Preparation method of copper-based neutron absorbing material

A technology for absorbing materials and neutrons, applied in the field of preparation of copper-based neutron absorbing materials, can solve the problems of low boron solid solubility, reduced matrix processing performance and mechanical properties, and high inability to withstand high wear resistance. The effect of uniform distribution and tight bonding, excellent electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]The following will be further described in detail in conjunction with the following drawings;

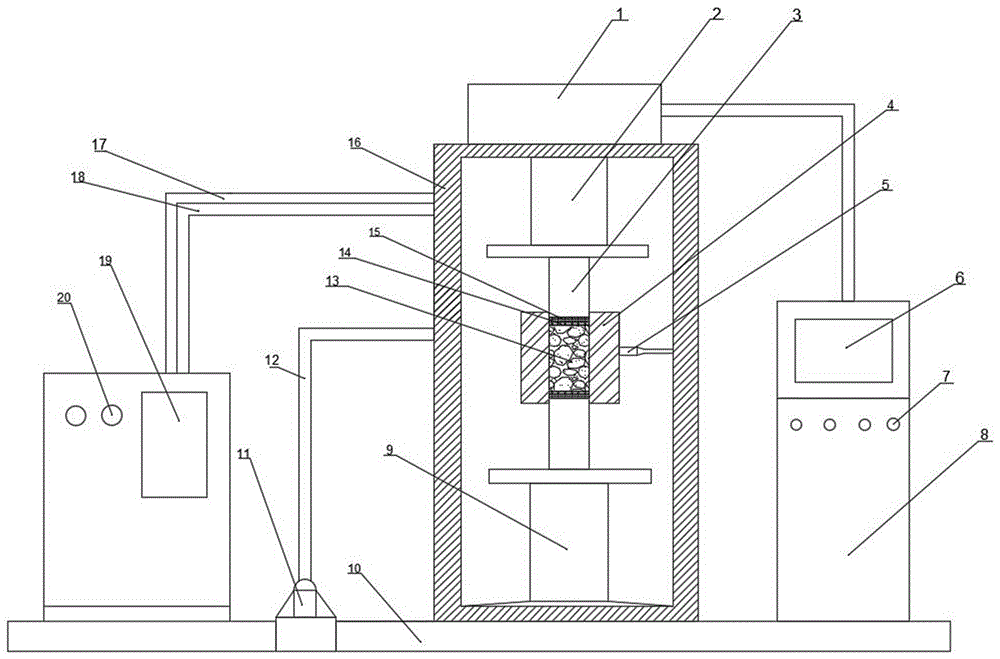

[0058] figure 1 The schematic diagram of the discharge plasma sintering furnace is shown, and all parts must be connected correctly, proportioned according to quantity, and operated in sequence. Copper-based neutron-absorbing materials are made by spark plasma sintering. Under the joint action of electric field, thermal field and force field, sintering at a temperature lower than the melting point of the material can break the oxide layer on the particle surface, purify the material and avoid grains. grow up, so that the sintered body maintains excellent mechanical properties and good particle dispersion. The spark plasma sintering furnace is a vertical structure, such as figure 1 The structures shown are 1. Servo motor, 2. Upper indenter, 3. Graphite indenter, 4. Graphite mold, 5. Thermocouple, 6. Control panel, 7. Control button, 8. Control electric control cabinet, 9. Low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com