Precipitation strengthening type high-temperature high-entropy alloy for in-situ precipitation of carbide and preparation method thereof

A technology for precipitation of carbides and precipitation strengthening, which can solve the problems that the final alloy content is not easy to guarantee, reduce the high-temperature plasticity of the alloy, and the difficulty of machining the alloy, etc., and achieve good structural stability, reduce shrinkage cavity and porosity, and excellent high-temperature mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

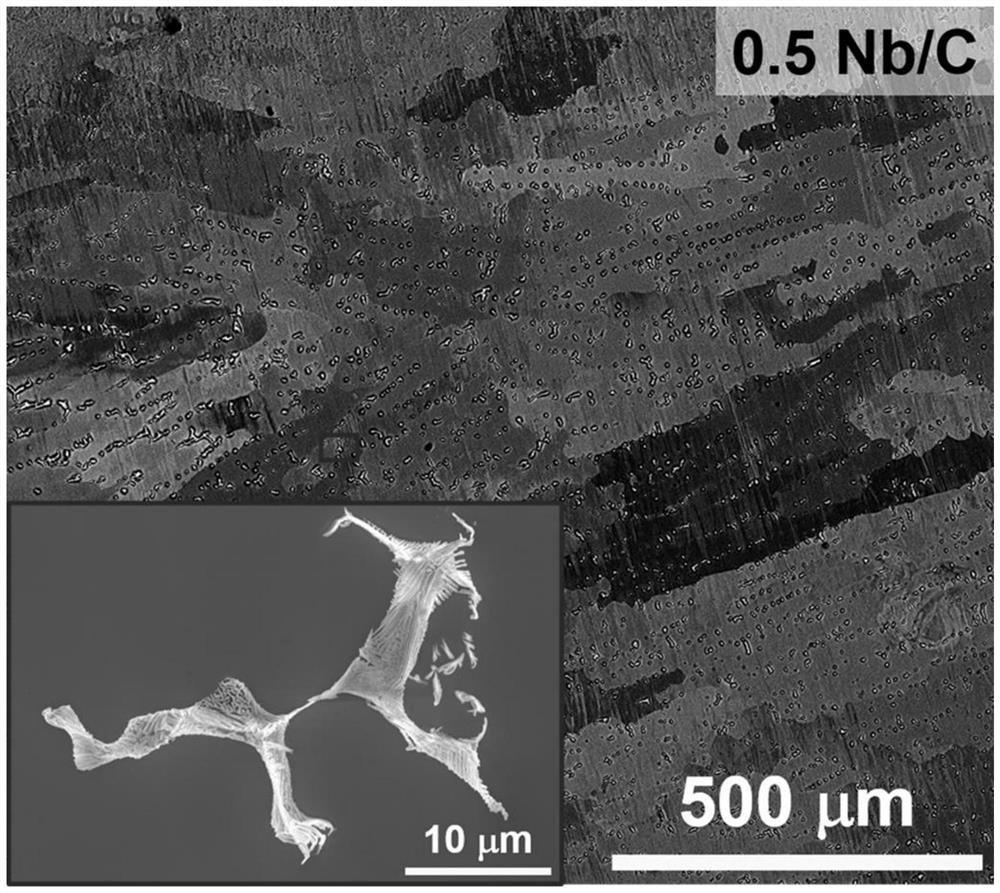

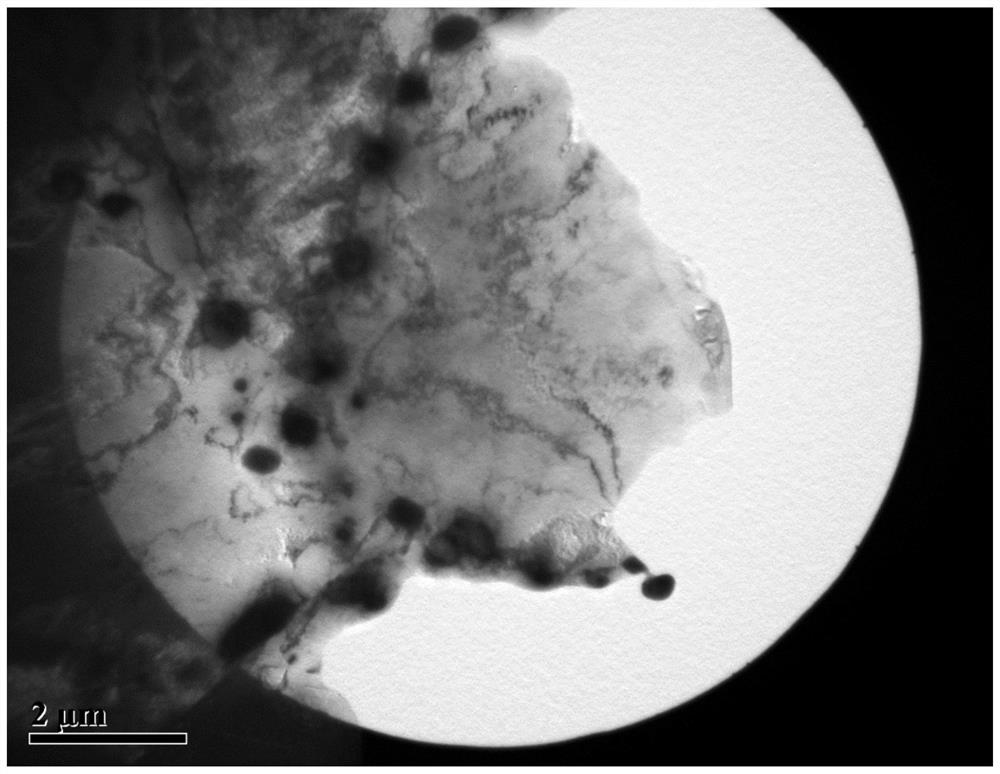

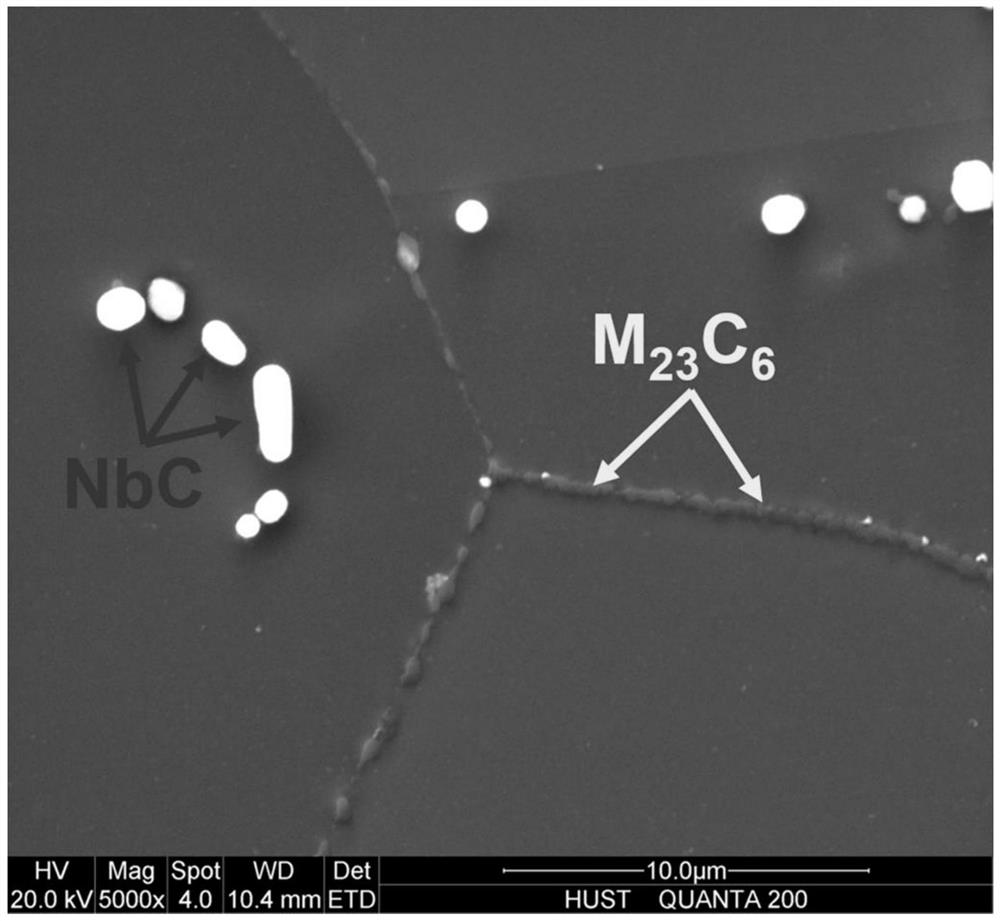

[0038] The in-situ carbide precipitation strengthening high-temperature high-entropy alloy in this embodiment includes: Cr: 24.75%, Fe: 24.75%, Co: 24.75%, Ni: 24.75%, Nb: 0.5%, C: 0.5%.

[0039] The preparation method of the high-temperature high-entropy alloy of the present embodiment comprises the following steps:

[0040] 1) Raw material preparation: the ingredients are calculated by atomic percentage, including: Cr: 24.75%, Fe: 24.75%, Co: 24.75%, Ni: 24.75%, Nb: 0.5%, C: 0.5%. Raw materials include: Cr, Fe, Co, Ni, Nb pure metals (purity>99.9wt.%) and Cr 3 C 2 (purity>99%).

[0041] 2) Melting step: Melting in an electric arc furnace. Put the above raw materials into the crucible of the furnace, and evacuate the furnace to ~5×10 -2 Pa, then backfill with argon, repeat twice, fill with argon to ~5×10 4 Pa. The melted button ingots are remelted five times, and then drop-cast using copper molds.

Embodiment 2

[0043] The in-situ carbide precipitation strengthening high-temperature high-entropy alloy in this embodiment includes: Cr: 24.75%, Fe: 24.75%, Co: 24.75%, Ni: 24.75%, Nb: 0.5%, C: 0.5%.

[0044] The preparation method of the high-temperature high-entropy alloy of the present embodiment comprises the following steps:

[0045] 1) Raw material preparation: the ingredients are calculated by atomic percentage, including: Cr: 24.75%, Fe: 24.75%, Co: 24.75%, Ni: 24.75%, Nb: 0.5%, C: 0.5%. Raw materials include: Cr, Fe, Co, Ni, Nb pure metals (purity>99.9wt.%) and Cr 3 C 2 (purity>99%).

[0046] 2) Melting step: Melting in an electric arc furnace. Put the above raw materials into the crucible of the furnace, and evacuate the furnace to ~5×10 -2 Pa, then backfill with argon, repeat twice, fill with argon to ~5×10 4 Pa. The melted button ingots are remelted five times, and then drop-cast using copper molds.

[0047] 3) Solid solution treatment: Clean the drop-cast sample with a...

Embodiment 3

[0050] The in-situ carbide precipitation strengthening high-temperature high-entropy alloy in this embodiment includes: Cr: 24.75%, Fe: 24.75%, Co: 24.75%, Ni: 24.75%, Nb: 0.5%, C: 0.5%.

[0051] The preparation method of the high-temperature high-entropy alloy of the present embodiment comprises the following steps:

[0052] 1) Raw material preparation: the ingredients are calculated by atomic percentage, including: Cr: 24.75%, Fe: 24.75%, Co: 24.75%, Ni: 24.75%, Nb: 0.5%, C: 0.5%. Raw materials include: Cr, Fe, Co, Ni, Nb pure metals (purity>99.9wt.%) and Cr 3 C 2 (purity>99%).

[0053] 2) Melting step: Melting in an electric arc furnace. Put the above raw materials into the crucible of the furnace, and evacuate the furnace to ~5×10 -2 Pa, then backfill with argon, repeat twice, fill with argon to ~5×10 4 Pa. The melted button ingots are remelted five times, and then drop-cast using copper molds.

[0054] 3) Solid solution treatment: Clean the drop-cast sample with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com