Low-oxygen-content titanium or titanium alloy spherical powder and preparing method and application thereof

A spherical powder, titanium alloy technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the problems of excessive oxygen impurity content, affecting the application of spheroidized powder, and increasing oxygen content, and achieves a beneficial effect. The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

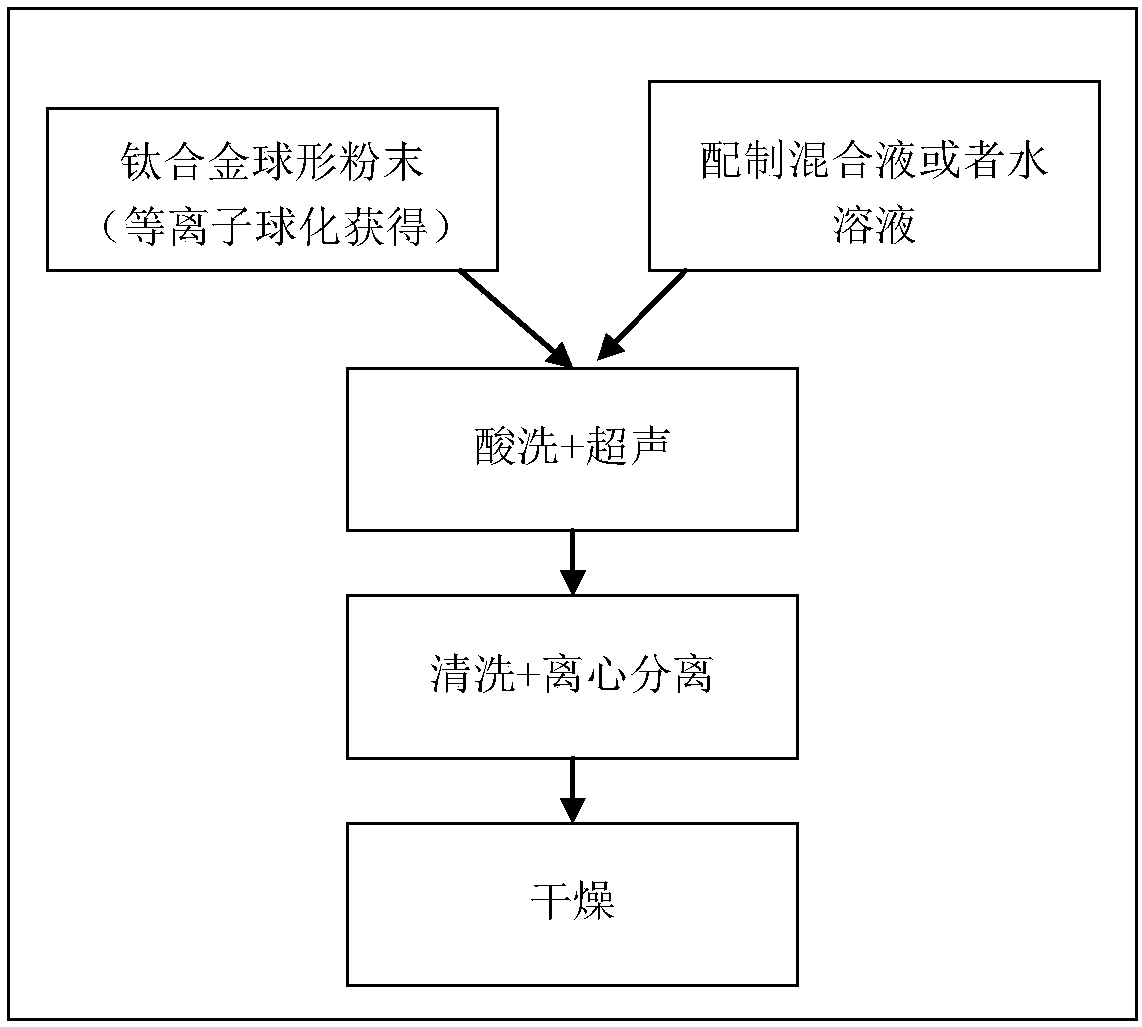

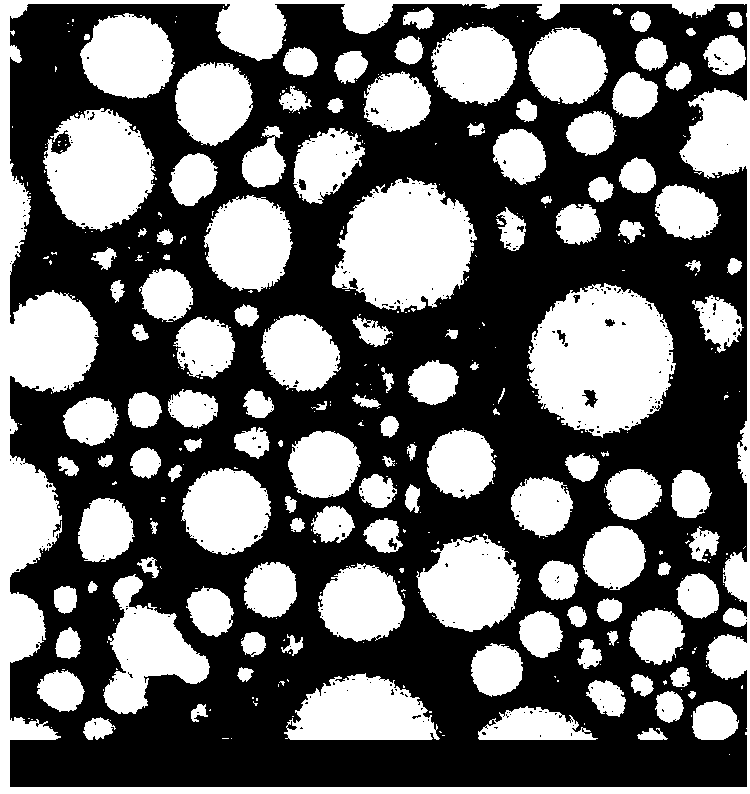

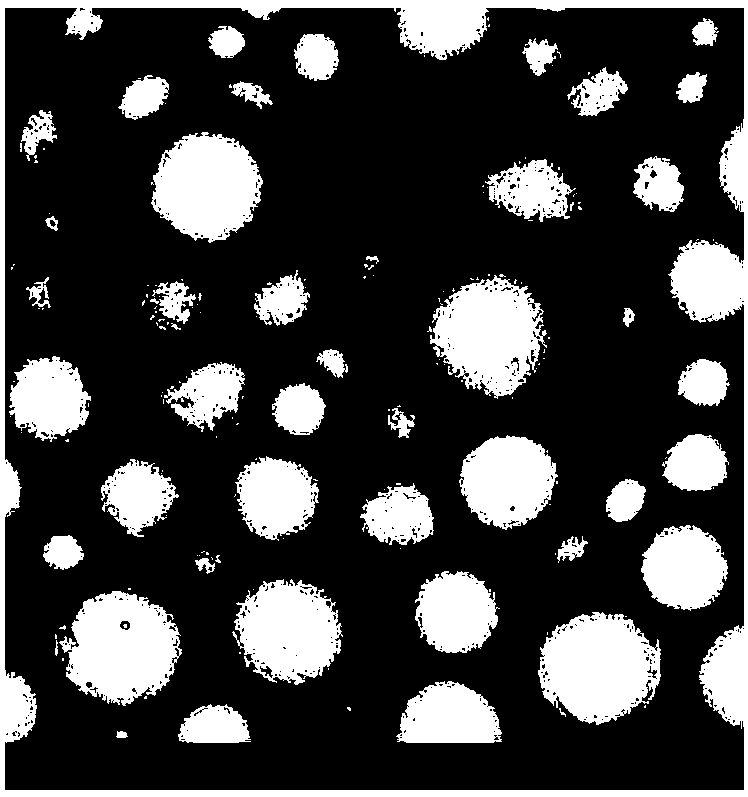

[0030] With -200 mesh irregular titanium alloy (TC4) powder as raw material, titanium alloy (TC4) spherical powder with a spheroidization rate of 95% is obtained through 60kW plasma spheroidization, and the powder yield is about 85% (within a certain period of time, the ball is collected powder weight divided by the original powder weight used), the microscopic appearance of the particles is as follows figure 2 shown. The oxygen content was tested by OHN elemental analyzer to be 3123ppm. Prepare a mixed solution of hydrofluoric acid and nitric acid with a molar ratio of 0.1:1, through such as figure 1 The pickling process is shown, wherein the pickling reaction time is 30 seconds, and the water is washed 4 times, and the obtained powder particle morphology is as follows: image 3 . The oxygen content was tested by OHN elemental analyzer to be 2258ppm.

Embodiment 2

[0032] Using -200 mesh irregular titanium alloy (TC4) powder as raw material, titanium alloy (TC4) spherical powder with a spheroidization rate of 95% is obtained by 60kW plasma spheroidization, and the powder yield is about 85%. The microscopic appearance of the particles is as follows figure 2 shown. The oxygen content was tested by OHN elemental analyzer to be 3123ppm. Prepare a mixed solution of hydrofluoric acid and nitric acid with a molar ratio of 0.1:1, through such as figure 1 The pickling process is shown, wherein the pickling reaction time is 60 seconds, and the water is washed 4 times. The oxygen content was tested by OHN elemental analyzer to be 1734ppm.

Embodiment 3

[0034] Using -200 mesh irregular titanium alloy (TC4) powder as raw material, titanium alloy (TC4) spherical powder with a spheroidization rate of 95% is obtained by 60kW plasma spheroidization, and the powder yield is about 85%. The microscopic appearance of the particles is as follows figure 2 shown. The oxygen content was tested by OHN elemental analyzer to be 3123ppm. Prepare a mixed solution of hydrofluoric acid and nitric acid with a molar ratio of 0.5:1, through such as figure 1 The pickling process is shown, wherein the pickling reaction time is 30 seconds, and the water is washed 4 times. The oxygen content was tested by OHN elemental analyzer to be 2349ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com