Oxidation dispersion strengthened steel and preparation method thereof

A dispersion strengthening and oxide technology, applied in the field of alloys, can solve problems affecting the high temperature mechanical properties of oxide dispersion strengthening steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method for the oxide dispersion strengthened steel, comprising the following steps:

[0041] Fe-Cr-Al-W pre-alloyed powder, Y 2 o 3 Powder and Hf powder are mixed and ball milled to obtain pre-sintered powder;

[0042] The pre-sintered powder is sintered by hot isostatic pressing to obtain oxide dispersion strengthened steel.

[0043] In the present invention, Fe-Cr-Al-W pre-alloyed powder, Y 2 o 3Powder and Hf powder are mixed and ball milled to obtain pre-sintered powder. In the present invention, the particle size of the Fe-Cr-Al-W pre-alloyed powder is preferably 30-100 μm, more preferably 40-80 μm, most preferably 50-60 μm. In the present invention, when the particle size of the Fe-Cr-Al-W pre-alloyed powder raw material meets the above requirements, the present invention preferably uses the Fe-Cr-Al-W pre-alloyed powder directly; when the Fe - When the particle size of the Cr-Al-W pre-alloyed powder raw mater...

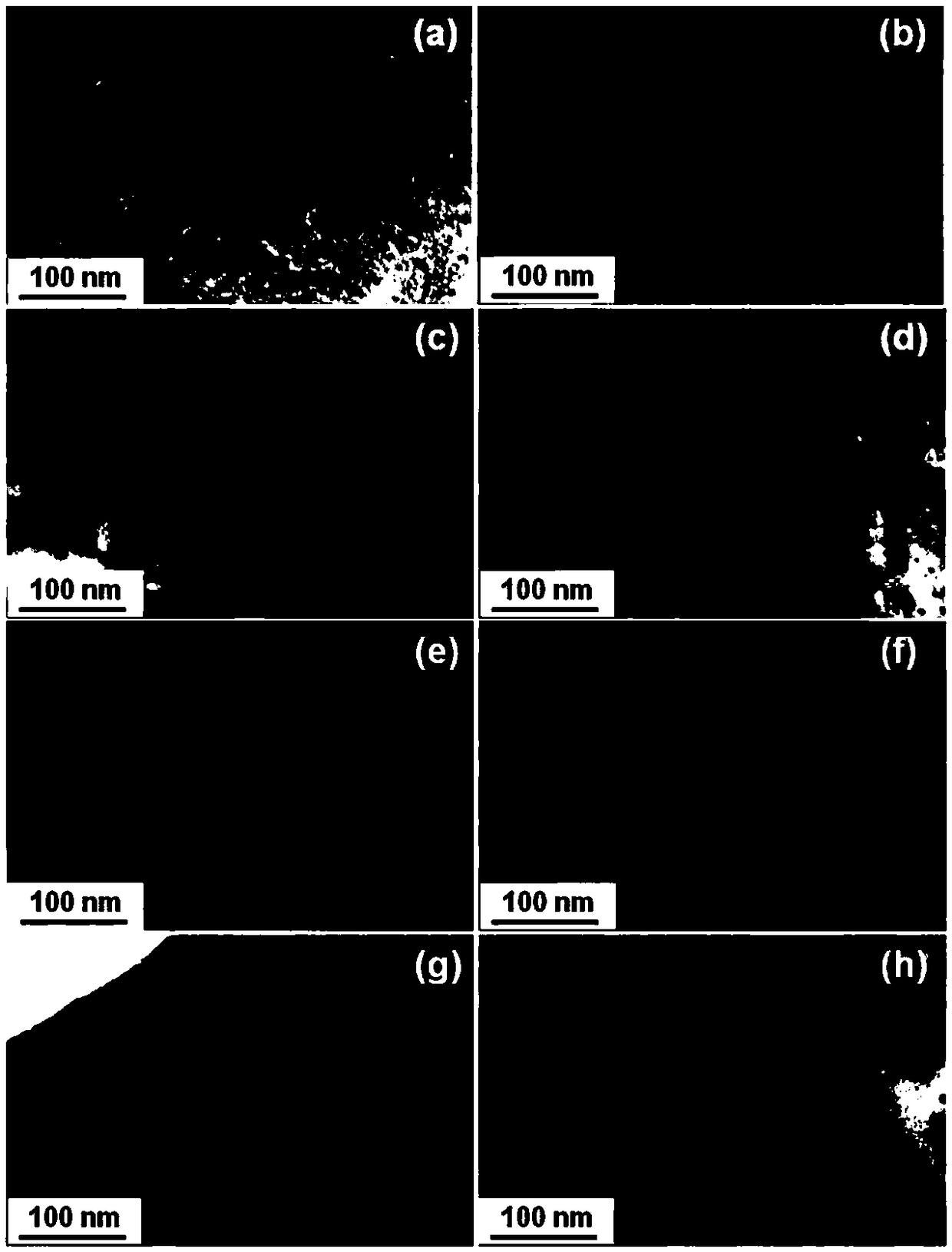

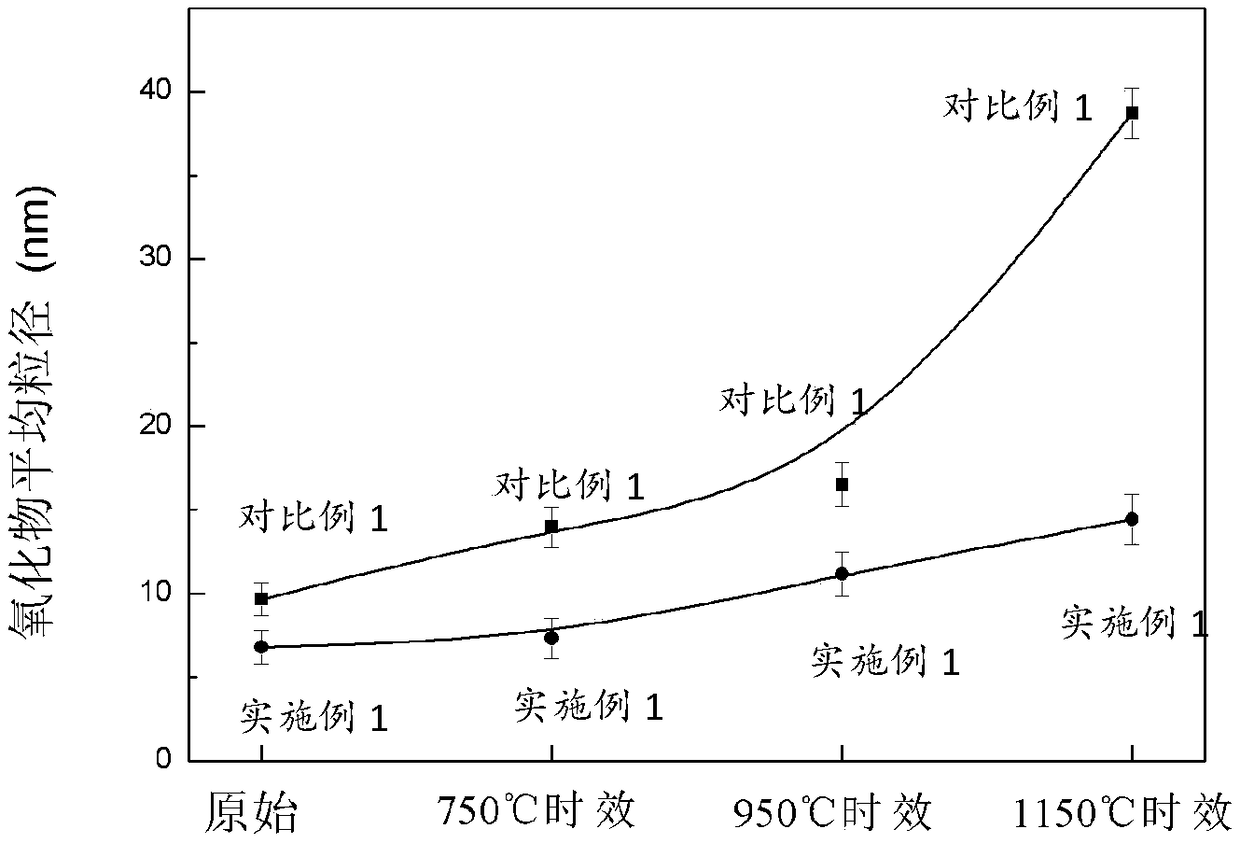

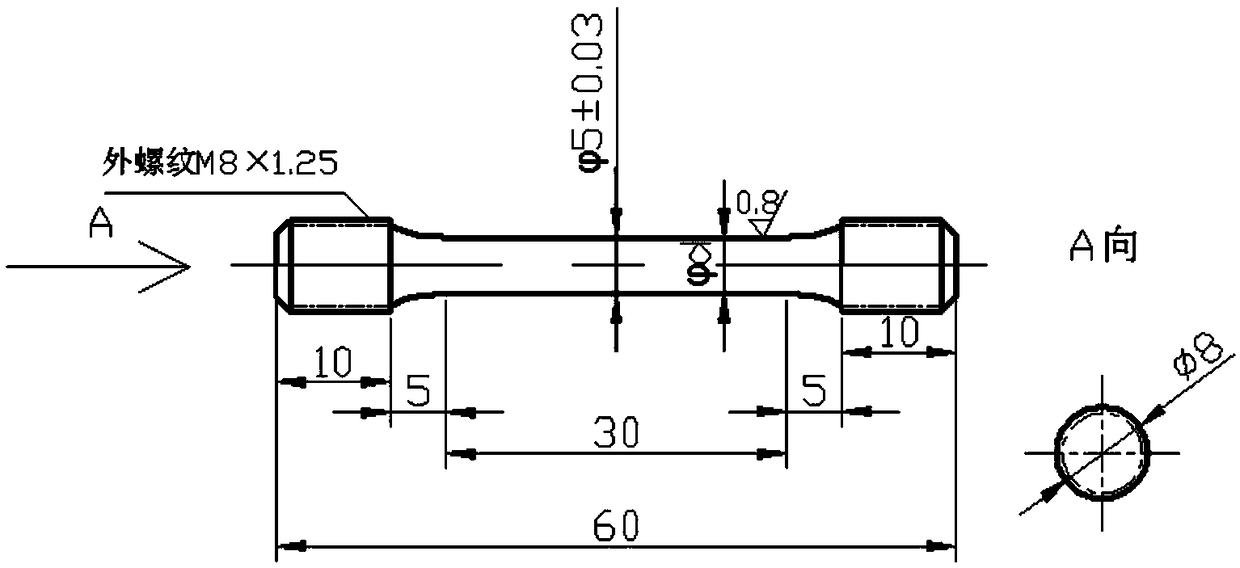

Embodiment 1

[0070] Weigh 149.025g of Fe-16wt%Cr-3wt%Al-1.5wt%W pre-alloyed powder with a particle size of 60μm, and 0.525g of Y with a particle size of 40nm 2 o 3 Put the particles and 0.75g of elemental Hf powder with a particle size of 10 μm into a 2000mL ball mill; then put 1500g of stainless steel balls into the ball mill respectively as the ball milling medium, wherein the weight ratio of steel balls with a diameter of 6mm and 10mm is 4:1;

[0071] Fill the ball mill jar with alloy raw materials and stainless steel balls with argon in a glove box and seal them, so that the ball milling process is carried out in an argon environment. The ball milling speed is 250r / min, and the ball milling time is 30h. During the ball milling process, every 8 hours of ball milling, stop for 40 minutes, repeat this way, the stop time is not included in the ball milling time. After ball milling, pre-sintered material is obtained;

[0072] Put the pre-sintered material into the stainless steel sheath,...

Embodiment 2

[0075] Weigh 149.025g of Fe-16wt%Cr-3wt%Al-1.5wt%W pre-alloyed powder with a particle size of 60μm, and 0.525g of Y with a particle size of 40nm 2 o 3 Put the particles and 0.75g of elemental Hf powder with a particle size of 10 μm into a 2000mL ball mill; then put 1500g of stainless steel balls into the ball mill respectively as the ball milling medium, wherein the weight ratio of steel balls with a diameter of 6mm and 10mm is 4:1;

[0076] Fill the ball mill jar with alloy raw materials and stainless steel balls with argon in a glove box and seal them, so that the ball milling process is carried out in an argon environment. The ball milling speed is 300r / min, and the ball milling time is 30h. During the ball milling process, every 8 hours of ball milling, stop for 40 minutes, repeat this way, the stop time is not included in the ball milling time. After ball milling, pre-sintered material is obtained;

[0077] Put the pre-sintered material into the stainless steel sheath,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com