Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Formed surely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

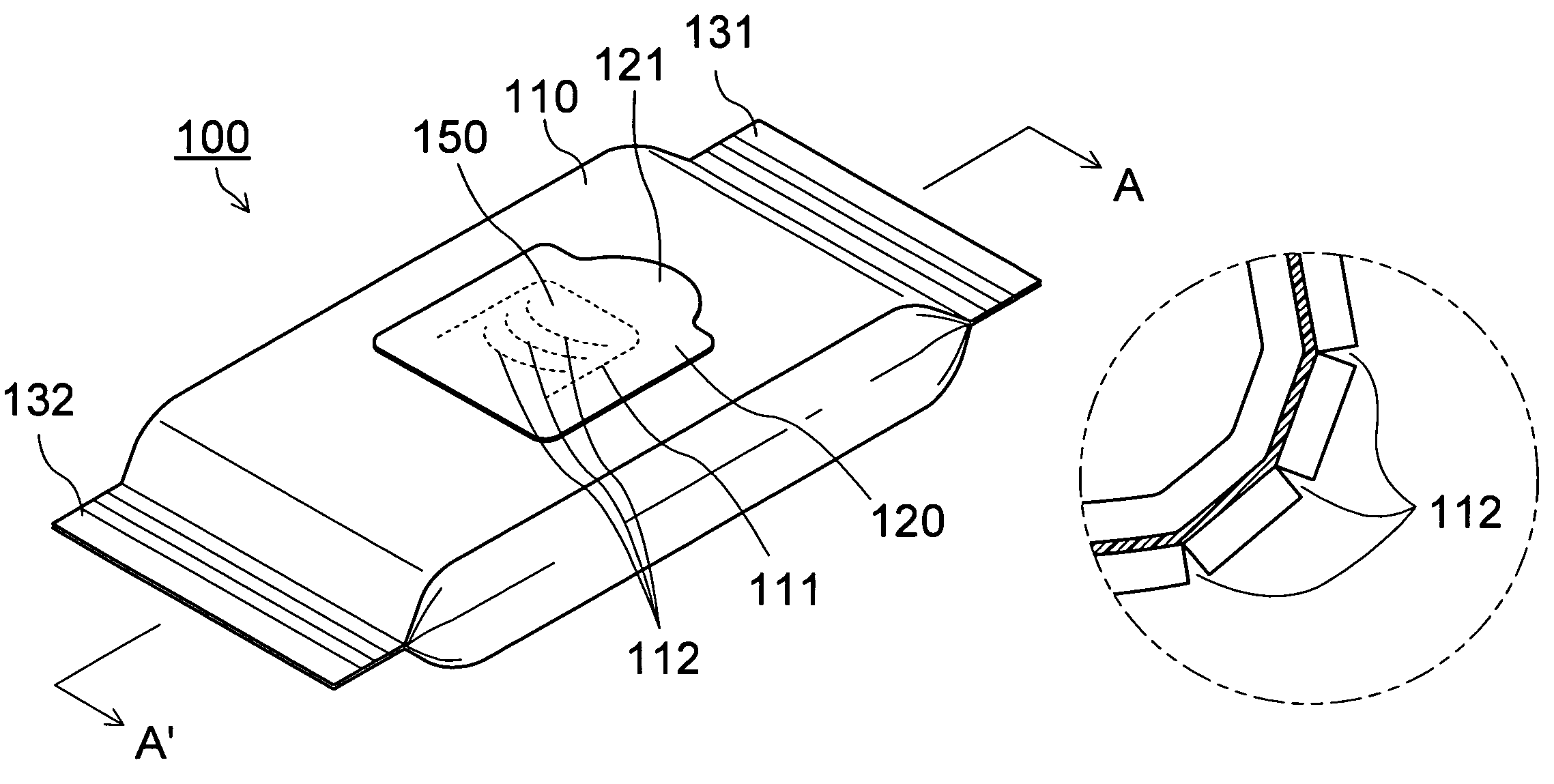

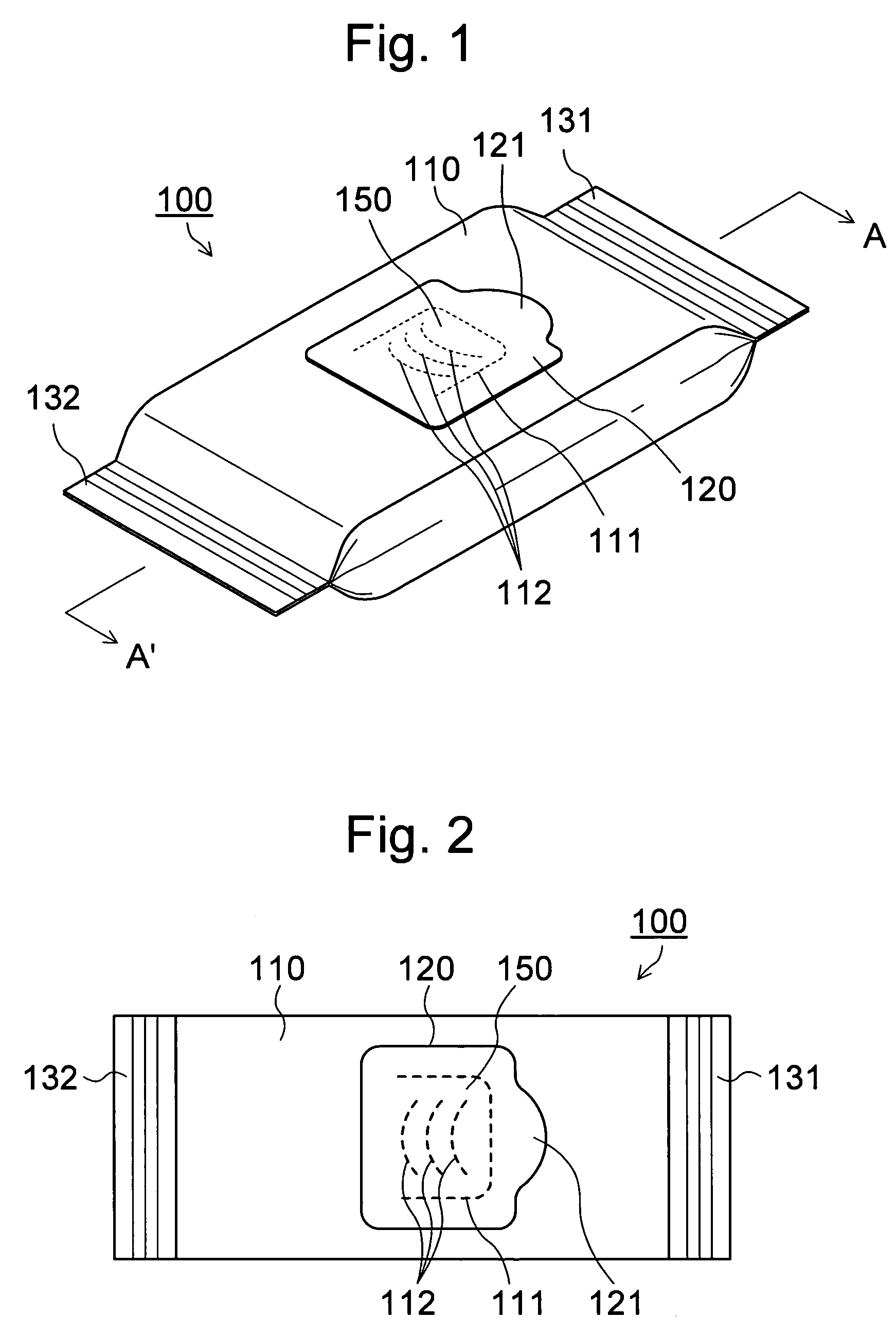

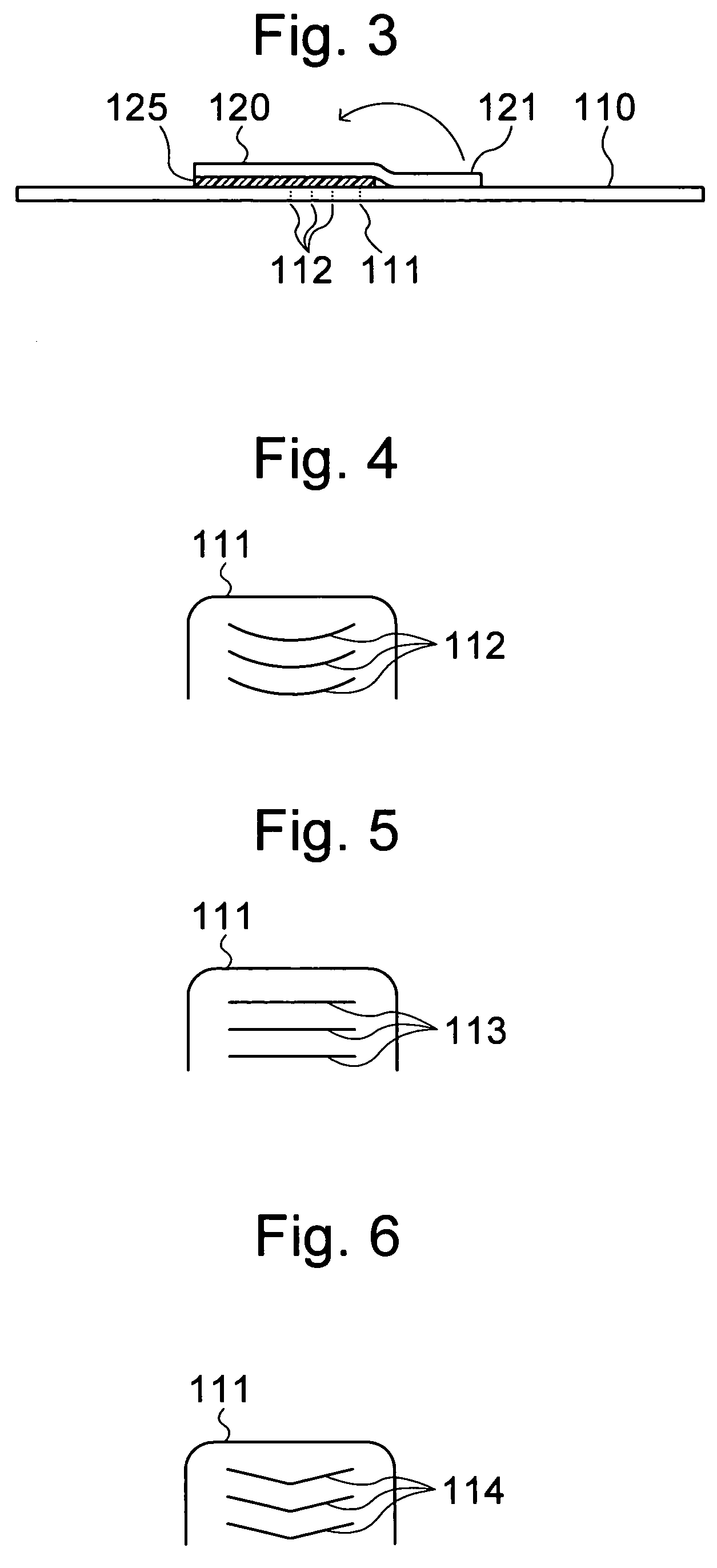

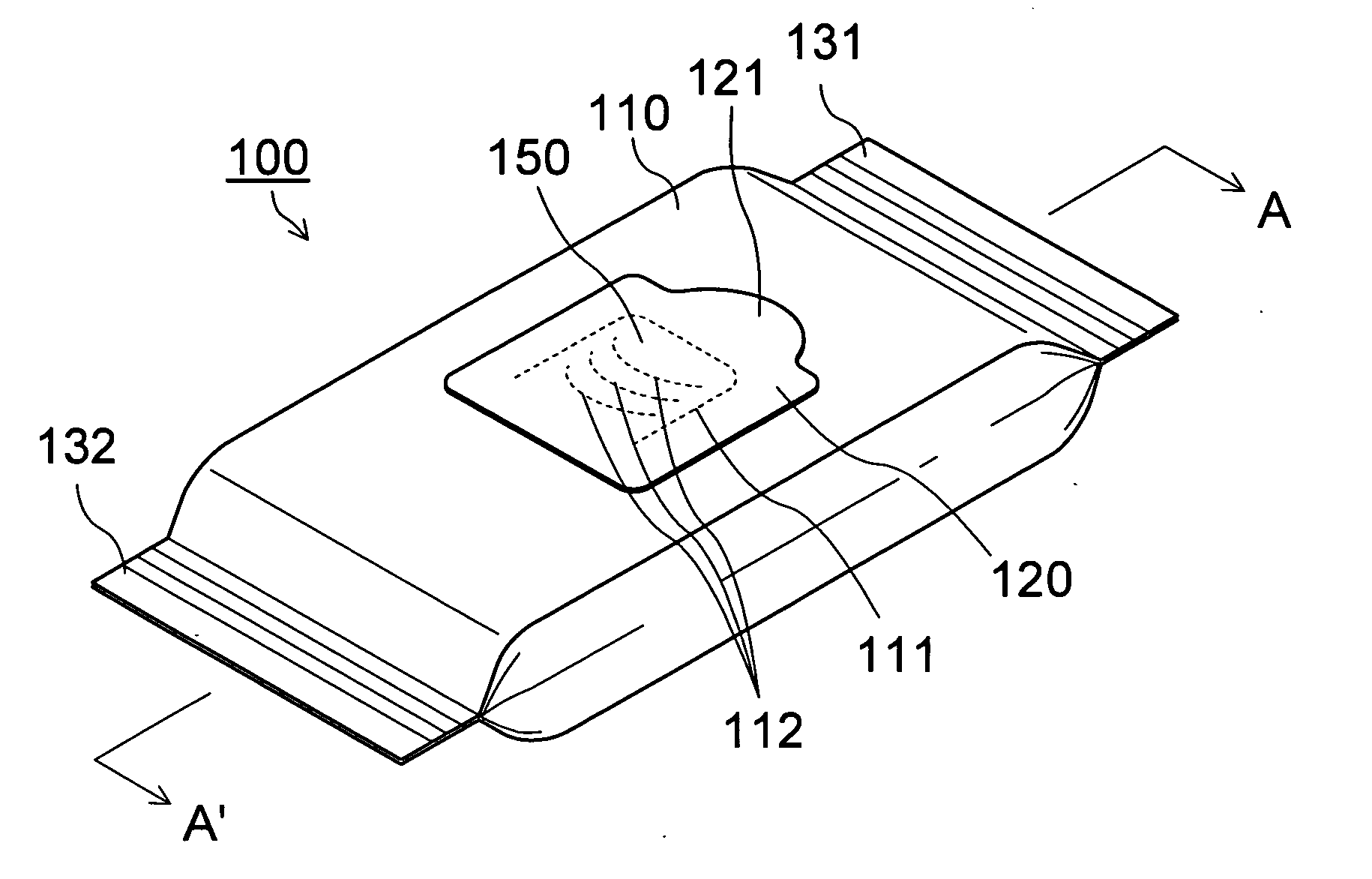

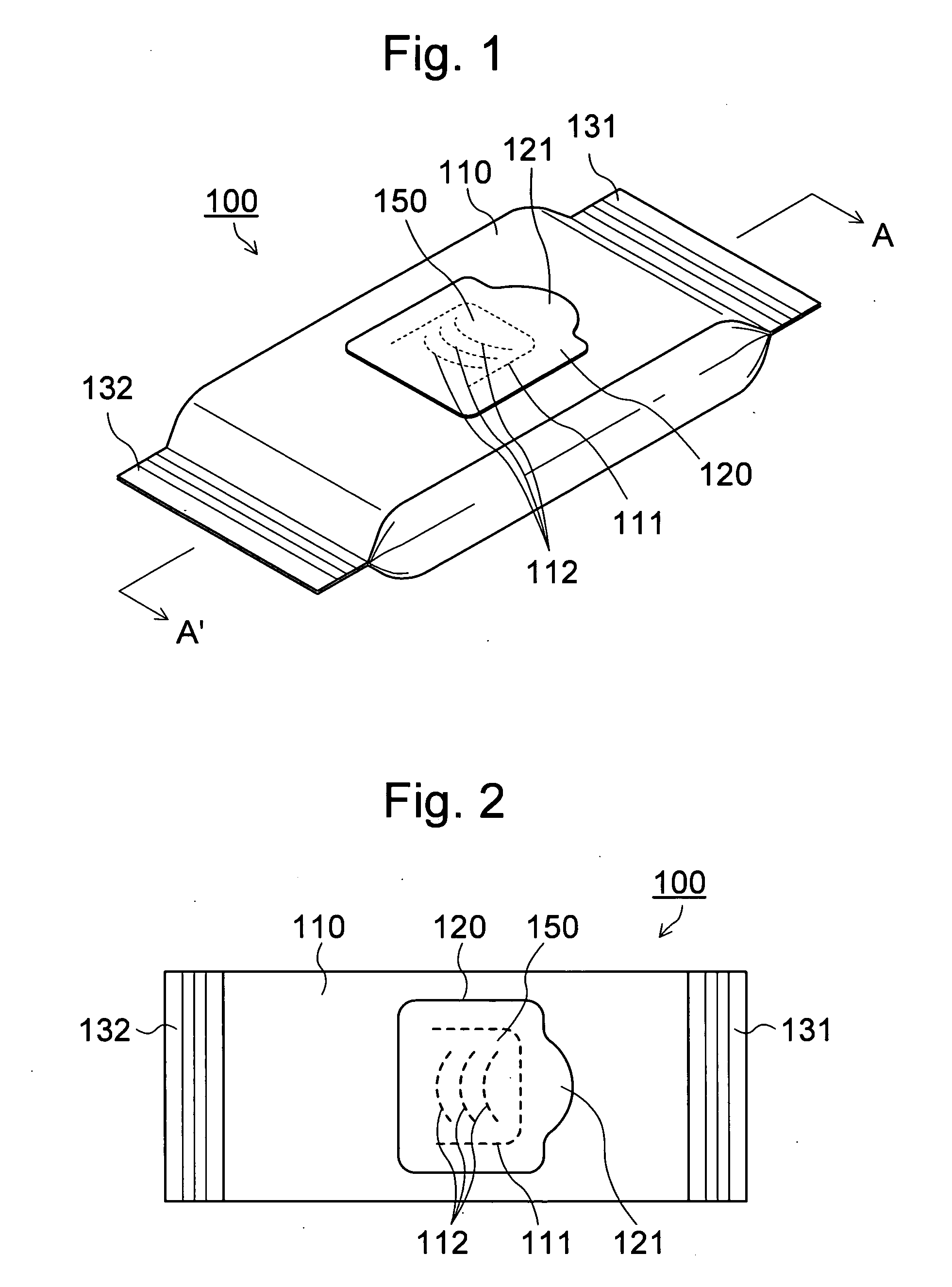

Easy-open package

InactiveUS7475781B2Reduce stiffnessEasy to stickWrappersDiagnosticsMechanical engineeringEngineering

A package is presented from which contents can be easily taken out. This package includes a film with a soft packaging material. On the surface of the soft packaging material is a cut line, such that, inside the cut line, an openable region is formed for taking contents out from the package. Further, inside the openable region, dashed lines are provided. When a lid member adhering to cover the openable region is peeled, the openable region easily adheres to the lid member side owing to the dashed lines to reliably form the opened portion.

Owner:UNI CHARM CORP

Easy-open package

InactiveUS20050284776A1Reduce stiffnessEasy to stickDiagnosticsSurgical needlesBiomedical engineeringEngineering

A package is presented from which contents can be easily taken out. This package includes a film with a soft packaging material. On the surface of the soft packaging material is a cut line, such that, inside the cut line, an openable region is formed for taking contents out from the package. Further, inside the openable region, dashed lines are provided. When a lid member adhering to cover the openable region is peeled, the openable region easily adheres to the lid member side owing to the dashed lines to reliably form the opened portion.

Owner:UNI CHARM CORP

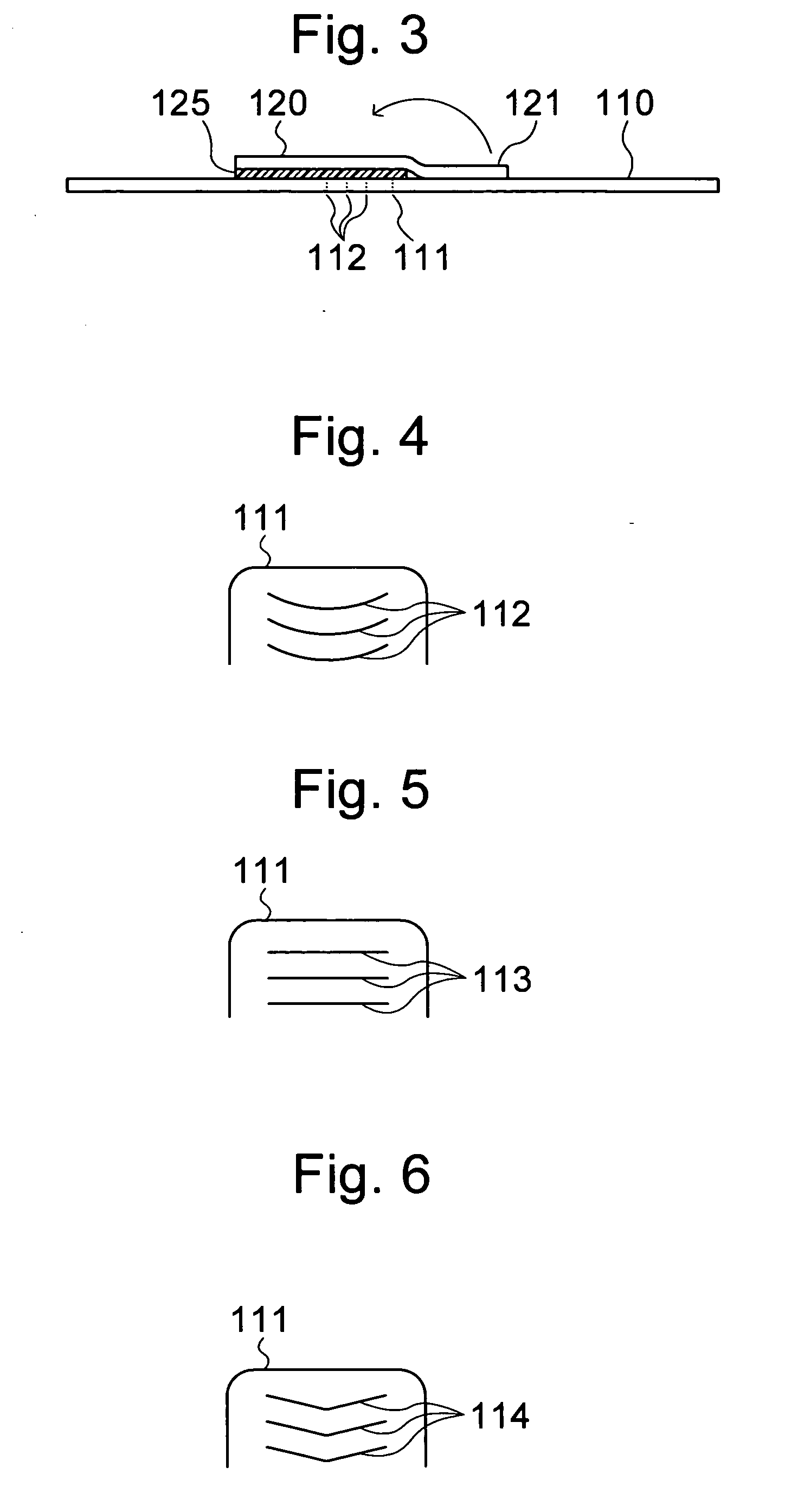

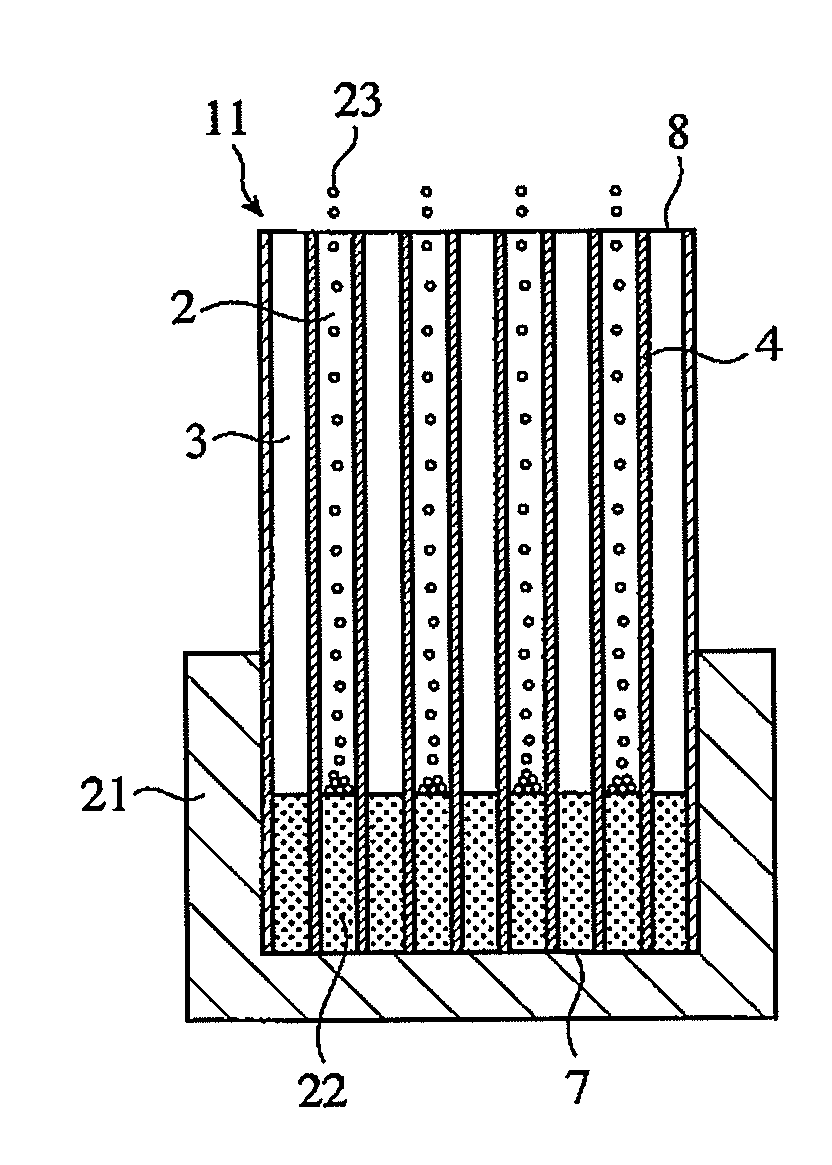

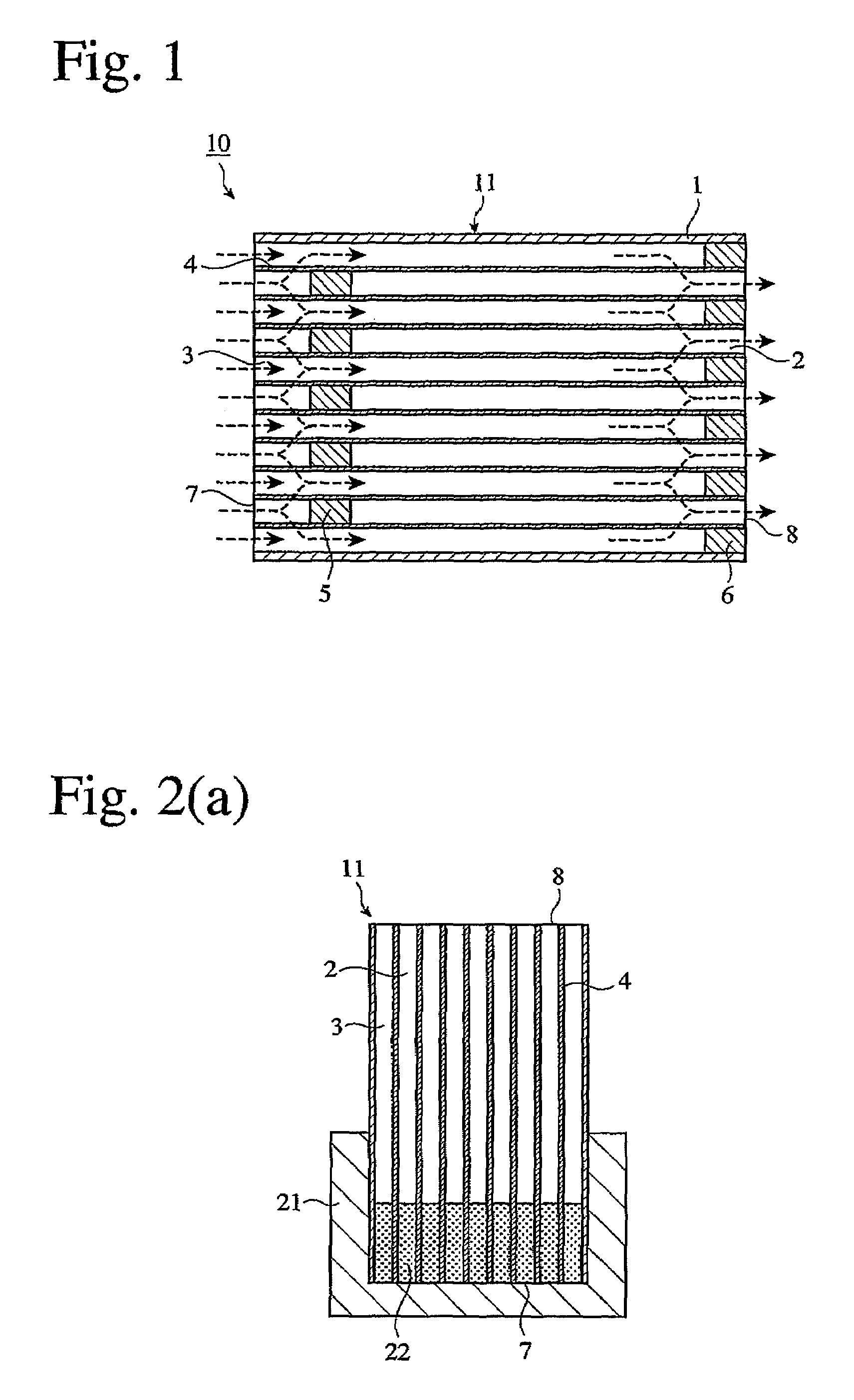

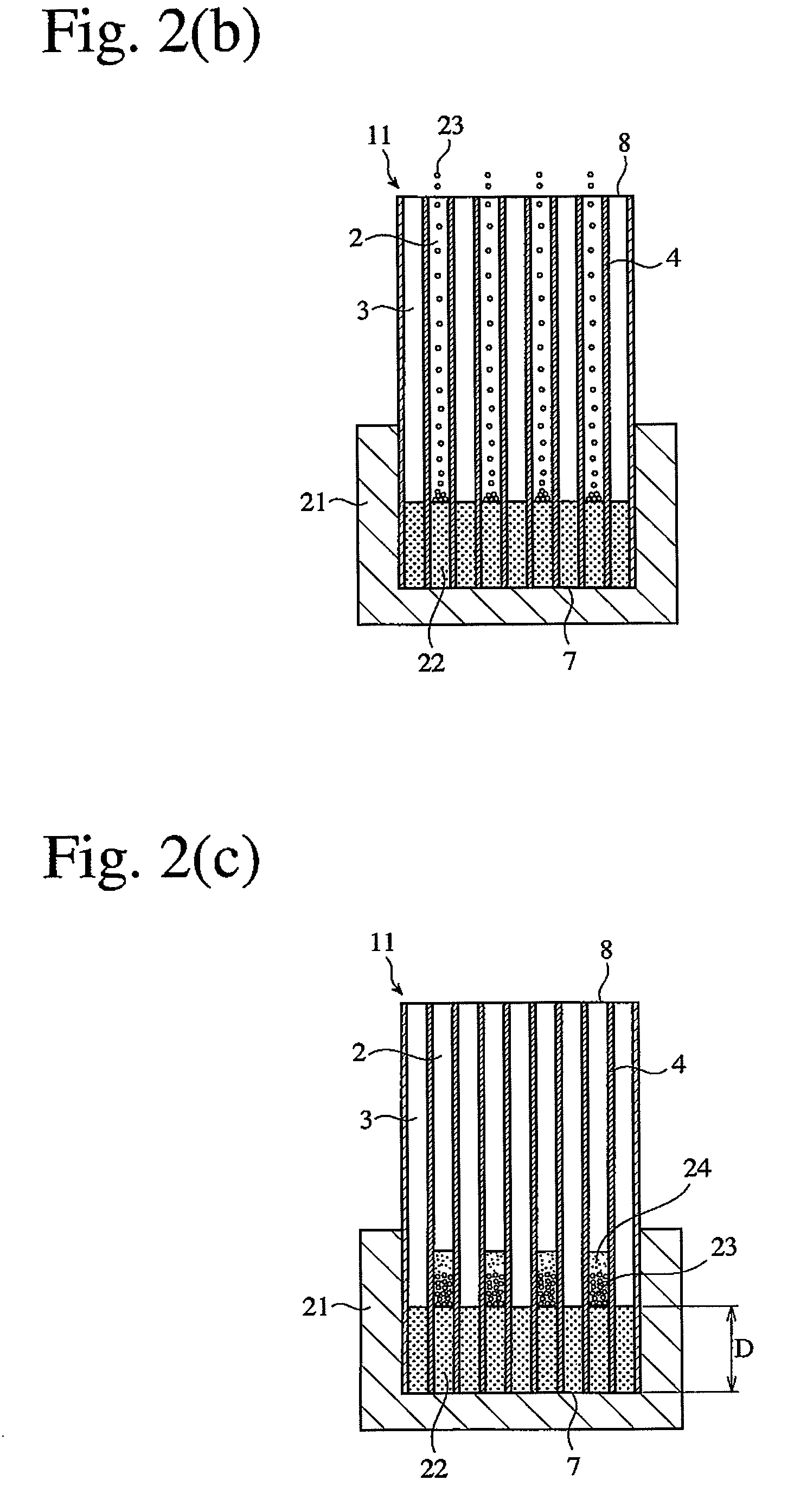

Method for Producing Ceramic Honeycomb Filter

ActiveUS20090008830A1Formed surelyGas treatmentInternal combustion piston enginesCell wallMaterials science

A method for producing a ceramic honeycomb filter having large numbers of flow paths partitioned by cell walls, the flow paths having plugs at positions separate from an end surface of the honeycomb filter, comprising the steps of introducing a base-forming material into the flow paths on one end surface side, charging a plug-forming material into flow paths to be provided with plugs from the other end surface side, and sintering it.

Owner:HITACHI METALS LTD

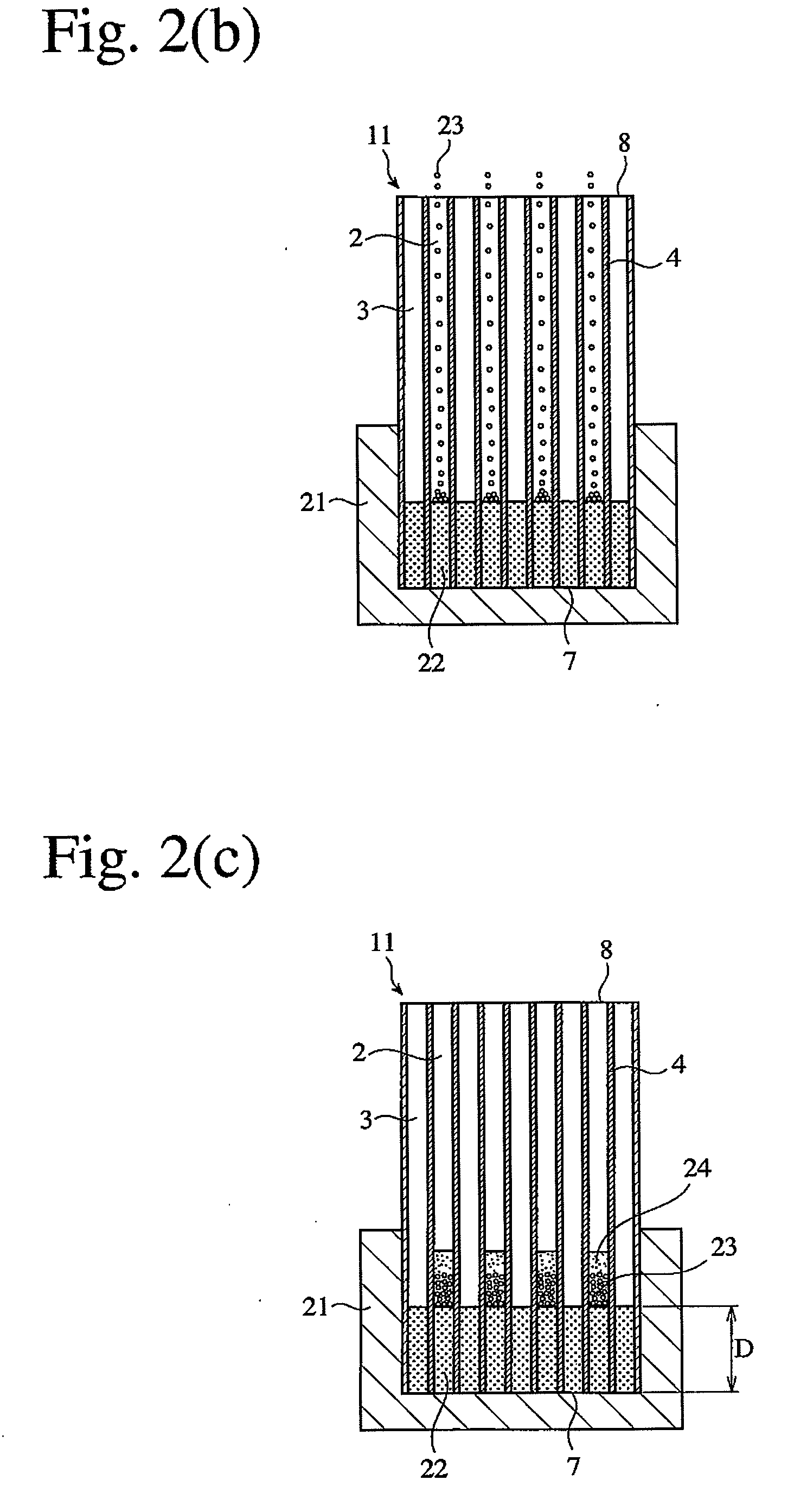

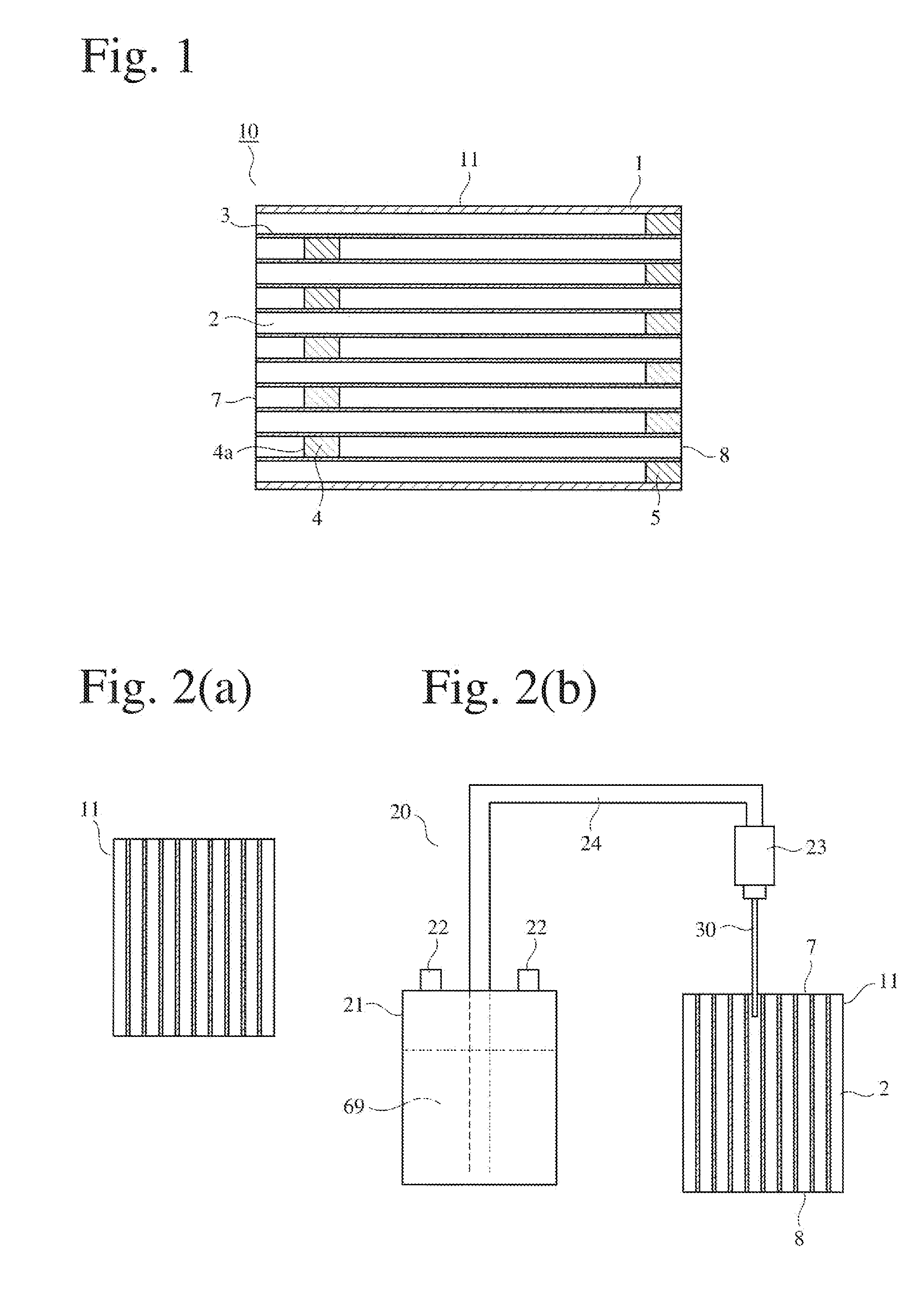

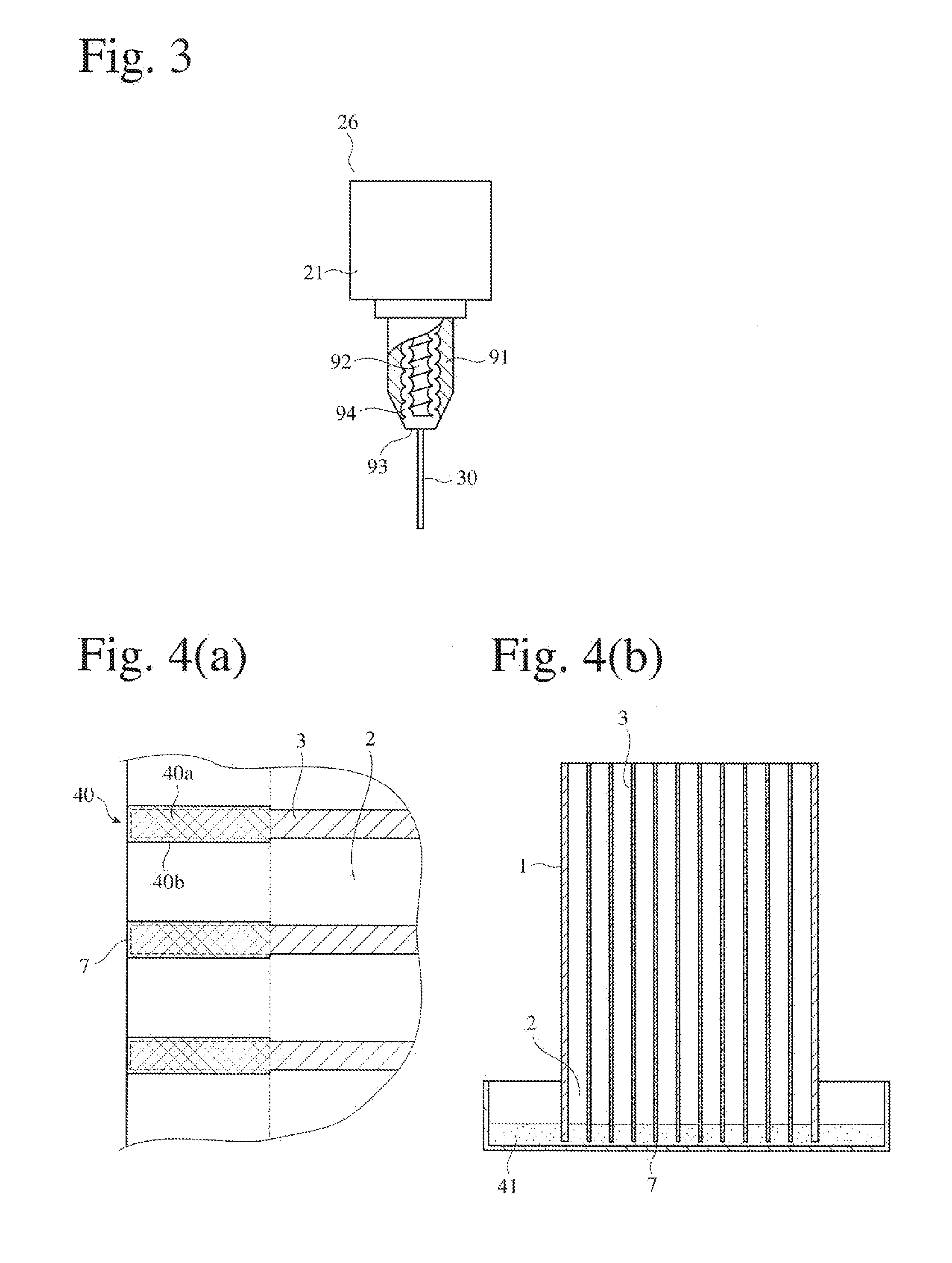

Production Method Of Honeycomb Filter And Honeycomb Filter

ActiveUS20080155952A1Avoid cloggingFormed surelyCombination devicesGas treatmentCell wallHoneycomb structure

A method for producing a honeycomb filter from a honeycomb structure having large numbers of flow paths partitioned by cell walls, comprising inserting a tubular member into each of the flow paths, and injecting a plugging material into each of the flow paths from the tubular member to form a plug in each of the flow paths at a position separate from the end surface of the honeycomb structure, the tubular member having an outer diameter that is 40-90% of the opening size of the flow path, the plugging material comprising at least a ceramic material having a maximum particle size that is 85% or less of the inner diameter of the tubular member, and an average particle size of 1 μm or more.

Owner:HITACHI METALS LTD

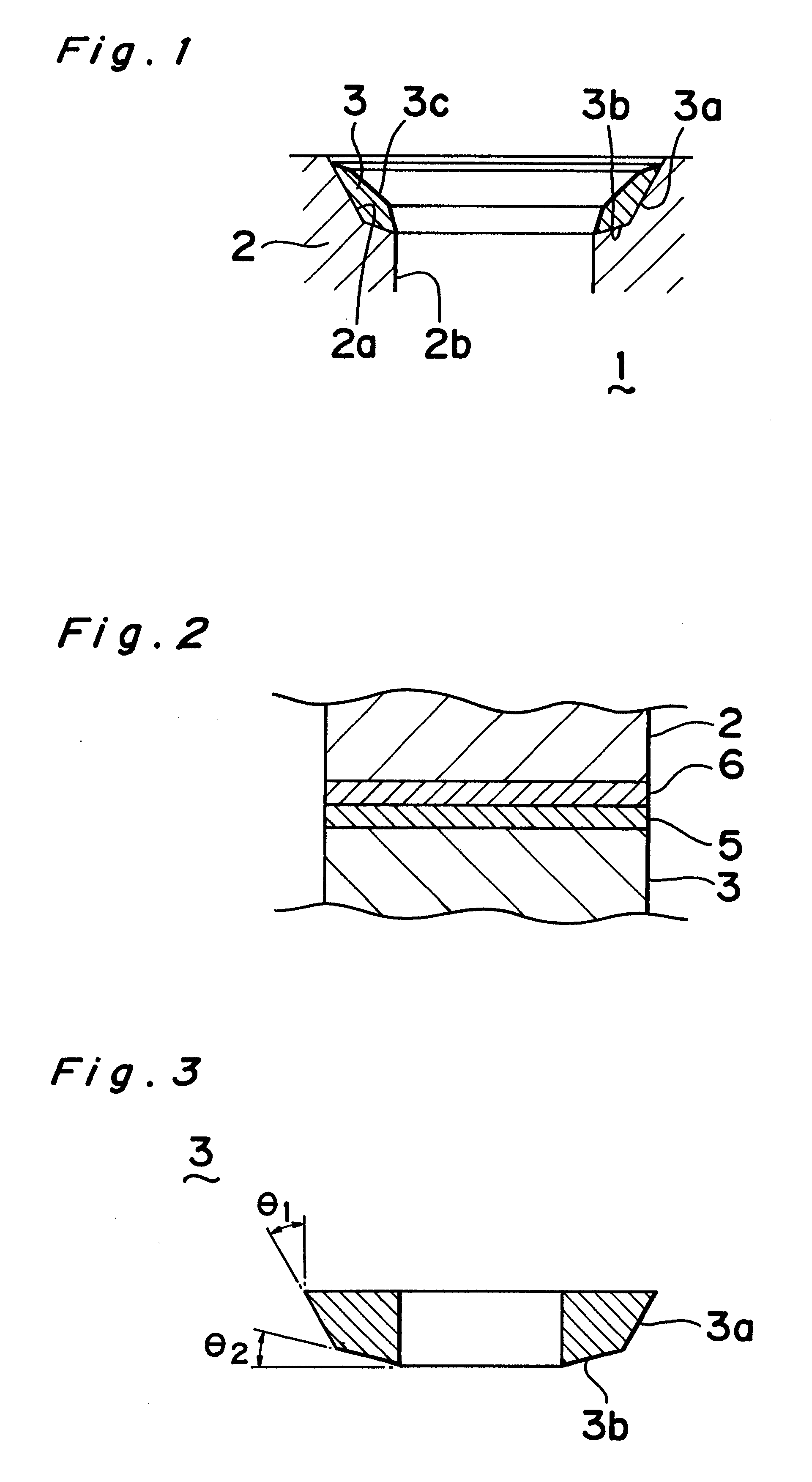

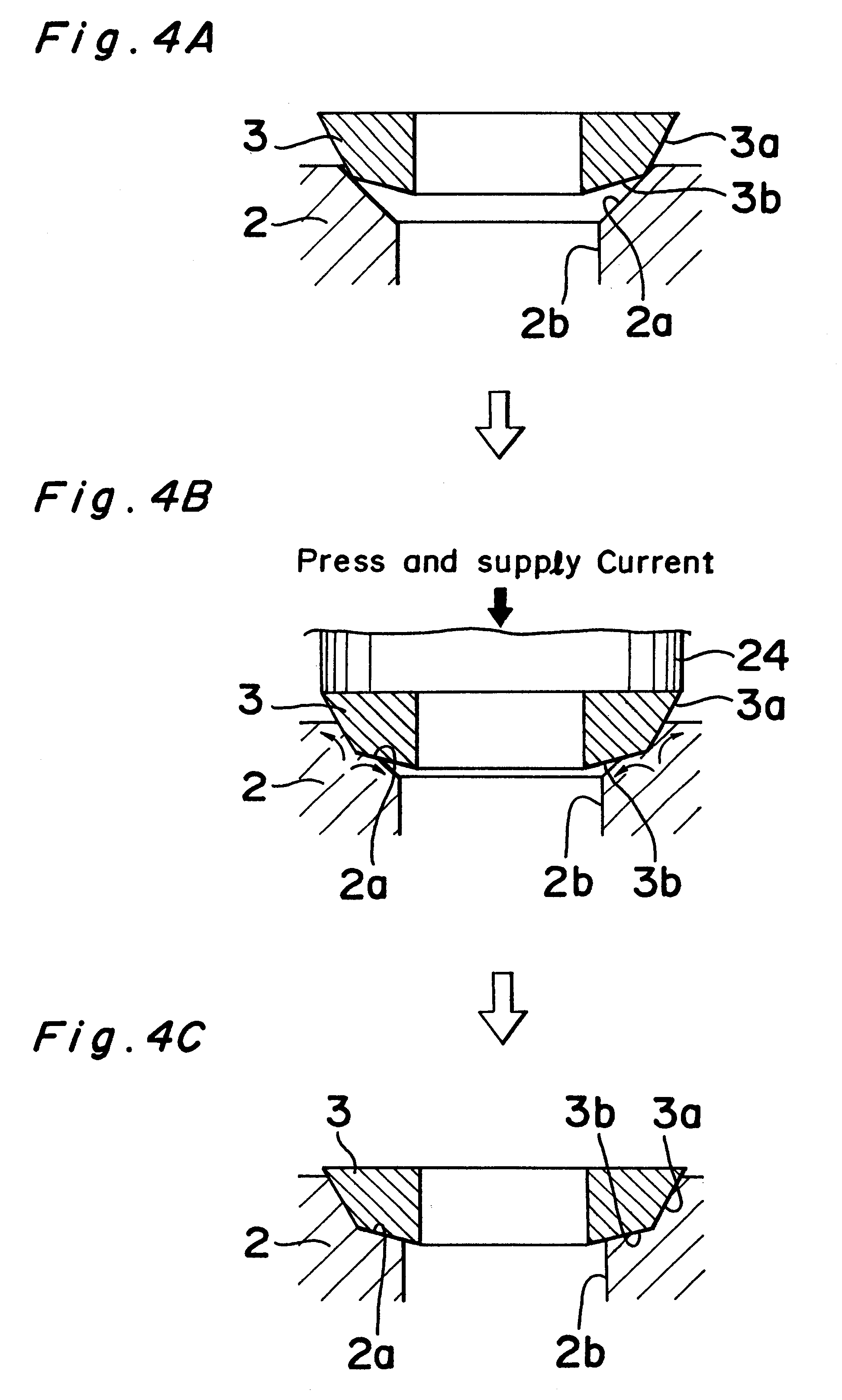

Joined metal member and method of joining said member

InactiveUS6323458B1Improve conductivityAvoid feverElectric heatingCylinder headsThermal conductivityEngineering

In order to provide a method of joining a cylinder head 2 and a valve seat 3 by press and heat generated on passing an electrical current through both members 2, 3, to achieve satisfactory joining with minimized heat generated inside when the current is supplied, while eliminating the need for an infiltration step and reduce the production cost, inhibiting an increase in thermal conductivity of the valve seat 3 and improving the wear resistance thereof. The valve seat 3 is made of a sintered material made from a powdery material with a high electrical conductivity element such as Cu dispersed therein. The current and the pressure are applied with a first joining surface 3a of the valve seat 3 and a joining surface 2a of the cylinder head body 2 being put into surface contact with each other in advance.

Owner:MAZDA MOTOR CORP

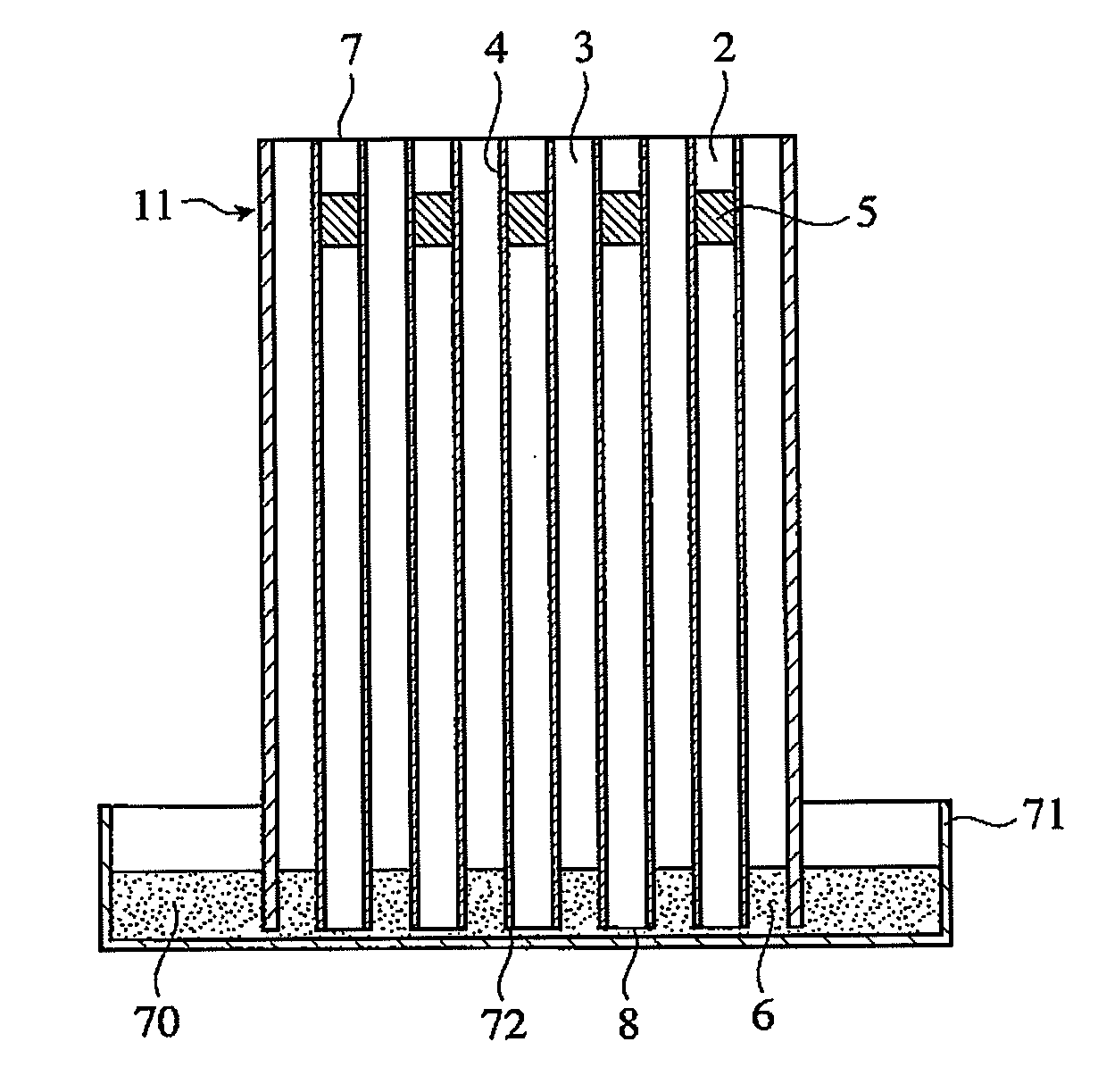

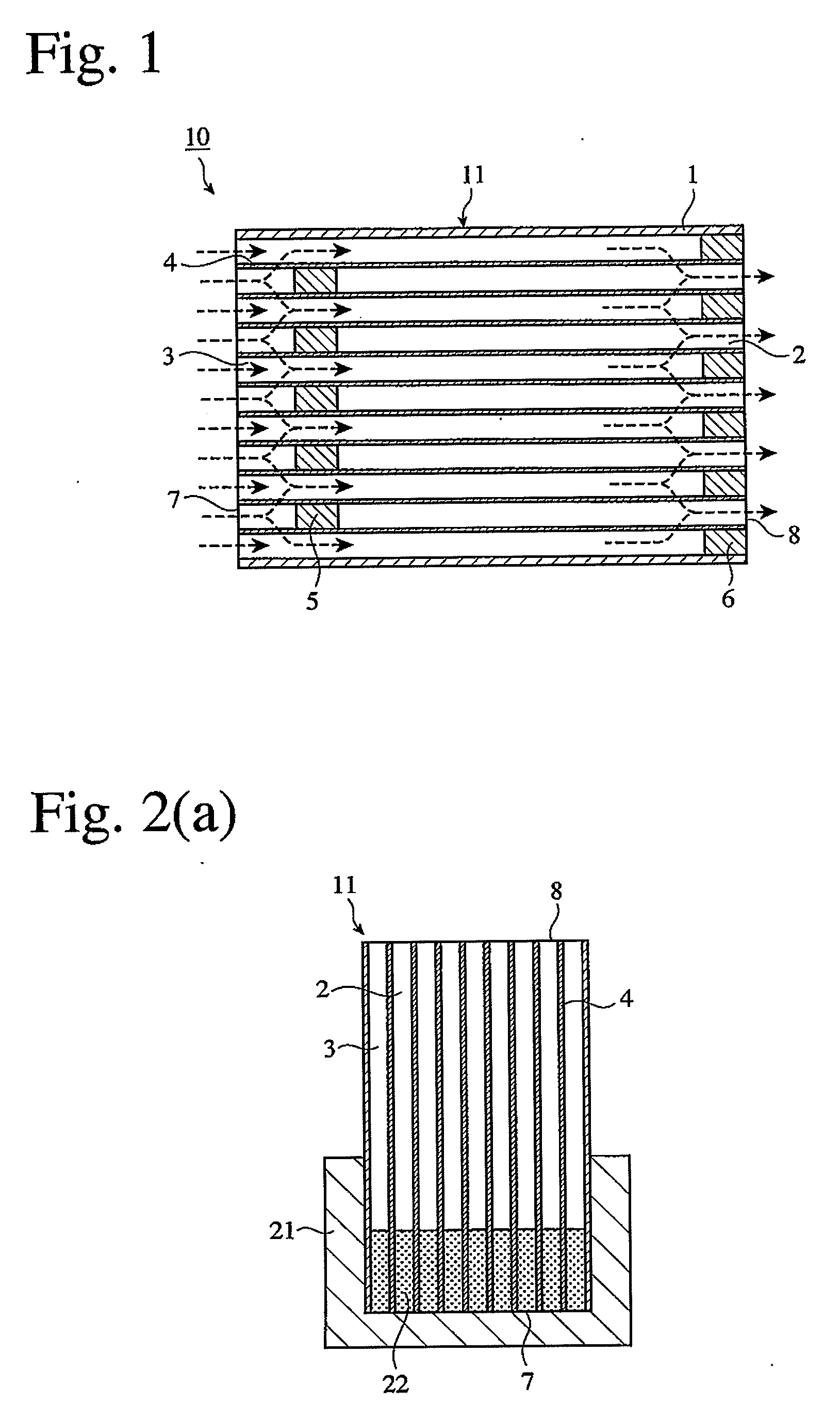

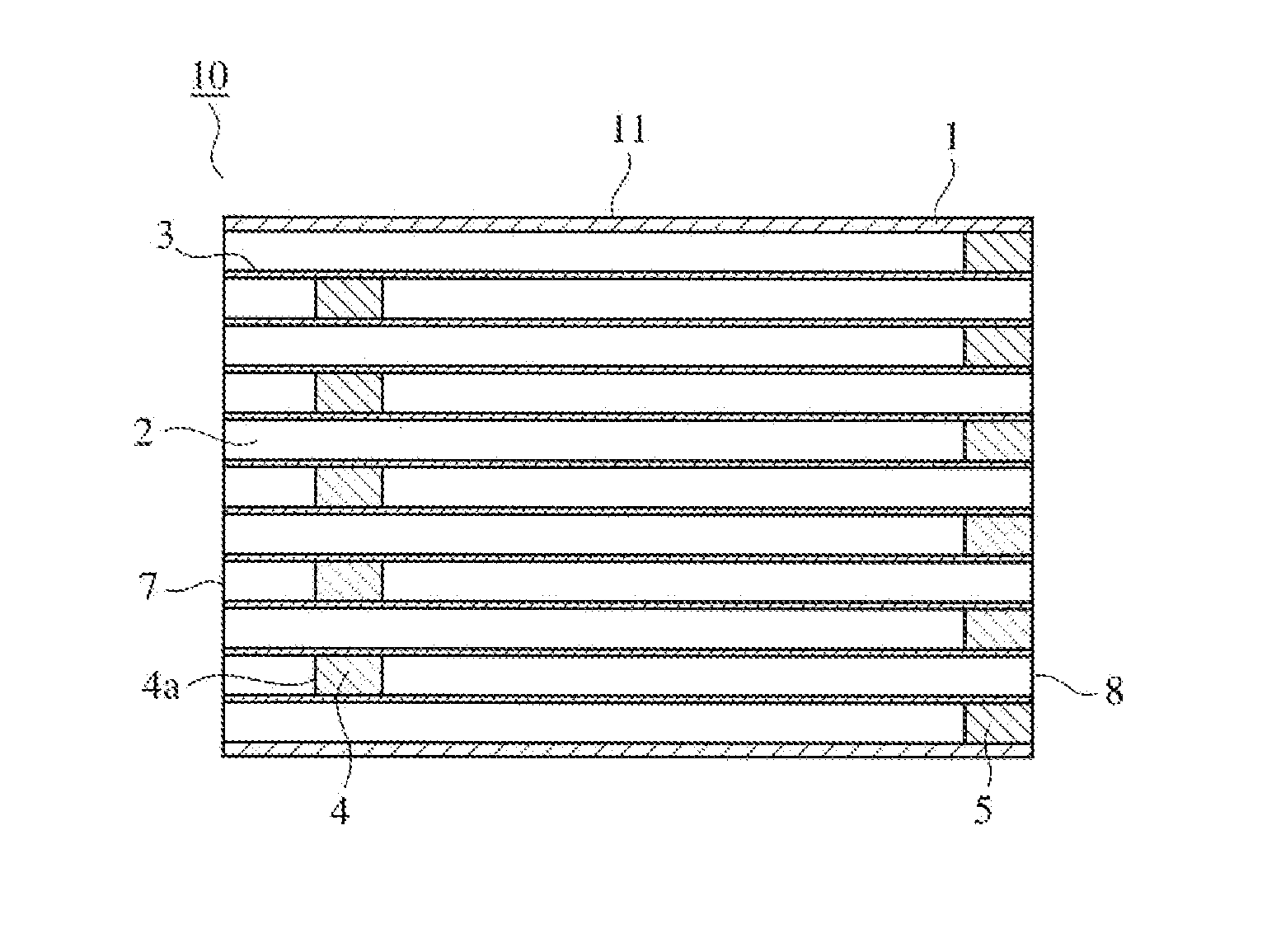

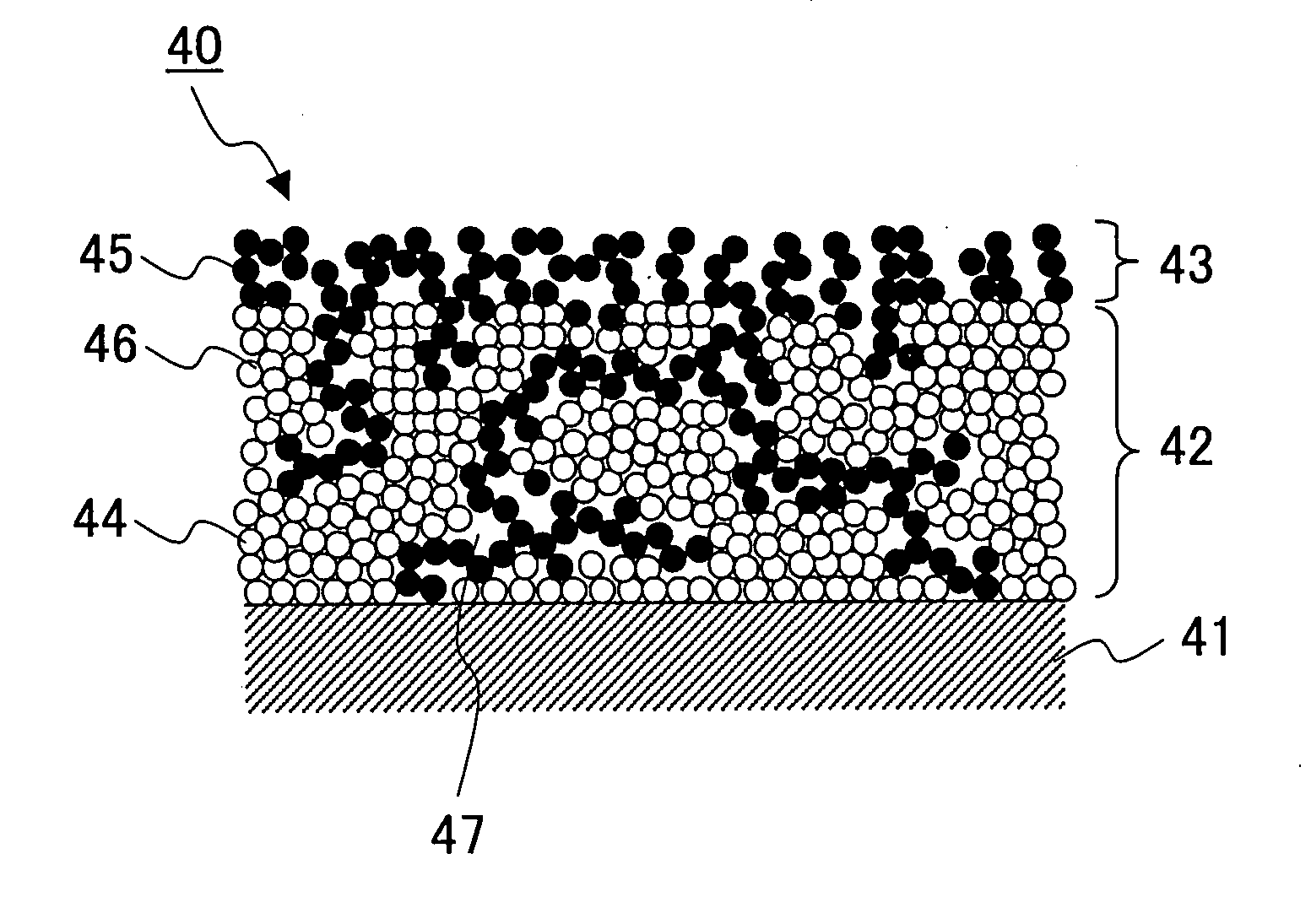

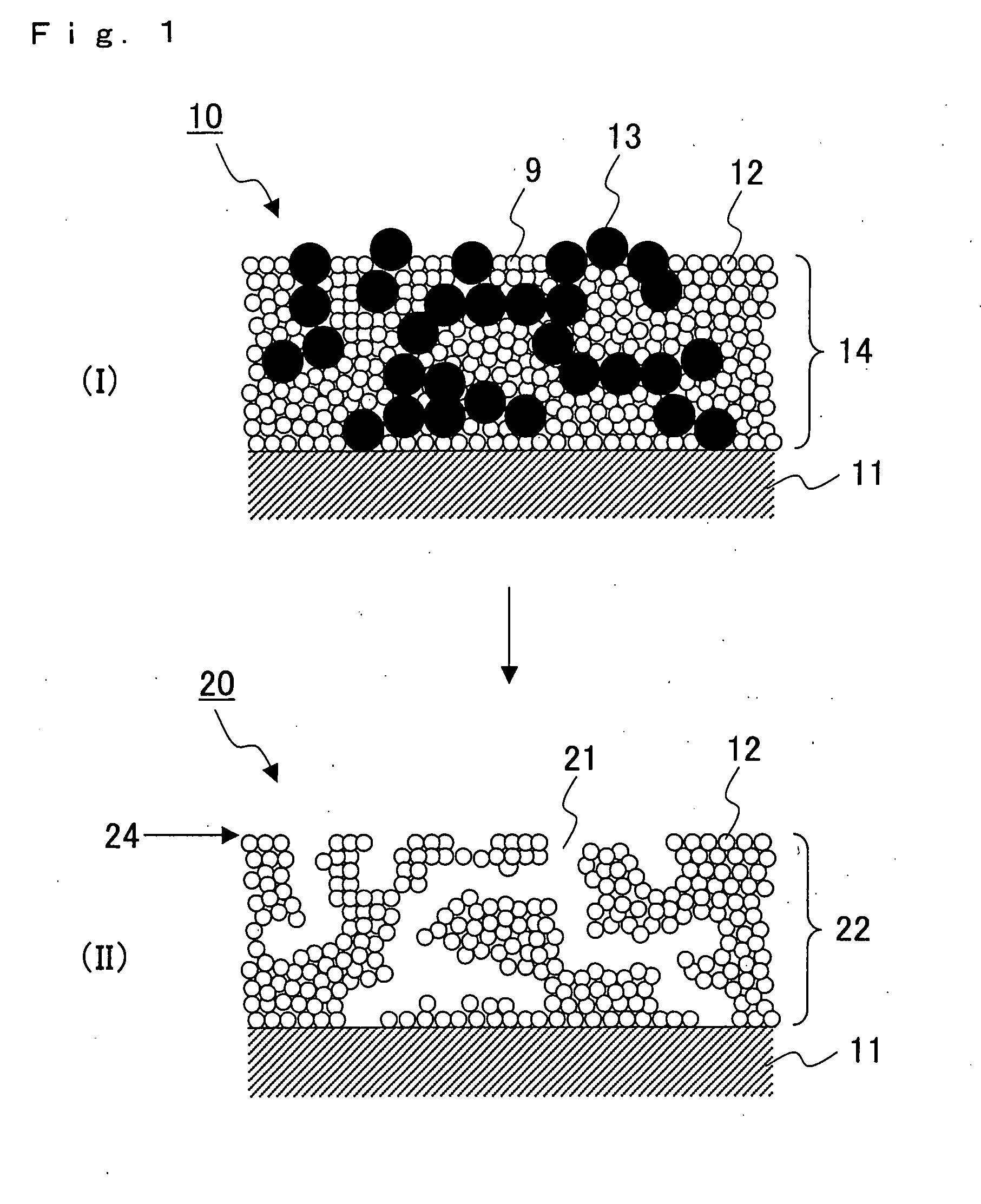

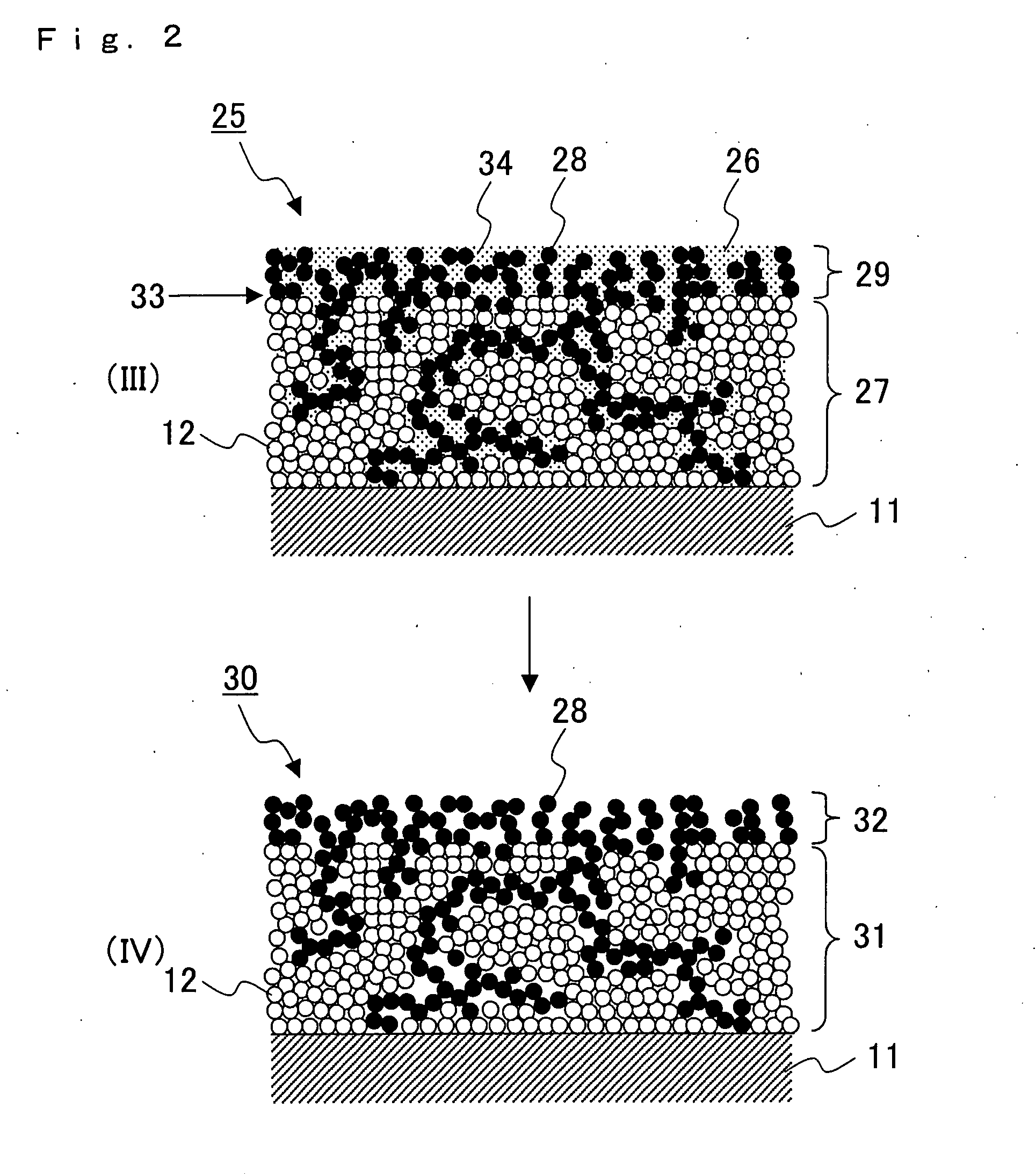

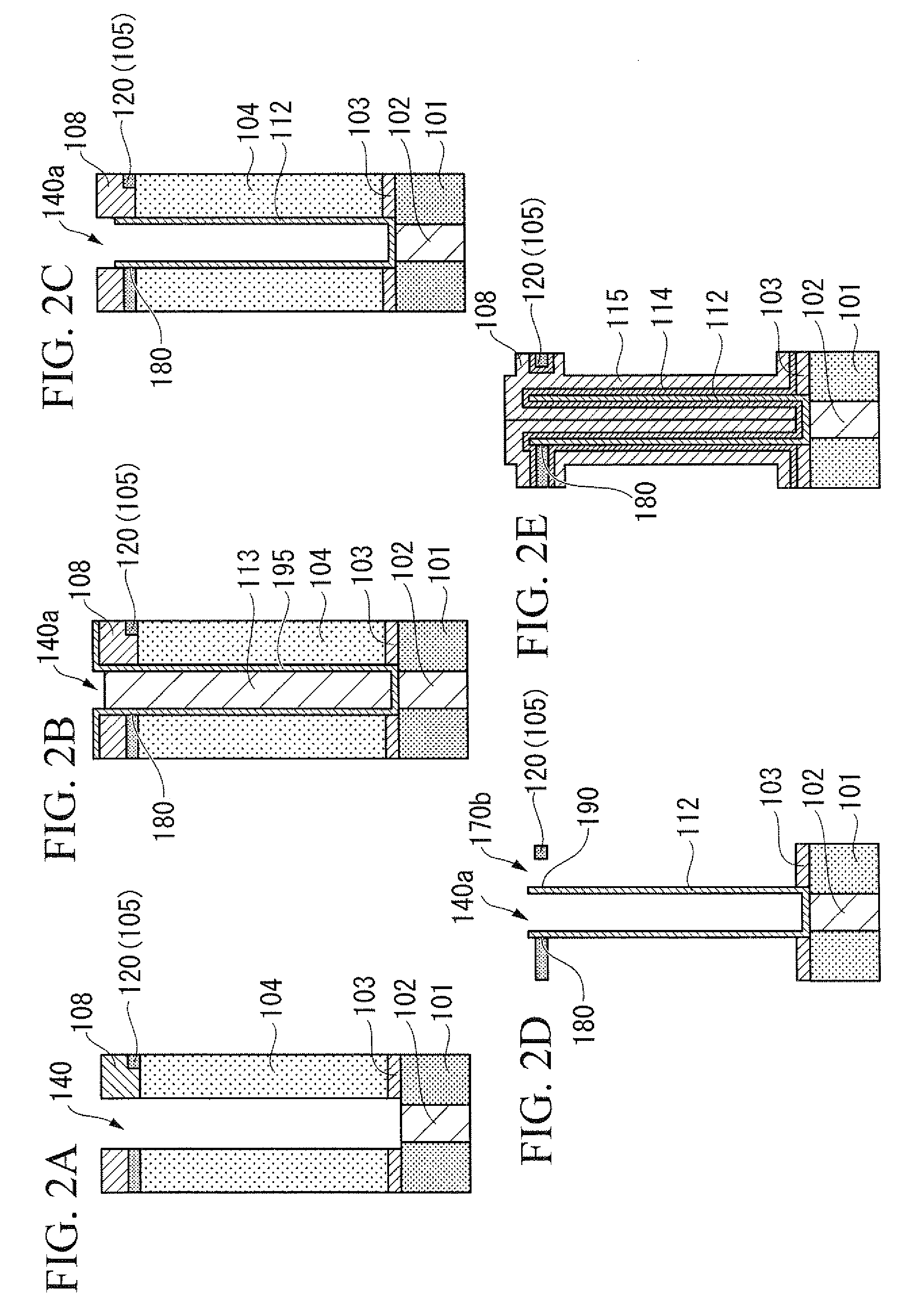

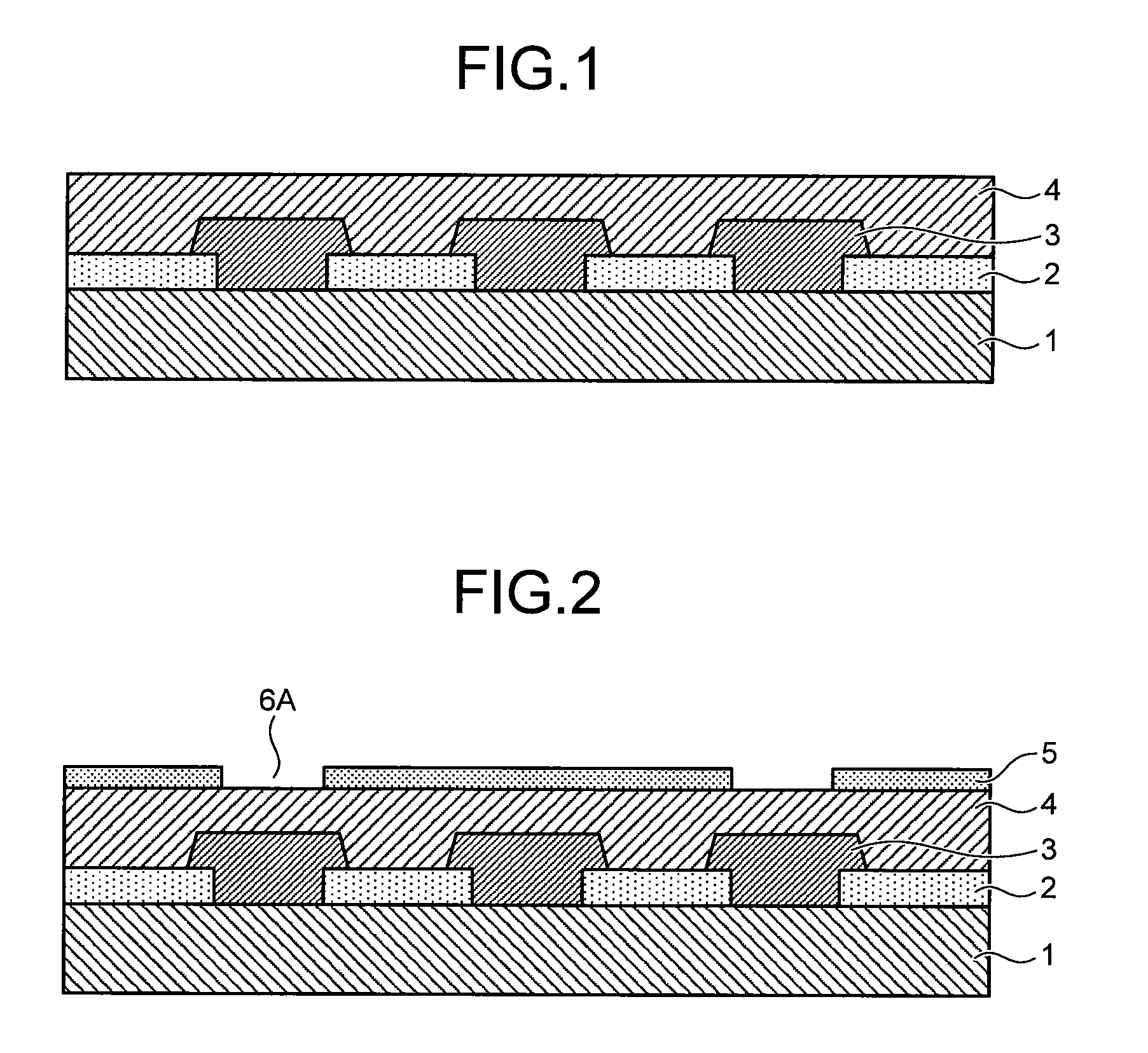

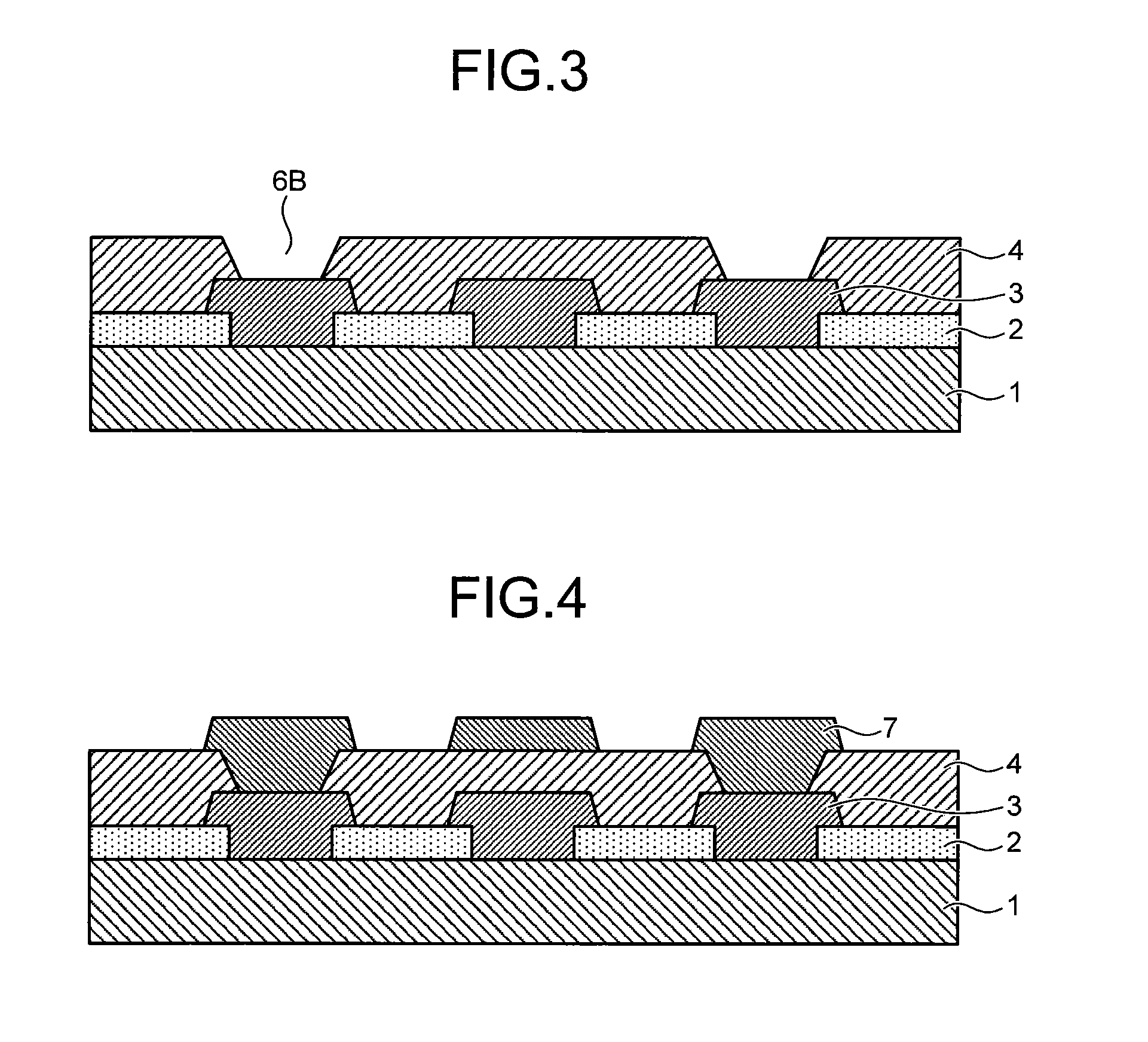

Solid Oxide Type Fuel Battery Cell and Process for Producing the Same

InactiveUS20080102337A1Small conductivityAdd three-phase interfaceSolid electrolytesFinal product manufactureFuel cellsSlurry

A process for producing a cell for solid oxide fuel cells comprising a porous electrolyte layer-forming step of obtaining an electrolyte substrate in which a porous electrolyte layer is formed by applying a slurry for forming an electrolyte layer containing an electrolyte substance powder and a pore-forming agent to the surface of an electrolyte substrate and burning the electrolyte substrate, and an electrode layer-forming step of obtaining an electrolyte substrate in which an electrode substance-filled porous electrolyte layer and an electrode layer are formed by applying a slurry for forming an electrode containing an electrode substance powder, a mixture of an electrode substance powder and an electrolyte substance powder, or a composite material powder of an electrode substance and an electrolyte substance, onto the surface of the porous electrolyte layer of the electrolyte substrate on which the porous electrolyte layer is formed, and burning the electrolyte substrate in which the porous electrolyte layer is formed. According to the present invention, a process for producing a cell for solid oxide fuel cells which can increase the three-phase interface of the porous electrolyte layer and exhibits only a small conductivity reduction of the electrolyte layer can be obtained.

Owner:THE TOKYO ELECTRIC POWER CO INC

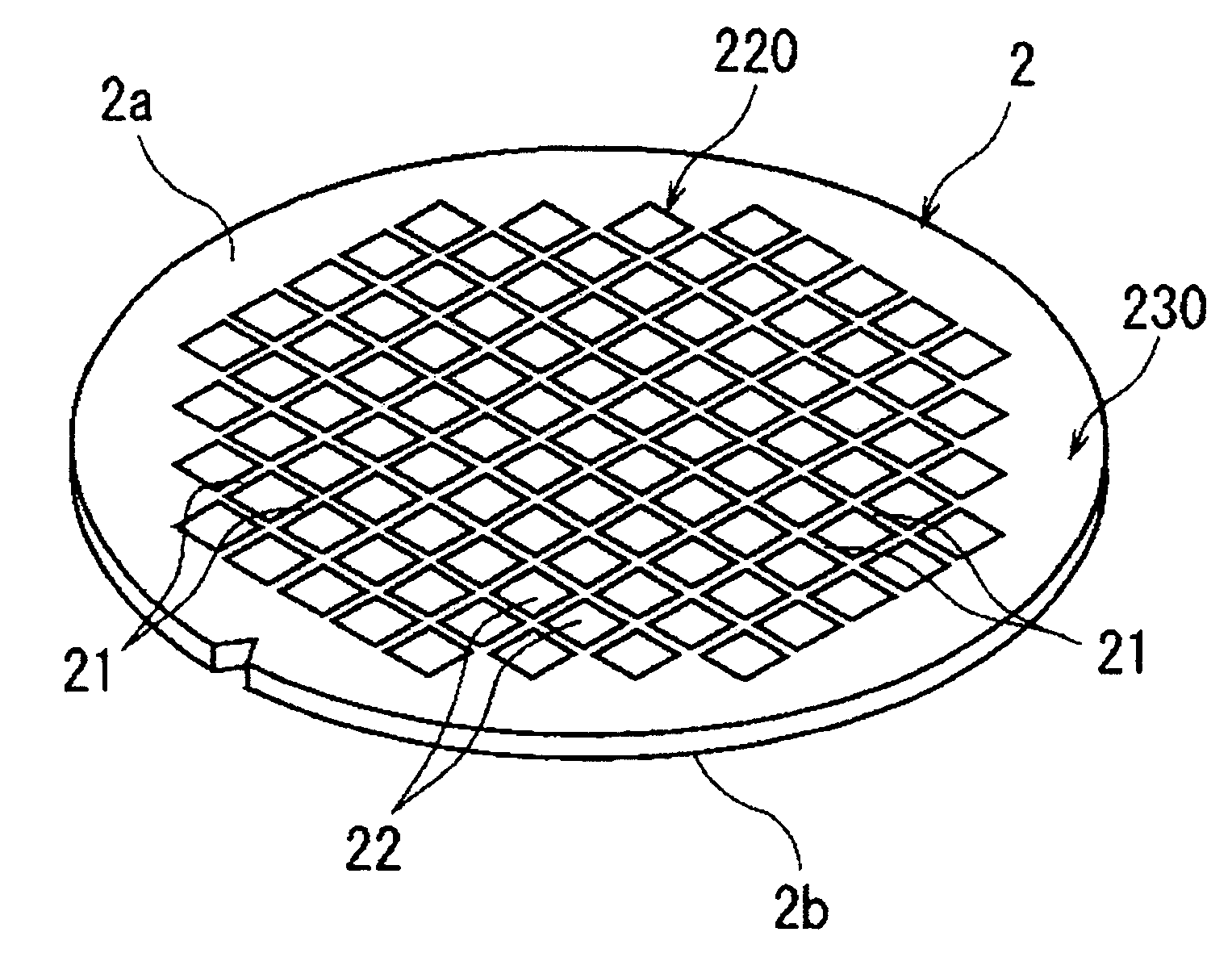

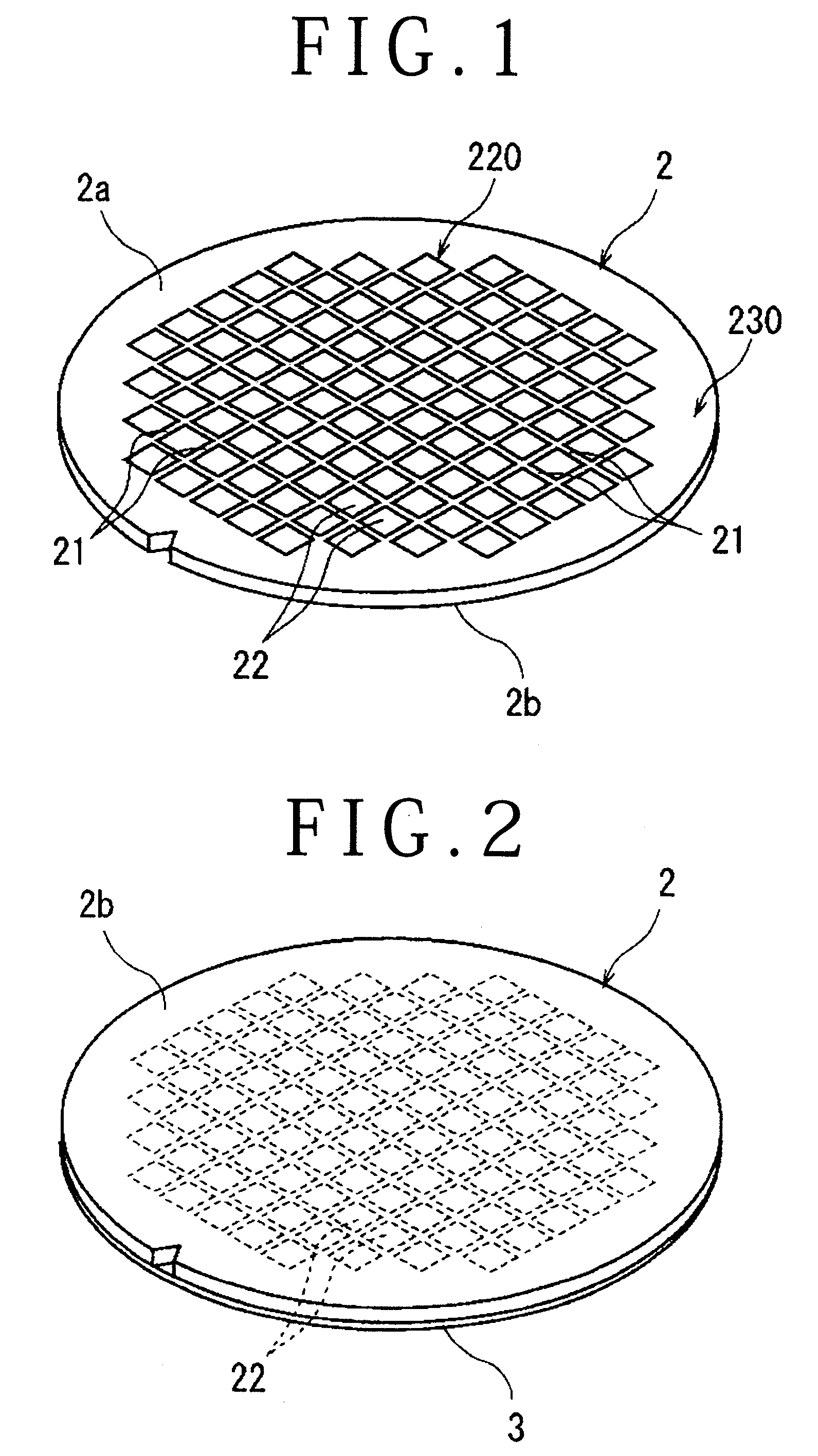

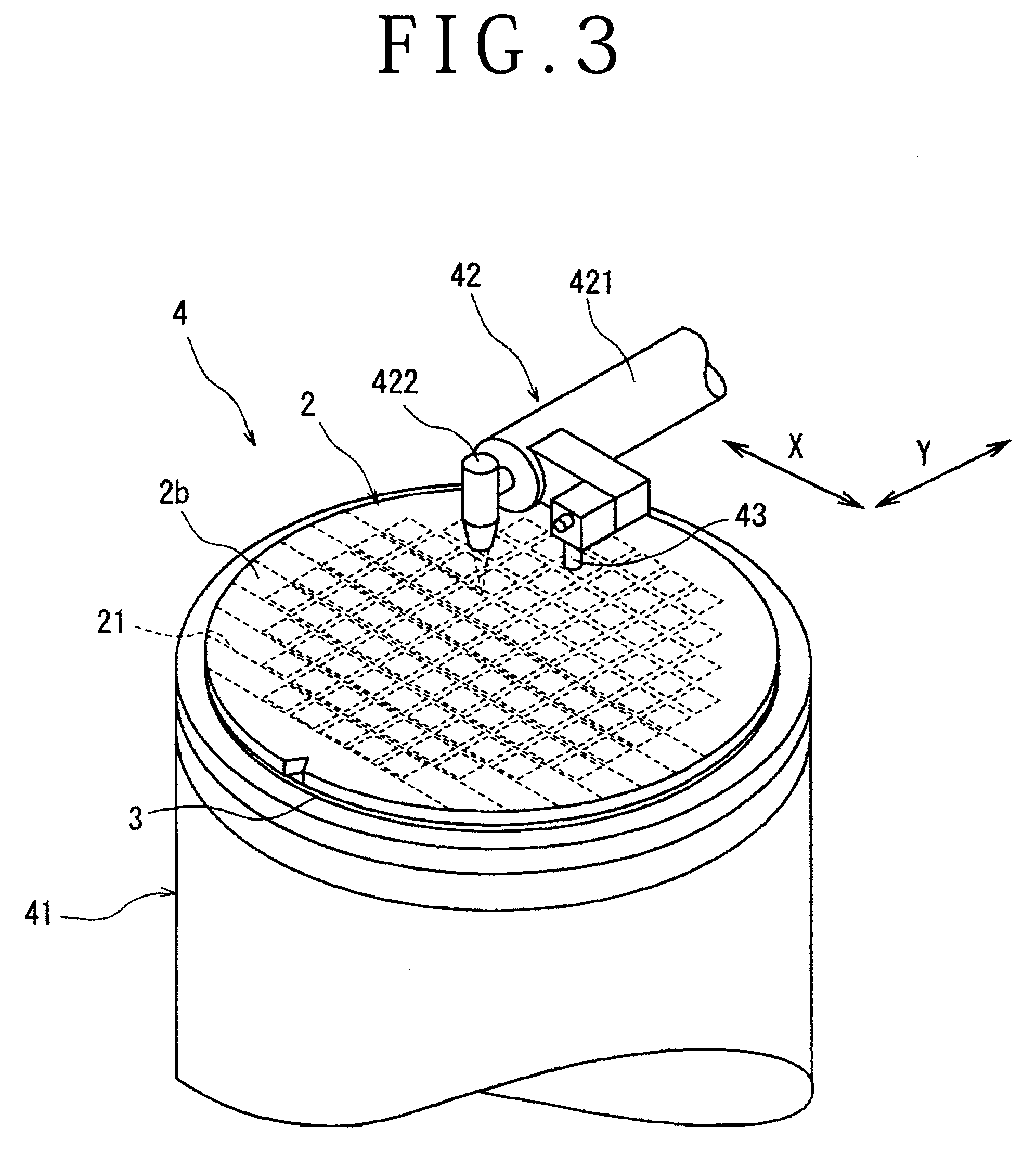

Wafer dividing method

InactiveUS20080280421A1Small thicknessFormed surelySolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeEngineering

A wafer dividing method that includes a modifying layer forming step in which a laser beam with a wavelength that can pass through the wafer is focused on the inside of the wafer from a rear surface side thereof, and applied along the street to form a modifying layer having a thickness corresponding to at least a device-finishing thickness from the front surface of the wafer; a rear surface grinding step in which an area, corresponding to the device area, of the rear surface of the wafer subjected to the modifying layer forming step is ground and formed to have a thickness corresponding to the device-finishing thickness and to have an annular reinforcing section at an area corresponding to the outer circumferential redundant area; a reinforcing section cutting step in which the wafer is cut along the inner circumference of the annular reinforcing section; a wafer support step in which the rear surface of the wafer whose annular reinforcing section is cut is stuck to a dicing tape attached to an annular frame; and a wafer rupture step in which an external force is applied to the wafer stuck to the dicing tape to rupture it along the street formed with the modifying layer.

Owner:DISCO CORP

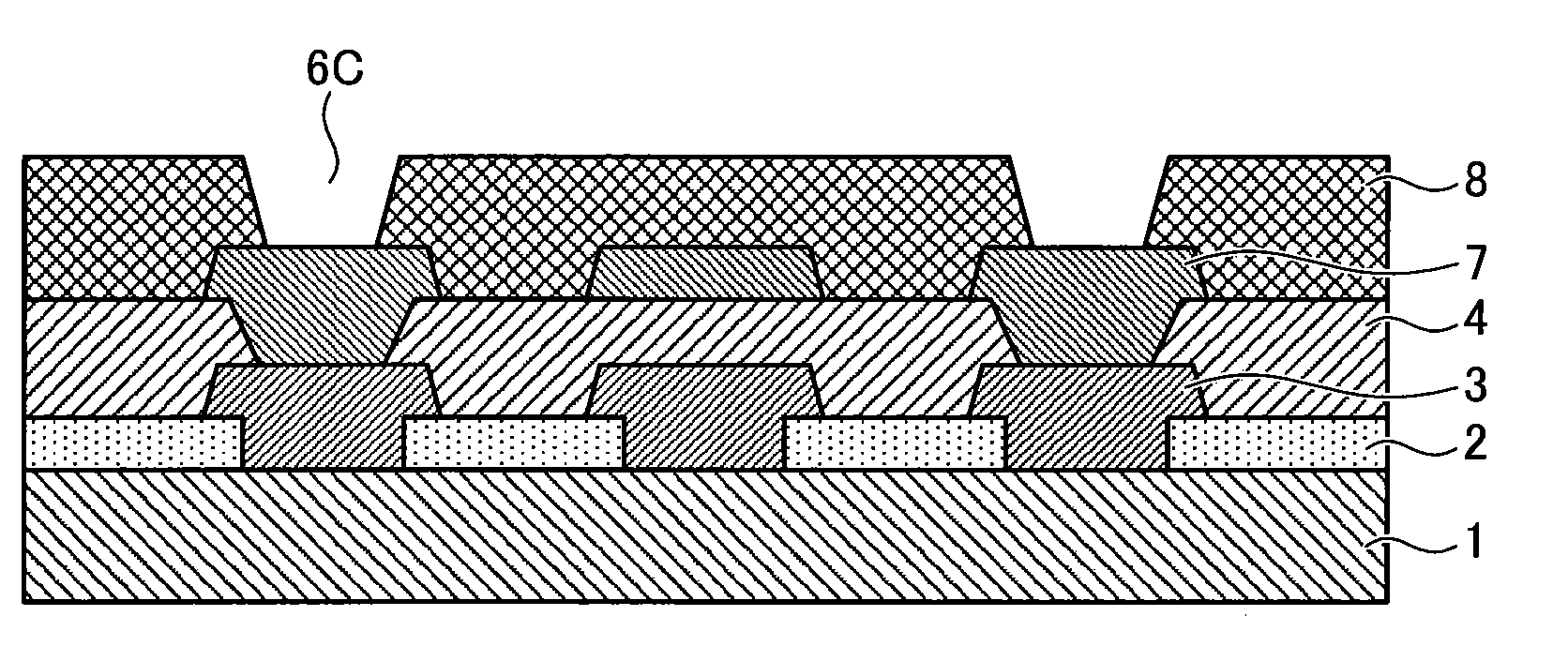

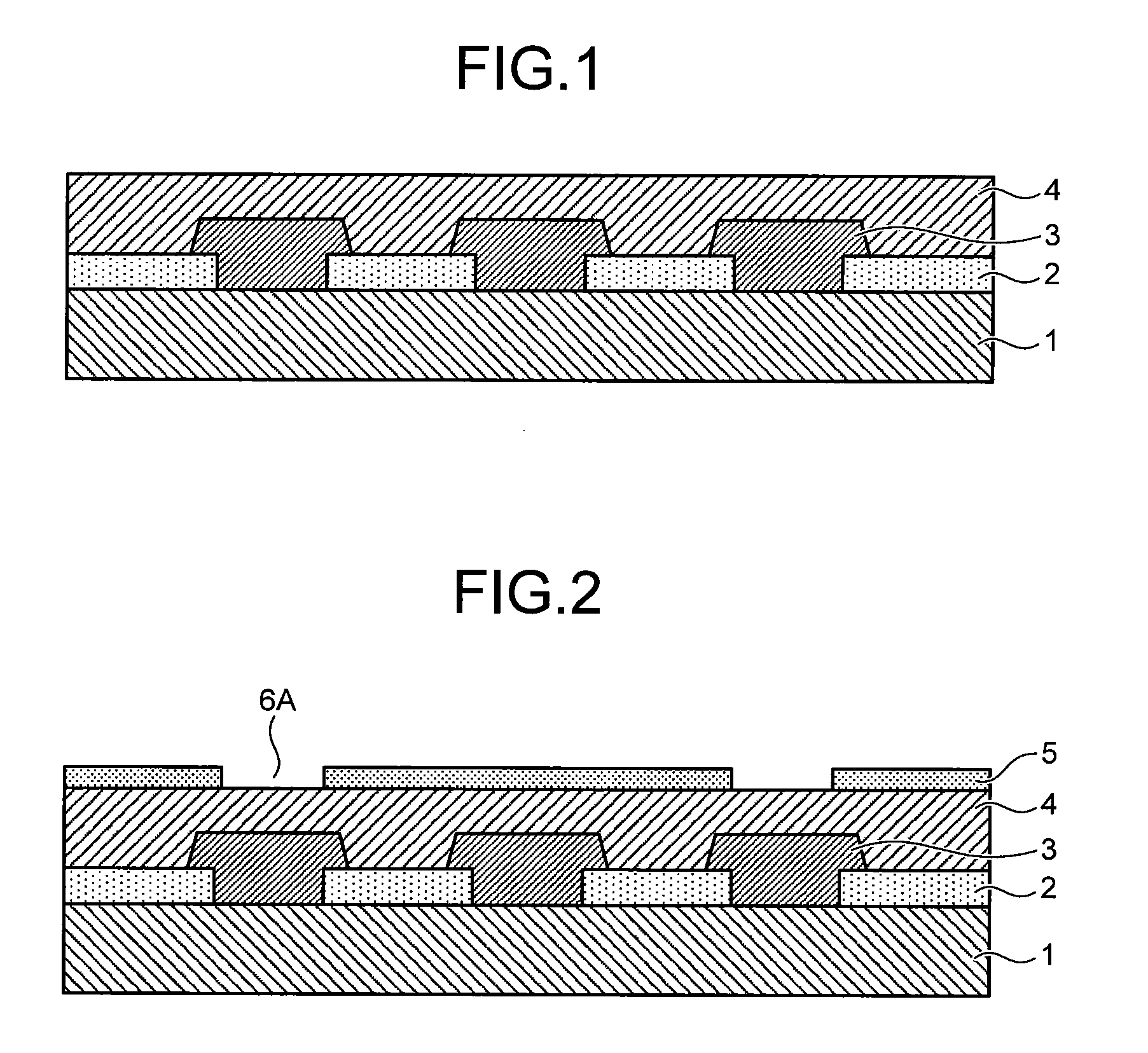

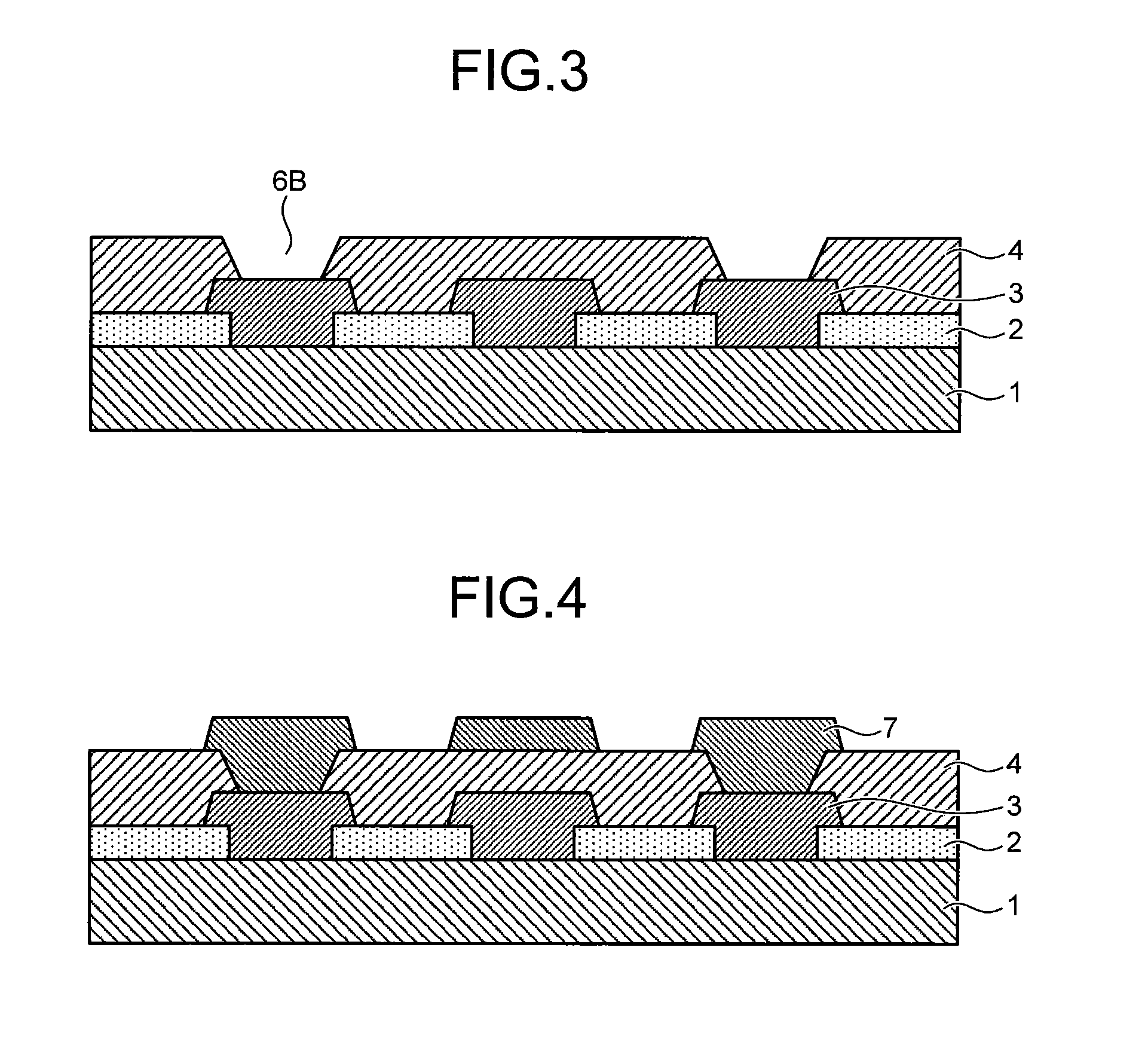

Photosensitive resin composition, process for producing patterned hardened film with use thereof and electronic part

ActiveUS20100092879A1Increase chanceFormed surelyPhotosensitive materialsSemiconductor/solid-state device manufacturingPhotosensitizerChain structure

To provide a photosensitive resin composition in which a hardened film obtained from the photosensitive resin composition has properties comparable to those of a film hardened at a high temperature, a method for manufacturing a patterned hardened film using the photosensitive resin composition, and an electronic part. The photosensitive resin composition includes (a) a polybenzoxazole precursor having a repeating unit represented by a general formula (I):wherein U and V represent a divalent organic group, and at least one of U and V is a group containing an aliphatic chain structure having 1 to 30 carbon atoms; (b) a photosensitizer; (c) a solvent; and (d) a crosslinking agent capable of causing crosslinking or polymerization by heating.

Owner:HITACHI CHEM DUPONT MICROSYSTEMS LTD

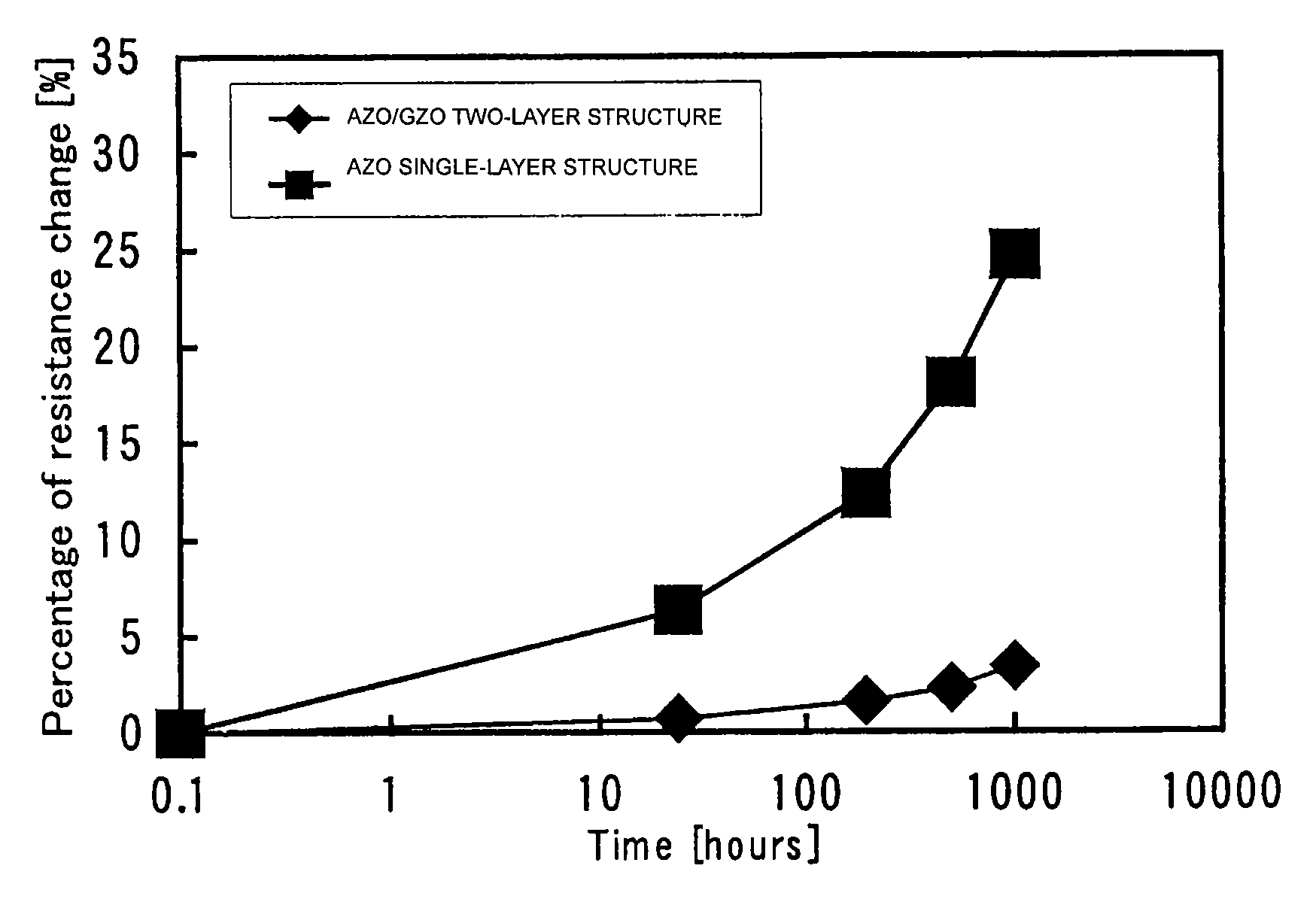

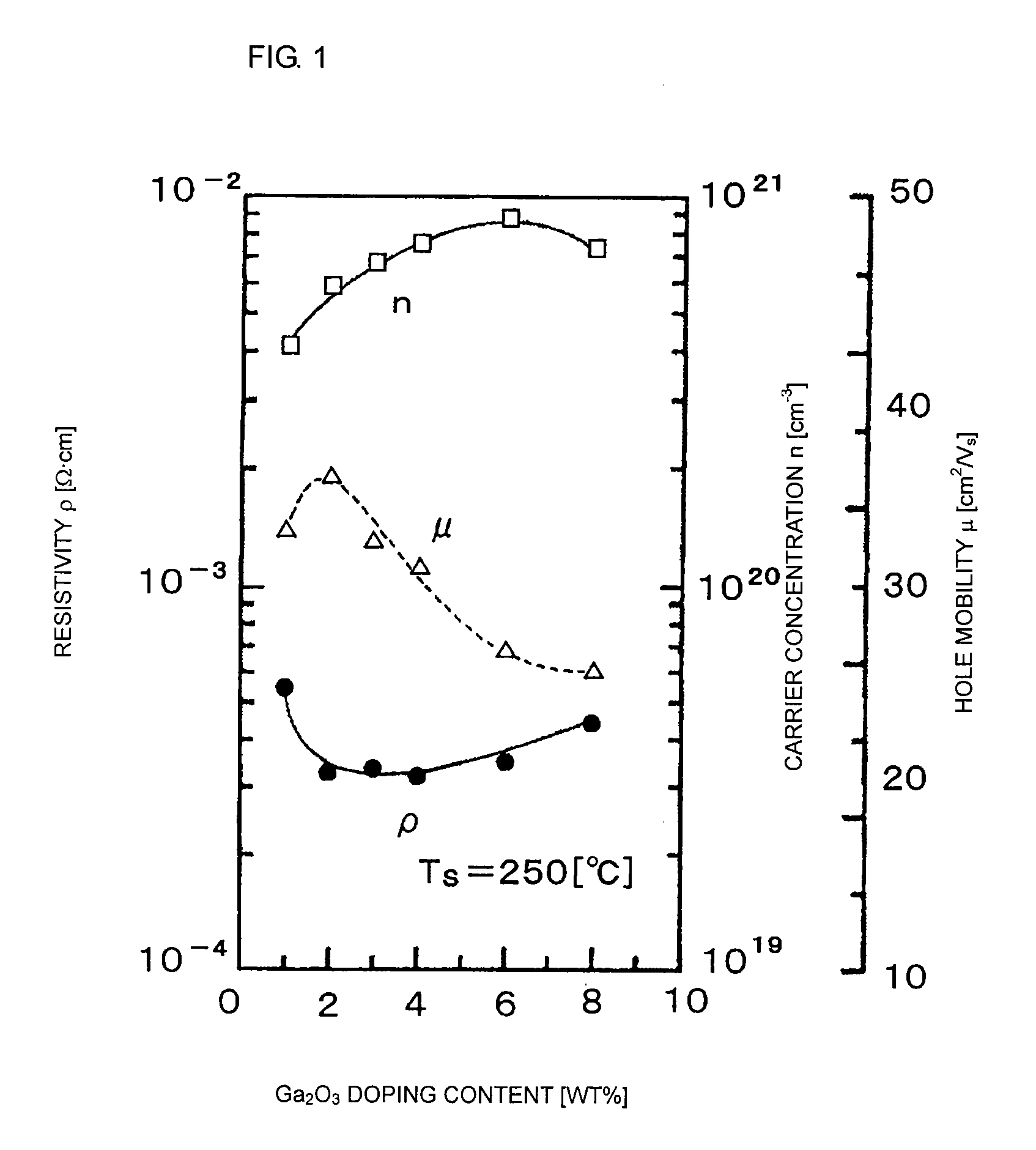

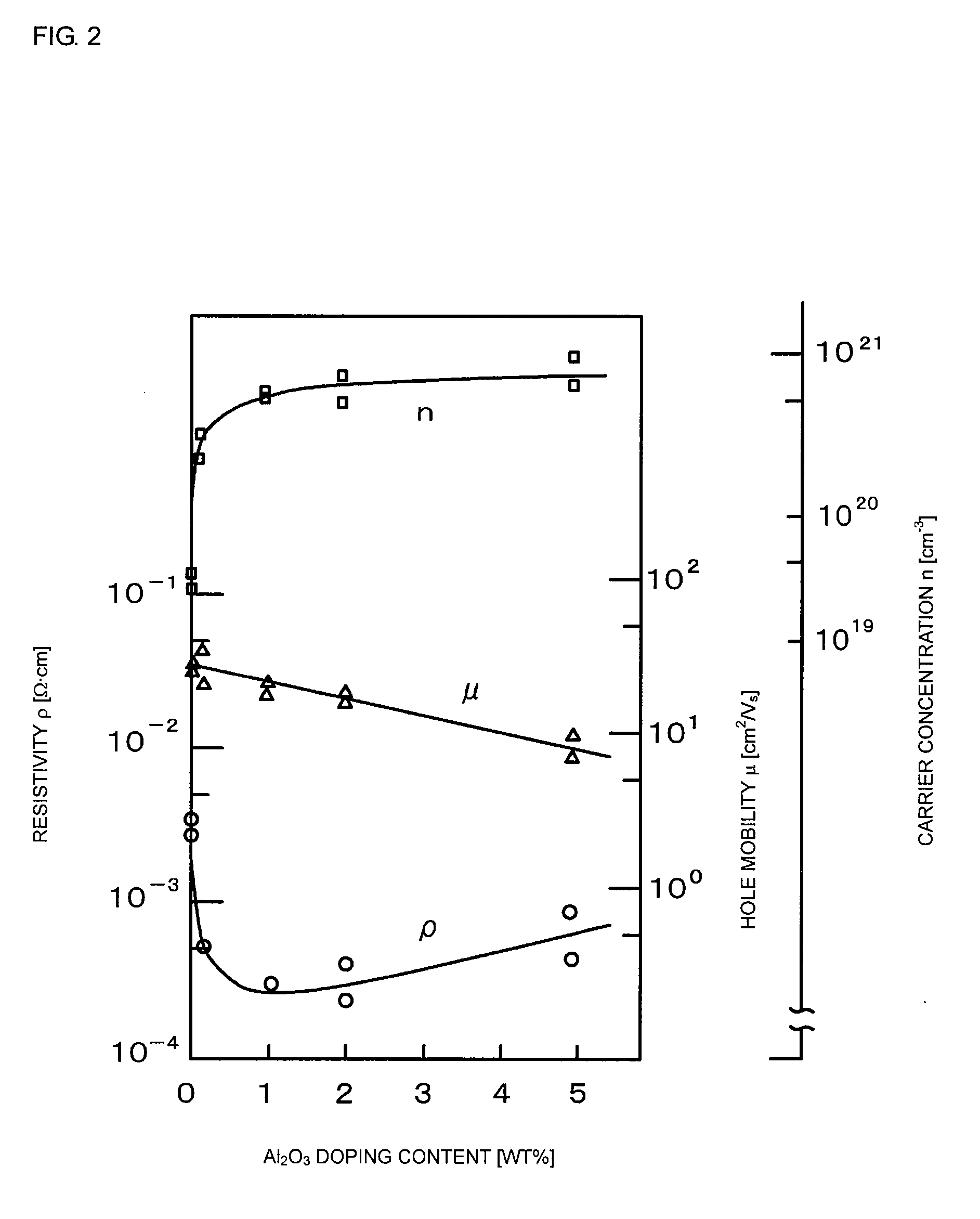

Conductive film and method for manufacturing the same

InactiveUS20080280119A1Economical efficiencyHigh crystallinityVacuum evaporation coatingSemiconductor/solid-state device manufacturingDopantTransparent conducting film

A ZnO-based conductive film having acceptable practical use moisture resistance, properties required for a transparent conductive film, and economical advantage and a method for manufacturing the film are provided. A first ZnO conductive film layer 1, optionally containing a Group III oxide dopant, is formed on a surface of a substrate 11 and a second ZnO conductive film layer 2, which is transparent and includes a Group III oxide different from a Group III oxide (if present) included in the first conductive film layer is formed on the first ZnO conductive film layer to form a multi-layer structure. The thickness of the first ZnO conductive film layer is preferably 5 to 50 nm, and the second and any following ZnO conductive film layers include a Group III oxide at a concentration of 7 wt % or less. The first ZnO conductive film layer is formed under a condition in which high crystallinity can be obtained (for example, under a heat treatment) so as to enhance the crystallinity of the second ZnO conductive film layer and following conductive film layers formed on the first ZnO conductive film layer.

Owner:MURATA MFG CO LTD

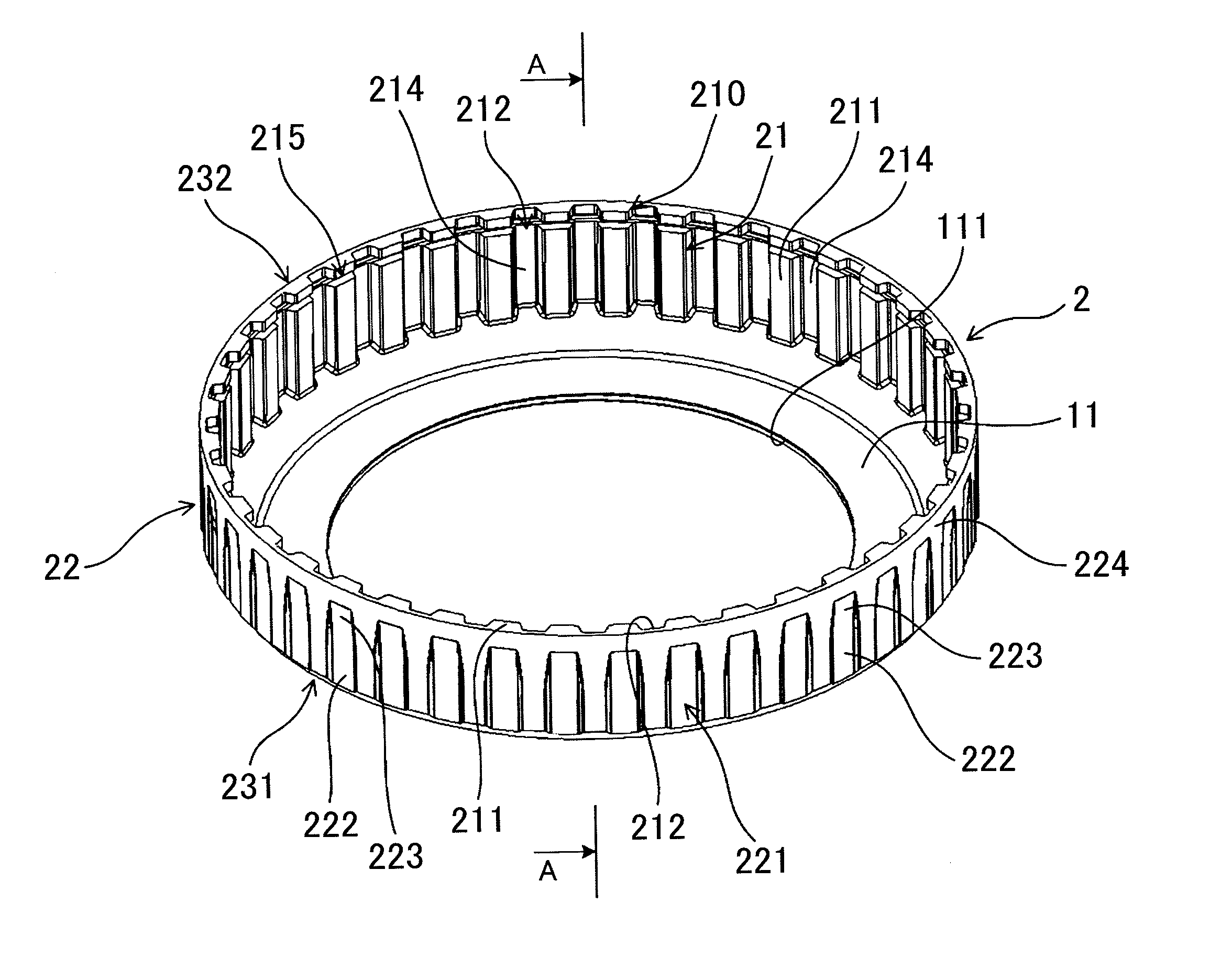

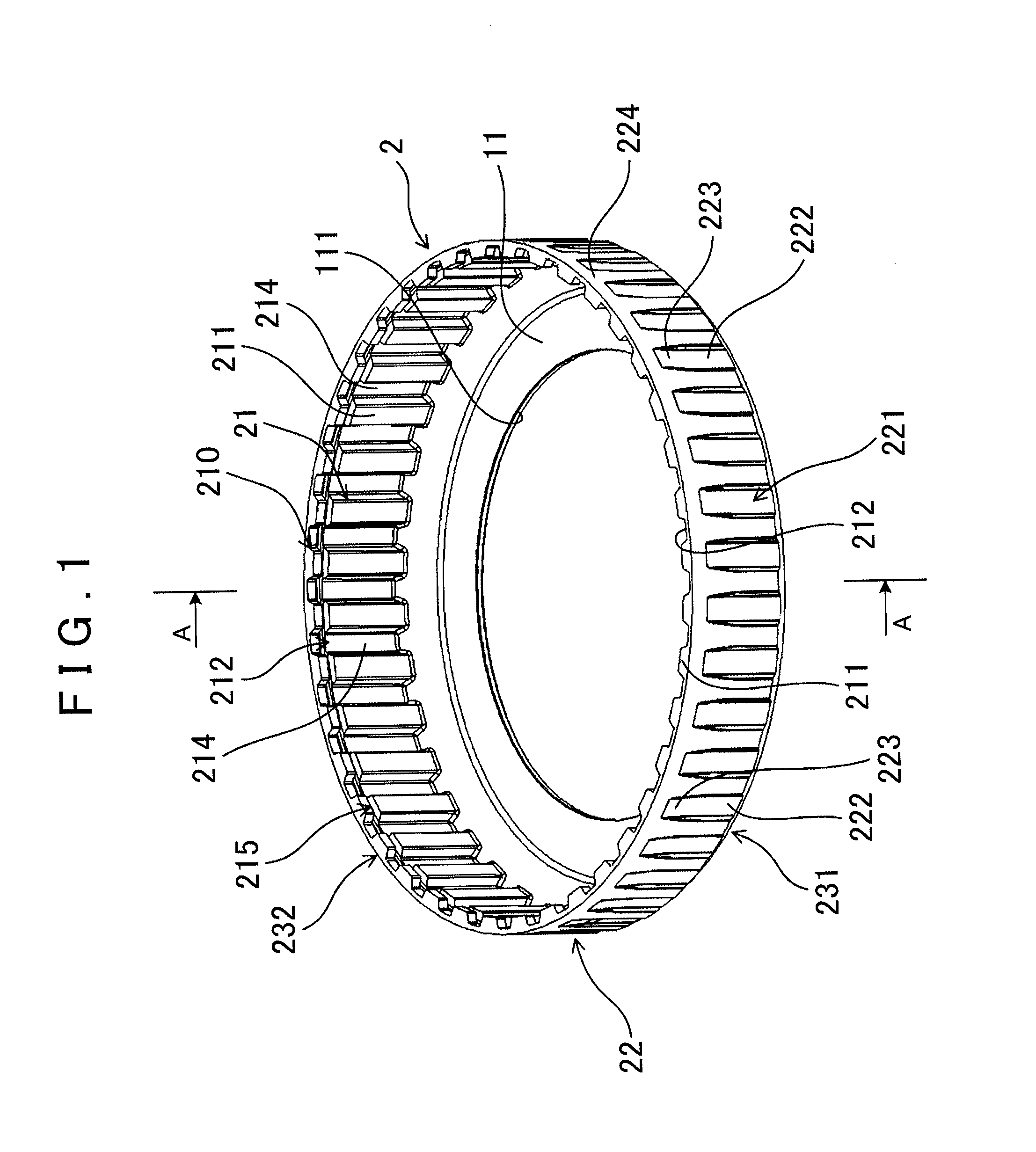

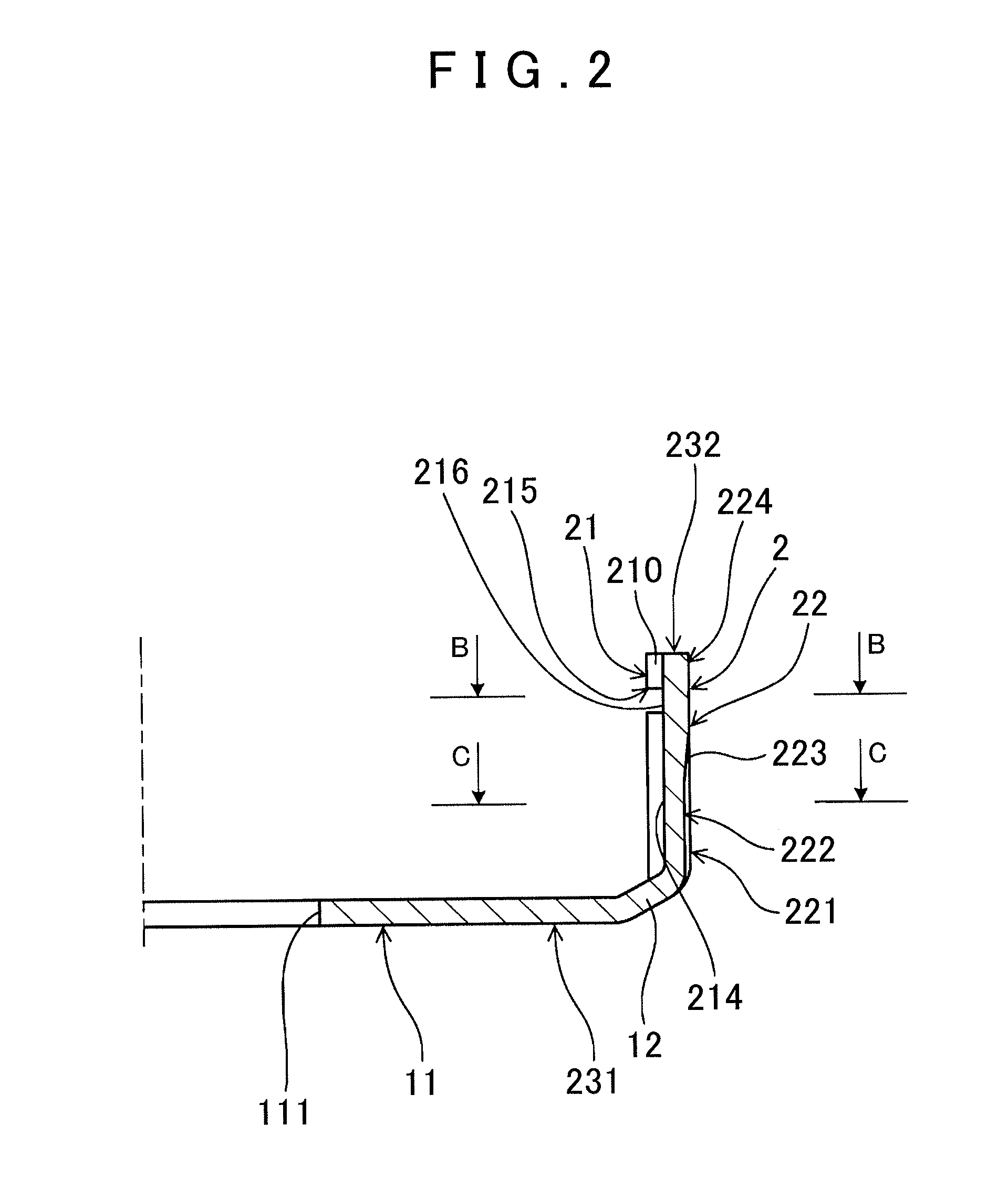

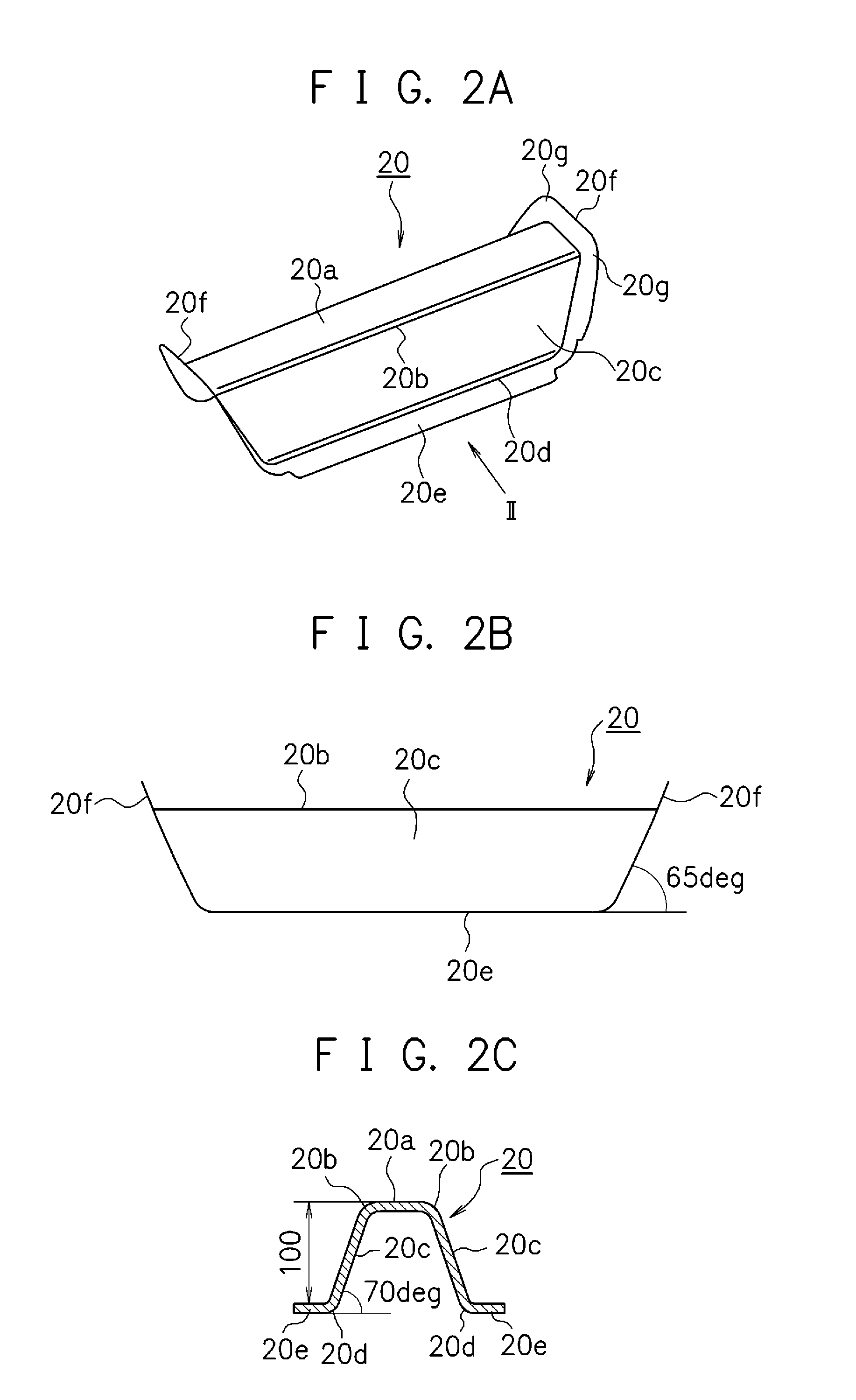

Cup-shaped member including inner peripheral corrugated portion and manufacturing method and manufacturing apparatus for the same

InactiveUS20130059166A1Increasing the thicknessHigh strengthLayered productsFriction clutchesEngineeringMechanical engineering

A cup-shaped member in which the outer peripheral recesses are formed on the base end portion side of the outer peripheral surface of the cylinder portion, on which the bottom portion is disposed, by denting the outer peripheral surface radially inward of the cylinder portion at positions that correspond to the inner peripheral protrusions. The smooth outer peripheral portion is formed on the opening end side of the outer peripheral surface of the cylinder portion that is opposite to the side on which the bottom portion is disposed. The smooth outer peripheral portion has no corrugation and has generally the same diameter over the entire circumference of the outer peripheral surface, thereby increasing the strength of the cup-shaped member, and allowing the inner peripheral corrugated portion to be surely formed.

Owner:AISIN AW CO LTD

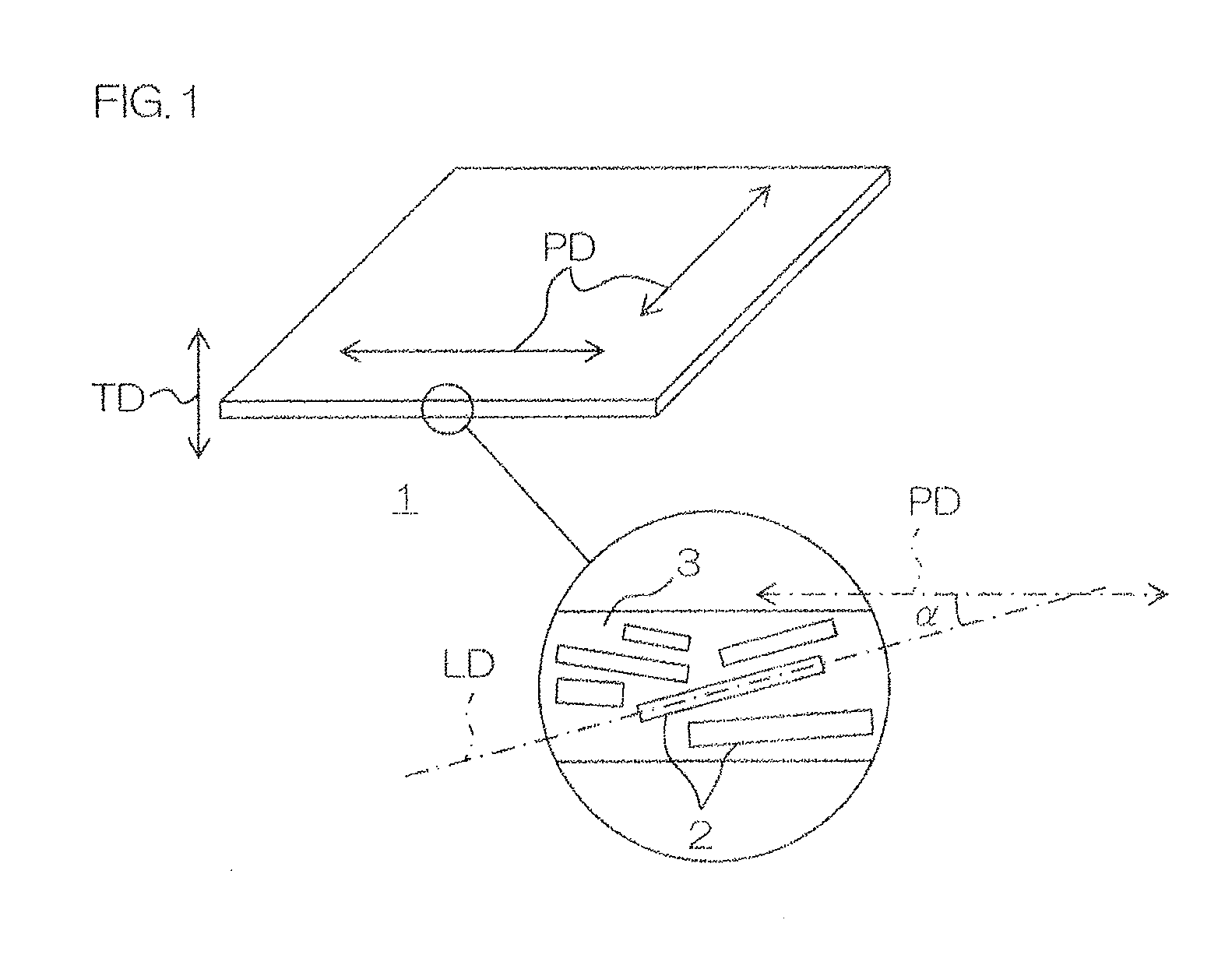

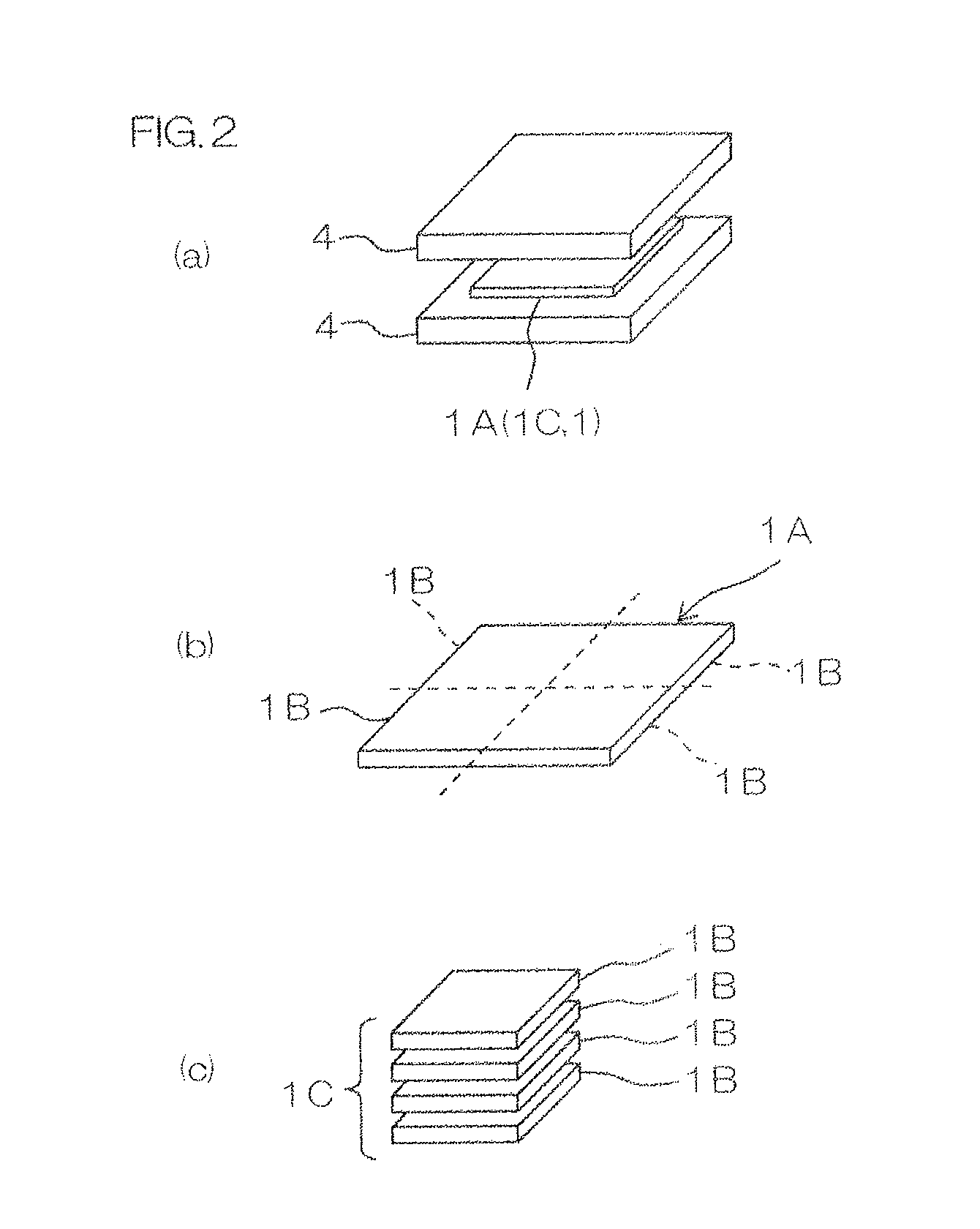

Thermal conductive sheet

InactiveUS20130200298A1Excellent formabilityExcellent heat resistanceSolid-state devicesHeat-exchange elementsChemistryBoron nitride

Owner:NITTO DENKO CORP

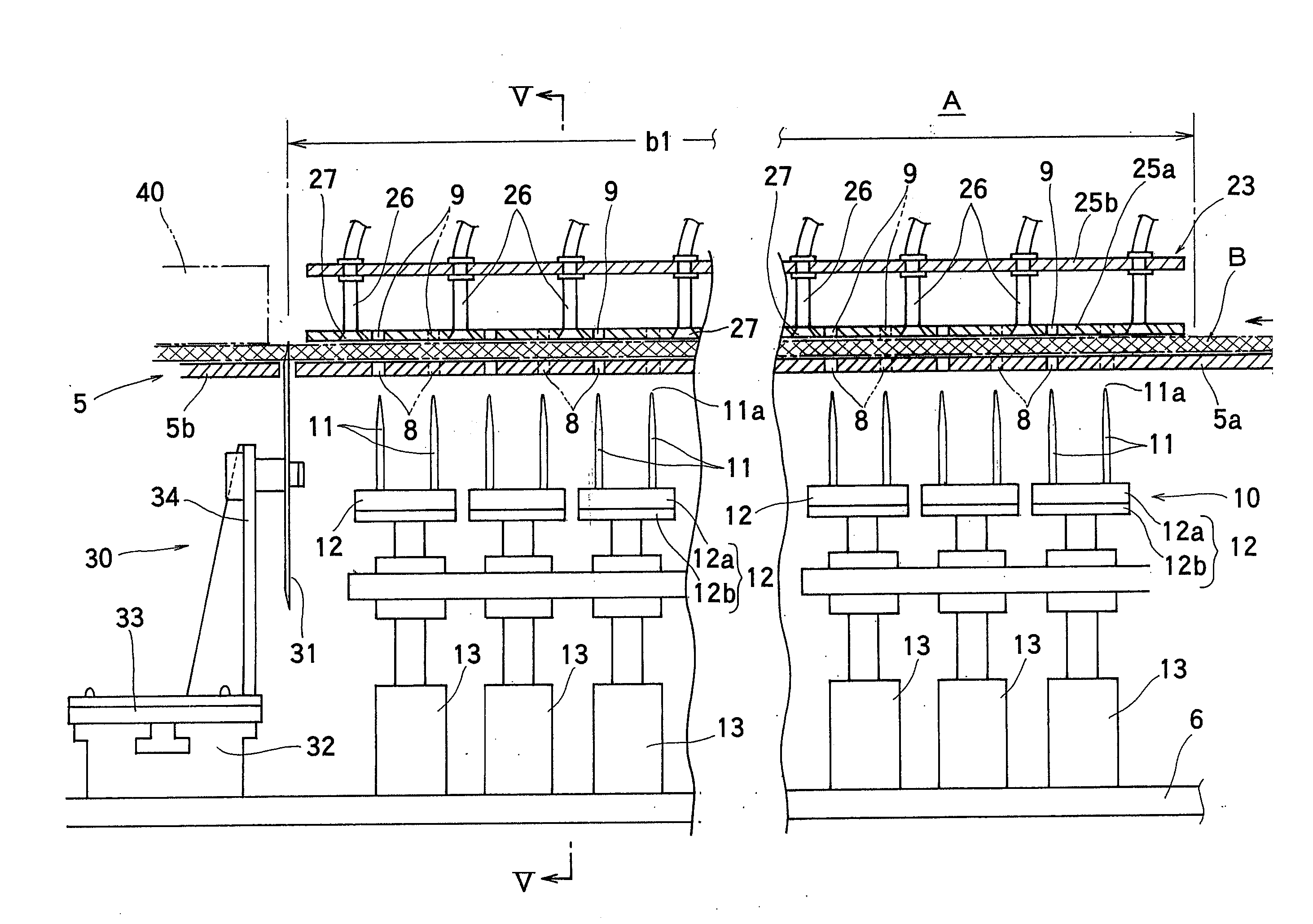

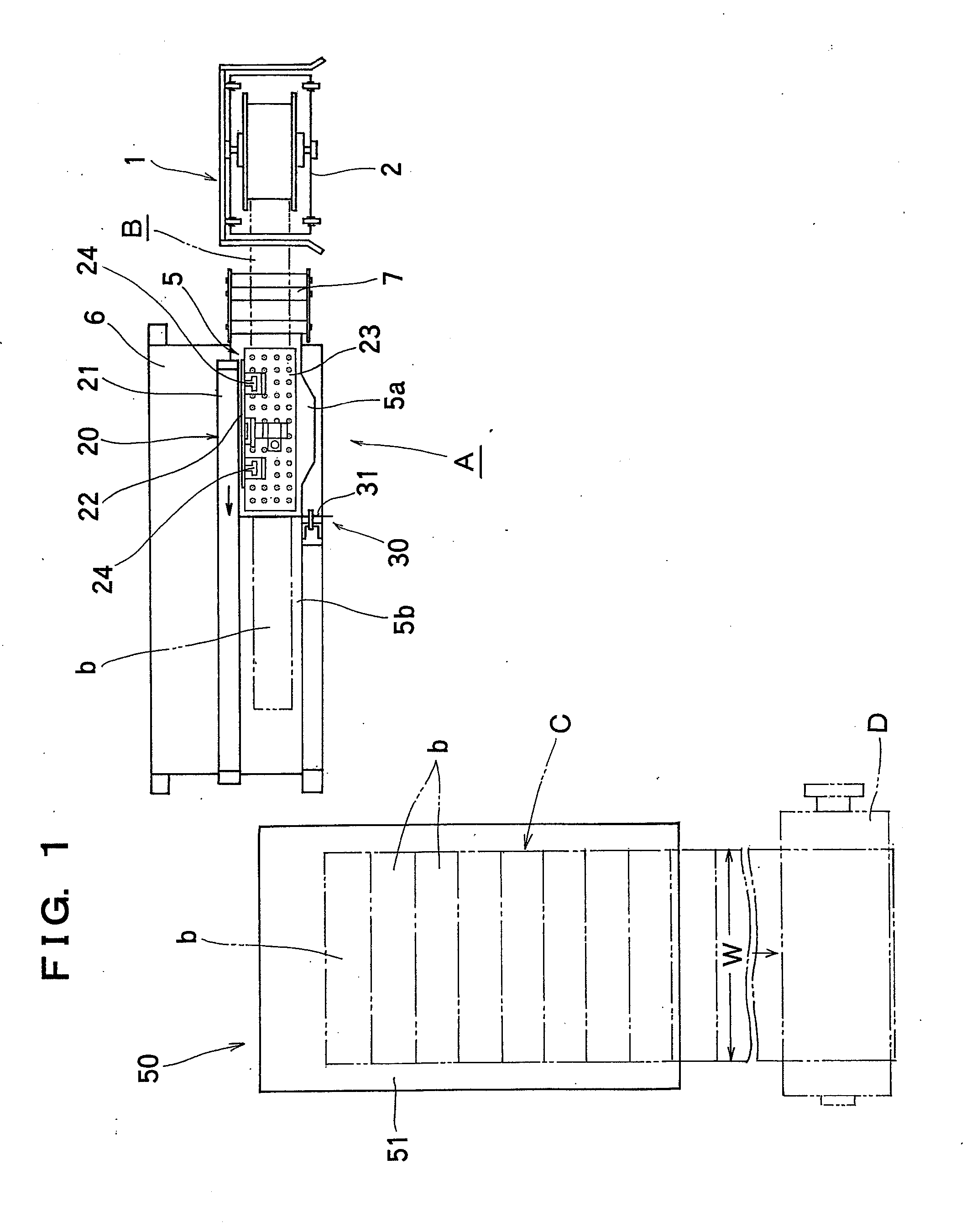

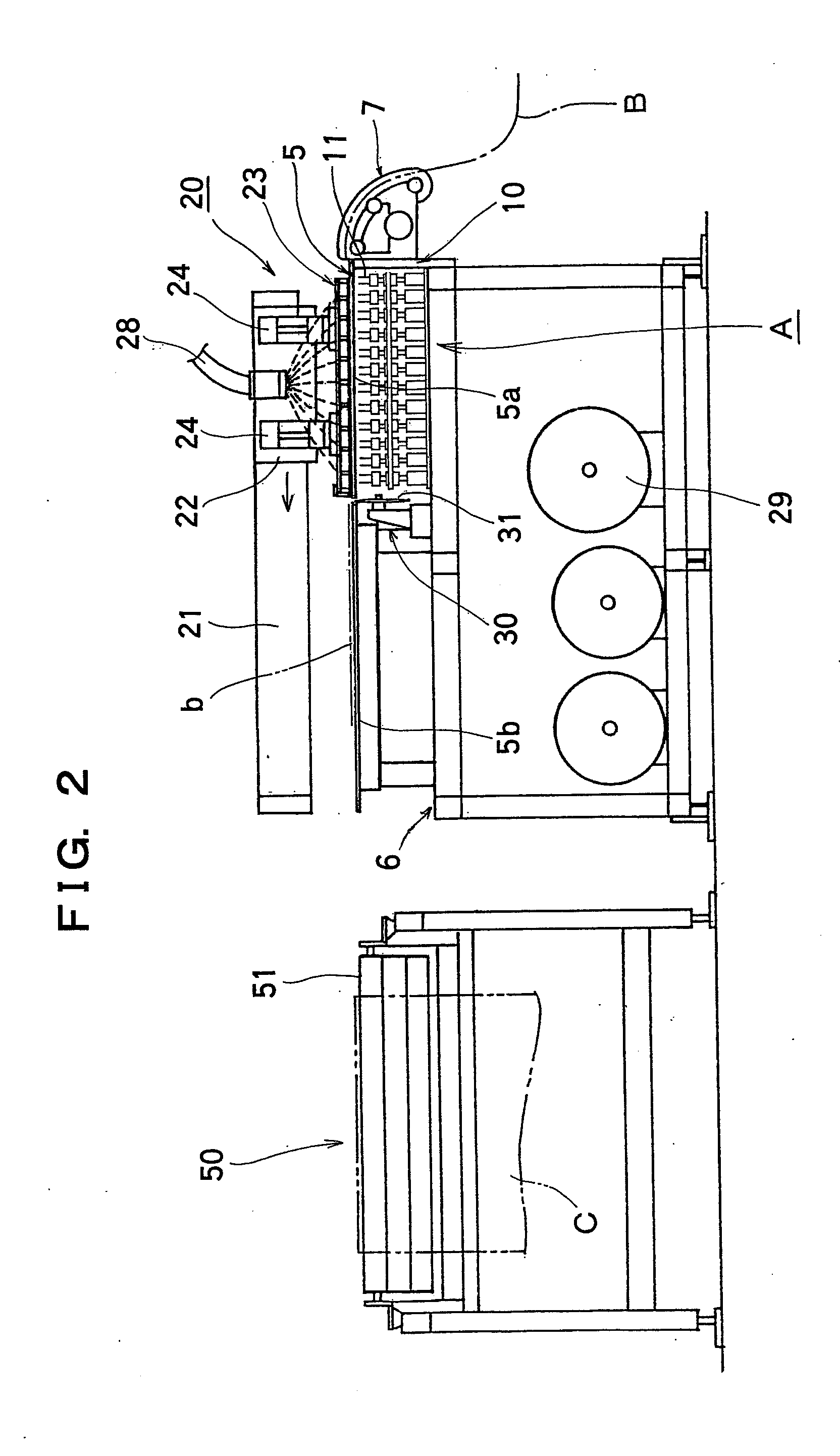

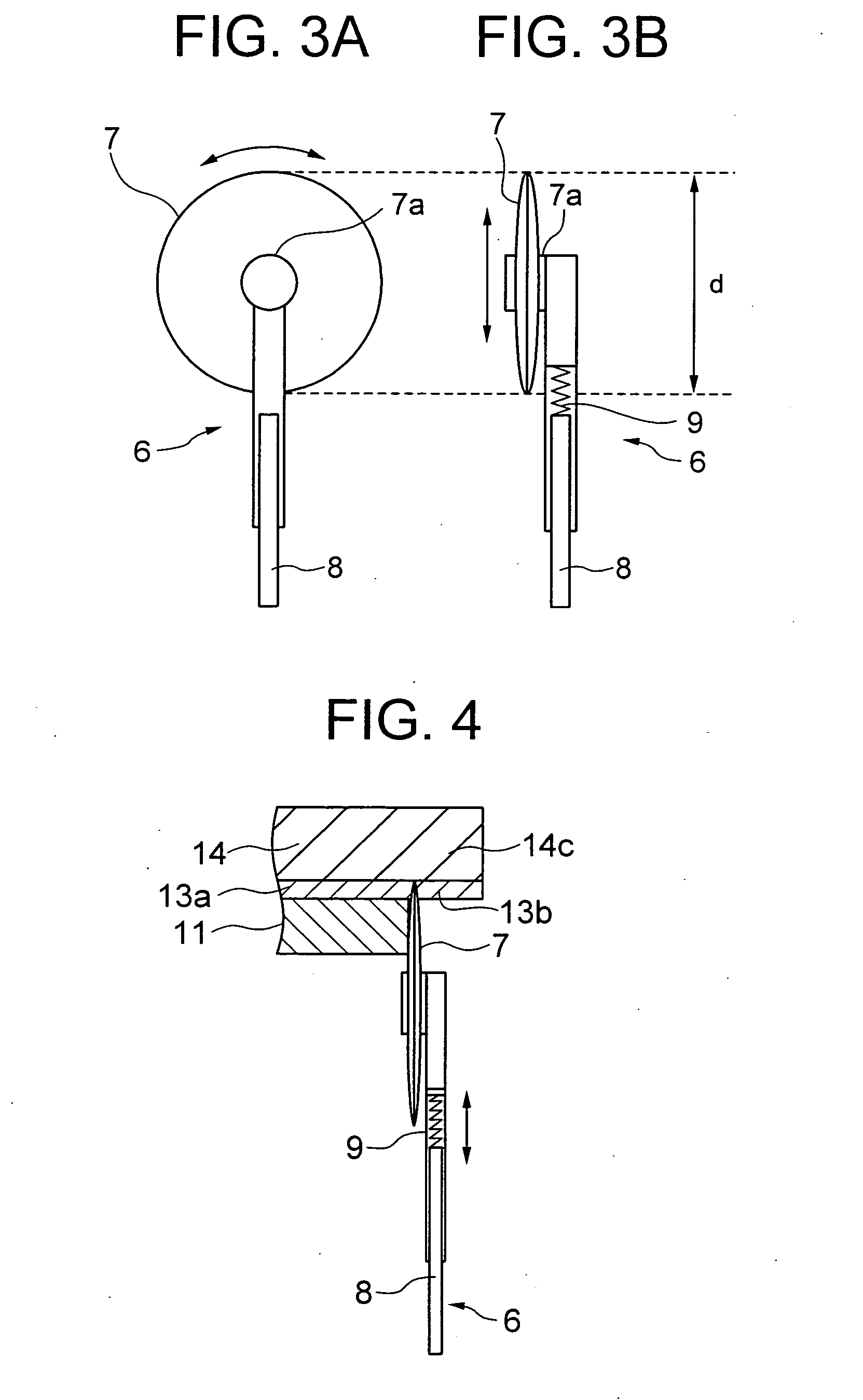

Perforating apparatus for tire constituent member

InactiveUS20100024986A1Formed surelyConvenient to accommodateTyresMetal working apparatusBand shapeEngineering

Owner:TOYO TIRE & RUBBER CO LTD

Semiconductor device and manufacturing method therefor

ActiveUS20090146254A1Reliable manufacturingLength can be ensuredTransistorSolid-state devicesSemiconductorBiomedical engineering

This semiconductor device according to the present invention includes a plurality of cylindrical lower electrodes aligned densely in a memory array region; a plate-like support which is contacted on the side surface of the cylindrical lower electrodes, and links to support the plurality of the cylindrical lower electrodes; a pore portion provided in the plate-like support; a dielectric film covering the entire surface of the cylindrical lower electrodes and the plate-like support in which the pore portion is formed; and an upper electrode formed on the surface of the dielectric film, wherein the boundary length of the part on the side surface of the cylindrical lower electrode which is exposed on the pore portion is shorter than the boundary length of the part on the side surface of the cylindrical lower electrode which is not exposed on the pore portion.

Owner:LONGITUDE SEMICON S A R L

Method for producing ceramic honeycomb filter

ActiveUS7687008B2Formed surelyGas treatmentInternal combustion piston enginesMaterials scienceCeramic honeycomb

A method for producing a ceramic honeycomb filter having large numbers of flow paths partitioned by cell walls, the flow paths having plugs at positions separate from an end surface of the honeycomb filter, comprising the steps of introducing a base-forming material into the flow paths on one end surface side, charging a plug-forming material into flow paths to be provided with plugs from the other end surface side, and sintering it.

Owner:HITACHI METALS LTD

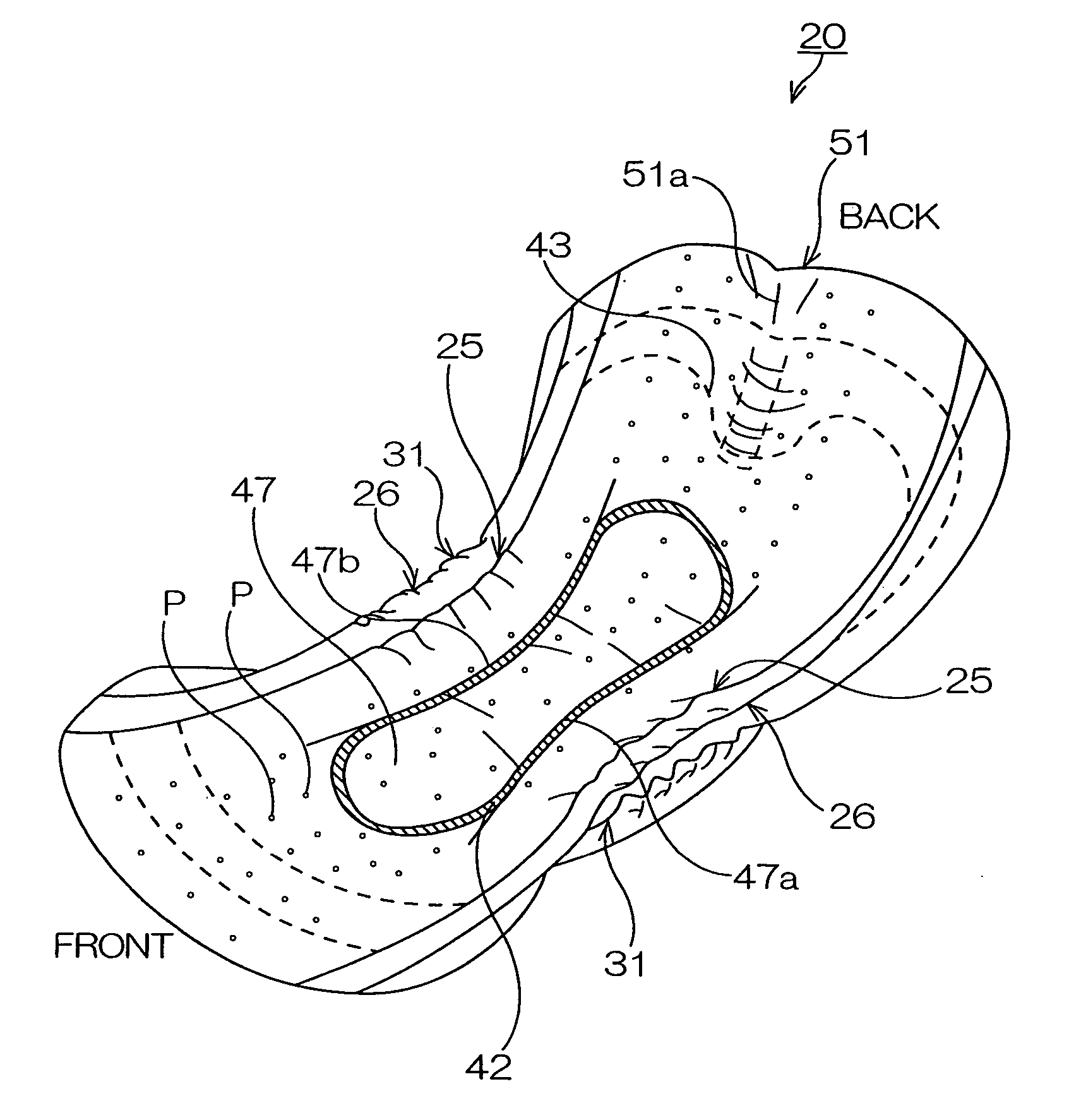

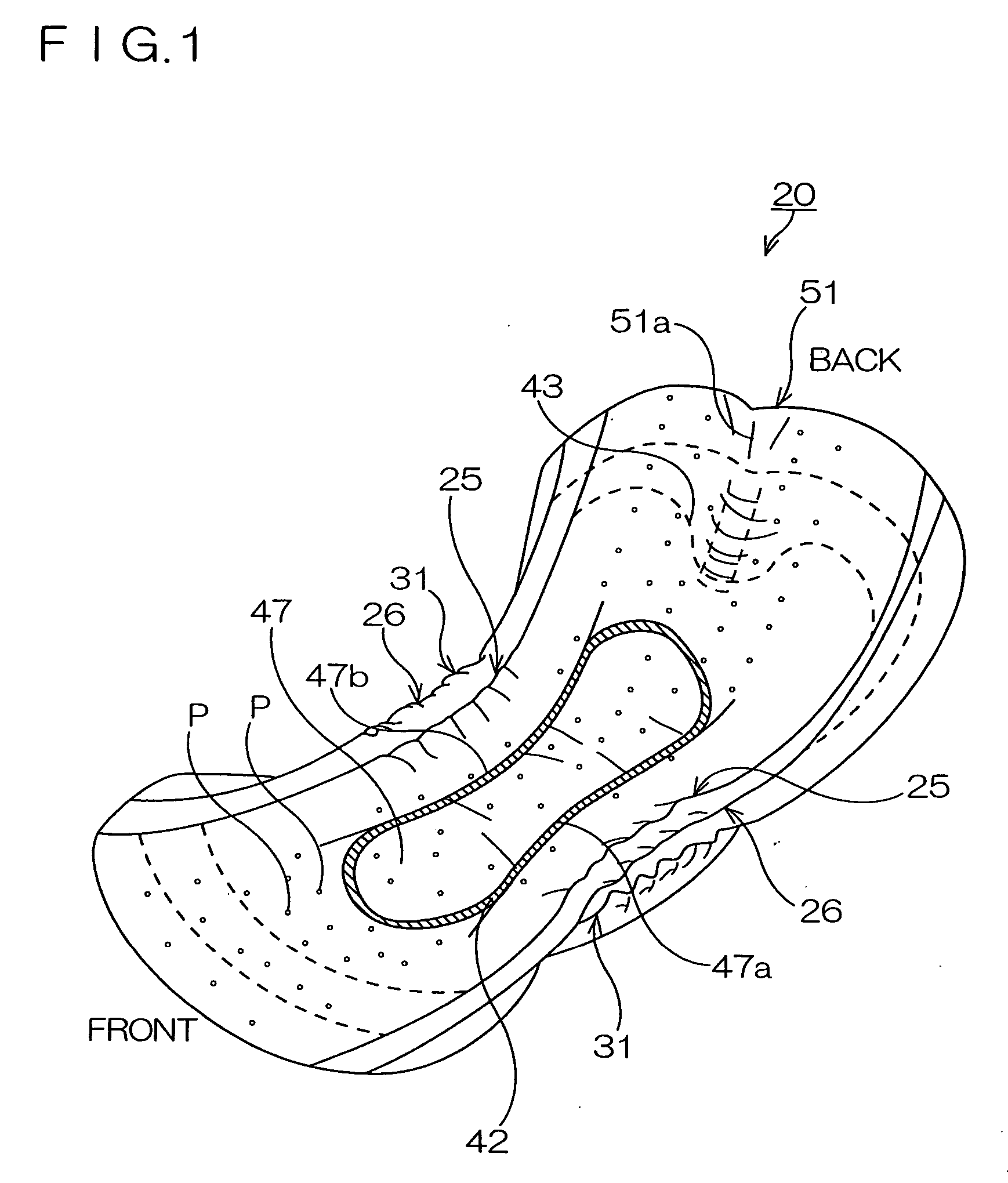

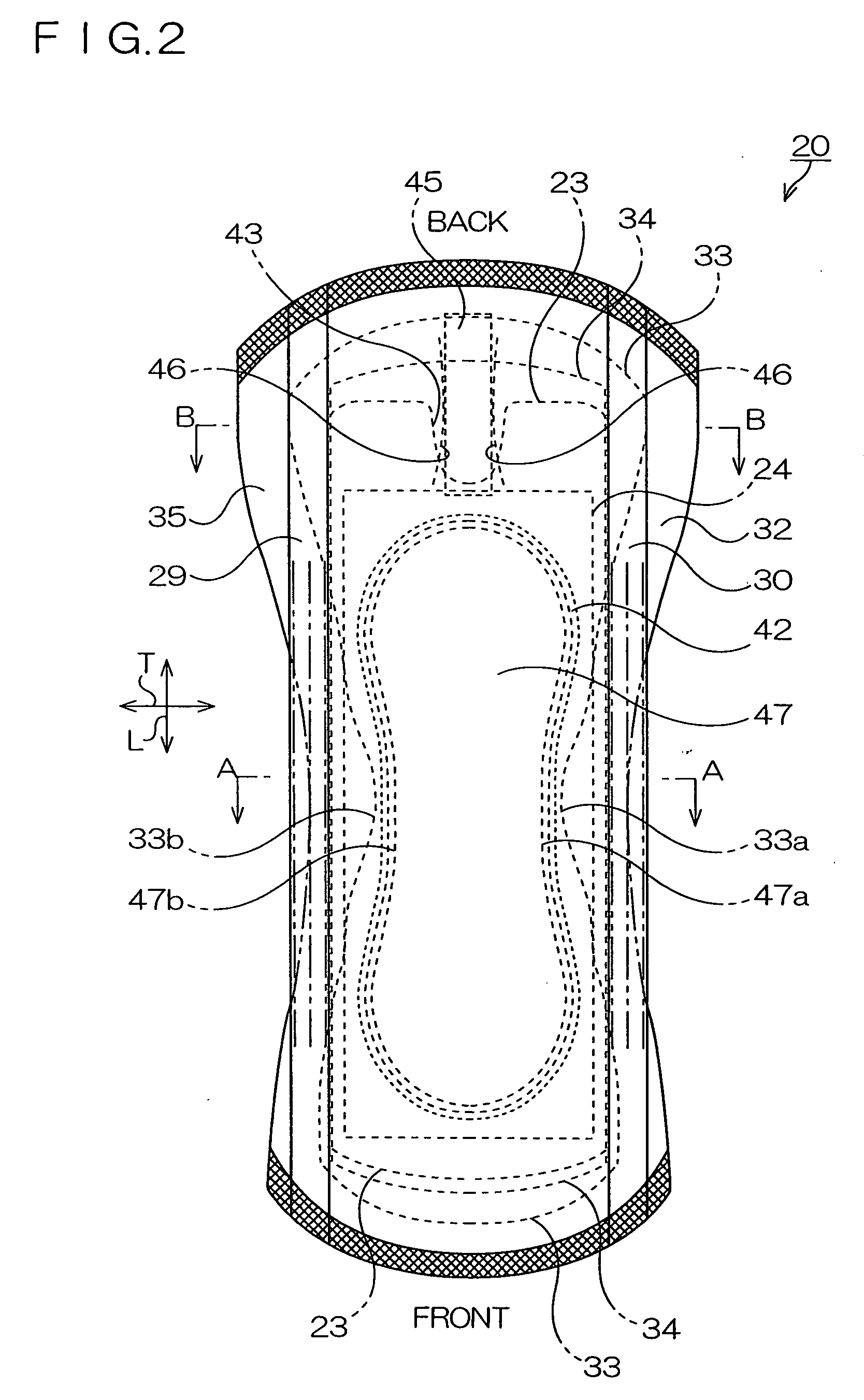

Absorbable product

InactiveUS20050256472A1Function increaseEasy to transformSanitary towelsBaby linensElastomerEngineering

An absorptive product can form and hold a stereoscopic shape which is properly formed to be snugly fitted on a complicated three-dimensional shape of a user's body to prevent leaking of an evacuated body fluid or the like to the outside of the body. The absorptive product includes a back sheet which has a shape elongated in one direction and prevents the permeation of liquid, a liquid permeable surface material (28) which is arranged on a surface side which is brought into contact with a body, and an absorbent (23), (33) which is arranged between the back sheet and the surface material and absorbs and holds the liquid which permeates the surface material. The absorptive product further includes a resilient body (45) which is fixed at least to the absorbent side in a center region in the lateral direction T of the product and imparts a contracting force with respect to the arrangement direction, and slits (46), (46) which are formed in the absorbent in the vicinity of a region on which the contracting operation of the resilient body acts.

Owner:PIGEON CORP

Tire

InactiveUS20080105346A1Improve drivabilityMaintain good propertiesSpecial tyresTyre tread bands/patternsRoad surfaceMechanical engineering

In order to solve the various conventional problems described above, the present invention provides a tire which is excellent in a braking property and a drivability (WET performance) on a wet road surface and which sufficiently displays an edge effect or a spike effect and is excellent in an on-ice performance (surface braking and driving performance). Further, the present invention provides a tire which enhances a workability in a plant and in which micro drain ditches exhibiting a water film-removing performance are surely formed. A foamed rubber layer provided on a surface of the tire substantially brought into contact with a road surface contains at least one inorganic compound powder having a particle diameter of 10 μm or less in a range of 5 to 20 mass parts per 100 mass parts of a rubber component.

Owner:BRIDGESTONE CORP

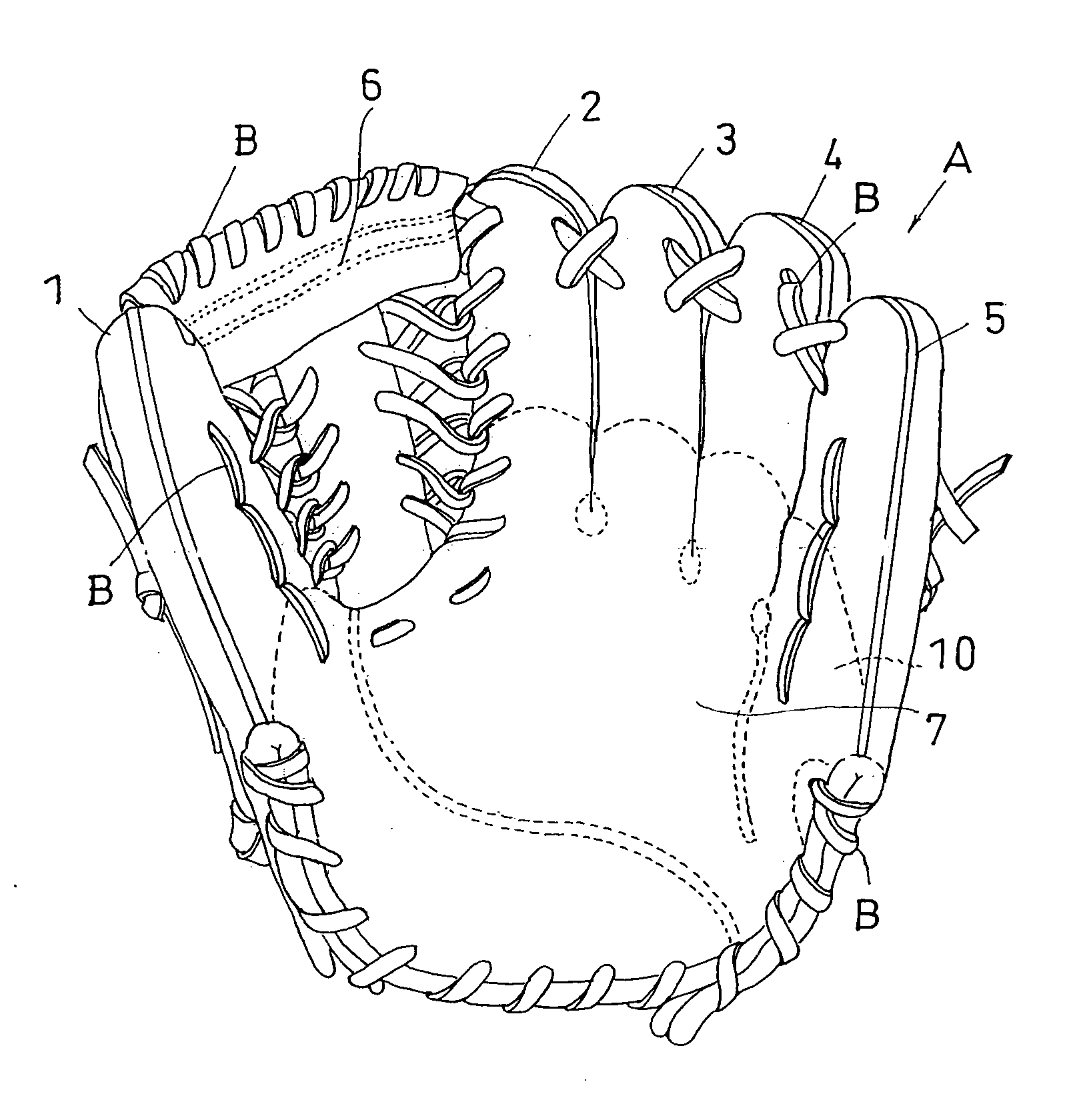

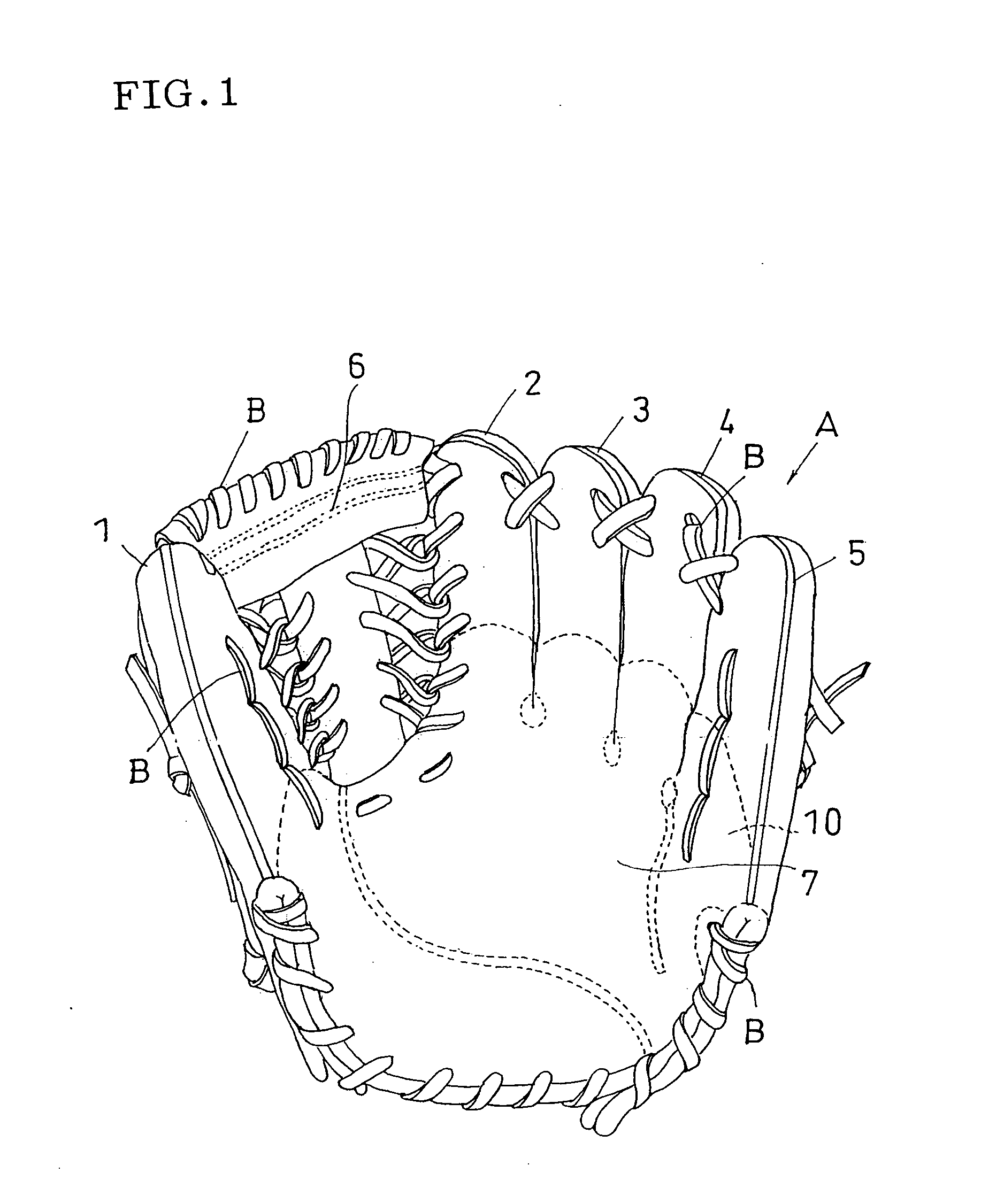

Ball catching apparatus

A ball catching apparatus according to the present invention comprises a main body in which a back-of-hand-side inner skin and a palm-side inner skin are respectively securely fitted to a back-of-hand-side outer skin and a palm-side outer skin, wherein a hand can be inserted into between the back-of-hand-side inner skin and the palm-side inner skin, an intermediate layer secured to one or both of the palm-side outer skin and the palm-side inner skin is interposed between the palm-side outer skin and the palm-side inner skin, and an air layer is formed between the intermediate layer and the palm-side outer skin and between the intermediate layer and the palm-side inner skin.

Owner:TRION CORP

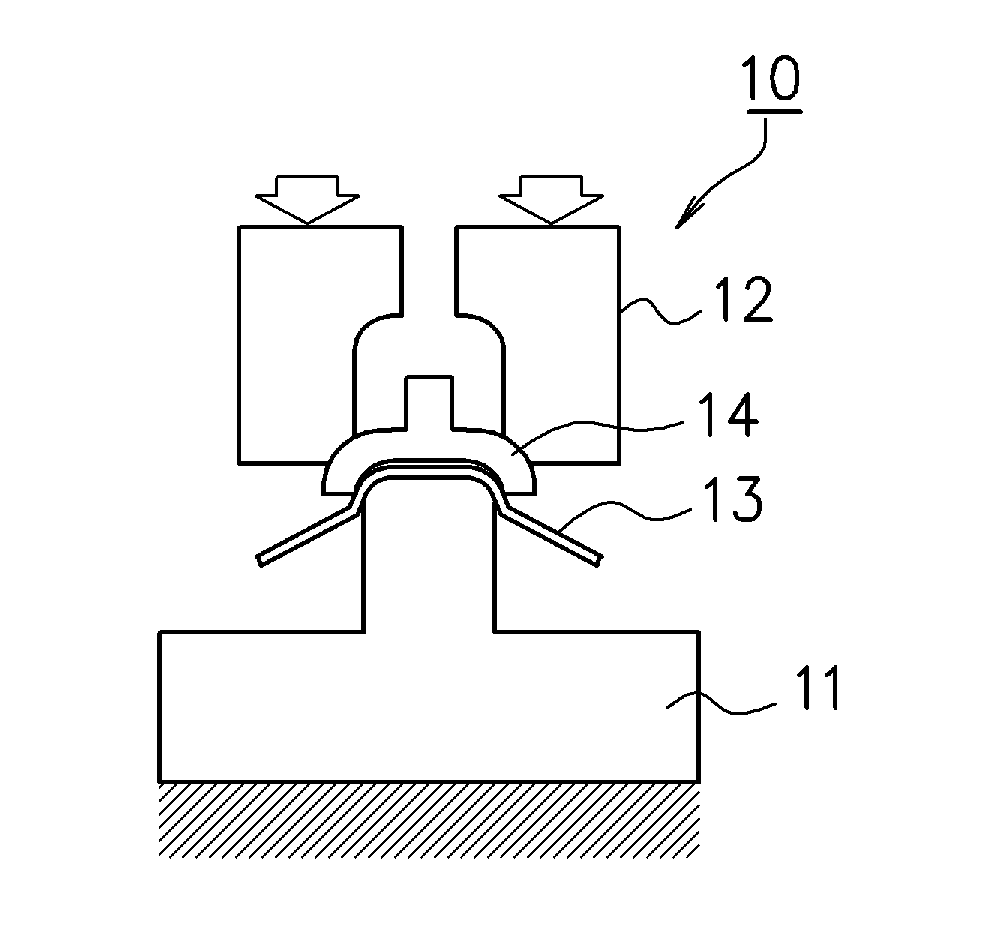

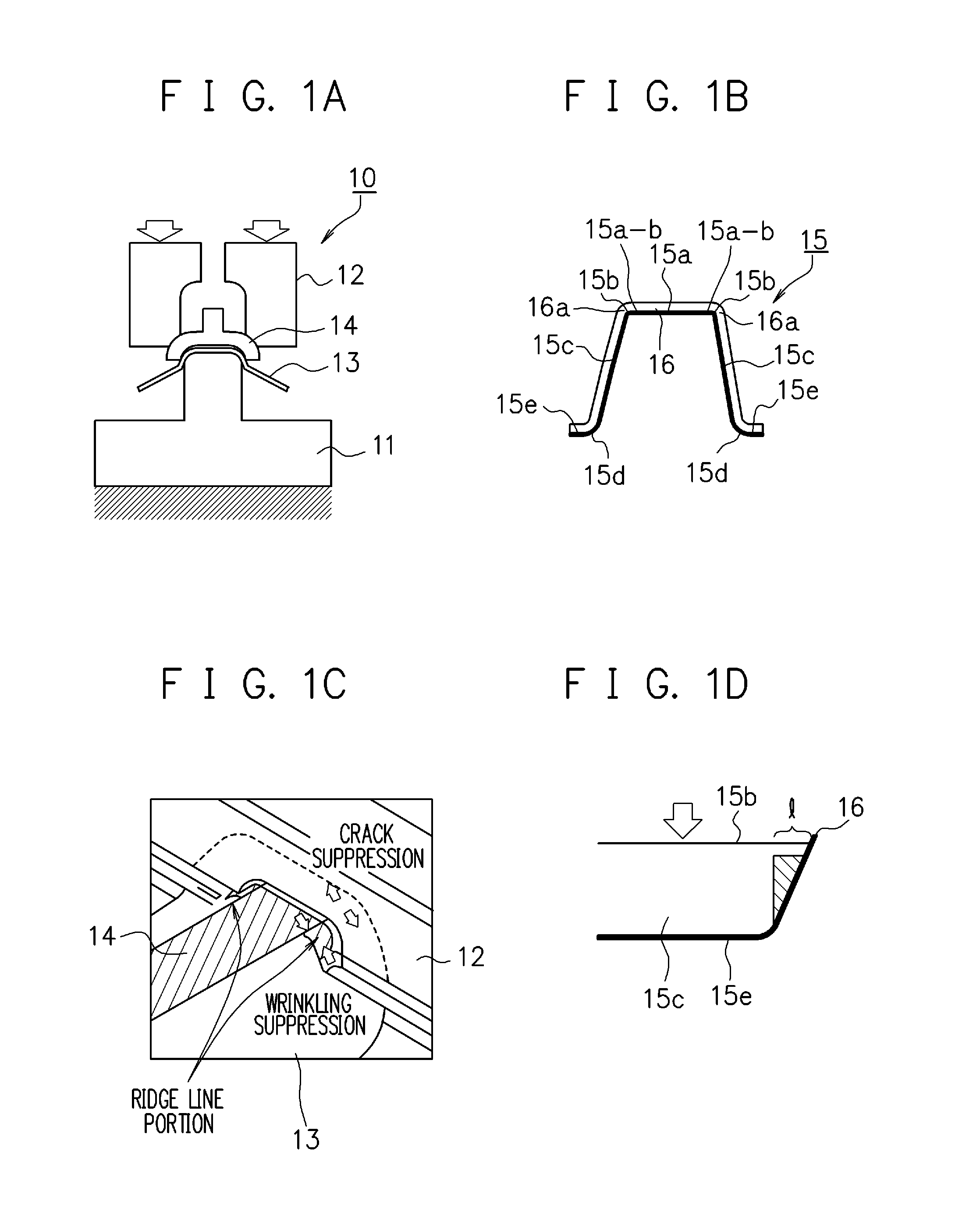

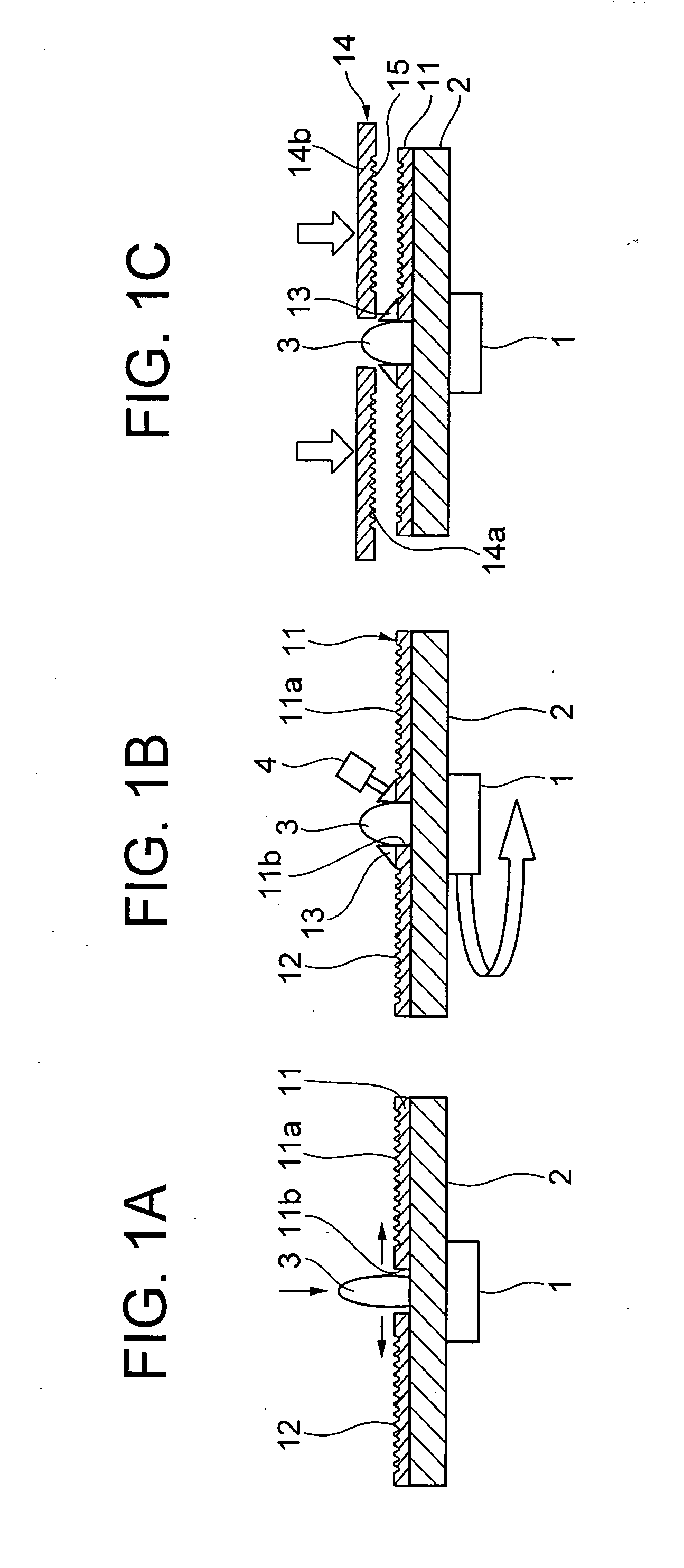

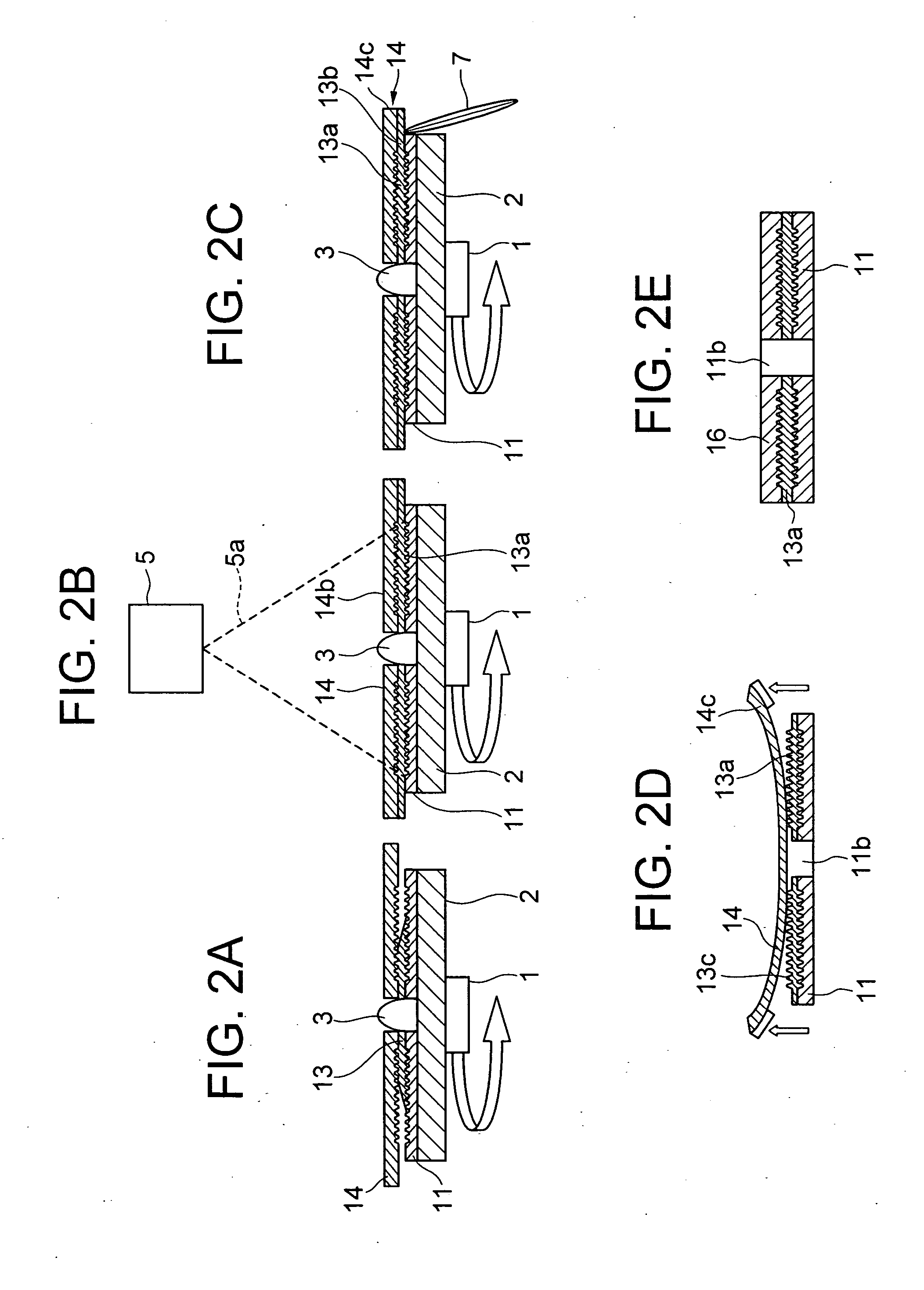

Manufacturing method and manufacturing apparatus of press-formed body

A press-formed body (15) made of a high-tensile strength steel sheet of 390 MPa or more including a groove bottom part (15a), ridge line parts (15b, 15b) continuous to the groove bottom part (15a), and side wall parts (15c, 15c) continuous to the ridge line parts (15b, 15b), and in which an outward flange (16) is formed at an end part in a longitudinal direction is manufactured by a press-forming apparatus including a punch (11), a die (12), and a pad (14) which presses and binds a press-forming material (13) to the punch (11). At a press-forming time, the pad (14) binds a part to be formed into the groove bottom part (15a) and a part having a length of one-third or more of a cross-sectional peripheral length of the ridge line part (15b) starting from a connecting part with the groove bottom part (15a) from among a part to be formed into the ridge line part (15b) in a vicinity of the outward flange (16) at the press-forming material (13). It is thereby possible to surely form the press-formed body (15) without providing cutouts at a ridge line part flange portion of the outward flange, or generating lowering of material yield.

Owner:NIPPON STEEL CORP

Photosensitive resin composition, process for producing patterned hardened film with use thereof and electronic part

ActiveUS8298747B2Improve dehydration rateFormed surelyPhotosensitive materialsSemiconductor/solid-state device manufacturingPhotosensitizerChain structure

To provide a photosensitive resin composition in which a hardened film obtained from the photosensitive resin composition has properties comparable to those of a film hardened at a high temperature, a method for manufacturing a patterned hardened film using the photosensitive resin composition, and an electronic part. The photosensitive resin composition includes (a) a polybenzoxazole precursor having a repeating unit represented by a general formula (I):wherein U and V represent a divalent organic group, and at least one of U and V is a group containing an aliphatic chain structure having 1 to 30 carbon atoms; (b) a photosensitizer; (c) a solvent; and (d) a crosslinking agent capable of causing crosslinking or polymerization by heating.

Owner:HITACHI CHEM DUPONT MICROSYSTEMS LTD

Ball catching apparatus

ActiveUS7437773B2Easily forming pocketFormed surelyGlovesSport apparatusBall-catchingBiomedical engineering

A ball catching apparatus according to the present invention comprises a main body in which a back-of-hand-side inner skin and a palm-side inner skin are respectively securely fitted to a back-of-hand-side outer skin and a palm-side outer skin, wherein a hand can be inserted into between the back-of-hand-side inner skin and the palm-side inner skin, an intermediate layer secured to one or both of the palm-side outer skin and the palm-side inner skin is interposed between the palm-side outer skin and the palm-side inner skin, and an air layer is formed between the intermediate layer and the palm-side outer skin and between the intermediate layer and the palm-side inner skin.

Owner:TRION CORP

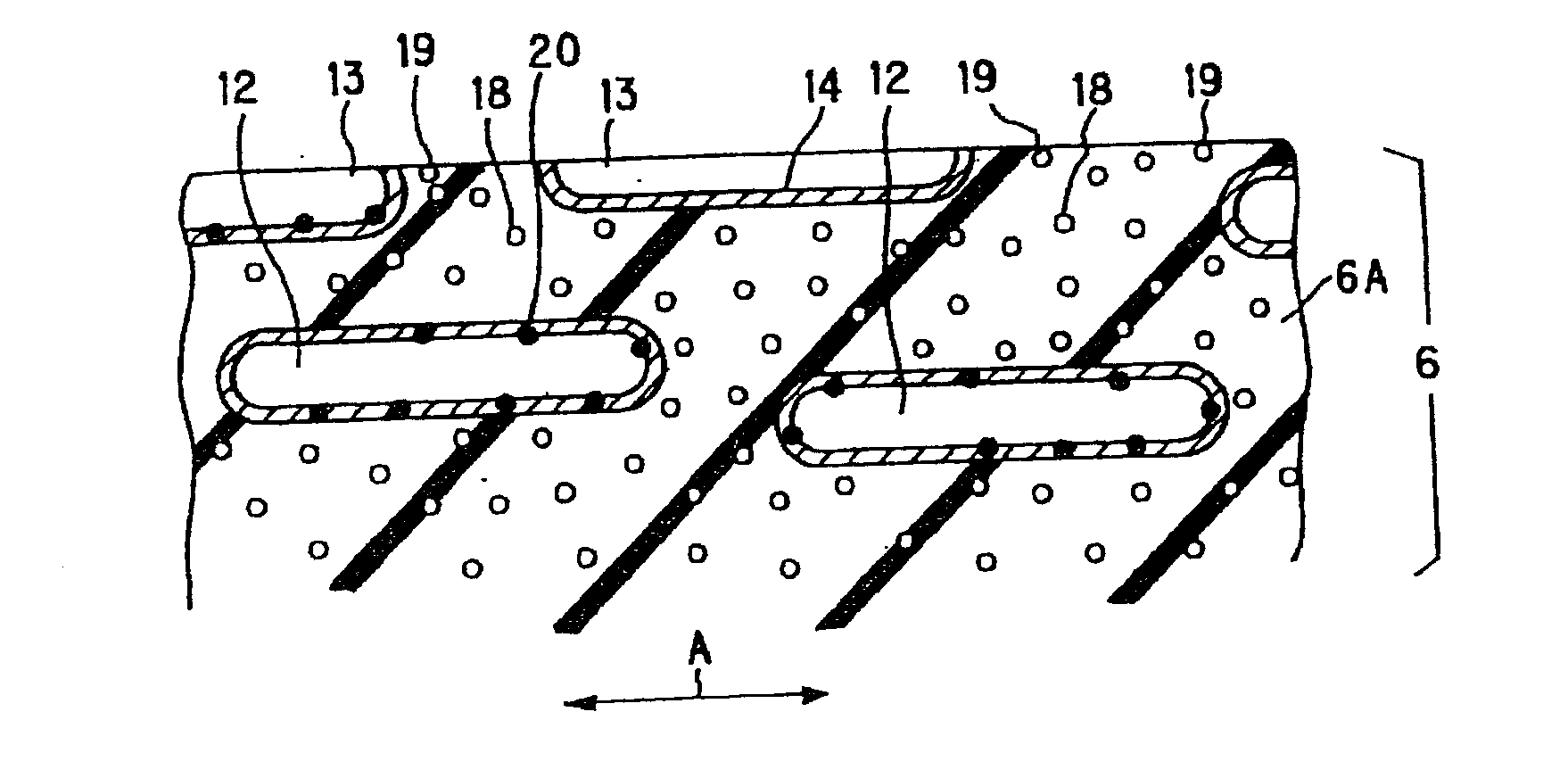

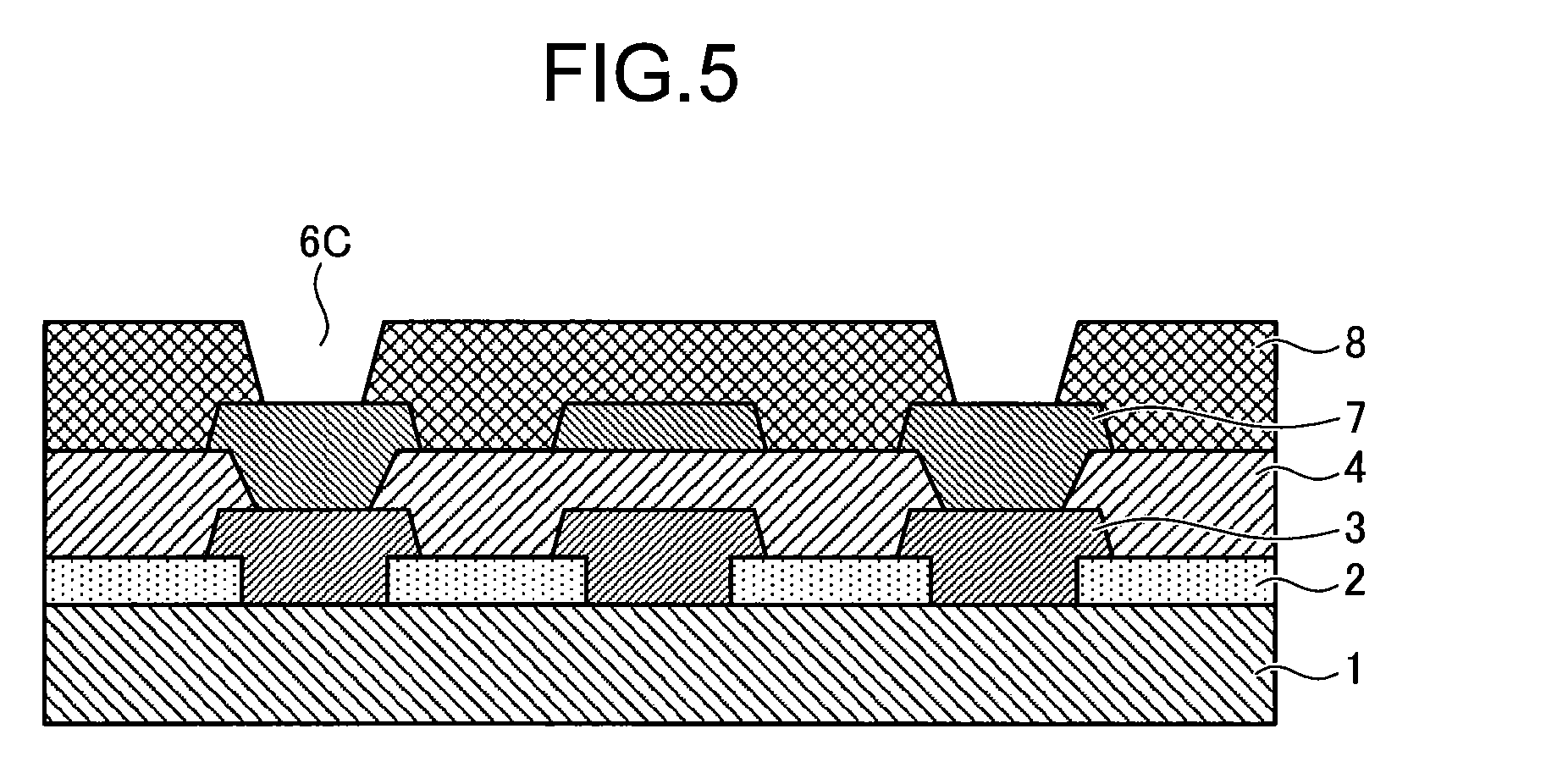

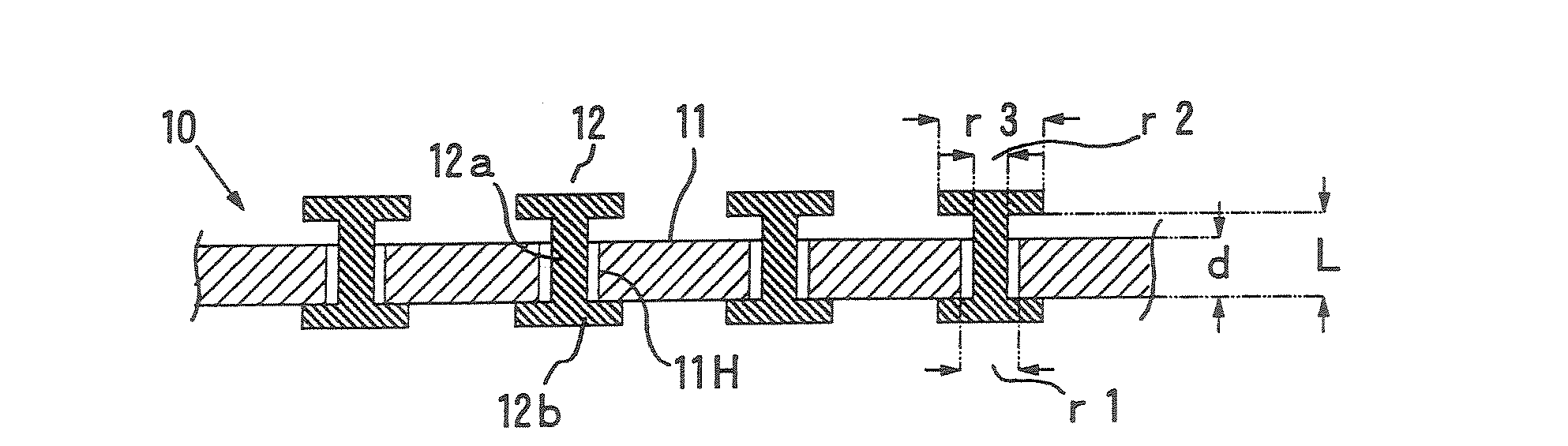

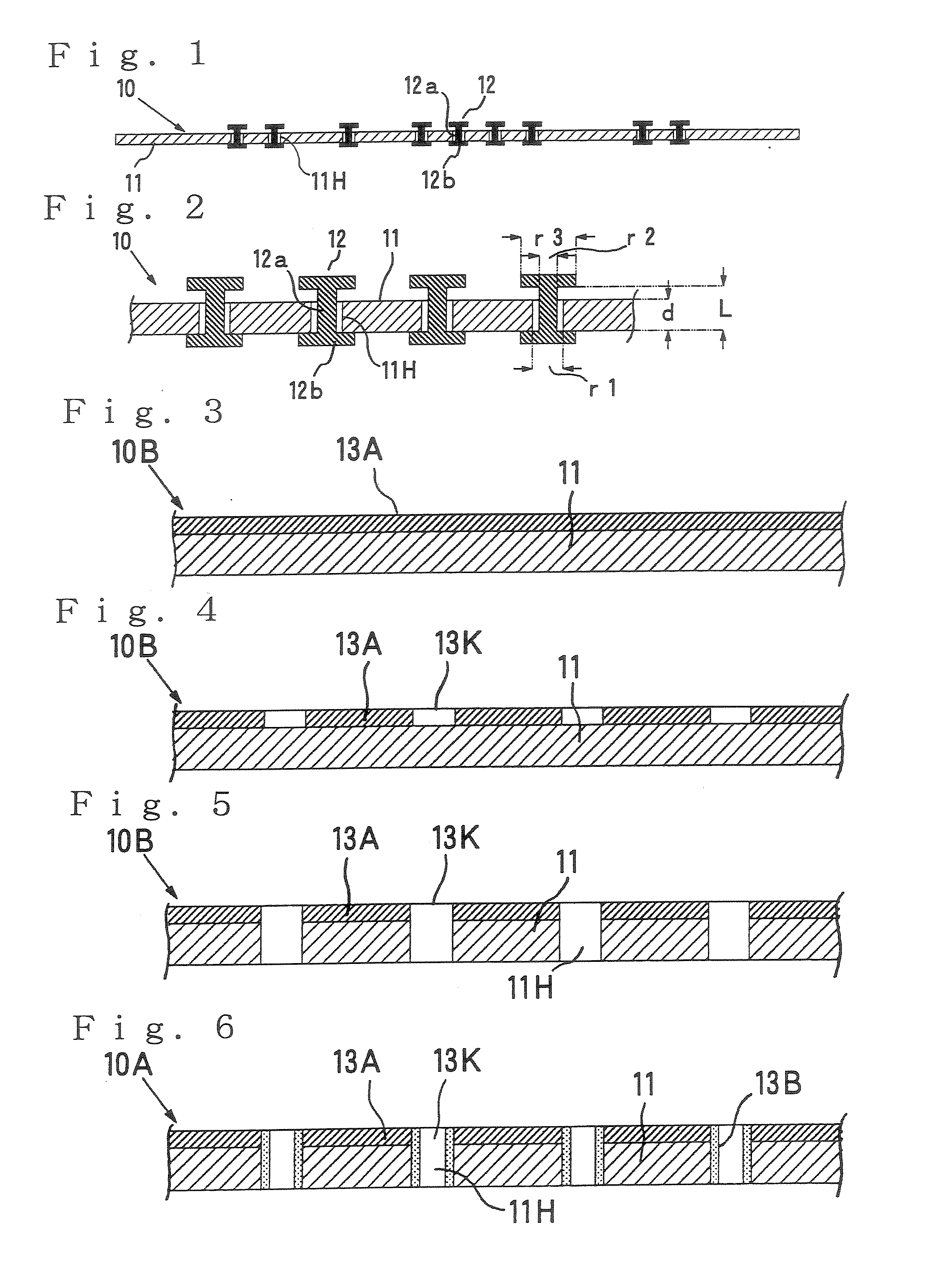

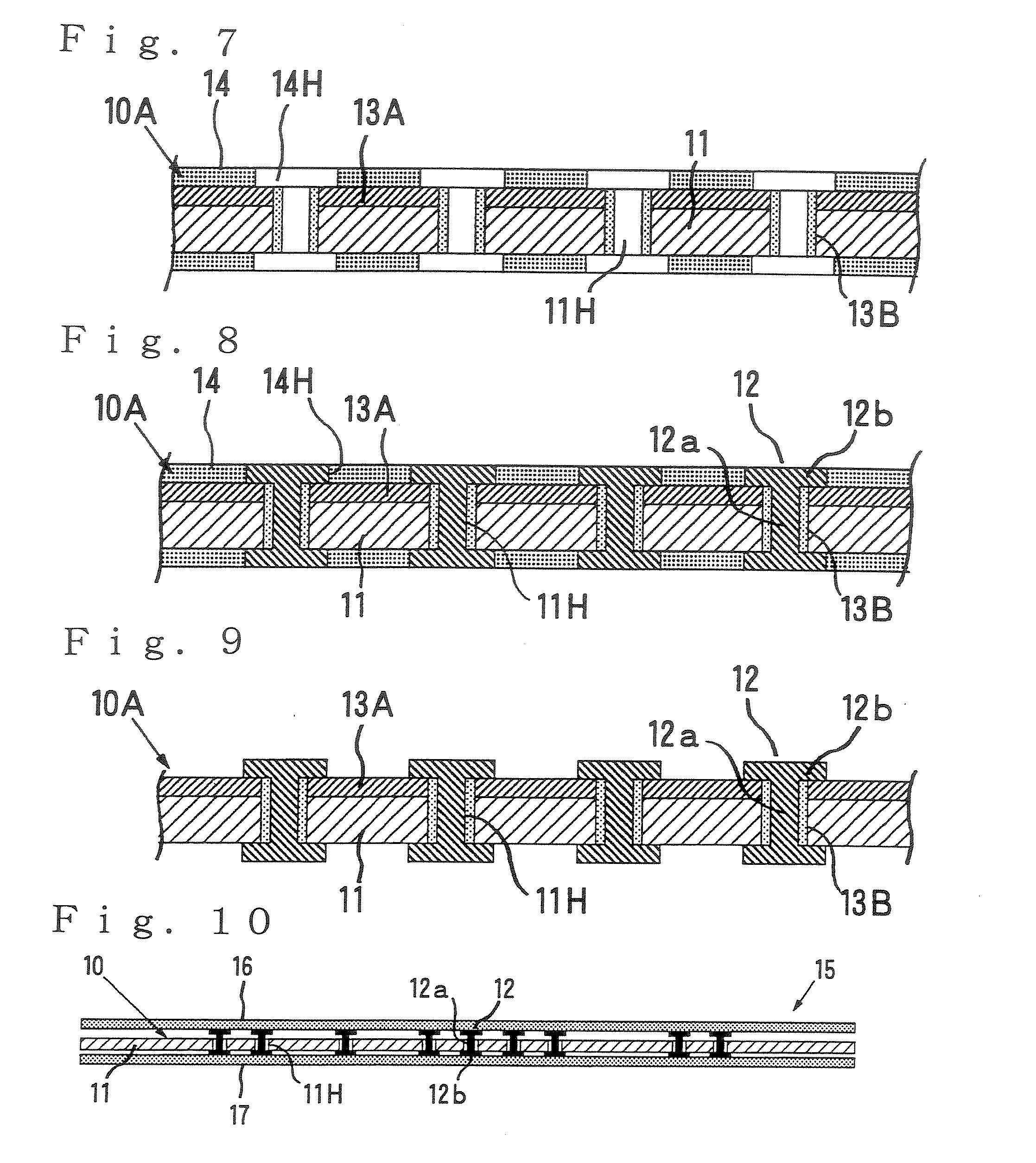

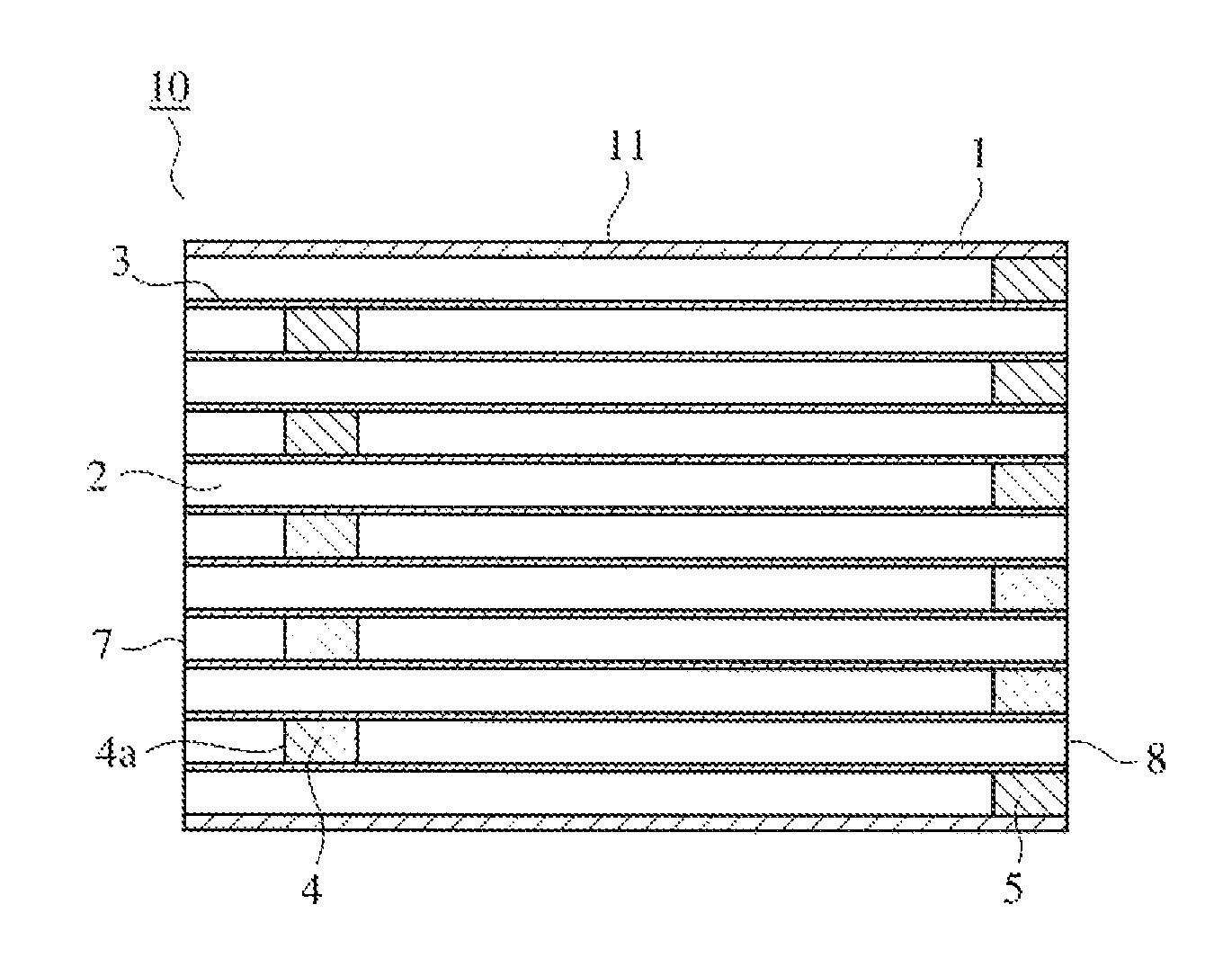

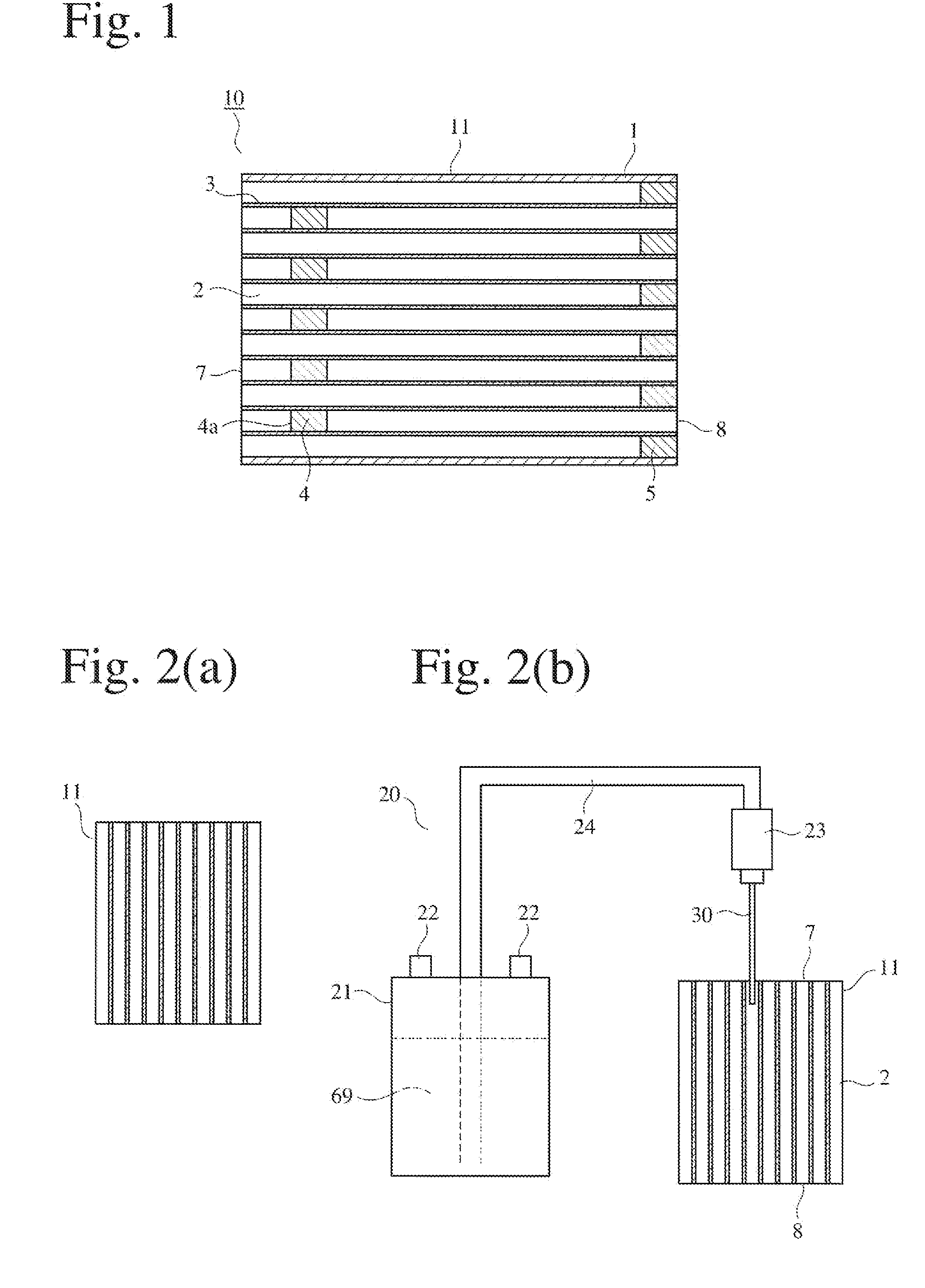

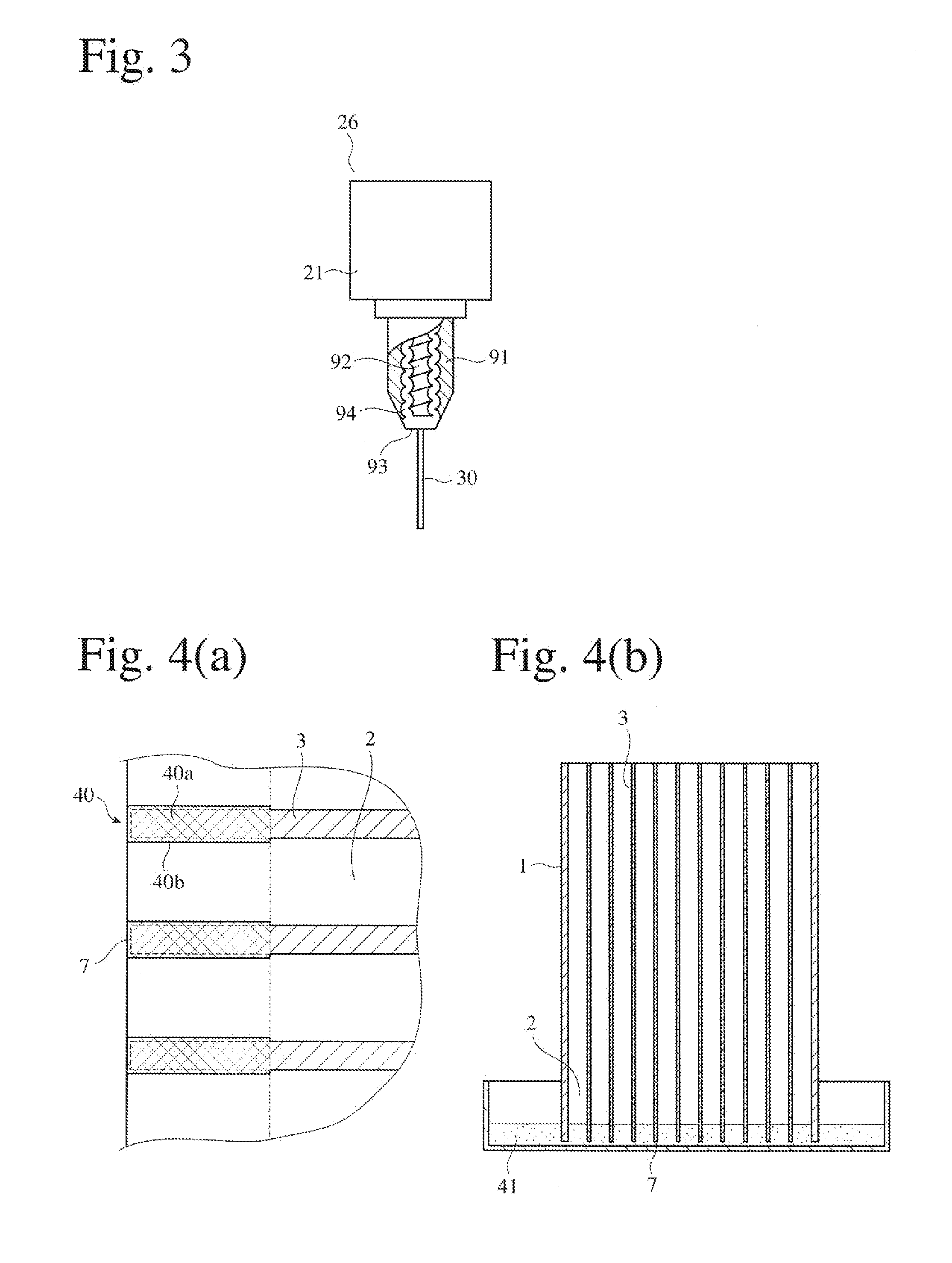

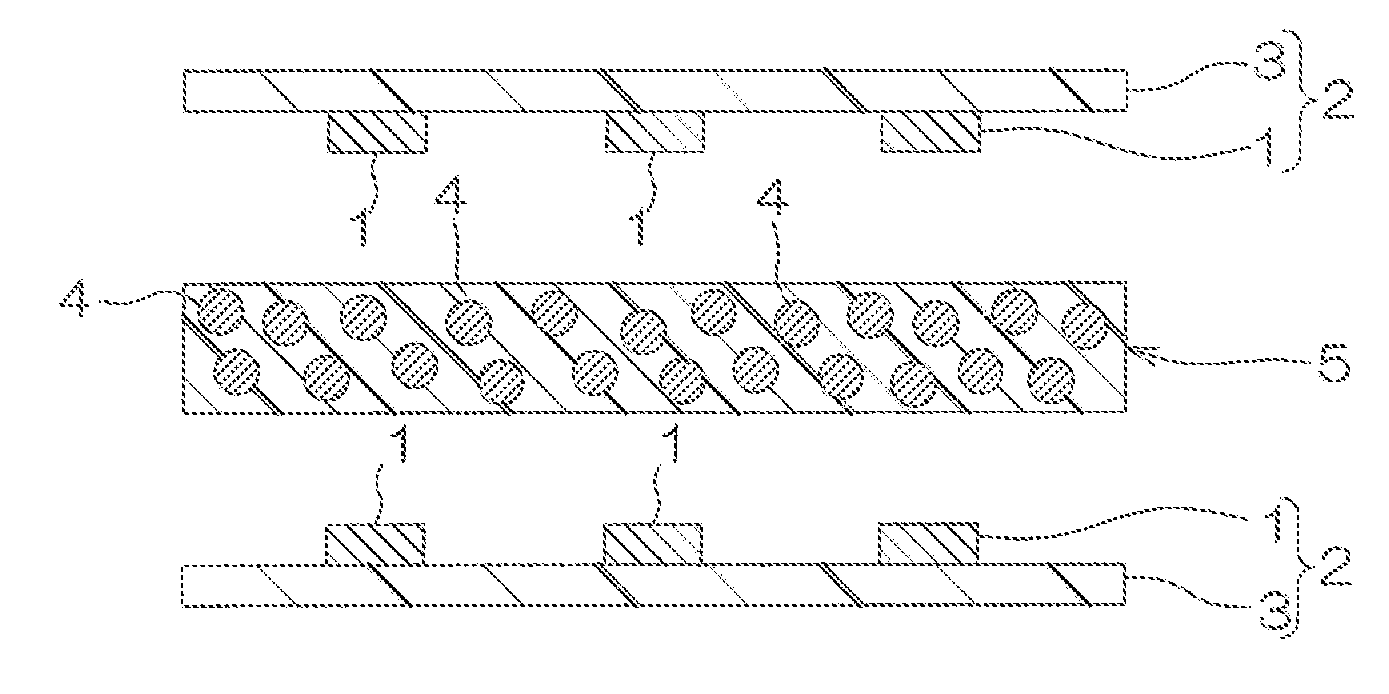

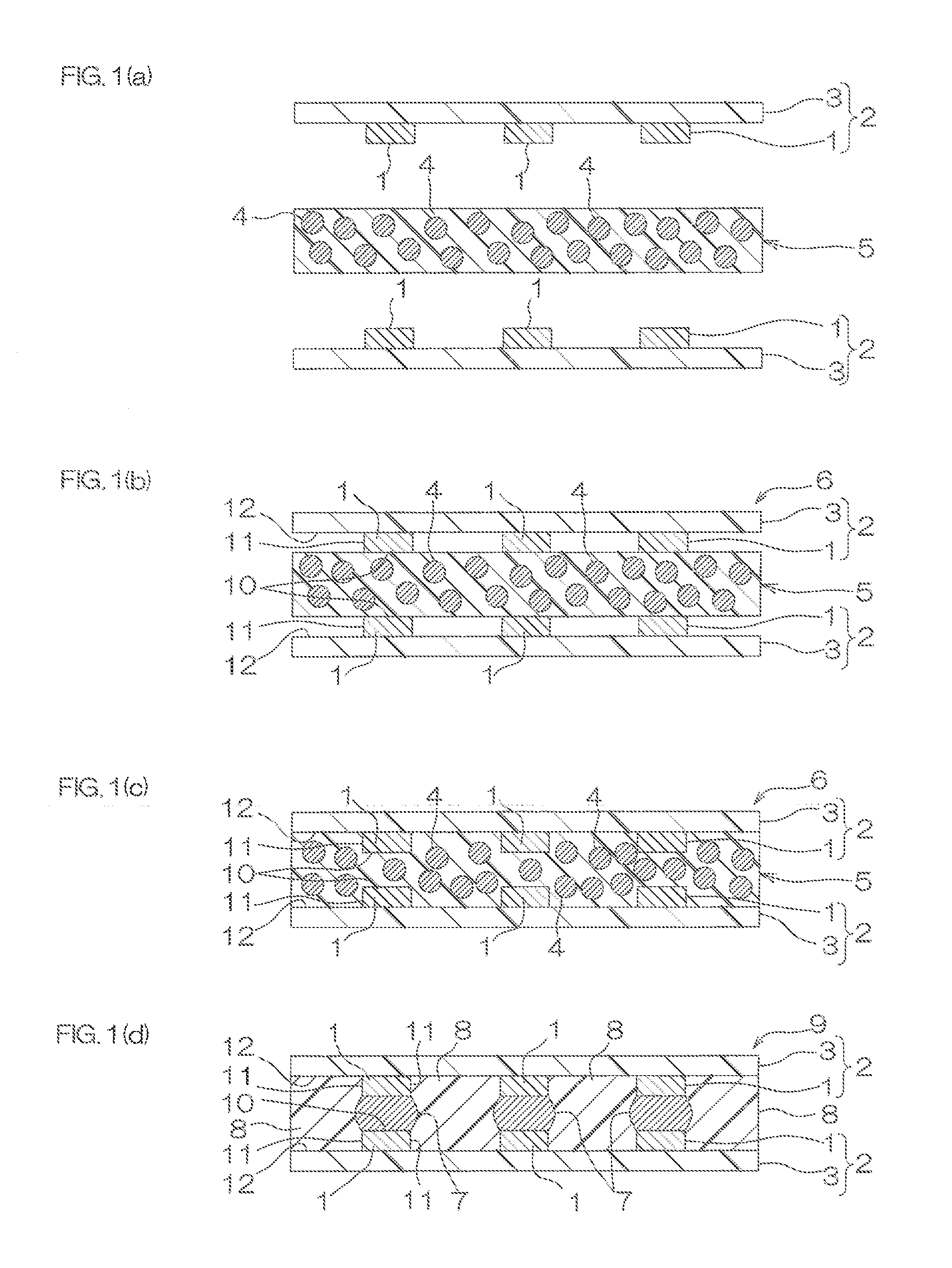

Composite conductive sheet, method for producing the same, anisotropic conductive connector, adapter, and circuit device electric inspection device

ActiveUS20090039905A1Easy to handleFormed surelyNon-insulated conductorsElectronic circuit testingElectricityElectrical conductor

Disclosed herein are a composite conductive sheet that has rigid conductors movable in a thickness-wise direction of an insulating sheet without falling off from the insulating sheet and is easy to handle by itself, a production process thereof, and an anisotropically conductive connector, an adaptor device and an electrical inspection apparatus for circuit devices, which are each equipped with this composite conductive sheet.The composite conductive sheet of the invention has an insulating sheet, in which a plurality of through-holes each extending in a thickness-wise direction of the sheet are formed, and rigid conductors arranged respectively in the through-holes in the insulating sheet so as to protrude from both surfaces of the insulating sheet, wherein each of the rigid conductors has terminal portions formed on both ends of a body portion inserted into the through-hole in the insulating sheet and each having a diameter greater than a diameter of the through-hole in the insulating sheet, and is movable in the thickness-wise direction of the insulating sheet.

Owner:ISC CO LTD

Semiconductor device and manufacturing method therefor

ActiveUS20120187537A1Increase capacitanceFormed surelySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorBiomedical engineering

Owner:LONGITUDE LICENSING LTD

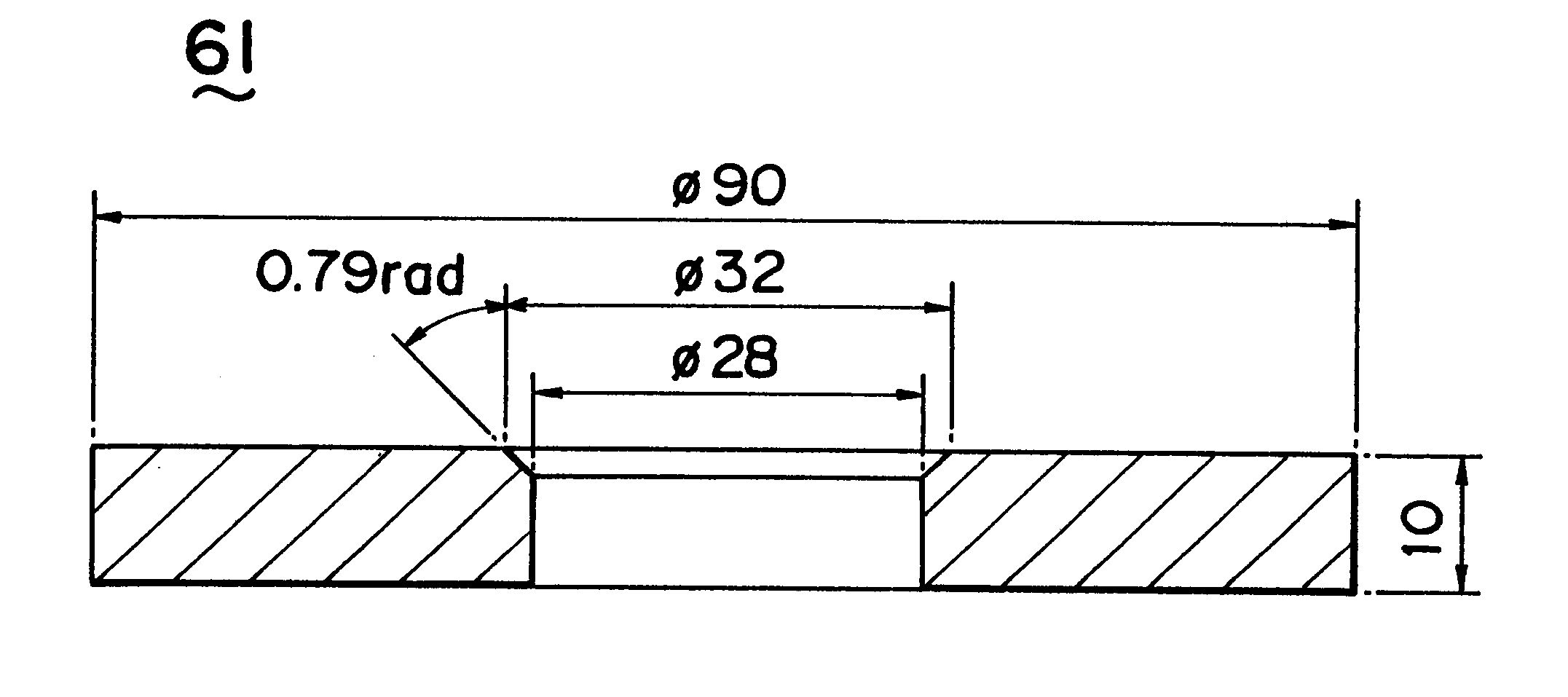

Method of manufacturing disc-shaped recording medium

InactiveUS20050048202A1Reduce swellingReduce wasteRecord carriersPretreated surfacesEngineeringRecording media

Disclosed is a disc-shaped recording medium manufacturing method capable of making it difficult to leave the cutting wastage produced upon forming a notch for exfoliating a stamper on a disc-shaped substrate in the case of adopting a stamper-based transfer method, and surely forming the notch to improve a manufacturing yield. This disc-shaped recording medium manufacturing method is that a spacer layer having recording faces on both surfaces thereof is formed between the disc-shaped substrate and the stamper, a notch is formed in the vicinity of an outer peripheral edge of the stamper by a rotary blade of a circle cutter, and the stamper is exfoliated through the notch while the spacer layer stays on the disc-shaped substrate.

Owner:TDK CORPARATION

Production method of honeycomb filter and honeycomb filter

ActiveUS7892309B2Avoid cloggingFormed surelyCombination devicesGas treatmentHoneycomb structureMaterials science

A method for producing a honeycomb filter from a honeycomb structure having large numbers of flow paths partitioned by cell walls, comprising inserting a tubular member into each of the flow paths, and injecting a plugging material into each of the flow paths from the tubular member to form a plug in each of the flow paths at a position separate from the end surface of the honeycomb structure, the tubular member having an outer diameter that is 40-90% of the opening size of the flow path, the plugging material comprising at least a ceramic material having a maximum particle size that is 85% or less of the inner diameter of the tubular member, and an average particle size of 1 μm or more.

Owner:HITACHI METALS LTD

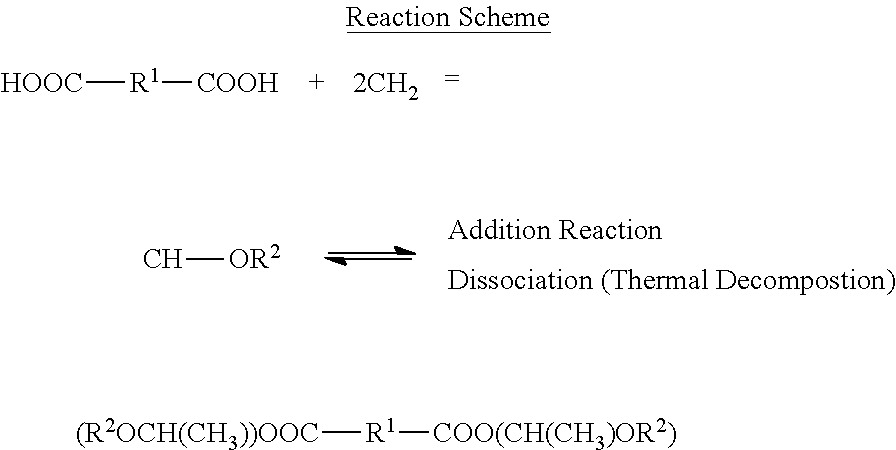

Joining sheet, electronic component, and producing method thereof

InactiveUS20130277092A1Excellent solder meltingEasy to joinSolid-state devicesEpoxy resin adhesivesCarboxylic acidElectronic component

A joining sheet contains solder particles, a thermosetting resin, a thermoplastic resin, and a blocked carboxylic acid.

Owner:NITTO DENKO CORP

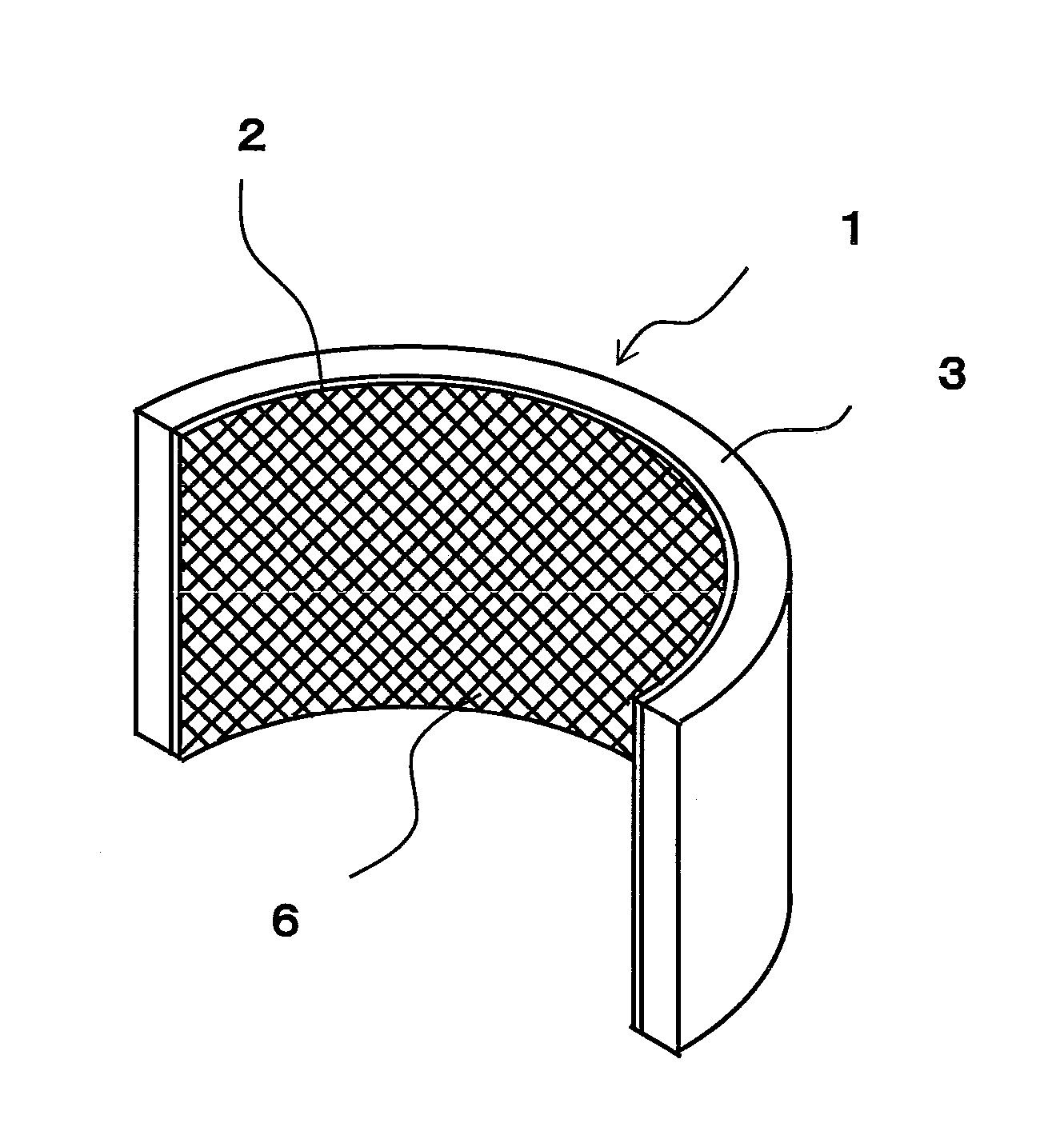

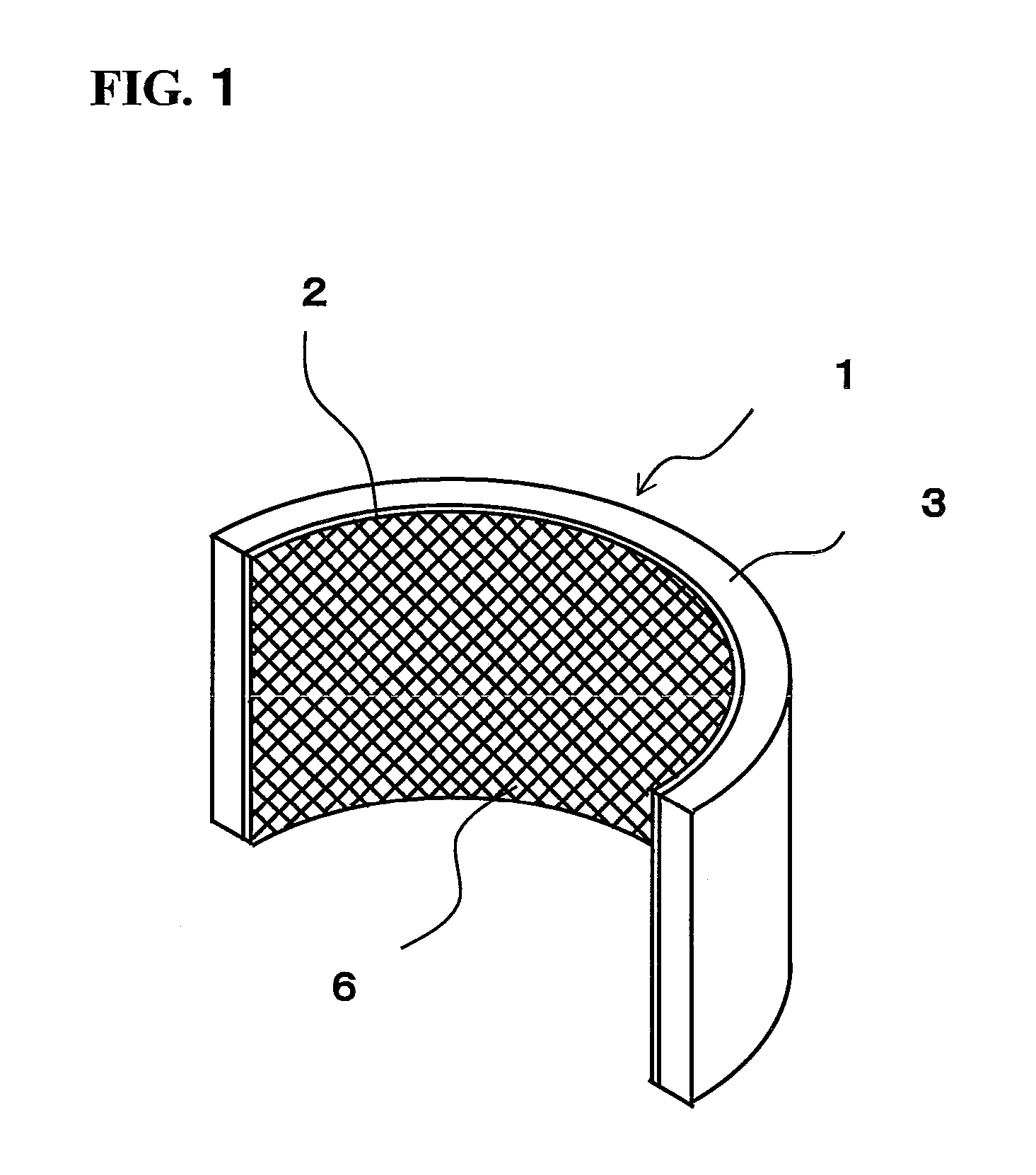

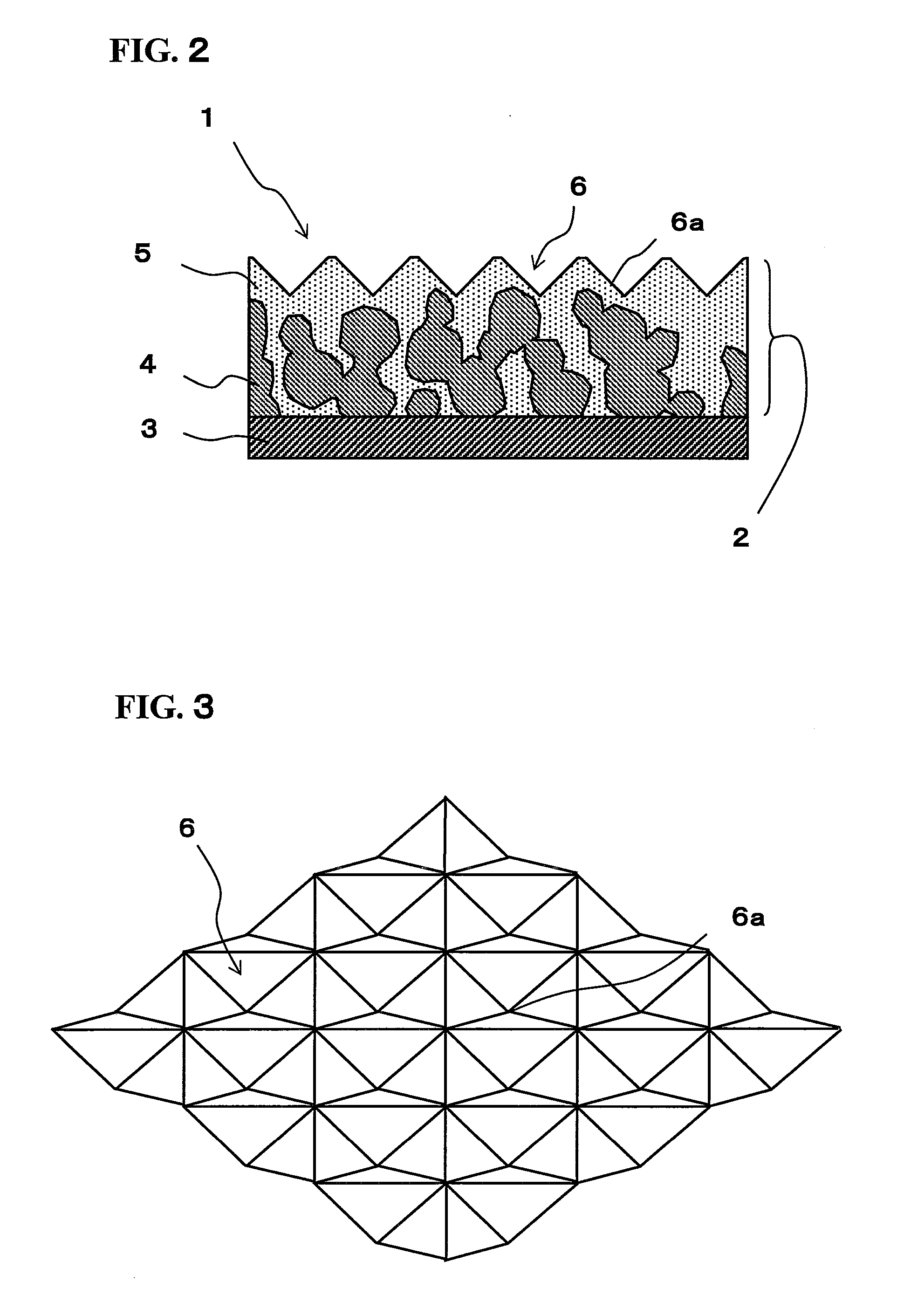

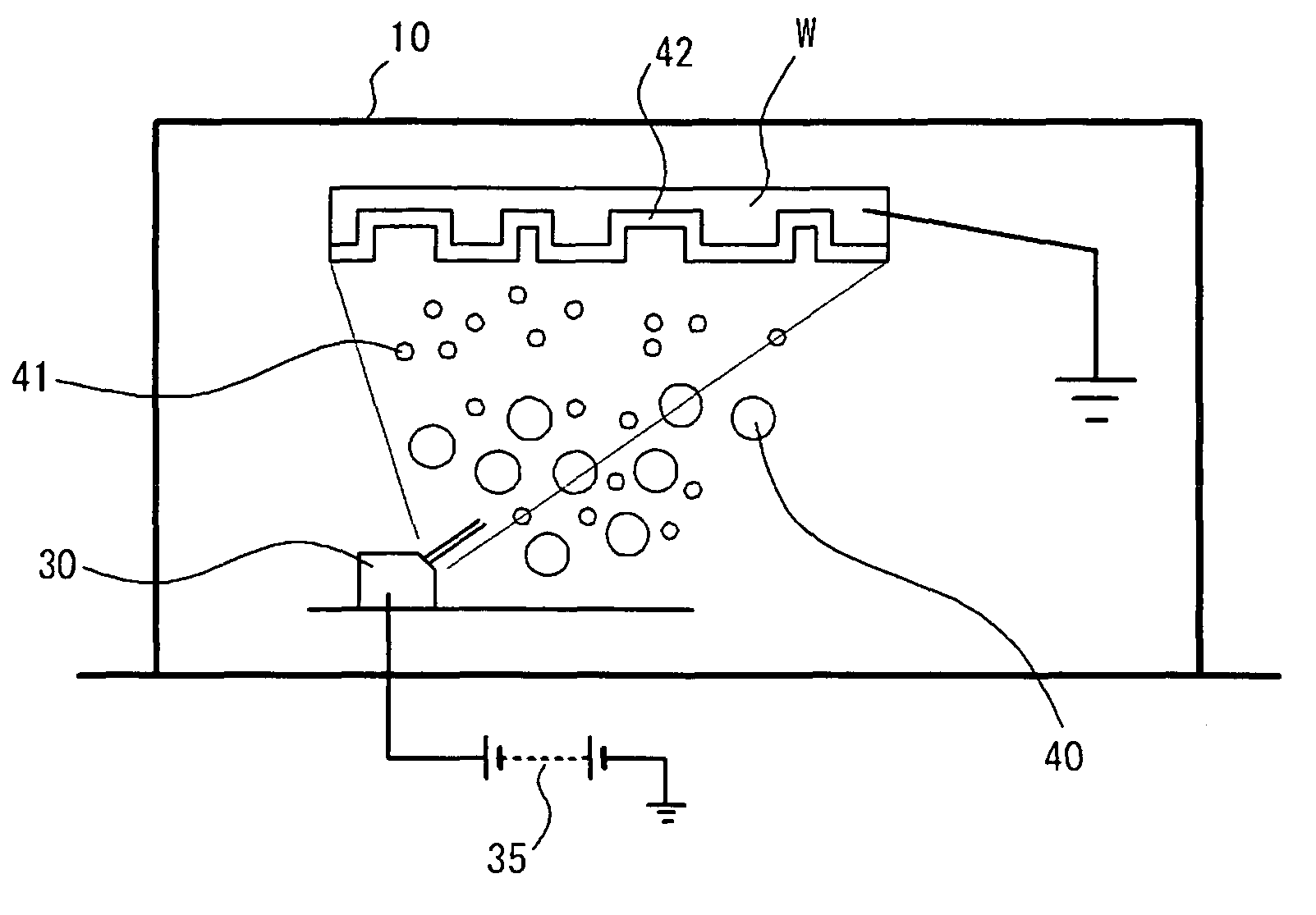

Half bearing

To provide a half bearing which has excellent abrasion resistance and surely forms an oil film under boundary lubrication in which it is difficult to form any oil film. A half bearing 1 formed on a circular arc along a direction in which the member to be slid swings is provided with a porous layer 4 composed of Cu—Sn series alloy, which is formed on a surface of a metal substrate 3, and a sliding layer 2 in which the porous layer 4 is covered with resin material 5 including at least polytetrafluoroethylene and a carbon fiber. An uneven surface 6 having a height which maintains oil to form an oil film and maintains the oil so that the oil film is formed against abrasion when a member to be slid is sliding, is formed on a surface of the sliding layer 2 slidably bearing the member to be slid.

Owner:SENJU METAL IND CO LTD

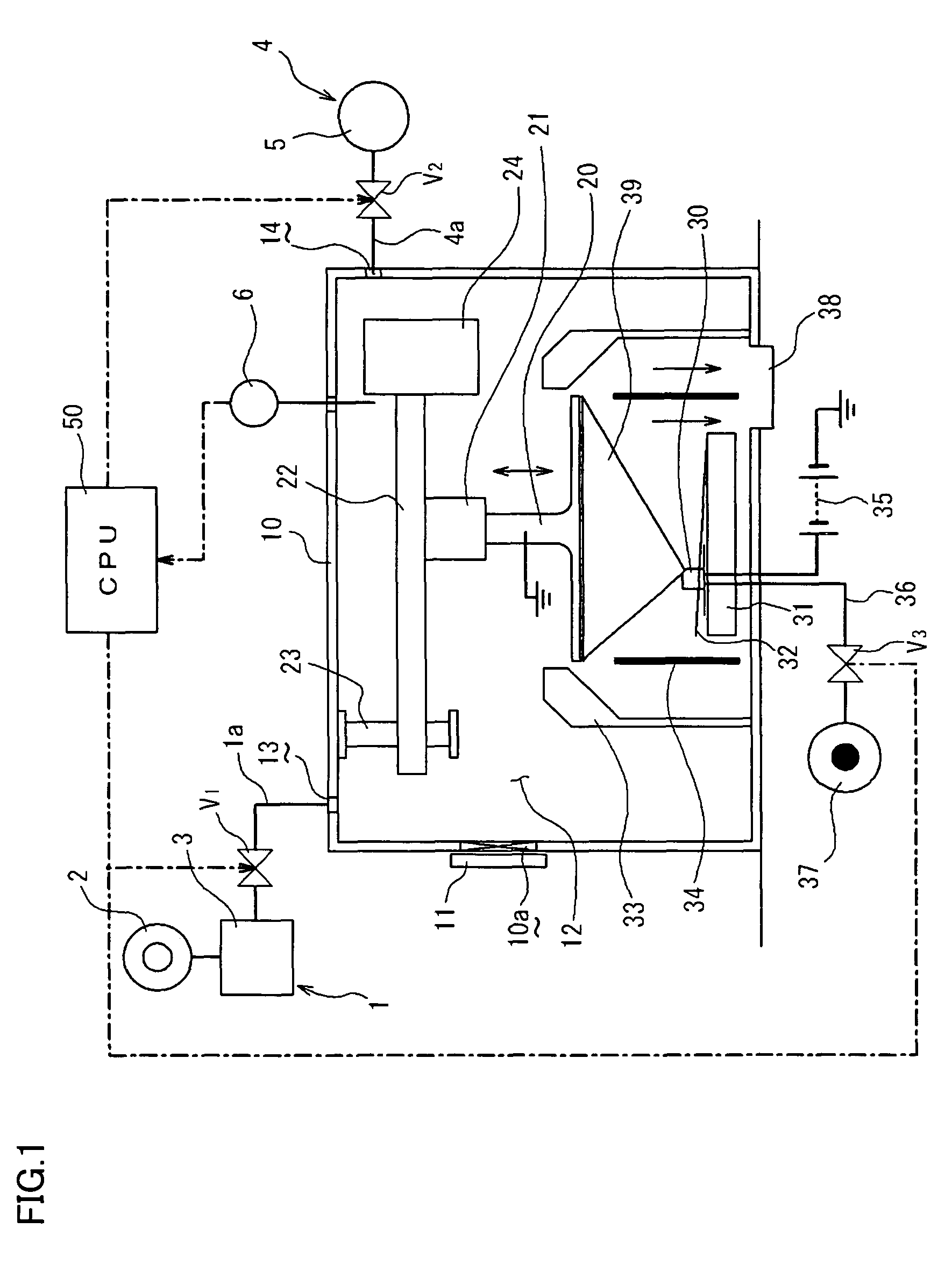

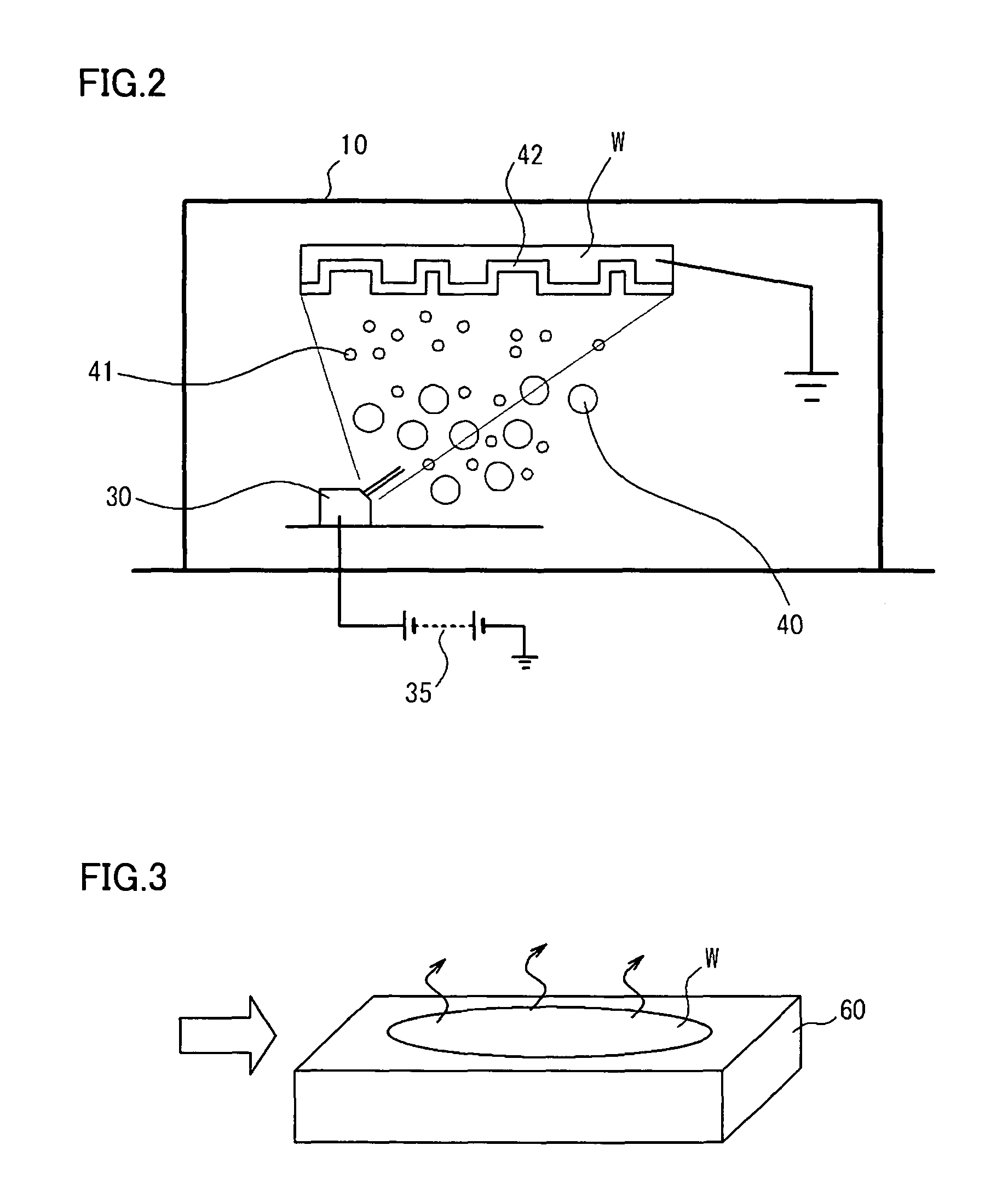

Method for forming thin film and film-forming device

InactiveUS7926444B2Simple treatmentBlocking fluidityElectric shock equipmentsSemiconductor/solid-state device manufacturingEngineeringSolvent

It is an object to provide a method for forming a thin film having a uniform thickness so as to follow asperities of a surface of a wafer to be processed and to provide a film-forming device used for the method. The film-forming device includes a treatment chamber for receiving a wafer and isolating the wafer from the air; a solvent-gas-supplying portion for supplying a solvent gas into the treatment chamber; a chuck for rotatably holding the wafer so that the downward-facing surface of the substrate is the surface on which a thin film is formed; a coating-solution-supplying portion for supplying a coating solution as a mist of charged particles toward the surface of the wafer; and a charging portion for charging the wafer with an electrical potential opposite to the charge of the particles.

Owner:TOKYO ELECTRON LTD

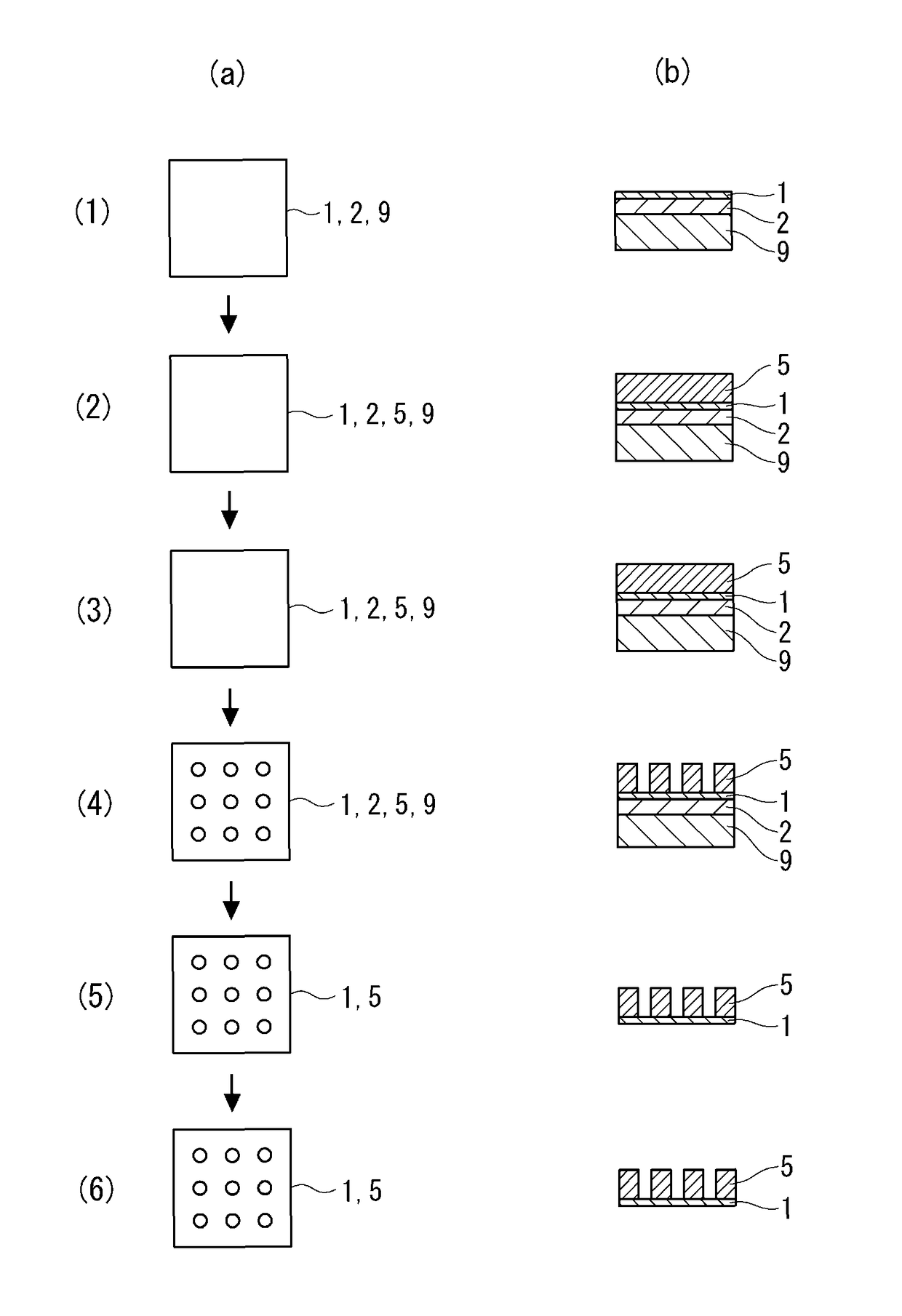

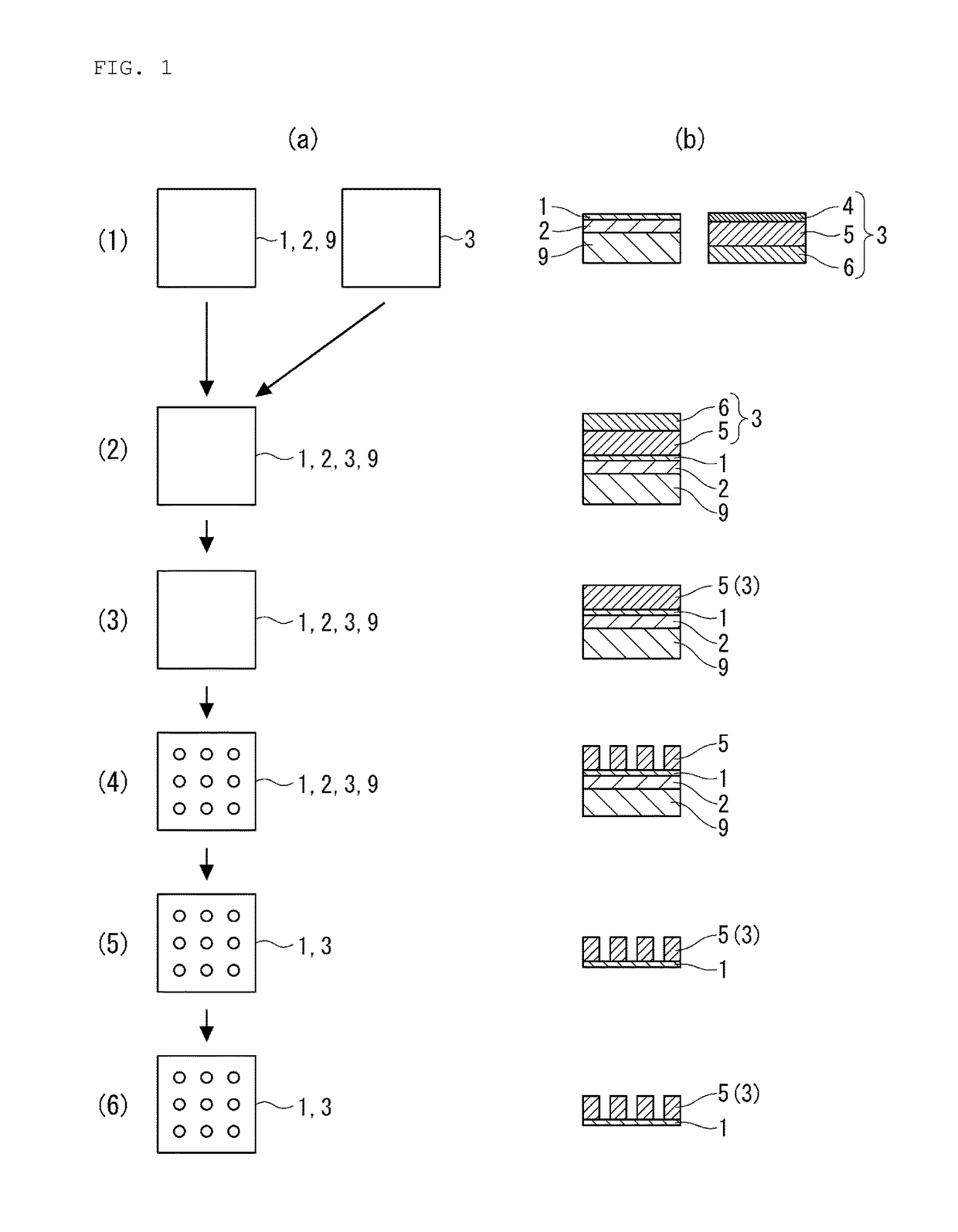

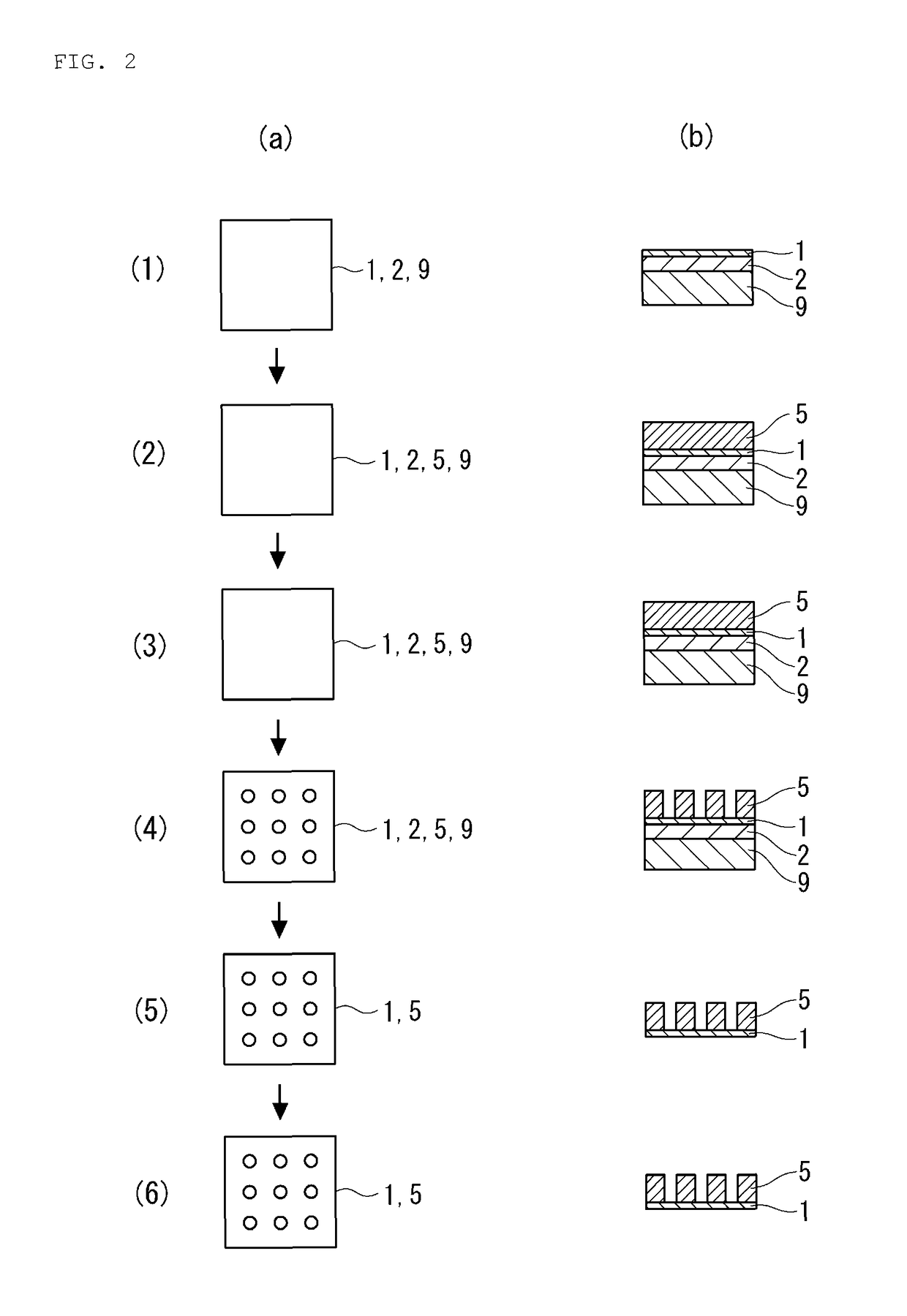

Method for producing filter molded article

ActiveUS9968890B2Mild responseAvoid supportMembranesSemi-permeable membranesOptoelectronicsFilter material

A filter molded article using a graphene with water passage holes having a desired size is produced in a simple step.A method for producing a filter molded article having a graphene layer as a filtering material is characterized by including a step of forming a support 3 layer on a surface of a graphene 1 layer formed on initial substrates for a graphene 2 and 9, a step of forming water passage holes in the support 3 layer, a step of removing the initial substrates for a graphene 2 and 9, and a step of forming water passage holes by heating and holding the graphene 1 layer at a low temperature in the air containing oxygen of 160 to 250° C. for a predetermined time.

Owner:KOTOBUKI HLDG CO LTD +1

Semiconductor device and manufacturing method therefor

ActiveUS8169015B2Increase capacitanceFormed surelyTransistorFixed capacitor dielectricSemiconductorBiomedical engineering

Owner:LONGITUDE SEMICON S A R L

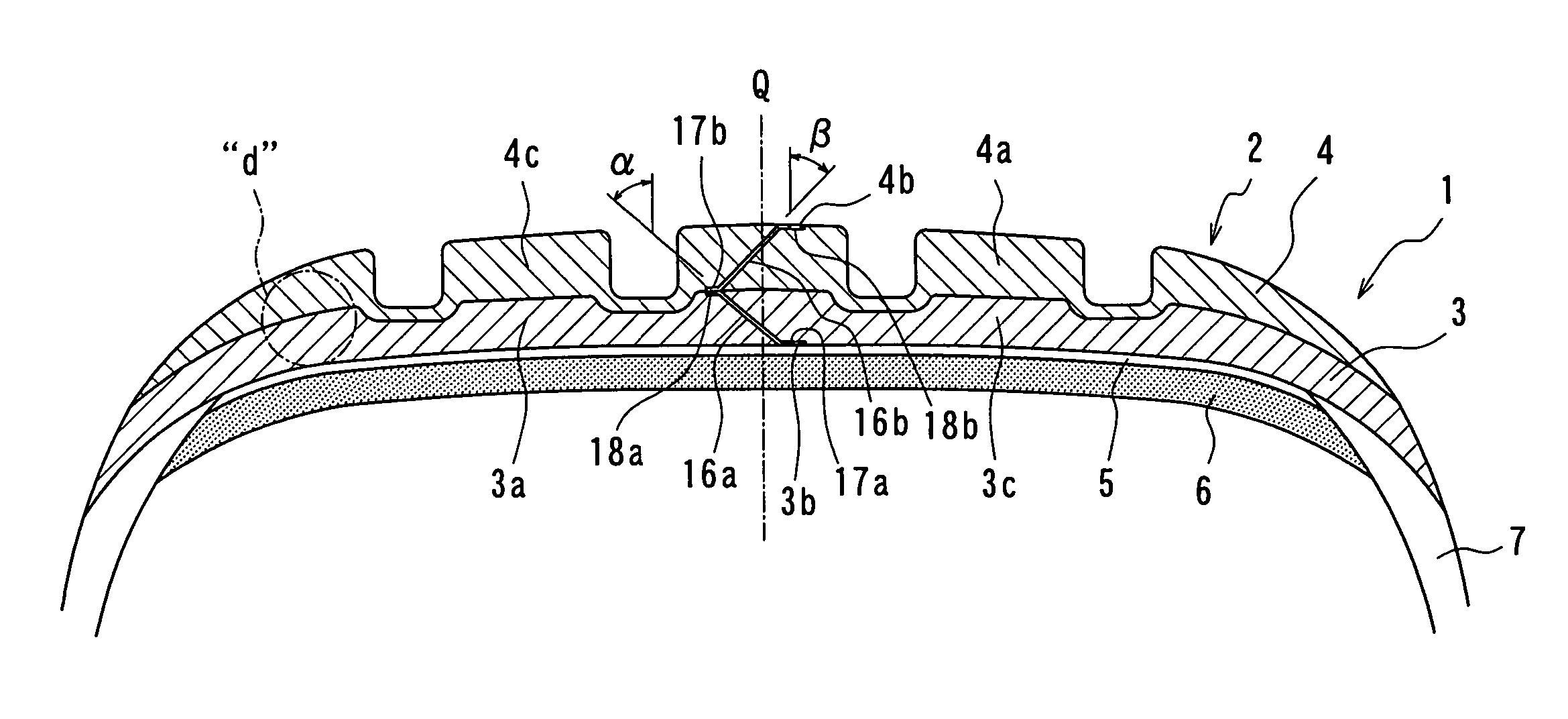

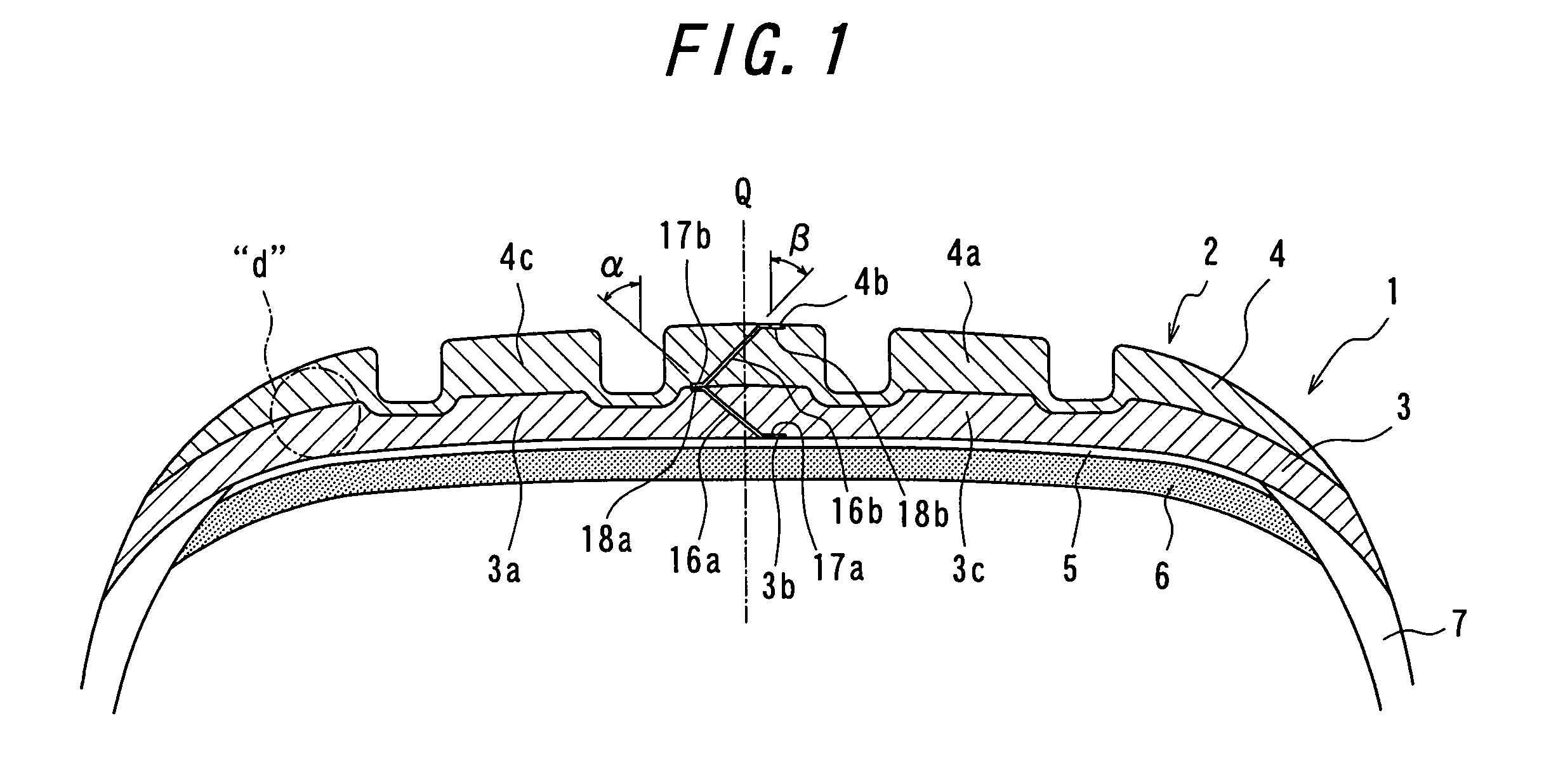

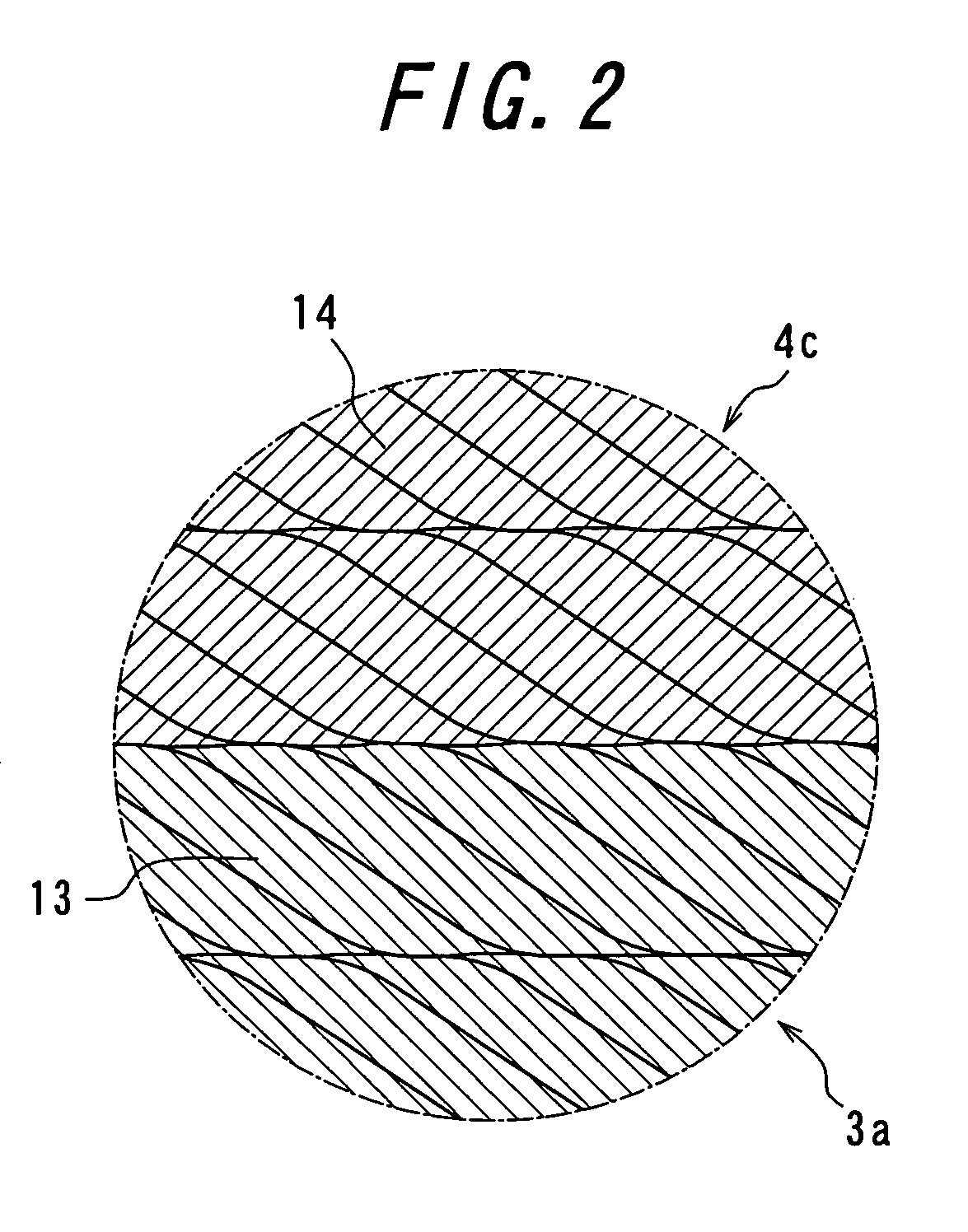

Tire and tire producing method

A tire comprising a tread layer comprised of a tread rubber and an electrically conductive band arranged in a widthwise middle portion thereof, and a method of producing the tire, wherein the tread rubber is made of a low-conductive continuous rubber ribbon circumferentially wound plural times, and the electrically conductive band is made of a high-conductive thin annular rubber sheet. Also, the electrically conductive band is arranged so as to extend in the widthwise region ranging from a part of the top face of the first tread rubber portion to a part of the bottom face of the second tread rubber portion, whereby the tire uniformity is improved and the production is possible in a multi-size mixed production system and the conductive path from the belt to the treading face can be surely formed at a low cost.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com