Laser-intervening micro-electrochemical machining method and device

A technology of micro-electrolysis and processing methods, which is applied in the field of micro-electrolytic machining, can solve the problems of limiting the ratio of depth to diameter of micro-electrolytic machining, the bottom of the processing area has protrusions, and low processing efficiency, so as to achieve high-efficiency processing, low taper, and improved The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

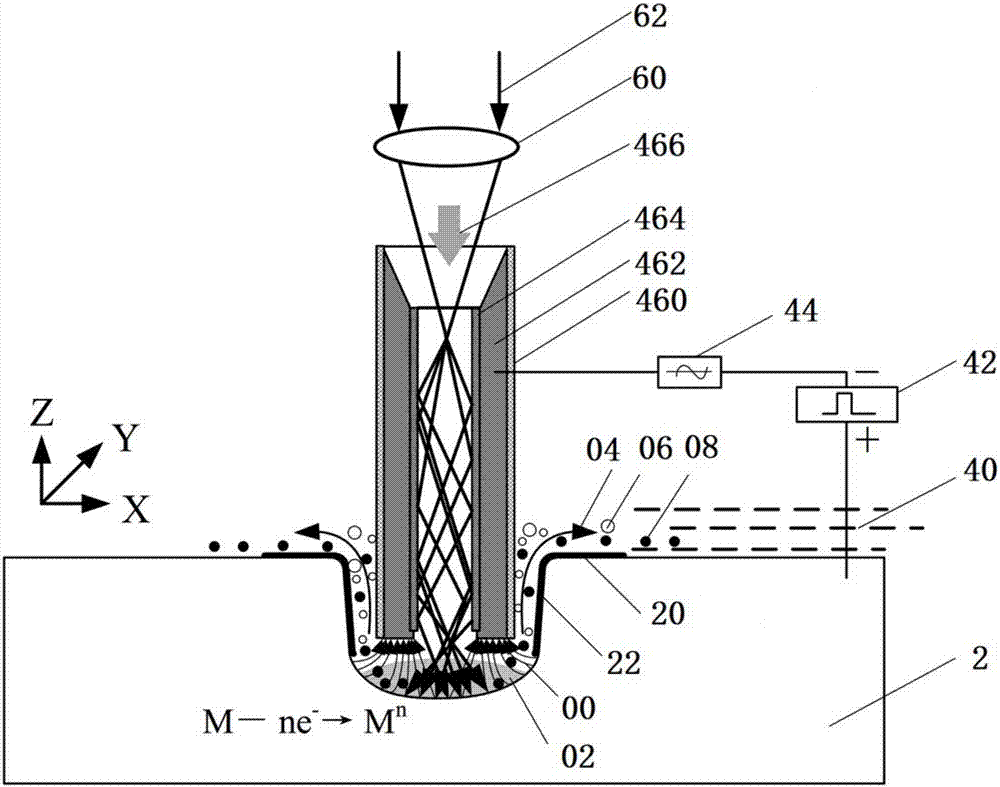

[0093] Example 1 Laser Interventional Micro Electrolytic Machining

[0094] In this embodiment, micro-electrolytic machining is performed based on the laser photothermal effect, and the schematic diagrams involved are as follows figure 1 shown. Specifically include the following steps:

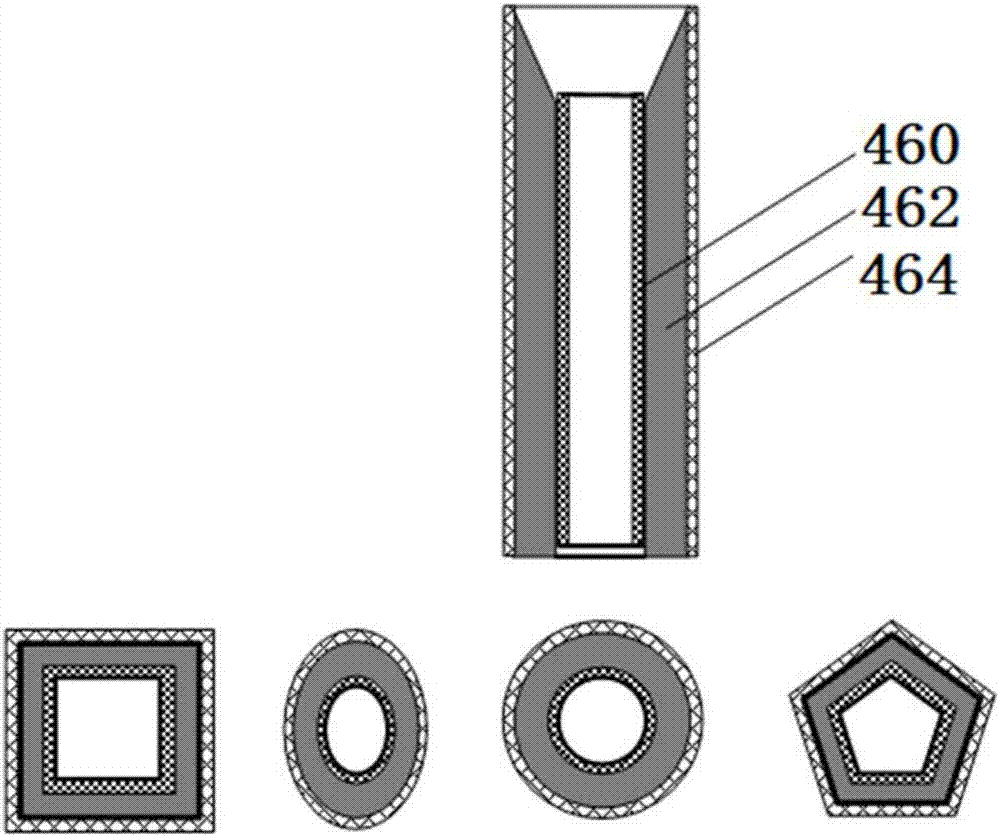

[0095] (1) installing the liquid-core optical fiber 464 in a side-insulated metal conduit 462 to form a tool electrode; the liquid-core optical fiber is coaxially located in the metal conduit;

[0096] (2) Clamp the tool electrode above the workpiece 2, and reasonably set the initial machining gap between the end of the tool electrode and the machining surface of the workpiece to be about 0.2 mm;

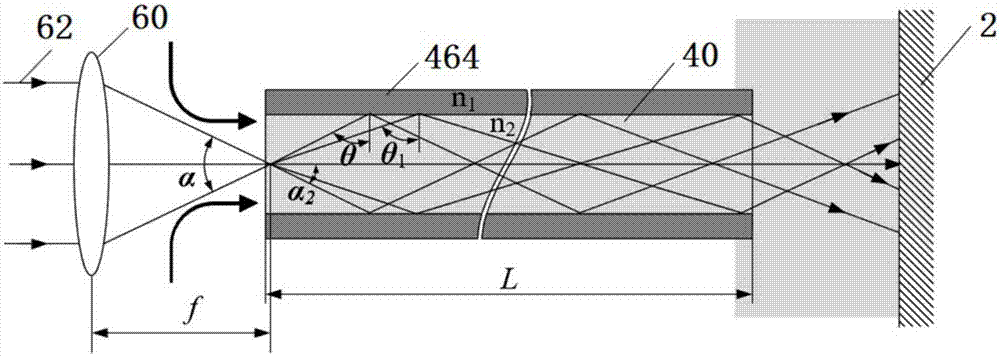

[0097] (3) The electrolyte 40 flows into the coupling system between the laser and the liquid-core optical fiber, and then flows into the liquid-core optical fiber 464 in the tool electrode to be transmitted to the processing area;

[0098] (4) adjust the laser beam 62 to pass through the focusin...

Embodiment 2

[0109] Example 2 Laser Interventional Micro Electrolytic Machining

[0110] The difference between laser-intervened micro-electrolytic machining in this embodiment and that in Embodiment 1 is:

[0111] (3) The electrolyte 40 flows into the coupling system of the laser and the liquid core fiber through the electrolyte through a high-pressure metering pump and a precision filter system, and flows into the liquid core fiber 464 in the tool electrode at a certain pressure and flow rate to be transported to the processing area.

[0112] The voltage amplitude between the tool electrode and the workpiece to be processed is 15V, and the frequency is 100KHz.

[0113] The electrolyte is a 0.05mol / L sodium nitrate solution with a flow rate of 0.01m 3 / h.

[0114] All the other operations are the same as in Example 1.

Embodiment 3

[0115] Example 3 Laser Interventional Micro Electrolytic Machining

[0116] The difference between laser-intervened micro-electrolytic machining in this embodiment and that in Embodiment 1 is:

[0117] (3) Electrolyte 40 flows into the laser and liquid core optical fiber coupling system through the electrolyte through the high pressure metering pump and precision filter system, and flows into the liquid core optical fiber 464 in the tool electrode at a certain pressure and flow rate to be transmitted to the processing area;

[0118] The pressure of the electrolyte is 0.1-0.5MPa;

[0119] (6) The tool electrode is fed to the workpiece 2 at a certain feed rate, and the tool electrode based on the liquid core optical fiber 464 can deeply intervene in the deep processing area of the workpiece 2 to obtain a fine structure with a large aspect ratio. The voltage amplitude between the tool electrode and the workpiece to be processed is 15V, and the frequency is 30KHz.

[0120] Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com