ZrC-SiC ceramic and TC4 titanium alloy brazing method

A brazing method and titanium alloy technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of excessive dissolution of metal base metal, easy formation of brittle compounds, large residual stress of joints, etc., and achieve optimal brazing seam structure , reliable connection and high joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

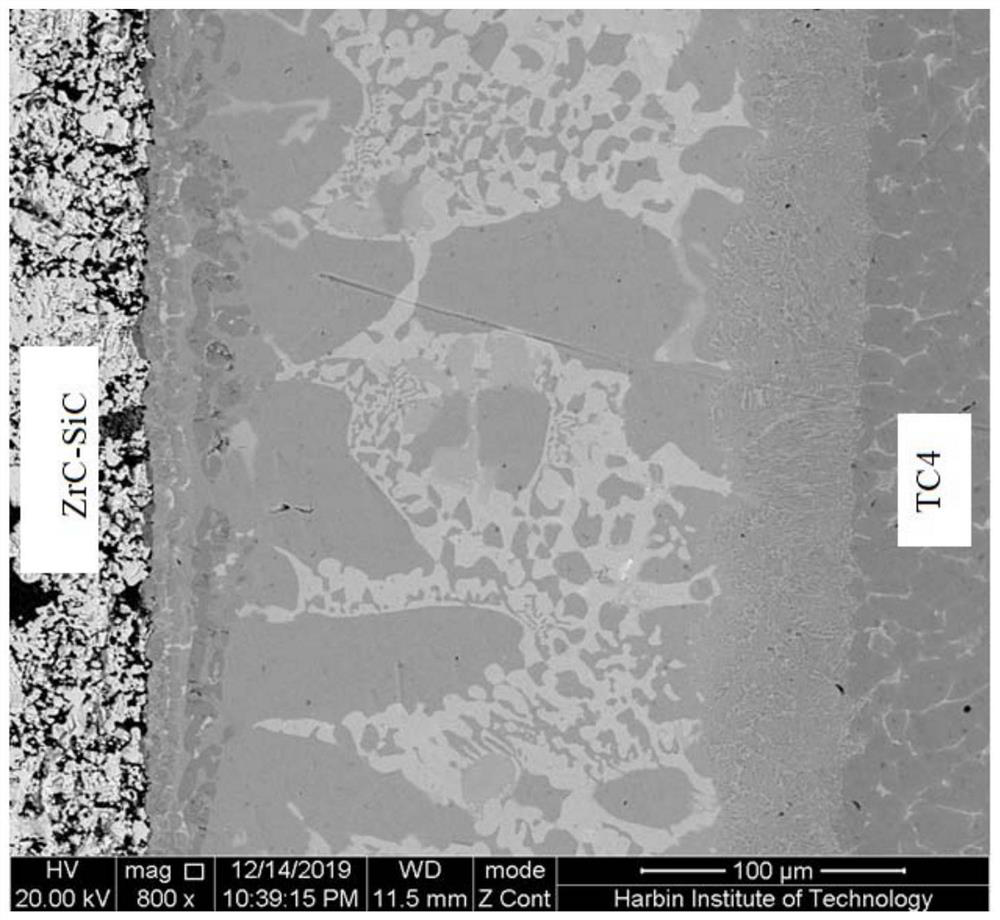

[0017] Specific embodiment one: present embodiment ZrC-SiC ceramics and TC4 titanium alloy brazing method are carried out according to the following steps:

[0018] Step 1. Add ZrH to pure Cu powder 2 The powder is used as a dispersant, and it is evenly spread on the silicon wafer after being fully mixed;

[0019] Step 2, using the PECVD method to grow graphene (VFG) on the surface of the copper powder on the silicon wafer in step 1, to obtain VFG-Cu;

[0020] Step 3: Weigh 80% to 92% of VFG-Cu and the remainder of ZrH by mass fraction 2 and mix evenly to obtain a mixed powder; Step 3 reweighs the ZrH 2 ;

[0021] Step 4, compressing the mixed powder obtained in step 3 to obtain brazing material foil;

[0022] Step 5, pre-cleaning ZrC-SiC ceramics to be brazed and TC4 titanium alloys to obtain pre-cleaned ZrC-SiC ceramics and TC4 titanium alloys;

[0023] Step 6. Place the solder foil obtained in step 4 between the pre-pre-cleaned ZrC-SiC ceramics and TC4 titanium alloy o...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thickness of the tiling in Step 1 is 44-75 μm. (Single-layer Cu powder at 44-75μm).

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass fraction of the dispersant in the Cu powder in Step 1 is 0.5%-3%. ZrH 2 Used as a dispersant, no graphene will grow during deposition, ZrH 2 It can prevent the Cu powder after growing graphene from sticking together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com