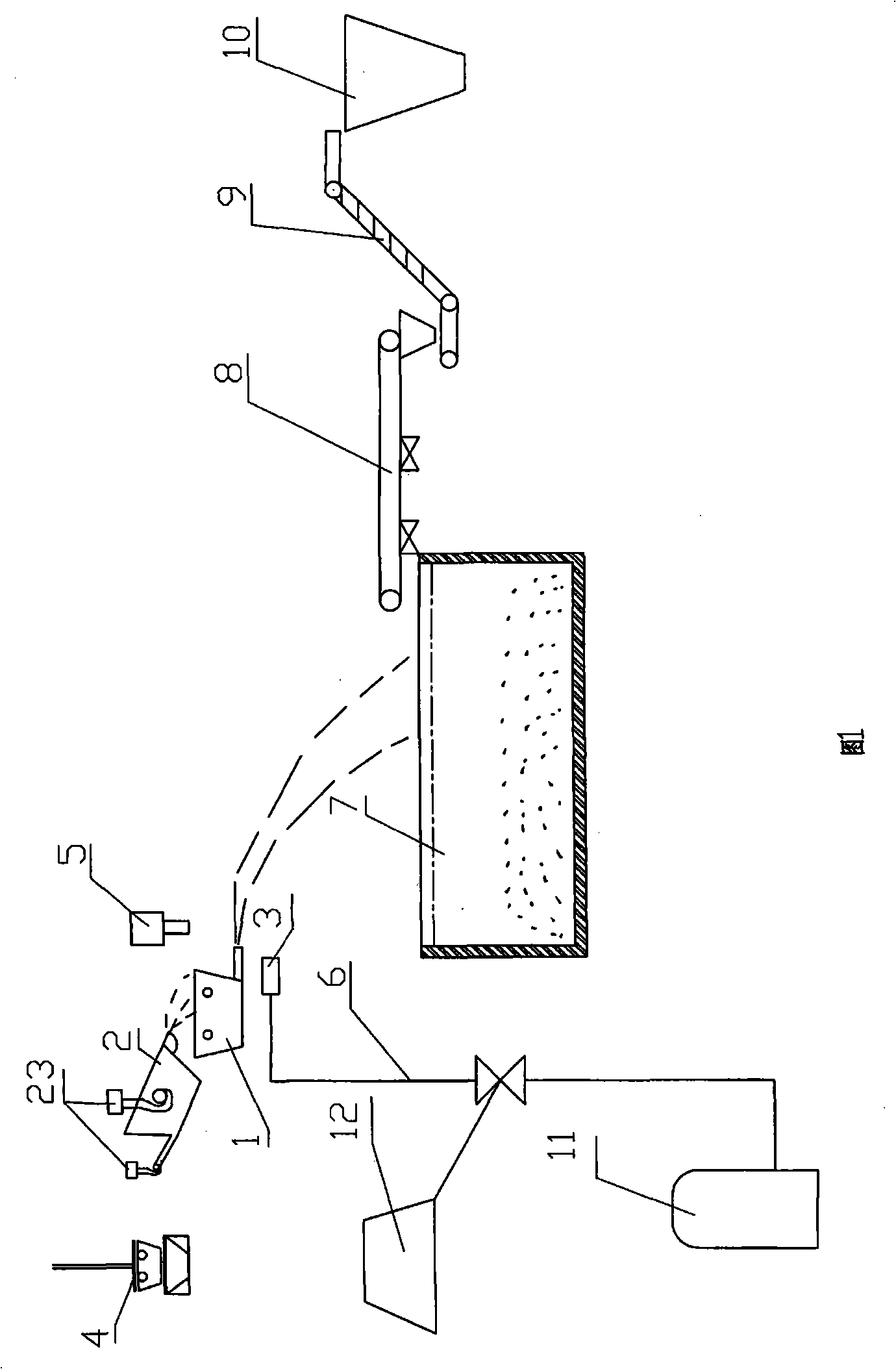

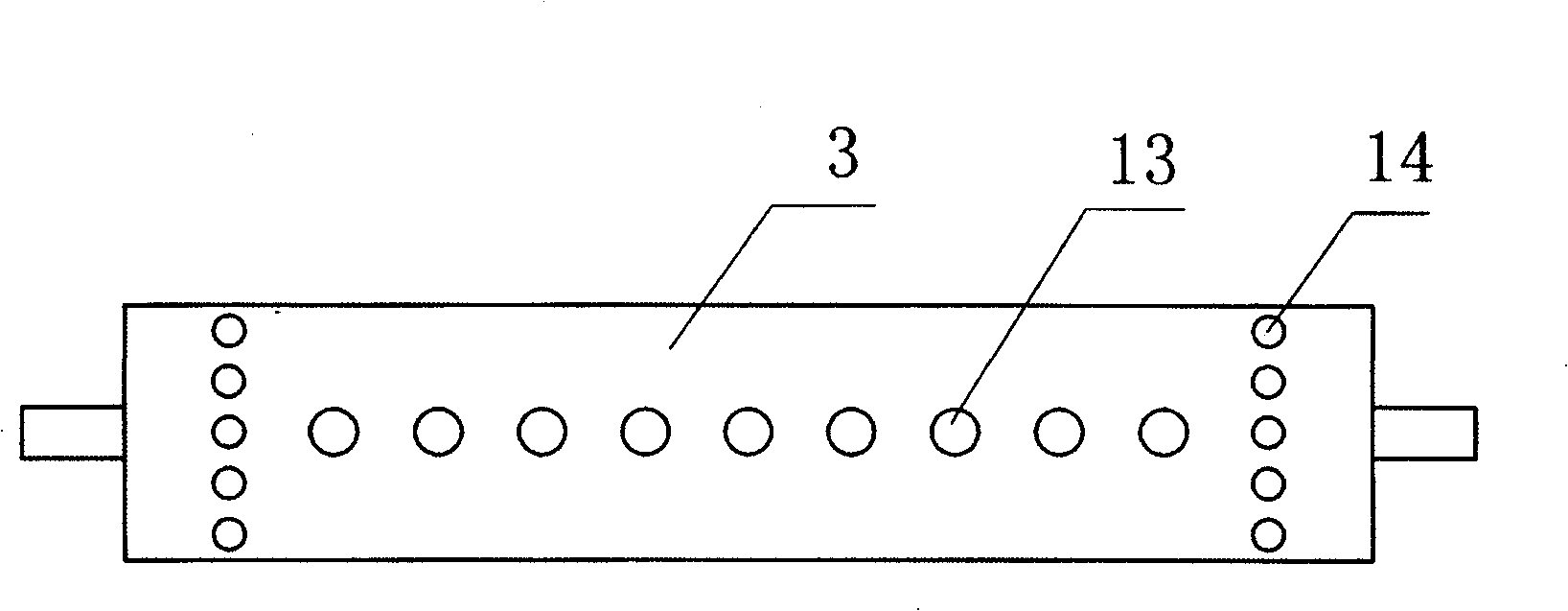

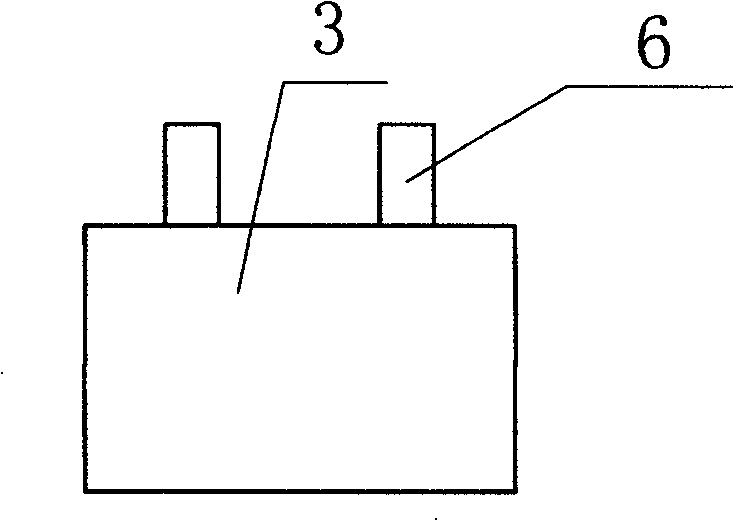

[0013] It can be seen from Figure 1 that after the converter (electric furnace) liquid steel slag is poured into the slag receiving tank 2, the slag receiving tank 2 is hoisted and transported to the front of the tundish 1 by the crane 23, and continuously and slowly poured into the tundish 1, and the liquid slag is controlled by the tundish After the flow, it flows out through the nozzle of the tundish, and falls continuously at the mouth of the flow slot. While the liquid slag is falling continuously, the compressed air generated by the air compressor station 11 is transported to the granulator 3 through the compressed air pipeline 6, and a high-speed air flow with a pressure of 0.59-0.70Mpa is ejected from the granulator 3. The granulation process of high-temperature liquid steel slag is realized instantly in the air, and the particle size of steel slag is 0-5mm. At the same time, the granulation of free calcium oxide phase and MgO phase in the liquid steel slag and RO phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com