Dynamic soft reduction method for detecting tail end of solidified liquid core of casting blank based on pressure feedback

A technology of feedback detection and solidification end, applied in the field of metallurgical continuous casting control, can solve the problems of lack of direct detection basis and verification, large relationship between model quality and complex calculation methods, etc., to ensure stability and execution efficiency, and save computer resources , The algorithm is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

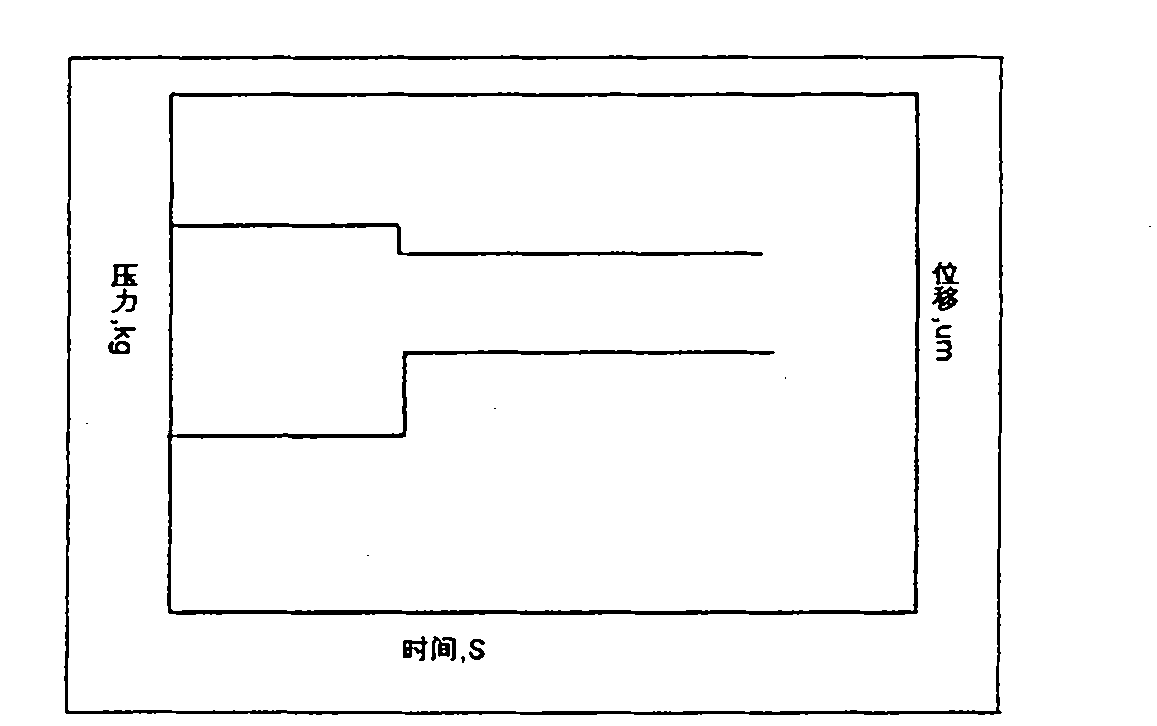

Embodiment 1

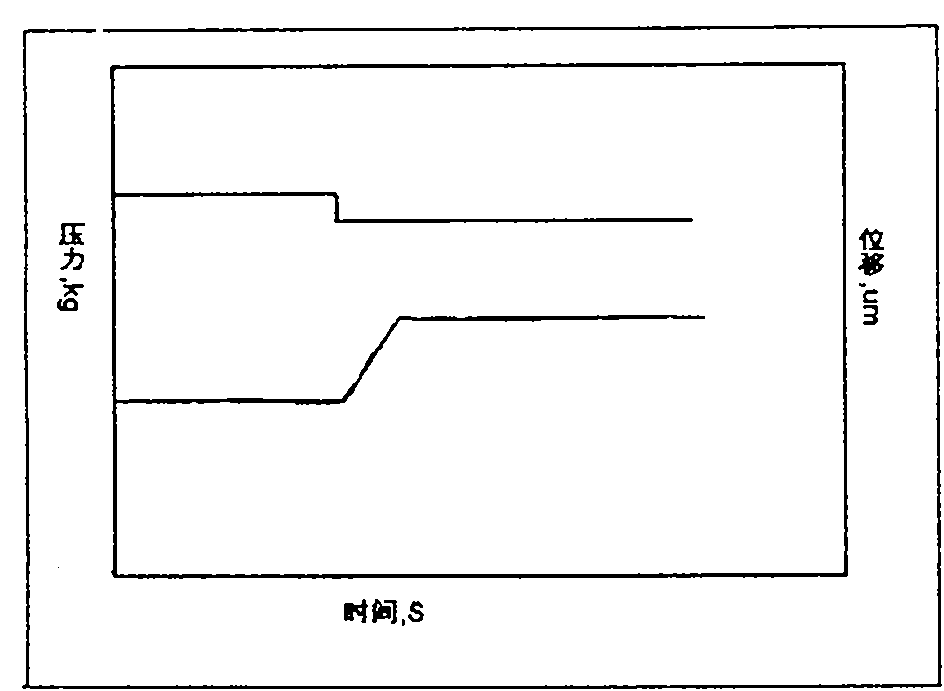

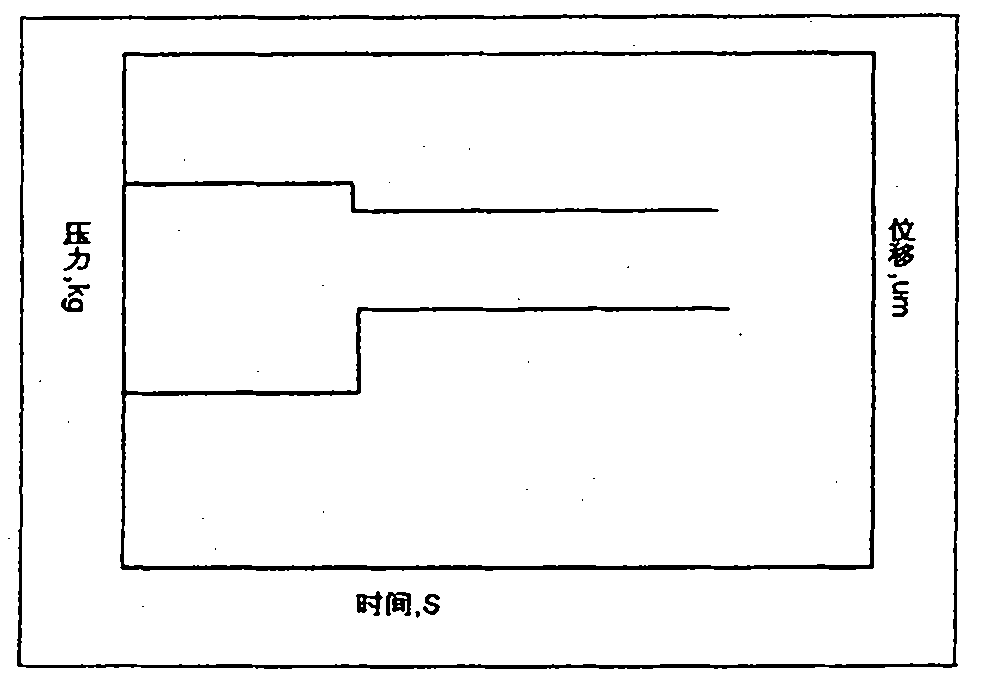

[0029] Embodiment 1, slab continuous casting machine, section 1800×230, casting machine structure: No. 0 is the foot roll section, a total of 1-10 sector sections. Casting steel type: Q235A. There are 14 consecutive casting furnaces in total, and the fourth furnace is selected. The tundish temperature is 1544°C and the casting speed is 0.90-0.95m / min. In the dynamic steel casting mode under light pressure, the pressure on the slab in the No. 5 sector was detected to be 50t, the fluctuation amplitude was 2-14t, the roll gap was lifted and pressed down by 0.3mm, and the slab feedback pressure change curve was The slope range is between 0.40-0.75; the pressure on the slab in the No. 6 segment is 68, the fluctuation amplitude is 0-5t, and the slope range of the change curve is between 0.75-1.00. The pressure on the slab in No. 7 sector and No. 8 sector is 85t, the fluctuation amplitude is 0-5.5t, and the slope of the change curve is in the range of 0.9-1.0. Therefore, it is judge...

Embodiment 2

[0030]Embodiment 2, slab continuous casting machine, cross section 1800×230, casting machine structure: No. 0 is the foot roll section, a total of 1-10 sector sections. Casting steel type: Q345B. The number of continuous casting furnaces is 8 furnaces. The third furnace is selected. The tundish temperature is 1542°C and the casting speed is 0.85-0.90m / min. In the mode of steel pouring under dynamic light pressure, the pressure on the casting slab in the No. 6 sector was detected to be 60t, the fluctuation amplitude was 2-15t, the roll gap was raised and lowered by 0.3mm, and the pressure change curve of the slab was fed back. The slope range is between 0.45-0.70; the pressure on the slab in the No. 7 segment is 75, the fluctuation amplitude is 0-5t, and the slope range of the change curve is between 0.85-1.00. The pressure on the slab in No. 8 segment is 80t, the fluctuation amplitude is 0-5.5t, and the slope of the change curve is in the range of 0.9-1.0. Therefore, it is ju...

Embodiment 3

[0031] Embodiment 3, slab continuous casting machine, cross section 1800×230, casting machine structure: No. 0 is the foot roll section, a total of 1-10 sector sections. Casting steel type: A32, 9 continuous casting furnaces in total, the fifth furnace is selected, the tundish temperature is 1546°C, and the casting speed is 0.85-0.9m / min. In the dynamic steel pouring mode under light pressure, the pressure on the slab in the No. 7 sector was detected to be 75t, the fluctuation amplitude was 1-14t, the roll gap was lifted and pressed down by 0.3mm, and the slab feedback pressure change curve was The slope range is between 0.40-0.60; the pressure on the slab in No. 8 segment is 70, the fluctuation amplitude is 0-7t, and the slope range of the change curve is between 0.80-0.90. The pressure on the slab in No. 9 segment is 77t, the fluctuation amplitude is 0-4.5t, and the slope of the change curve is in the range of 0.85-1.00. Therefore, it is judged that the solidification end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com