Process for preparing SiBONC ceramic with high temp stabilized

A high-temperature stable, ceramic technology, applied in the field of preparation of amorphous silicon-based ceramics, can solve the problems of poor reliability and relatively high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

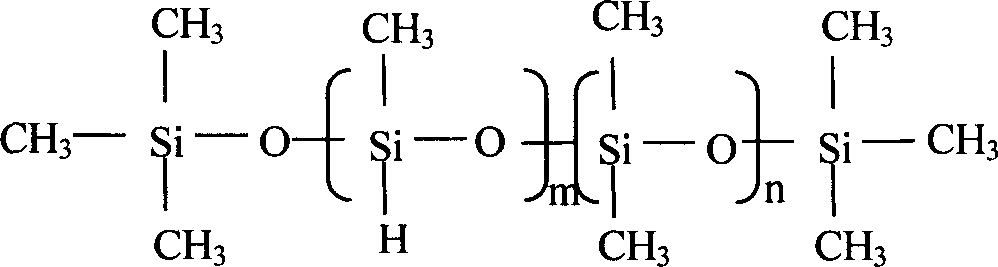

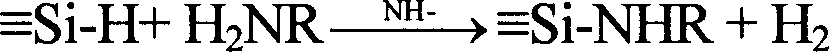

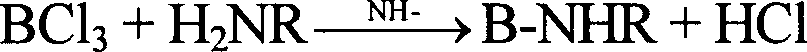

[0015] Specific embodiment one: this embodiment includes the following steps: (one) synthesizing SiONC precursor; (two) synthesizing SiBONC precursor; (three) cracking SiBONC precursor, making SiBONC ceramic powder; the core content of this method In the step (1), the SiONC precursor is synthesized as follows: organic silicone oil and alkylamine are used as raw materials, dissolved in an organic solvent, mixed and stirred, and kept at 70-100° C. for 20-30 hours to synthesize the SiONC precursor. In the step (2) of this embodiment, the SiBONC precursor is synthesized as follows: Boride is introduced into the SiONC organic polymer, and reacted at 60-150°C for 5-15 hours to obtain the SiBONC organic polymer, wherein Si The molar ratio of / B is between 1:0.1-0.5, and the boron compound is boron trichloride, borane or diborane. In step (3), the SiBONC precursor is cracked to obtain SiBONC powder: In a tubular atmosphere protection furnace, nitrogen or inert gas is introduced, at 30...

specific Embodiment approach 2

[0016] Specific embodiment two: this embodiment differs from specific embodiment one in that it also includes step (four): the prepared SiBONC powder is sintered to obtain dense SiBONC amorphous and microcrystalline ceramic products, which can be passed through the following steps: The above two methods are realized: one method is to sinter the prepared Si-B-O-N-C powder in a pressure sintering furnace, feed nitrogen or inert gas, control the reaction temperature at 1100-1900 °C, and the heating rate is 5-50 °C / min , pressure of 0.1 ~ 10Mpa under the condition of heat preservation for 2 ~ 4 hours, after sintering to obtain dense SiBONC amorphous and microcrystalline ceramic products; another method is to prepare SiBONC powder in a vacuum / atmosphere hot pressing sintering furnace Sintering, heat preservation under the conditions of 1400-1900°C and 10-40MPa for 1-3 hours, and obtain dense SiBONC amorphous and microcrystalline ceramic products after sintering. Other reaction step...

specific Embodiment approach 3

[0017] Specific embodiment three: this embodiment takes high hydrogen-containing methyl silicone oil (HPSO) and ethylenediamine as raw materials, and toluene is a solvent, and it prepares SiBONC ceramics in this way: (1) get 120ml HPSO and be dissolved in 400ml toluene, and 44ml ethylenediamine and 100ml toluene are slowly dripped into the mixed solution of HPSO and toluene with a dropping funnel, and stirred for 24 hours with a stirrer to form a SiONC organic precursor; (2) 300gAlCl 3 with 200gKBF 4 Ball mill and mix in a special stainless steel reactor for 3-11 hours, and generate BCl in an oil bath at 70-180°C 3 , then the resulting BCl 3 The gas is passed into the SiONC organic precursor, and reacted at 70-100 °C for 10 hours to obtain the SiBONC organic polymer; (3) In the tubular atmosphere protection furnace, nitrogen gas is introduced, at 800-1000 °C, the heating rate Control the reaction at 1-5°C / min for 10 hours to crack the SiBONC organic polymer to obtain SiBONC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com