Performance-modified oxide ceramic core body for thermal neutron reactor, and preparation method thereof

An oxide ceramic and reactor technology, which is applied in the fields of reactor fuel material, nuclear power generation, and greenhouse gas reduction, etc., can solve the problems of control affecting reactivity, reducing the reactivity value of neutron absorbers, affecting the safety and controllability of reactors, etc. Achieve the effect of improving thermal conductivity, improving moderation performance, and good moderation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking the uranium-plutonium mixed oxide fuel core (MOX) fuel core for pressurized water reactor as an example, the present invention will be further explained.

[0028] MOX contains Pu extracted from spent fuel. Using MOX fuel core as PWR fuel can improve the utilization rate of nuclear fuel; but PuO 2 The existence of the MOX core makes the thermal conductivity of the MOX core lower than that of ordinary UO 2 Core, the core temperature is higher, which affects the core operating performance; at the same time, the introduction of Pu will harden the core neutron energy spectrum, thereby reducing the reactivity value of the neutron absorber.

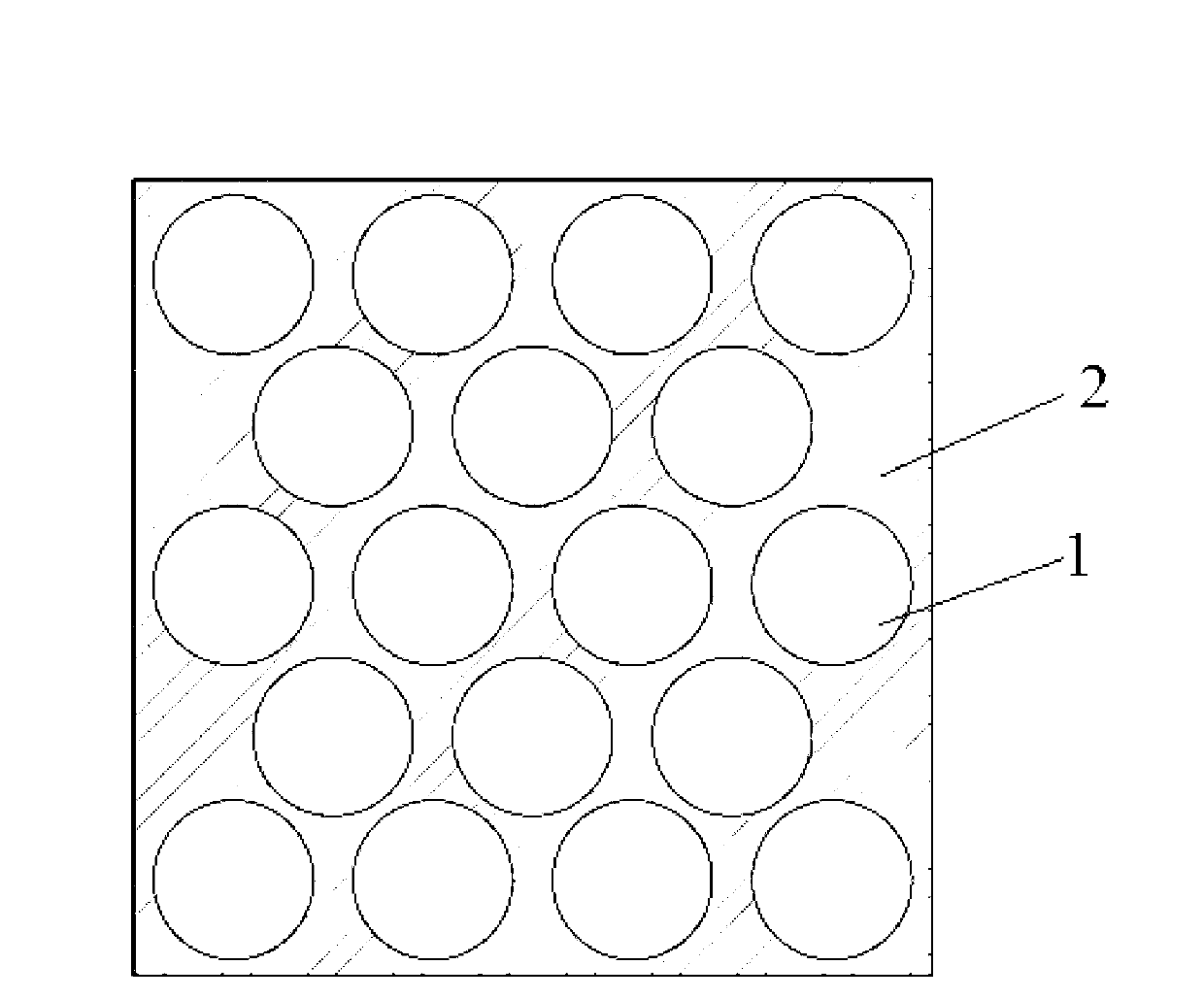

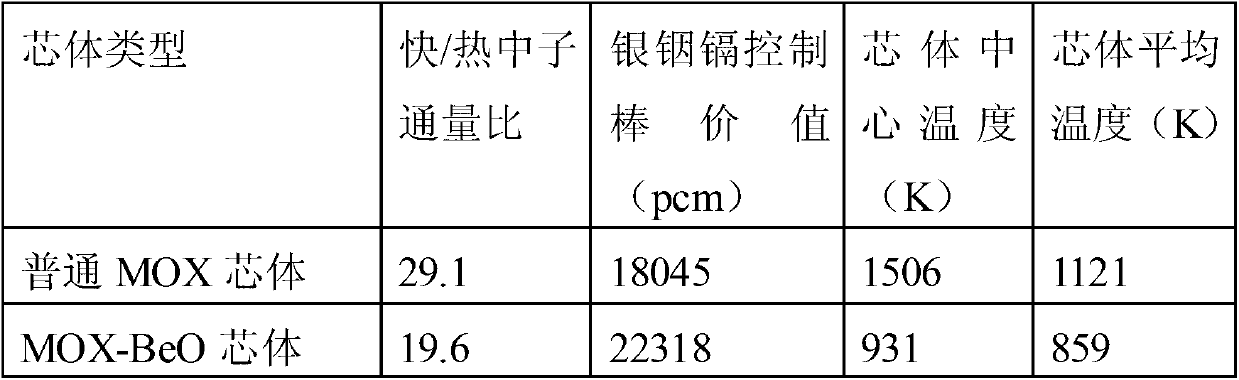

[0029] The invention adds a second phase material with high thermal conductivity and slowing effect to MOX. The second phase material is ultra-high thermal conductivity oxide material BeO. The addition ratio is shown in Table 1 below. BeO forms a continuous phase in MOX, such as figure 1 As shown, an improved performance oxide ceramic co...

Embodiment 2

[0042] The improved performance oxide ceramic core for thermal neutron reactors according to the present invention and the preparation method thereof are as follows:

[0043] (1) Preparation of raw materials: oxide ceramic core powder and second phase material powder are shown in Table 3;

[0044] table 3

[0045] ingredient Proportion (mass percentage) UO2 90.4% PuO 2 6.6% BeO 3.0%

[0046] (2) Mixing: the oxide ceramic core powder and the second phase material powder described in step (1) are mixed and ball milled, and the ball milling time is 45 minutes; before the mixed ball milling, the oxide ceramic described in step (1) The core powder is pre-fired for 3h;

[0047] (3) Compaction: the powder obtained by mixing in step (2) is calmly pressed into a green compact with a pressure of 200MPa;

[0048] (4) Sintering: The green body obtained in step (3) is sintered in a sintering furnace at a sintering temperature of 1750°C for 2 hours. The sintering atmosphere is a mixed gas of ...

Embodiment 3

[0051] The improved performance oxide ceramic core for thermal neutron reactors according to the present invention and the preparation method thereof are as follows:

[0052] (1) Preparation of raw materials: oxide ceramic core powder and second phase material powder are shown in Table 4;

[0053] Table 4

[0054] ingredient Proportion (mass percentage) UO2 88.4%

[0055] PuO 2 10.6% BeO 1.0%

[0056] (2) Mixing: the oxide ceramic core powder and the second phase material powder described in step (1) are mixed and ball milled, and the ball milling time is 2h; before mixing ball milling, the oxide ceramic described in step (1) The core powder is pre-fired, and the pre-fire time is 5h;

[0057] (3) Compaction: the powder obtained by mixing in step (2) is calmly pressed into a green compact with a pressure of 200MPa;

[0058] (4) Sintering: Place the green body obtained in step (3) for sintering in a sintering furnace at a sintering temperature of 1700°C for 1 hour. The sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com