Method for preparing carbon fiber toughened silicon carbide wood-ceramics

A technology of wood ceramics and tough silicon carbide, which is applied in the field of preparation of silicon carbide wood ceramics, can solve the problems of easy deformation and cracking, large volume shrinkage, and poor toughness of products, and achieve simple and feasible process, overcome large volume shrinkage, and high elastic mold. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

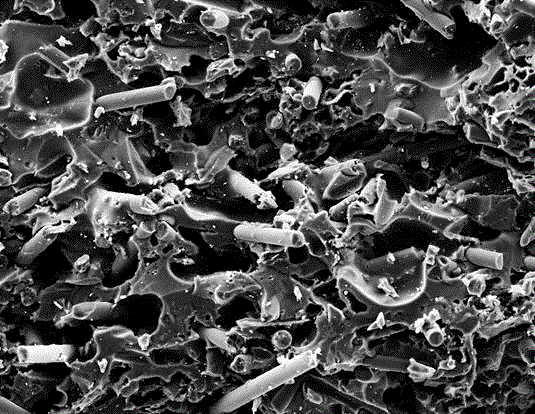

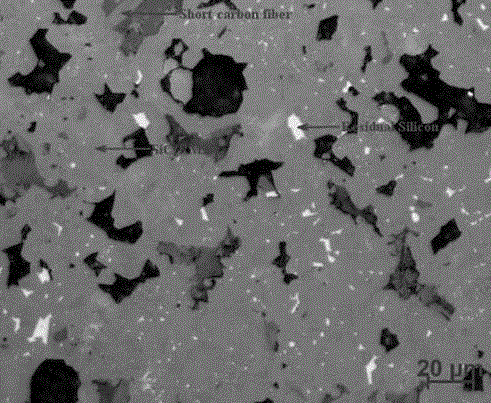

Image

Examples

Embodiment 1

[0024] A method for preparing carbon fiber toughened silicon carbide wood ceramics, the steps are as follows:

[0025] (1) Put oak powder (with a particle size of 100 mesh), carbon fiber (with a length of 50 μm) and thermosetting phenolic resin powder (with a particle size of 100 mesh) into water to make a slurry; among them, in terms of parts by mass, 4 parts of wood powder , 6 parts of carbon fiber, 15 parts of thermosetting phenolic resin powder, 50 parts of water;

[0026] (2) Pour the slurry prepared in step (1) into a metal container, put it into a freeze dryer, freeze to -50°C under vacuum, and keep it for 30 minutes; raise the temperature to -10°C, and keep it for 30 minutes; continue to heat up to -5°C, keep warm for 30 minutes; continue to heat up to -1°C, keep warm until completely dry; release the vacuum, take it out, and get the carbon fiber reinforced body; in the whole process, heat up at a heating rate of 2°C / h;

[0027] (3) Pour the carbon fiber reinforced bo...

Embodiment 2

[0031] A method for preparing carbon fiber toughened silicon carbide wood ceramics, the steps are as follows:

[0032] (1) Put maple wood powder (with a particle size of 300 mesh), carbon fiber (with a length of 400 μm) and thermosetting phenolic resin powder (with a particle size of 500 mesh) into water to make a slurry; among them, in terms of parts by mass, wood powder 5 5 parts, 5 parts of carbon fiber, 20 parts of thermosetting phenolic resin powder, 60 parts of water;

[0033] (2) Pour the slurry prepared in step (1) into a metal container, put it into a freeze dryer, freeze to -40°C under vacuum, and keep it for 30 minutes; raise the temperature to -10°C, and keep it for 30 minutes; continue to heat up to -5°C, keep warm for 30 minutes; continue to heat up to -1°C, keep warm until completely dry; release the vacuum, take it out, and get the carbon fiber reinforced body; in the whole process, heat up at a heating rate of 3°C / h;

[0034] (3) Pour the carbon fiber reinfor...

Embodiment 3

[0038] A method for preparing carbon fiber toughened silicon carbide wood ceramics, the steps are as follows:

[0039] (1) Put peach wood powder (with a particle size of 200 mesh), carbon fiber (with a length of 200 μm) and thermosetting phenolic resin powder (with a particle size of 300 mesh) into water to make a slurry; among them, in terms of parts by mass, 6 parts of wood powder , 4 parts of carbon fiber, 15 parts of thermosetting phenolic resin powder, 50 parts of water;

[0040] (2) Pour the slurry prepared in step (1) into a metal container, put it into a freeze dryer, freeze to -30°C under vacuum, and keep it for 30 minutes; raise the temperature to -10°C, keep it for 30 minutes; continue to heat up to -5°C, keep warm for 30 minutes; continue to heat up to -1°C, keep warm until completely dry; release the vacuum, take it out, and get the carbon fiber reinforced body; in the whole process, heat up at a heating rate of 5°C / h;

[0041] (3) Pour the carbon fiber reinforced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com