Zirconium/niobium/copper/bismuth alloy for fuel cladding of nuclear power plant

A technology for fuel cladding and nuclear power plants, which is applied in the field of zirconium alloy materials to achieve excellent corrosion resistance and improve corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

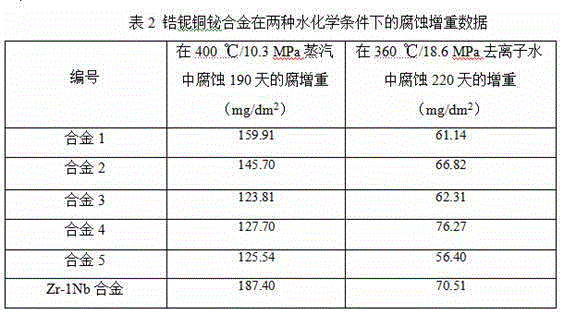

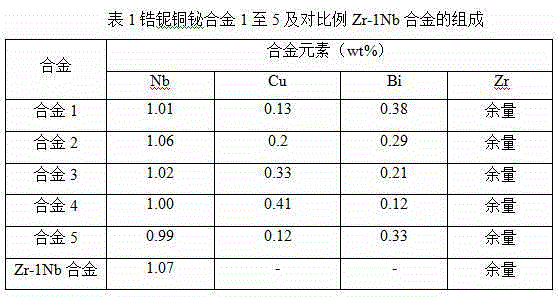

[0017] See Table 1, which shows the composition of five typical zirconium-niobium-copper-bismuth materials according to the present invention.

[0018]

[0019] The alloy materials with the composition in Table 1 were prepared according to the following steps:

[0020] (1) According to the above formula and ingredients, use a vacuum non-consumable electric arc furnace to melt into an alloy ingot with a weight of about 65g, fill it with high-purity argon for protection during melting, and turn the alloy over and smelt it 6 times to make an alloy ingot with a uniform composition;

[0021] (2) The above-mentioned alloy ingot is hot-pressed at 700°C for several times, and processed into a billet, the purpose is to break the coarse as-cast grain structure;

[0022] (3) After removing the scale and pickling, the billet is subjected to β-phase homogenization treatment at 1030-1050 °C in vacuum for 0.5-1 h and then air-cooled; then it is hot-rolled at 700 °C. After hot-roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com