Ultra-alloy minitype heater and method for making

A production method and superalloy technology, which can be applied in ohmic resistance heating, heating element materials, electric heating devices, etc., and can solve problems such as reliability decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the present invention, specific examples are listed below, together with descriptions such as illustrations and component symbols, to describe in detail the composition and effects of the present invention.

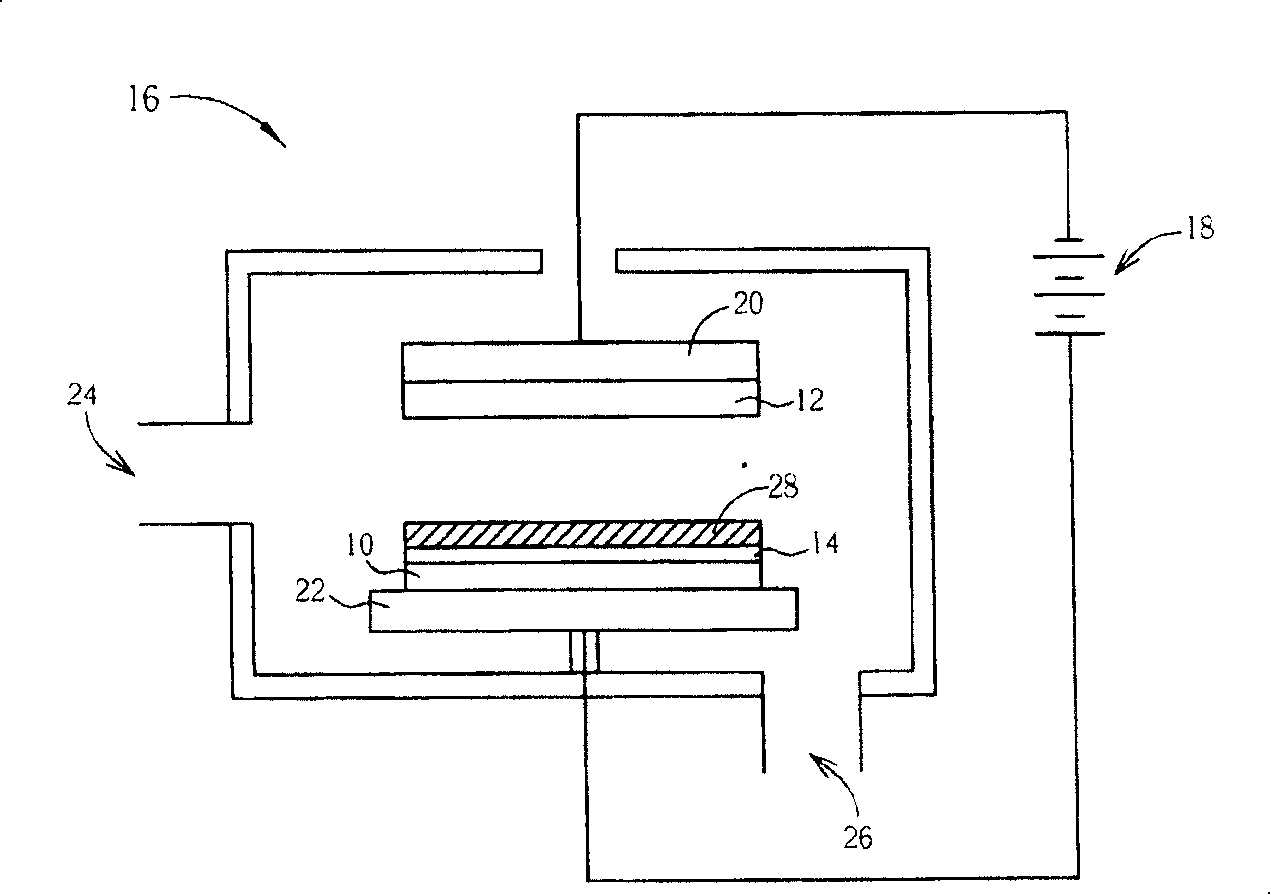

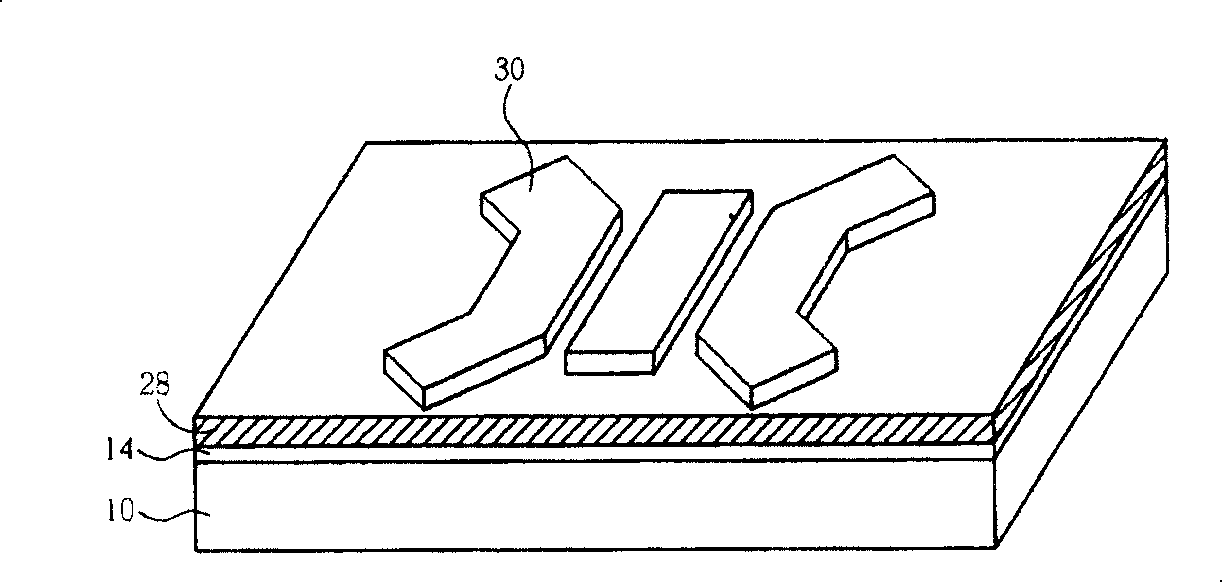

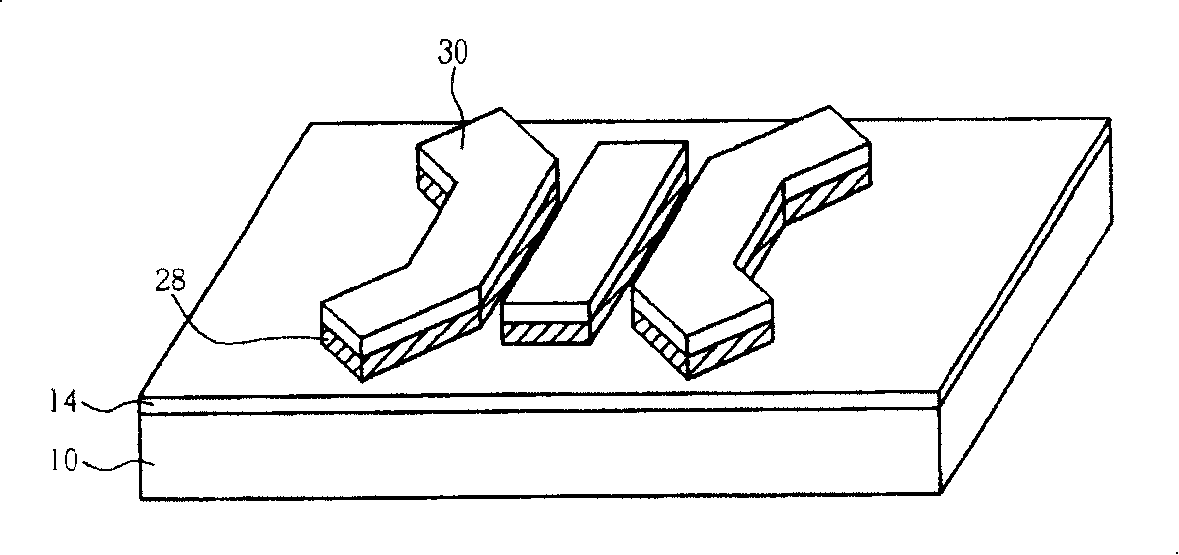

[0022] Please refer to Figure 1 to Figure 6 , Figure 1 to Figure 6 A schematic flow chart of the manufacturing method of the superalloy micro-heater according to the first preferred embodiment of the present invention. First, a substrate 10 and a superalloy sputtering target 12 are provided, and an insulating layer 14 is provided on the front surface of the substrate 10 . The substrate 10 used in this preferred embodiment is a silicon substrate, but it is not limited thereto. The superalloy sputtering target 12 can include nickel-based superalloy (Inconel), high nickel-based ratio superalloy (Nimonic), nickel-cobalt-based superalloy The sintered bodies of superalloy metals such as alloy (Incoloy), iron-based superalloy (Invar), nick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com