Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

240results about How to "Excellent etch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flowable silicon-carbon-nitrogen layers for semiconductor processing

InactiveUS20130217240A1Reduce in quantityIncrease the number ofSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionDielectric layer

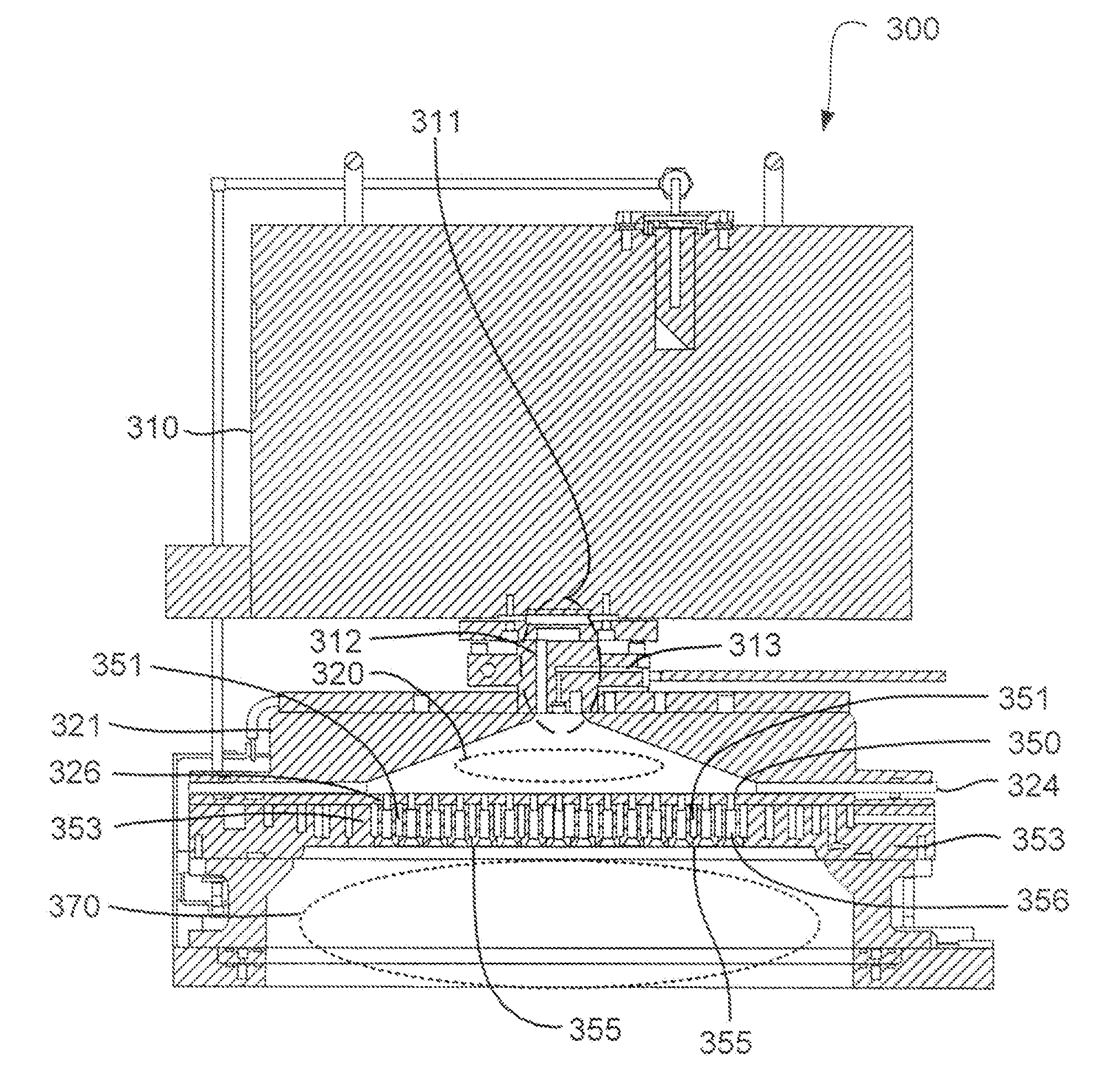

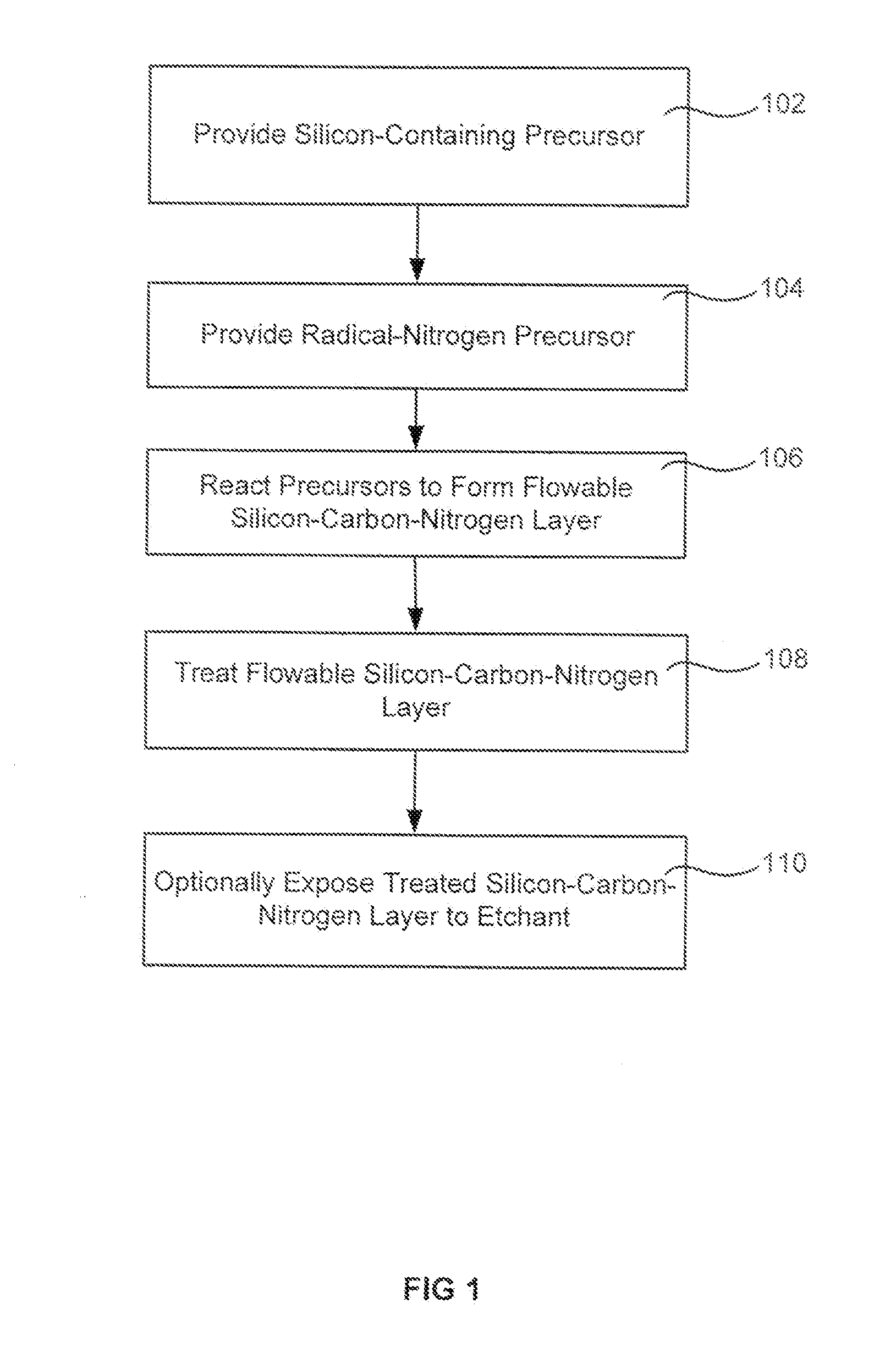

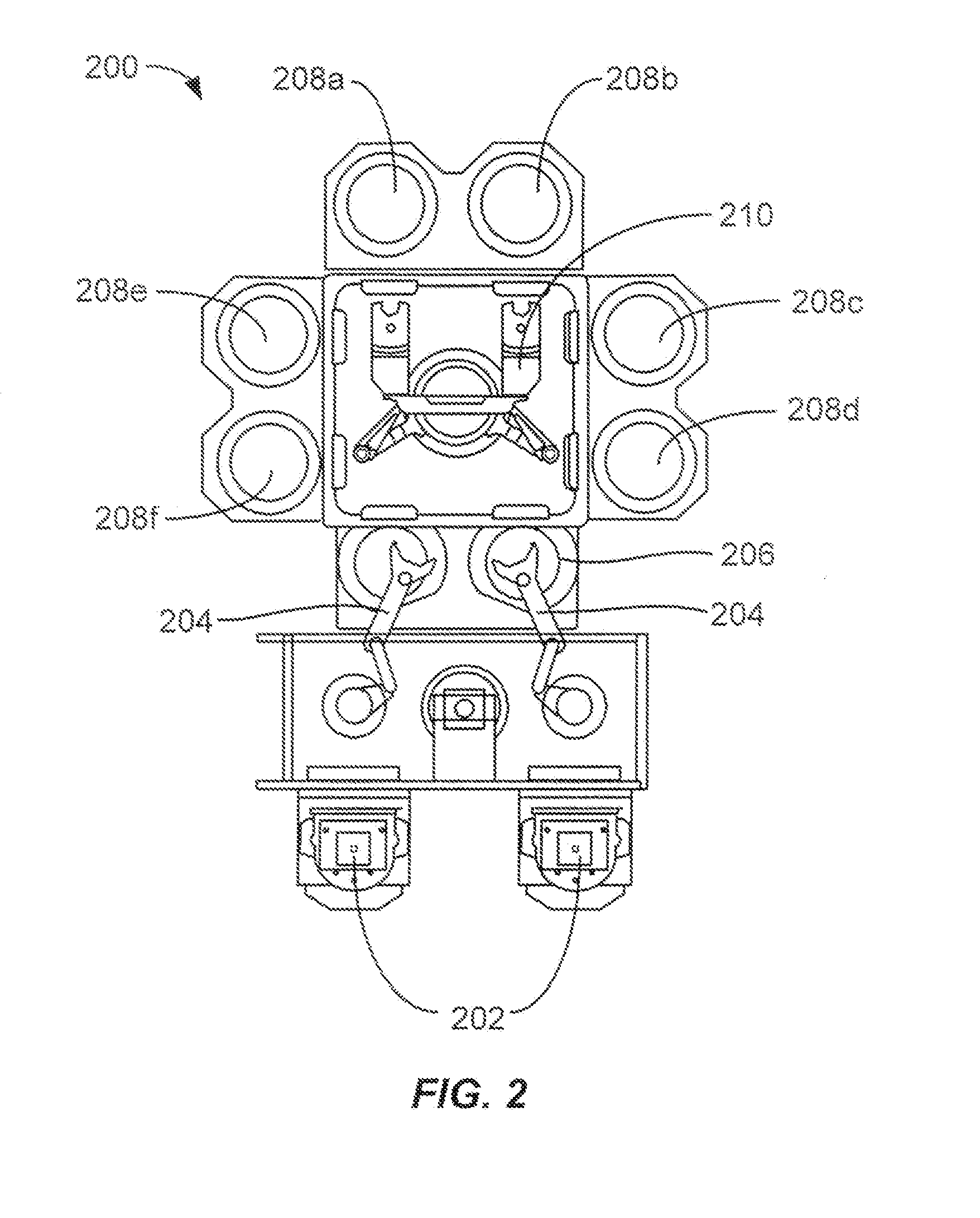

Methods are described for forming a dielectric layer on a semiconductor substrate. The methods may include providing a silicon-containing precursor and an energized nitrogen-containing precursor to a chemical vapor deposition chamber. The silicon-containing precursor and the energized nitrogen-containing precursor may be reacted in the chemical vapor deposition chamber to deposit a flowable silicon-carbon-nitrogen material on the substrate. The methods may further include treating the flowable silicon-carbon-nitrogen material to form the dielectric layer on the semiconductor substrate.

Owner:APPLIED MATERIALS INC

Resist composition and patterning process

ActiveUS20080096128A1High resolutionImproved pattern profileElectric discharge tubesPhotosensitive materialsChemistryResist

A chemically amplified positive resist composition comprises a compound having an amine oxide structure as a basic component, a base resin, a photoacid generator, and an organic solvent. The resist composition exhibits a high resolution, significantly prevents a line pattern from collapsing after development, and has improved etch resistance.

Owner:SHIN ETSU CHEM CO LTD

Silica film forming material, silica film and method of manufacturing the same, multilayer wiring structure and method of manufacturing the same, and semiconductor device and method of manufacturing the same

InactiveUS20070026689A1Reduced parasitic capacityImprove signal transmission speedSemiconductor/solid-state device manufacturingCoatingsSilicon dioxideSemiconductor

Owner:FUJITSU LTD

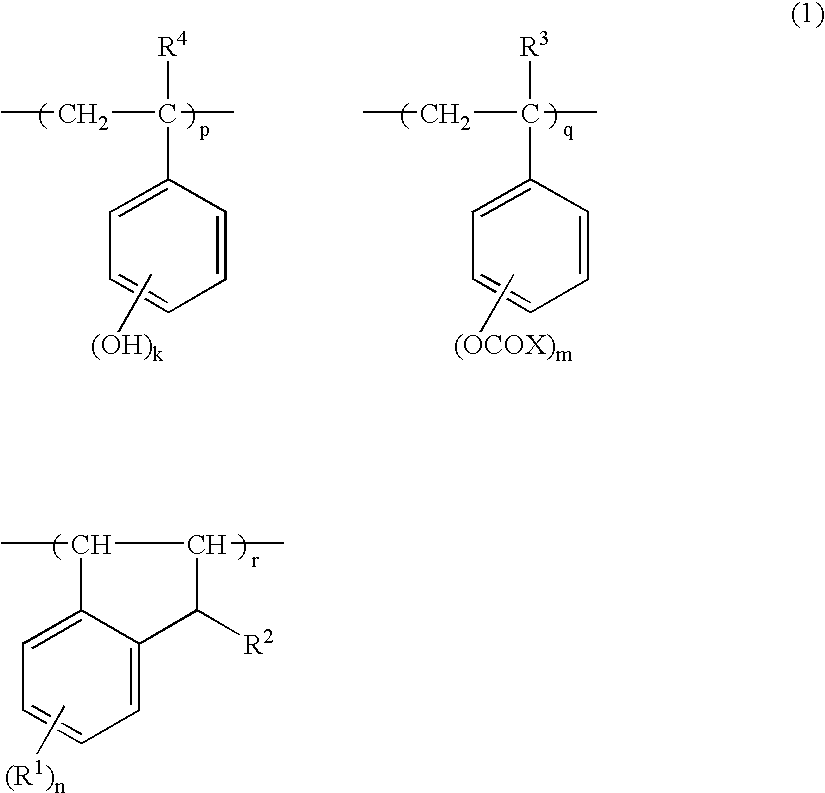

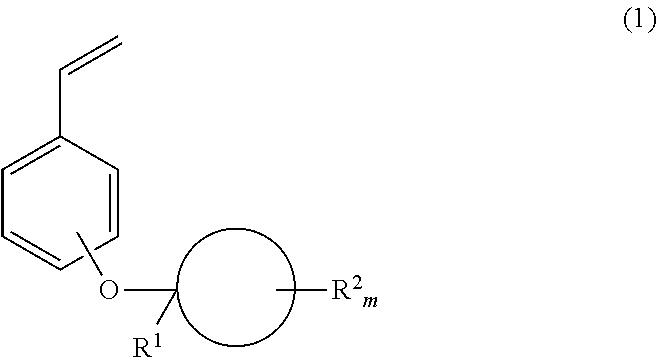

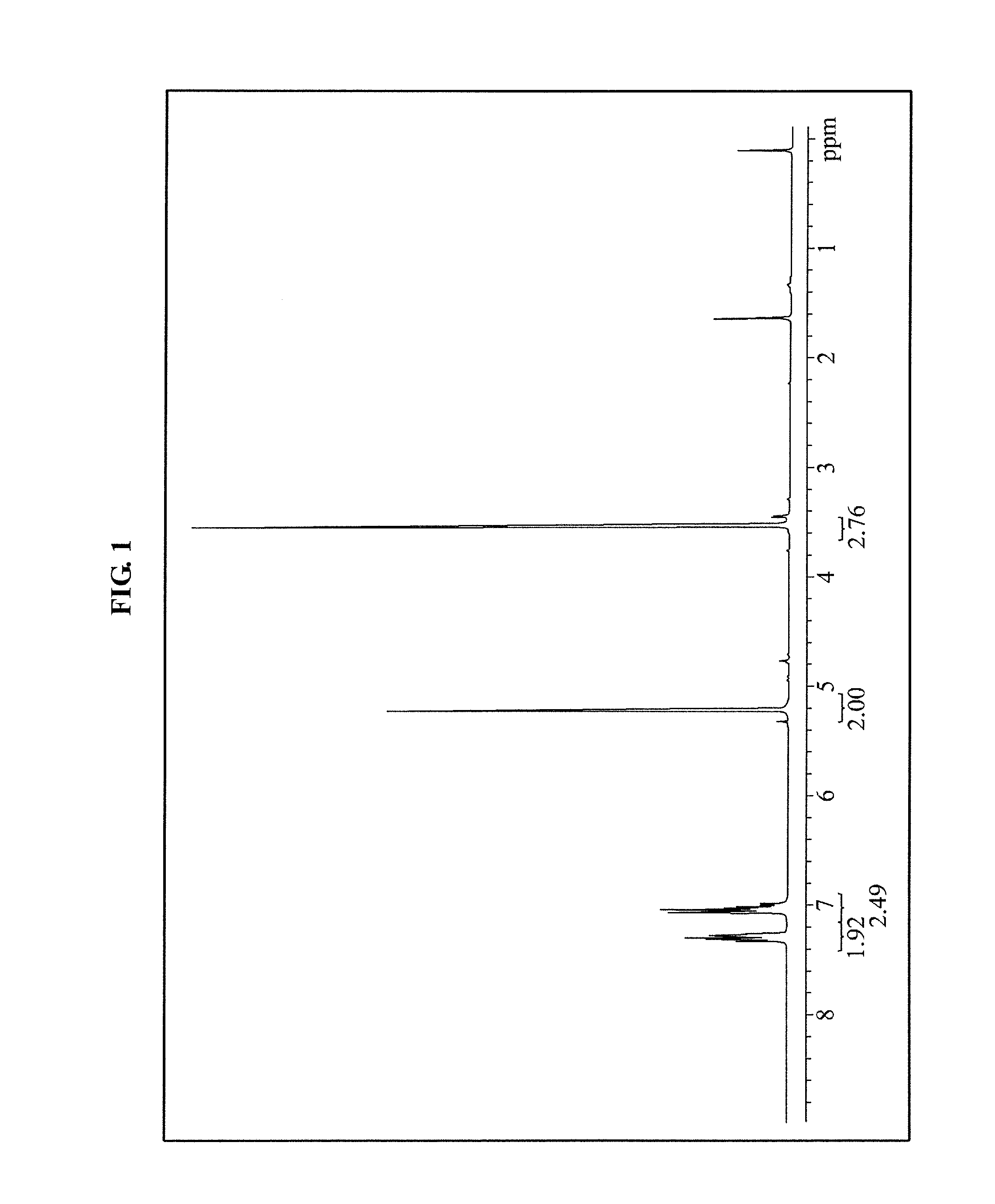

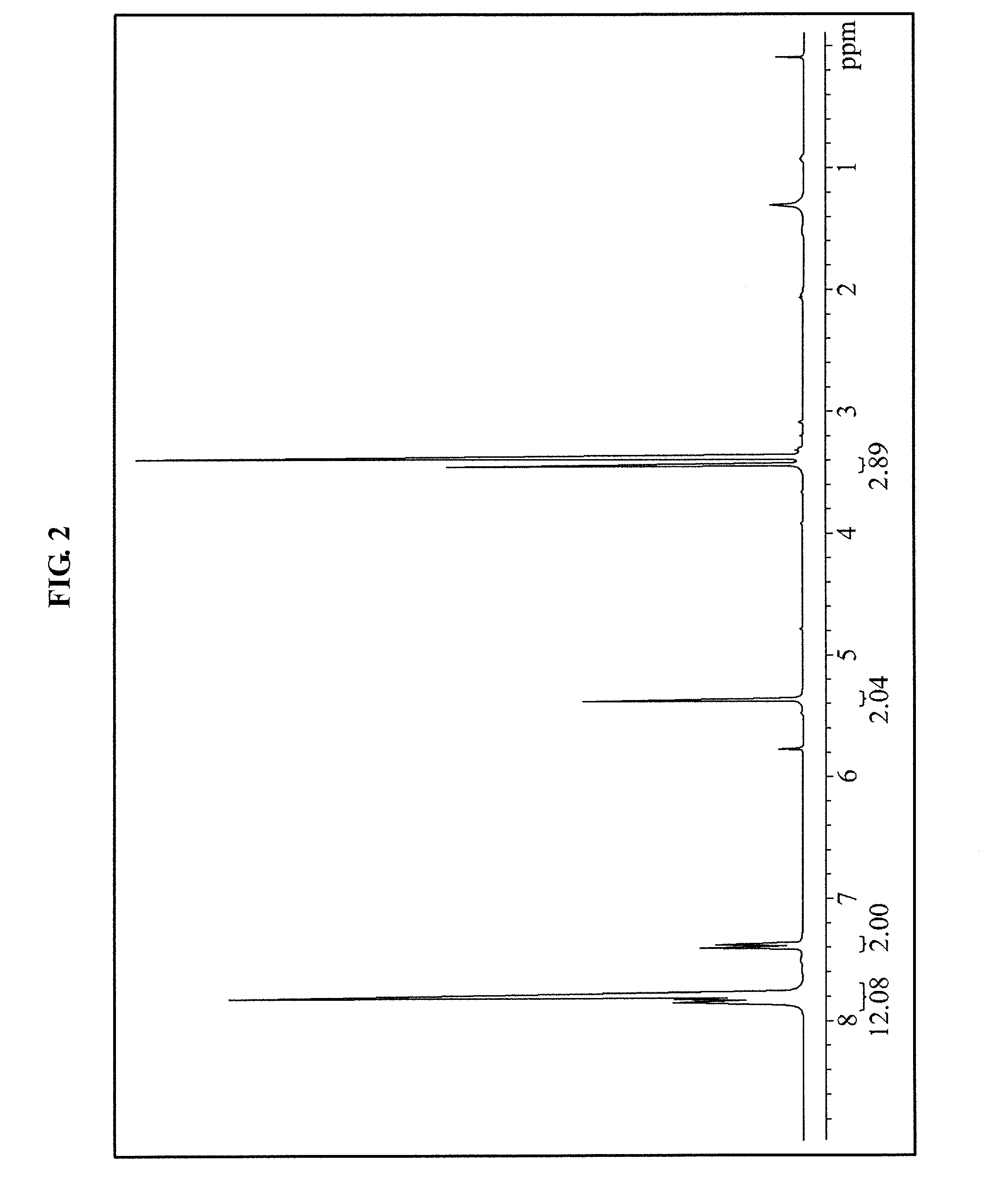

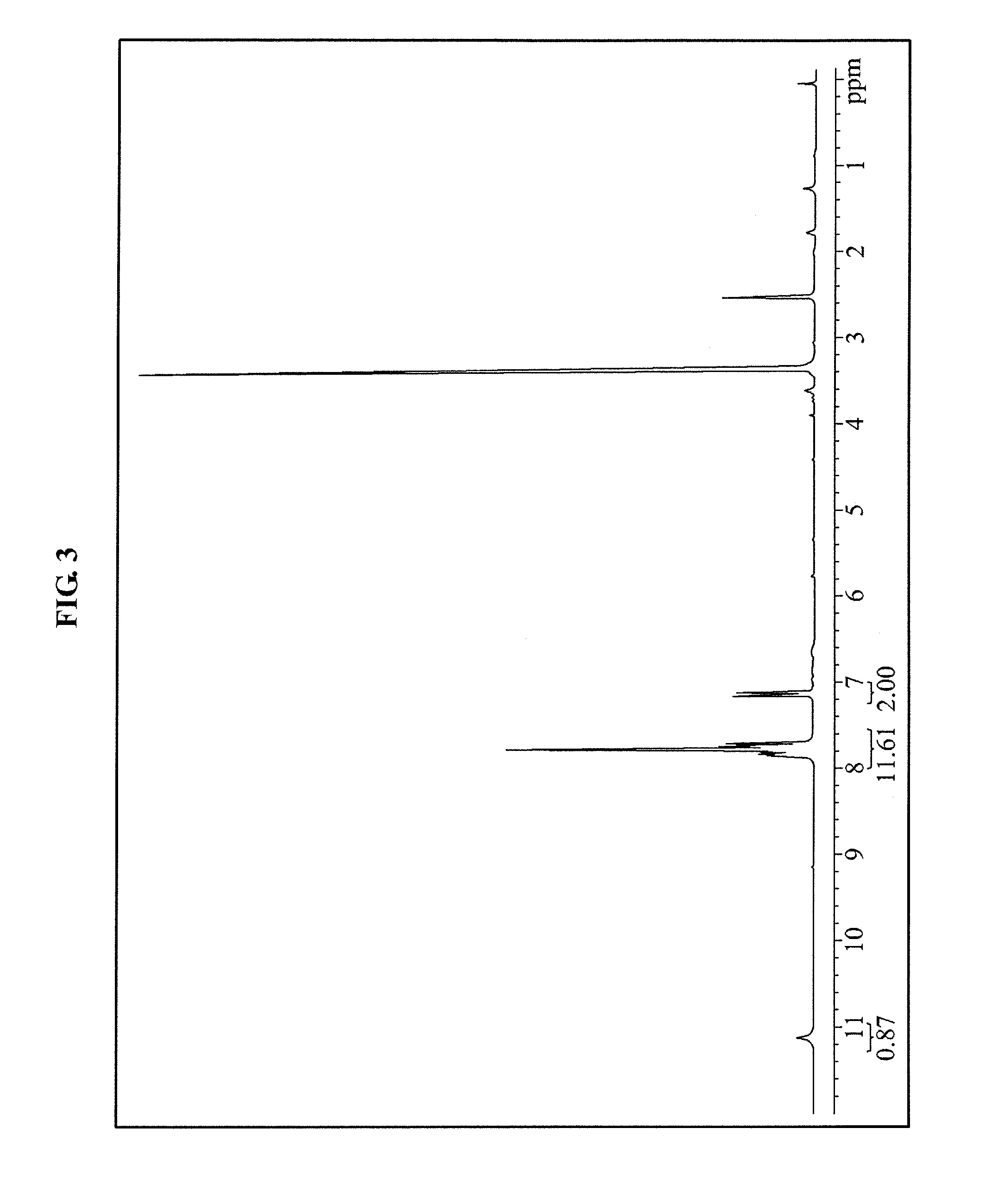

Negative resist composition and patterning process

InactiveUS20060166133A1Increase contrastExcellent etch resistancePhotomechanical apparatusPhotosensitive material auxillary/base layersPolymer scienceHalogen

A negative resist composition is provided comprising a polymer comprising recurring units having formula (1), a photoacid generator, and a crosslinker. In formula (1), X is alkyl or alkoxy, R1 and R2 are H, OH, alkyl, substitutable alkoxy or halogen, R3 and R4 are H or CH3, n is an integer of 1 to 4, m and k are an integer of 1 to 5, p, q and r are positive numbers. The composition has a high contrast of alkali dissolution rate before and after exposure, high sensitivity, high resolution and good etching resistance.

Owner:SHIN ETSU CHEM IND CO LTD

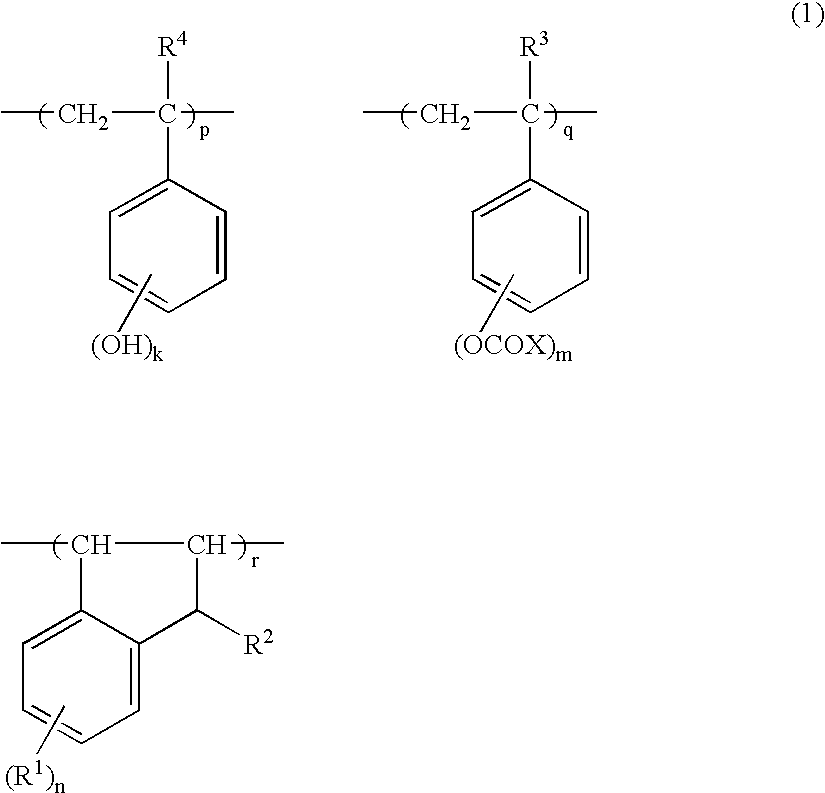

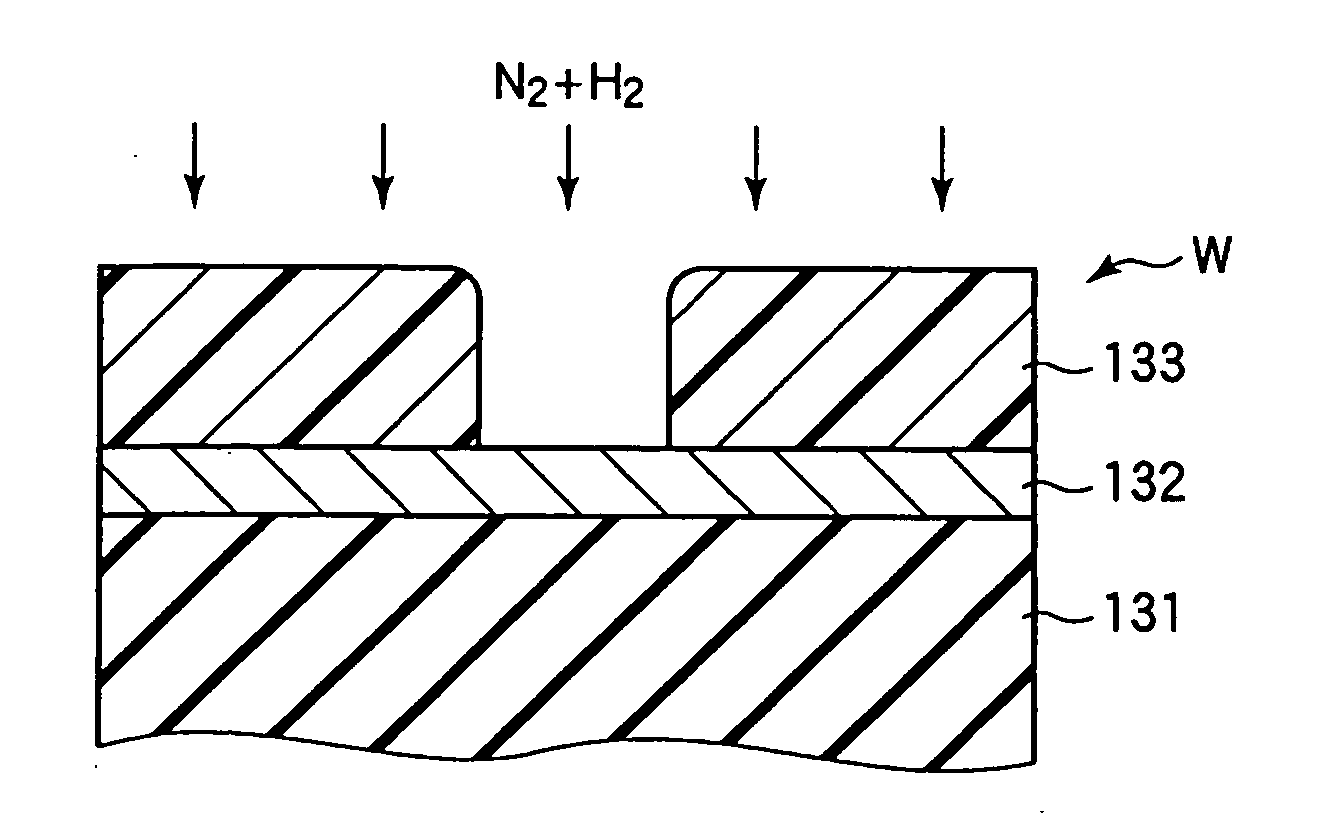

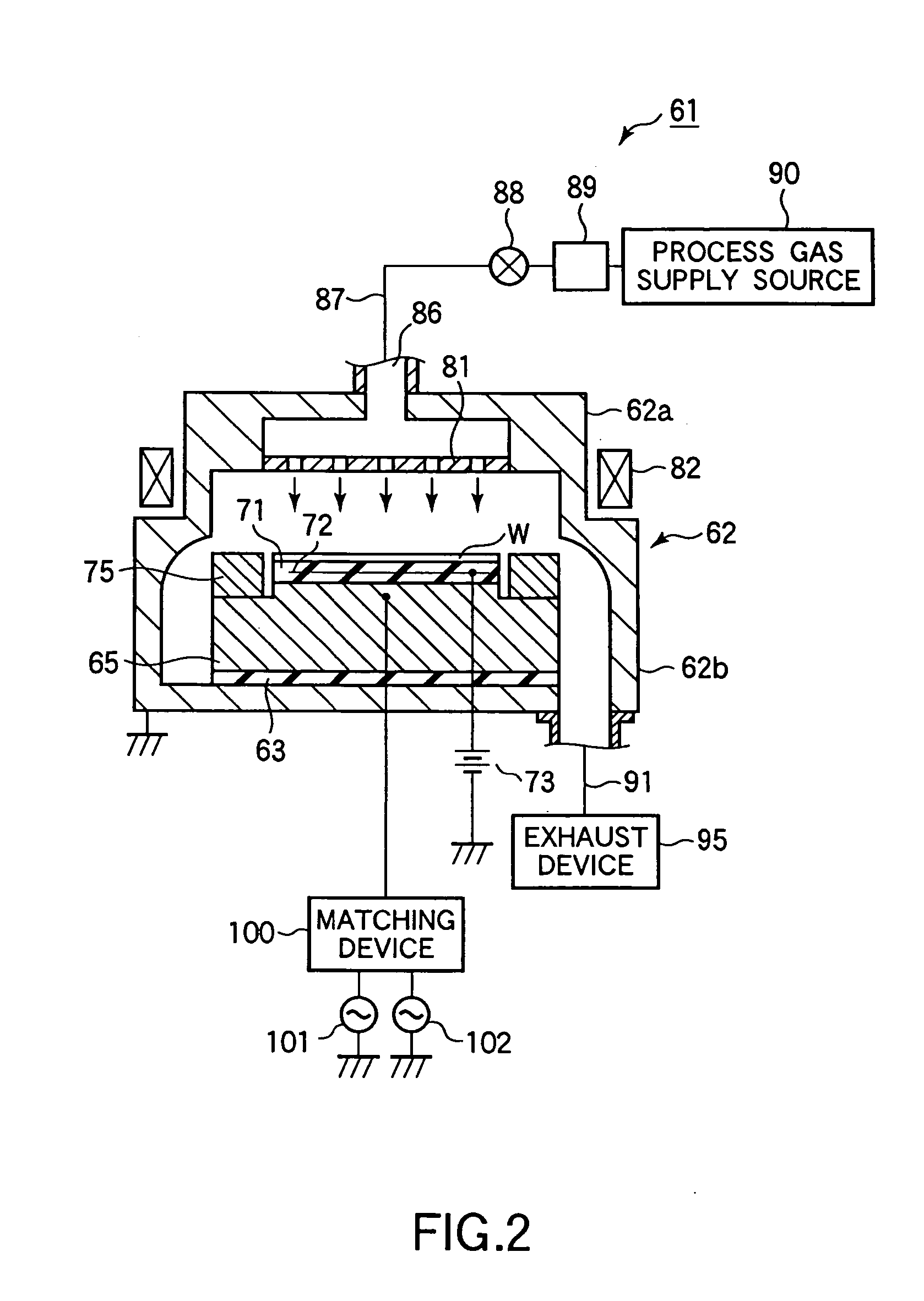

Plasma processing method

ActiveUS20050103748A1Improve the immunityReduce yieldDecorative surface effectsPhotomechanical apparatusOrganic layerPlasma processing

A plasma processing method includes a step of preparing a process subject having an organic layer on a surface thereof, and a step of irradiating the process subject with H2 plasma to improve plasma resistance of the organic layer.

Owner:TOKYO ELECTRON LTD

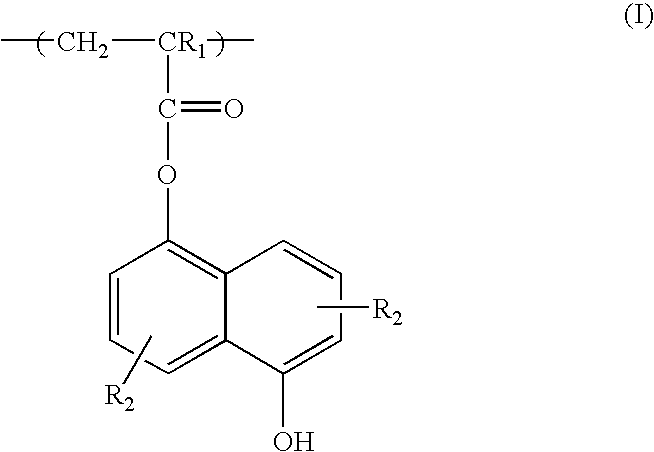

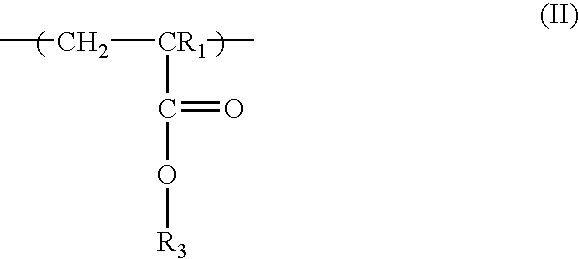

Positive resist containing naphthol functionality

ActiveUS20060105267A1Improve photolithographic effectExcellent etch resistancePhotosensitive material auxillary/base layersPhotosensitive material processingResistMethacrylate

Acid-catalyzed positive resist compositions which are imageable with 193 nm radiation are obtained using a polymer having acrylate / methacrylate monomeric units comprising a naphthol ester group. The resist may optionally contain polymer having acrylate / methacrylate monomeric units with fluorine-containing functional groups. The resists containing the polymer having acrylate / methacrylate monomeric units comprising a naphthol ester group have an improved process window, including improved etch resistance and reduced swelling compared to conventional fluorine-containing 193 nm resist.

Owner:IBM CORP

Naphthalene derivative, resist bottom layer material, and patterning process

ActiveUS20120064725A1Excellent etch resistanceMinimizing outgassingOrganic chemistryOrganic compound preparationBenzeneResist

A naphthalene derivative having formula (1) is provided wherein An and Art denote a benzene or naphthalene ring, and n is such a natural number as to provide a weight average molecular weight of up to 100,000. A material comprising the naphthalene derivative or a polymer comprising the naphthalene derivative is spin coated to form a resist bottom layer having improved properties. A pattern forming process in which a resist bottom layer formed by spin coating is combined with an inorganic hard mask formed by CVD is available.

Owner:SHIN ETSU CHEM IND CO LTD

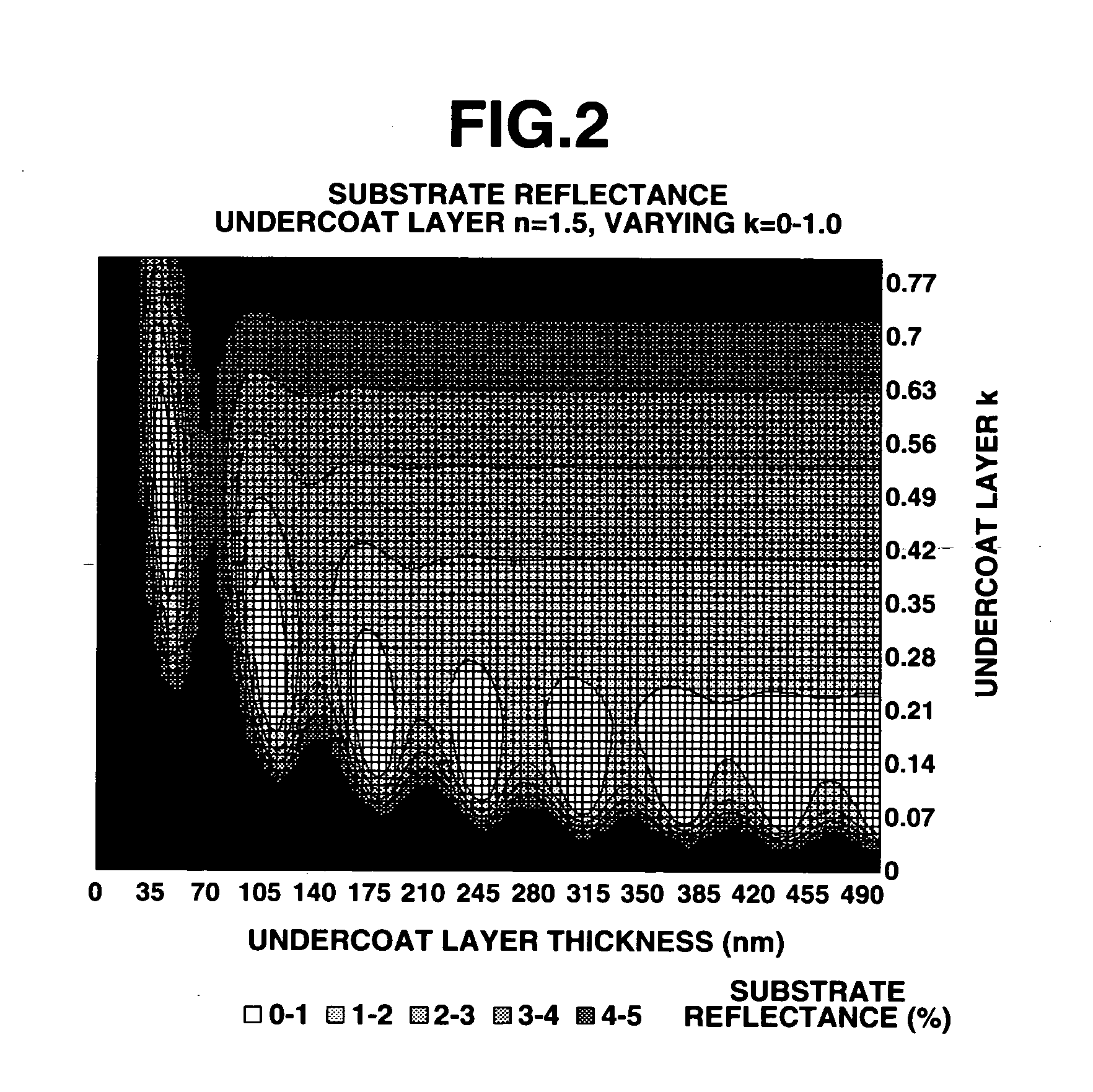

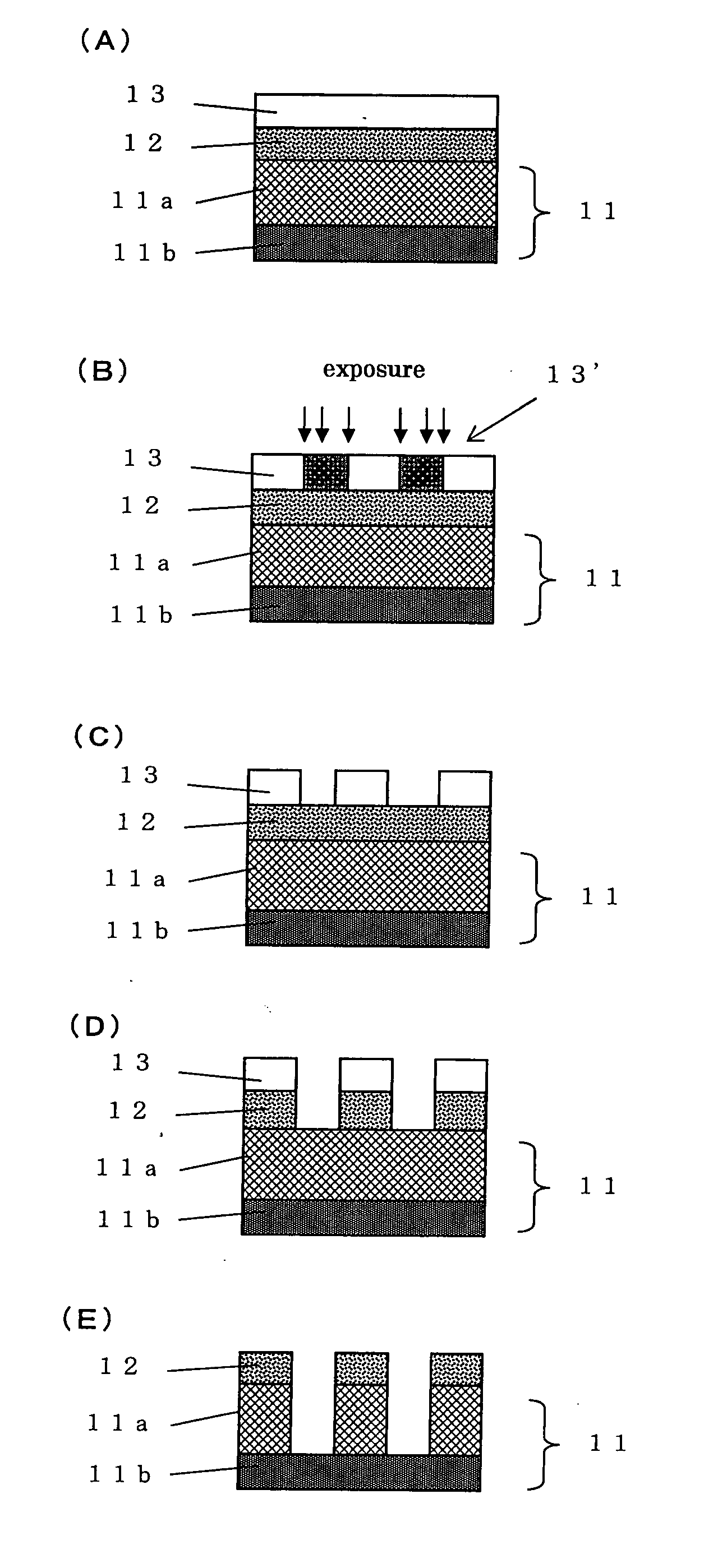

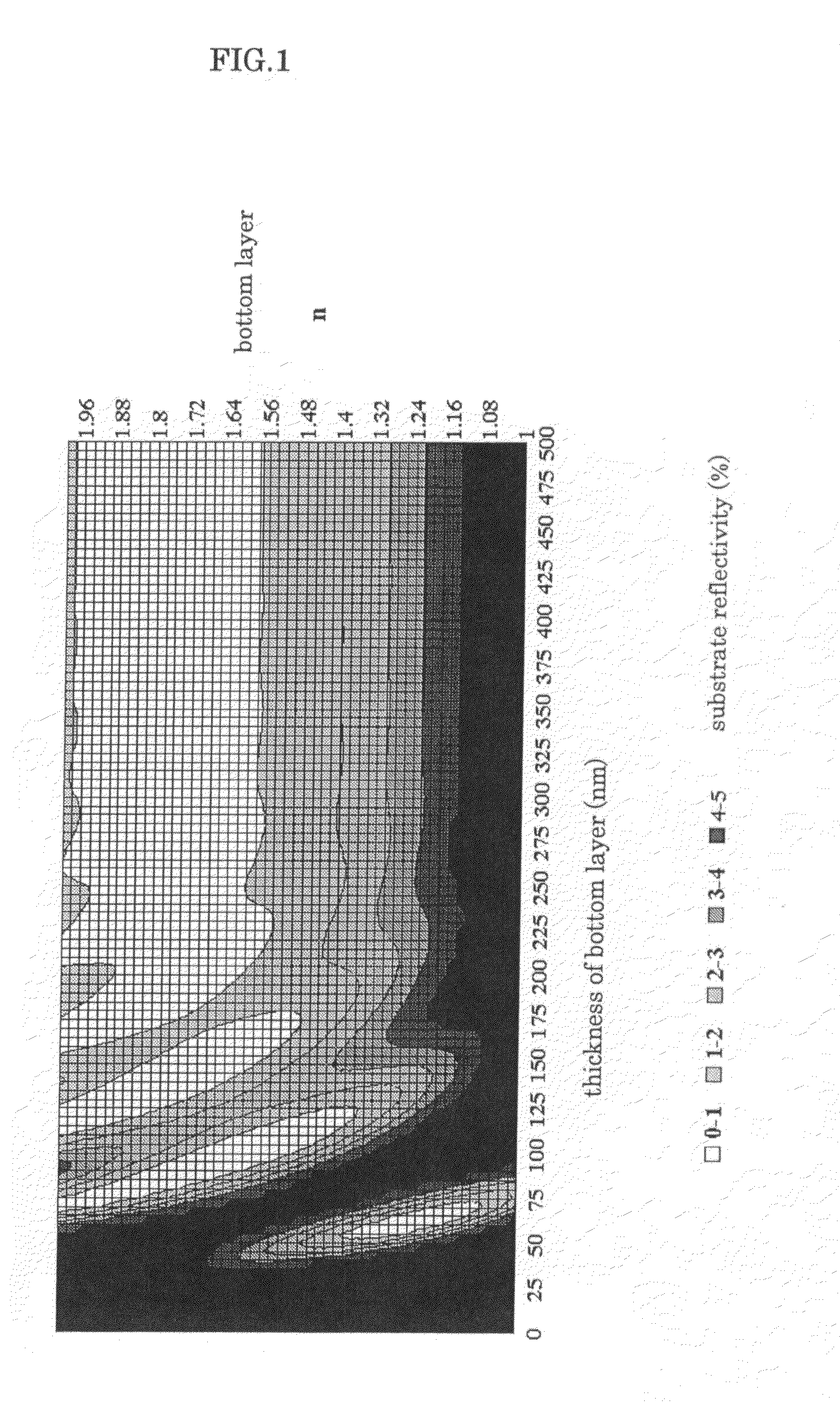

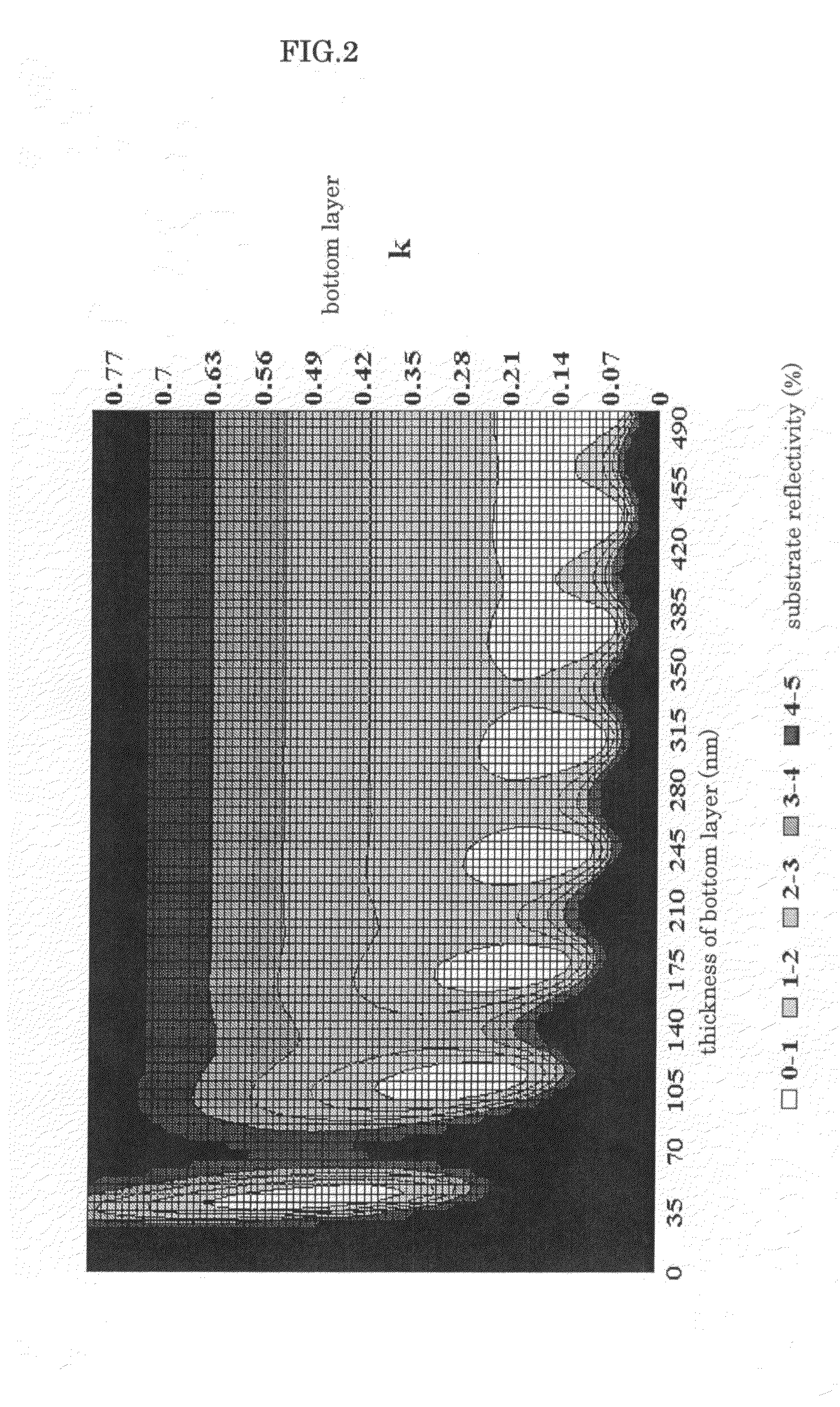

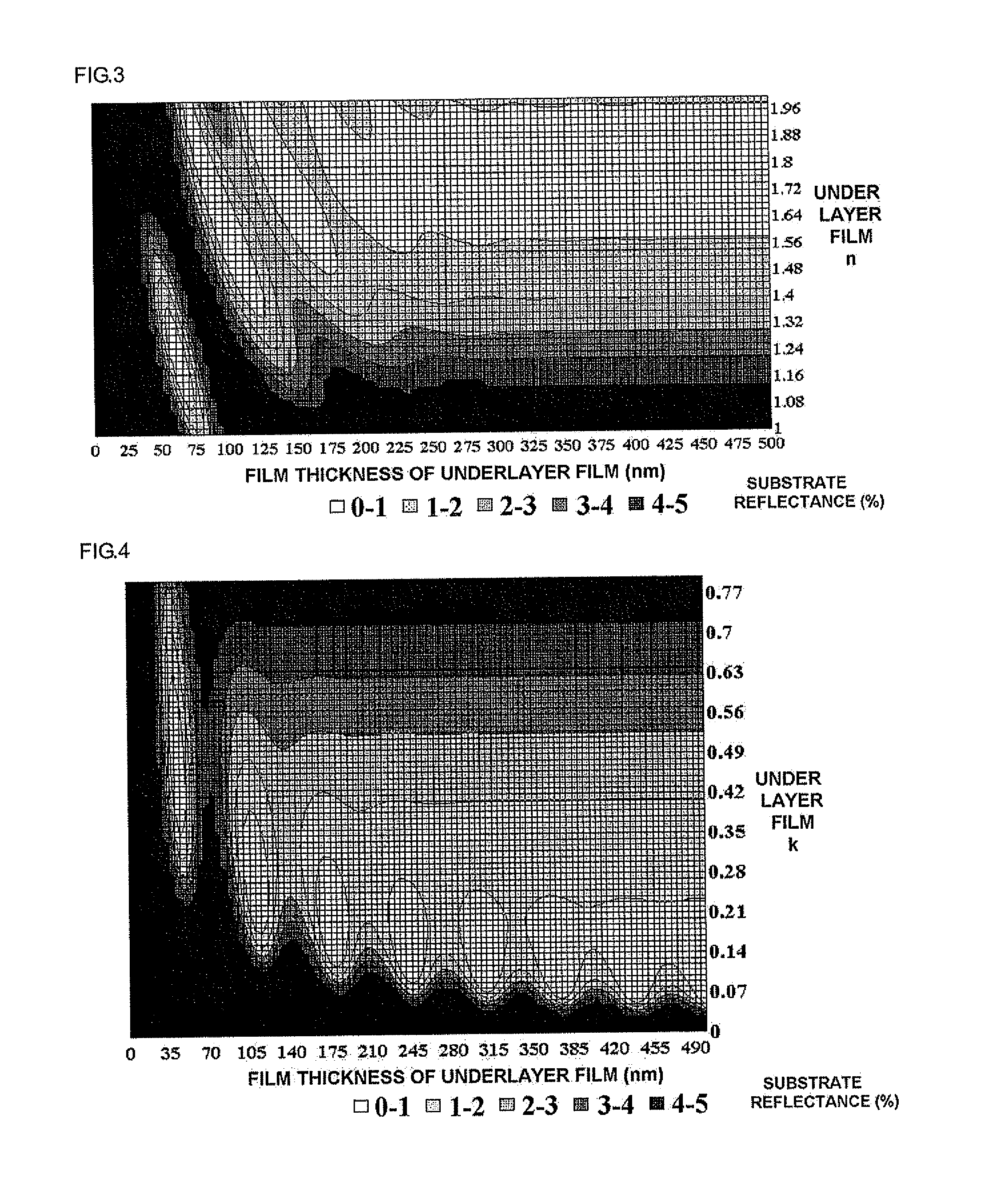

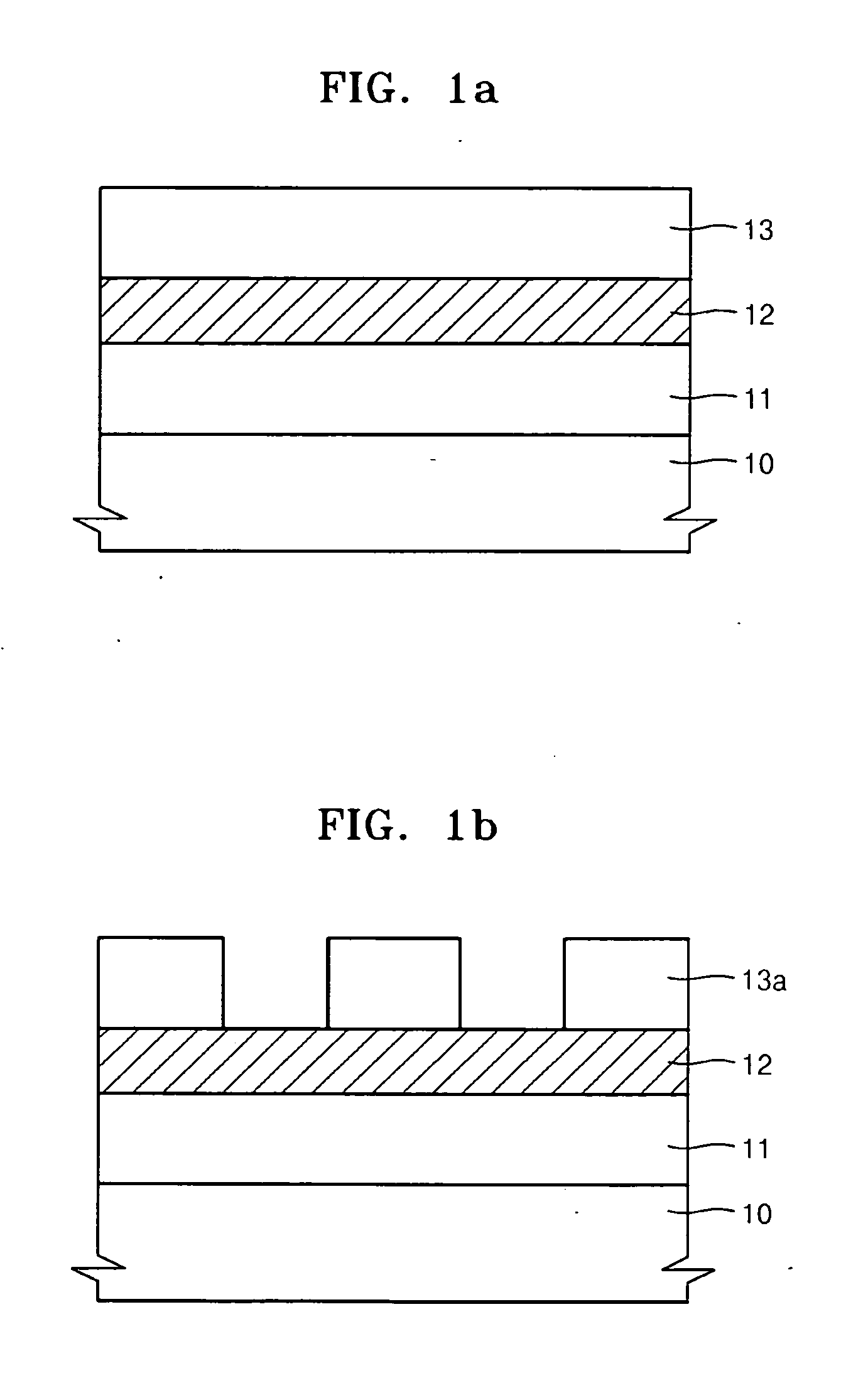

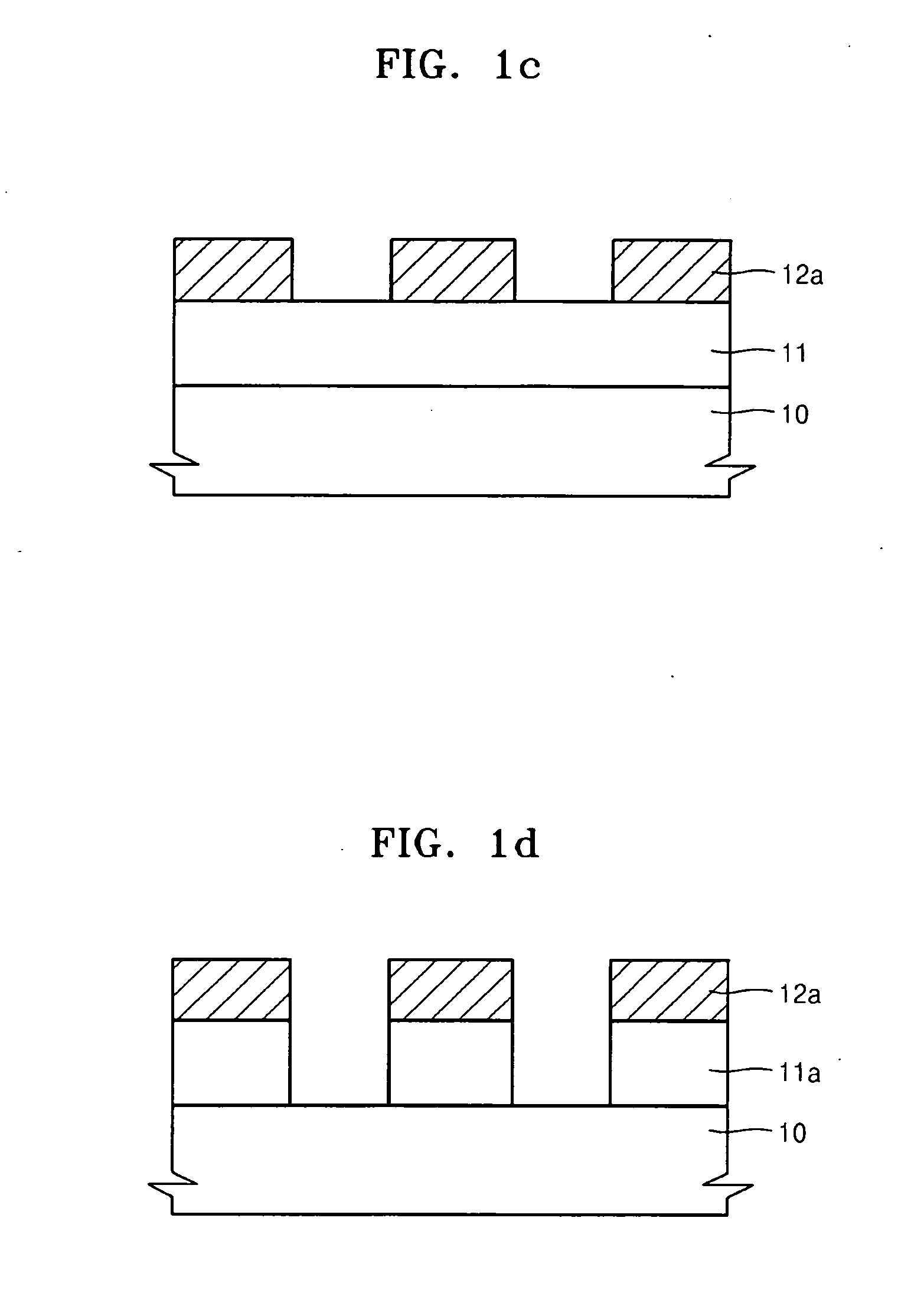

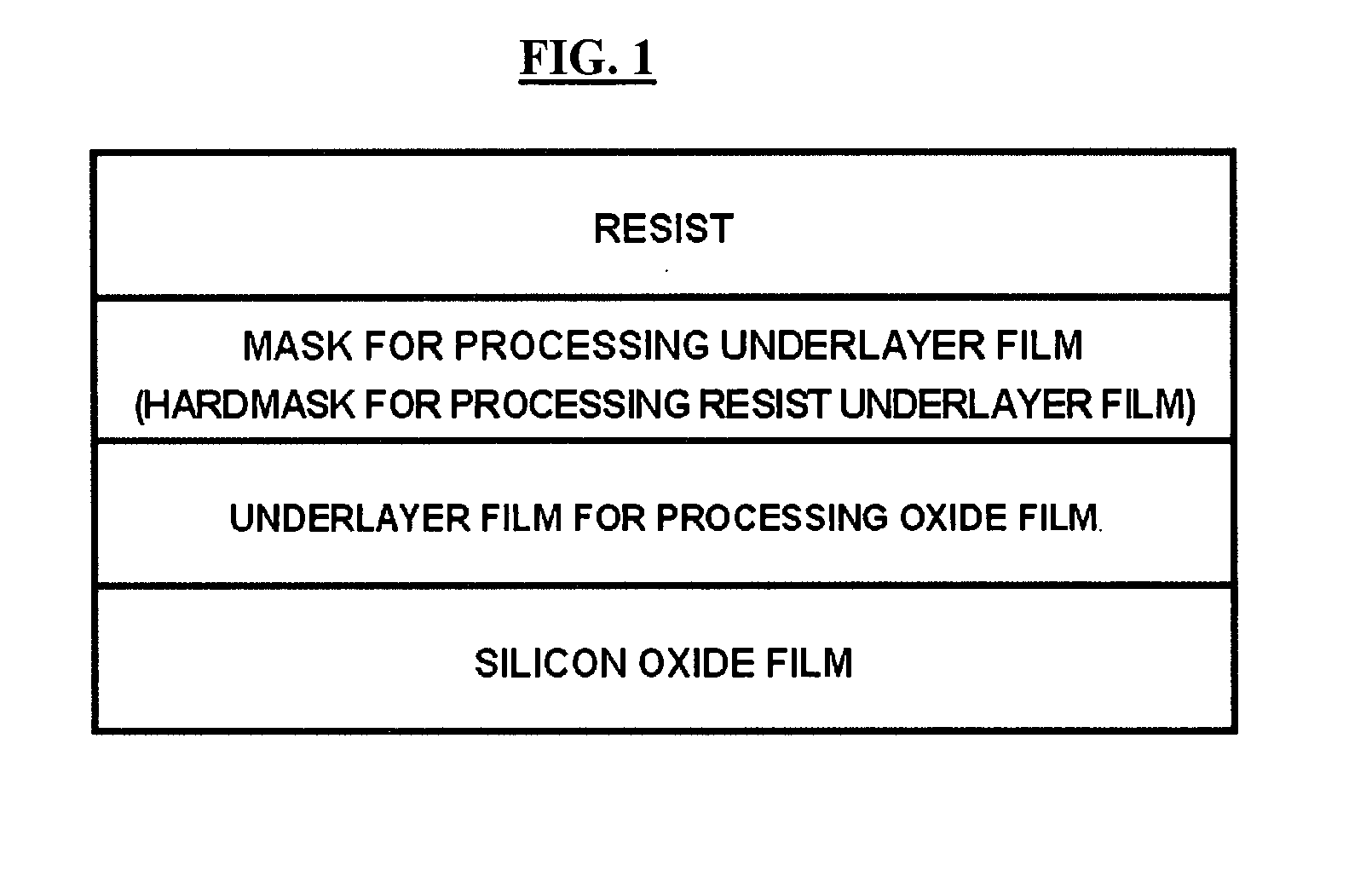

Resist undercoat-forming material and patterning process

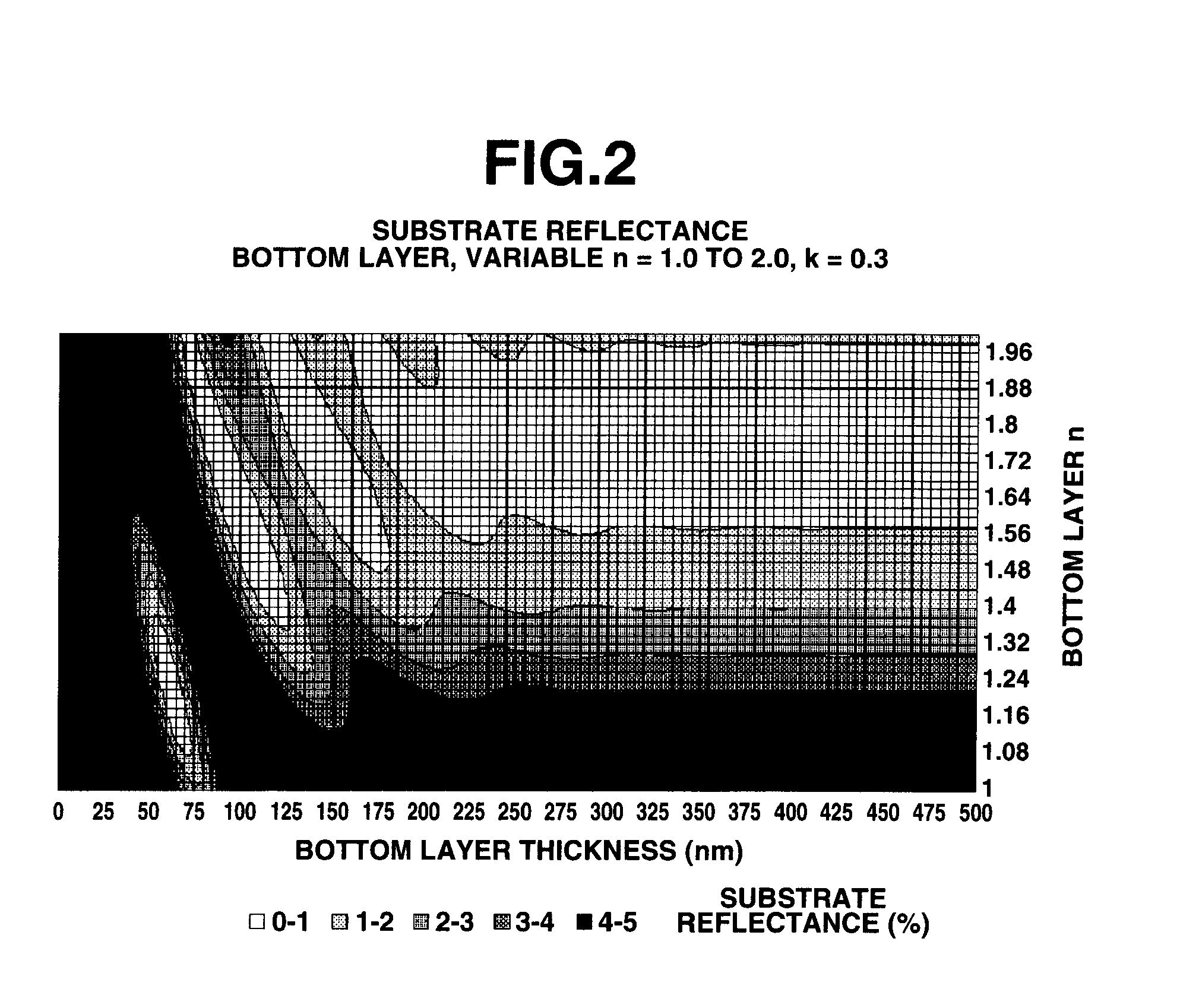

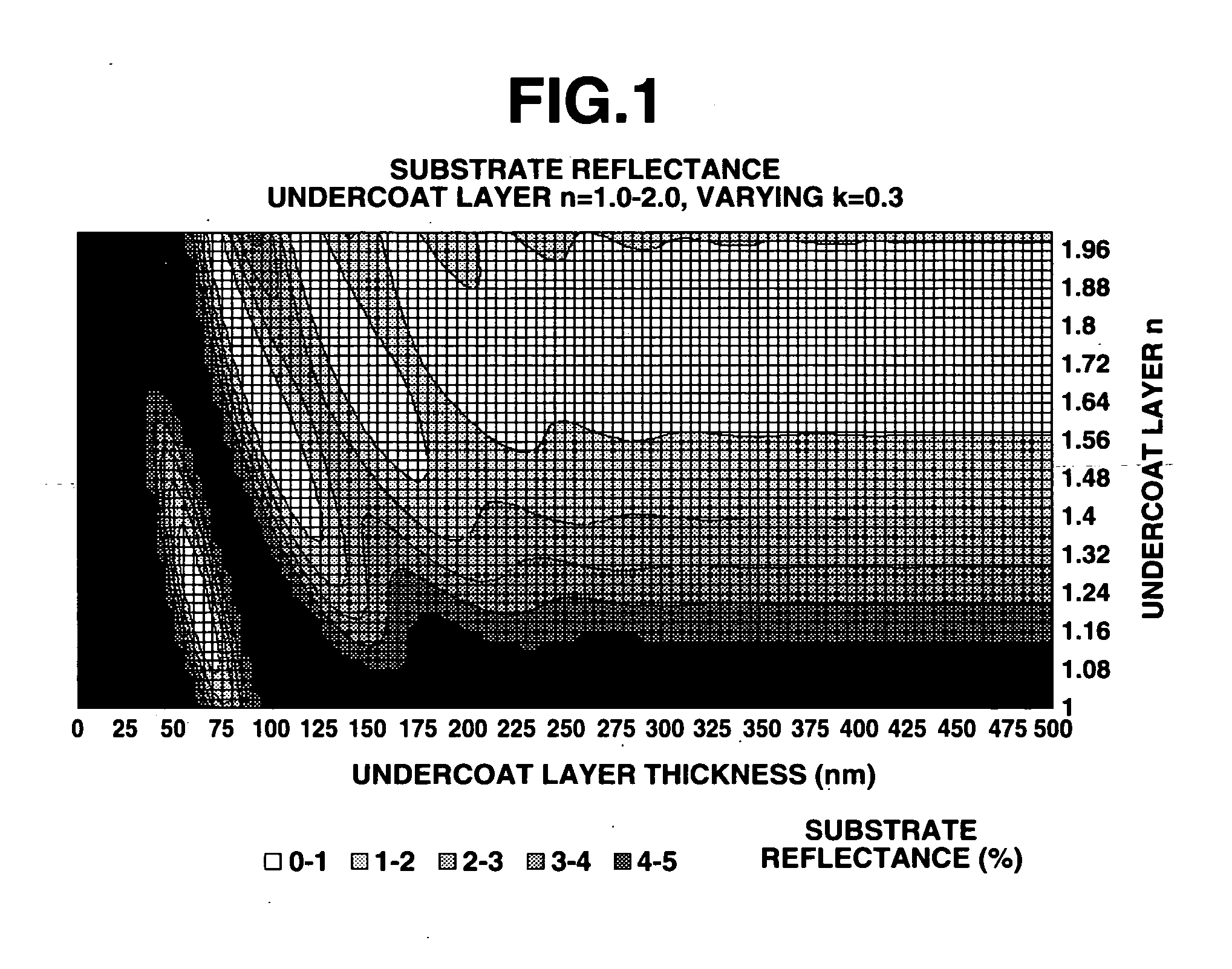

ActiveUS20070122740A1High transparencyExcellent etch resistancePhotosensitive materialsSemiconductor/solid-state device manufacturingResistAnti-reflective coating

In the lithographic multilayer resist process, a material comprising a copolymer of a hydroxy-containing vinylnaphthalene with hydroxy-free olefins is useful in forming a resist undercoat. The undercoat-forming material has a high transparency and optimum values of n and k so that it functions as an antireflective coating during short-wavelength exposure, and has etching resistance during substrate processing by etching.

Owner:SHIN ETSU CHEM IND CO LTD

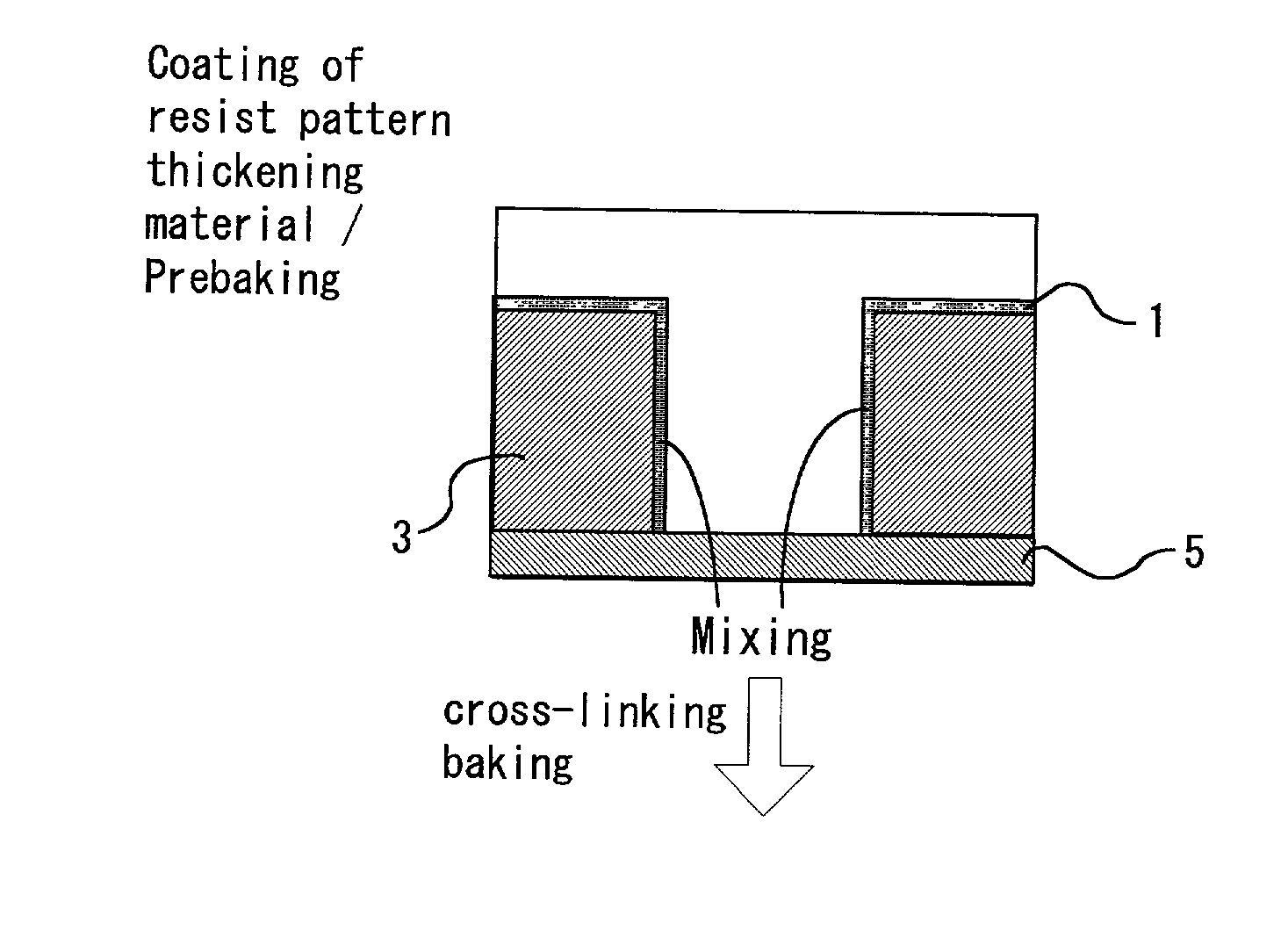

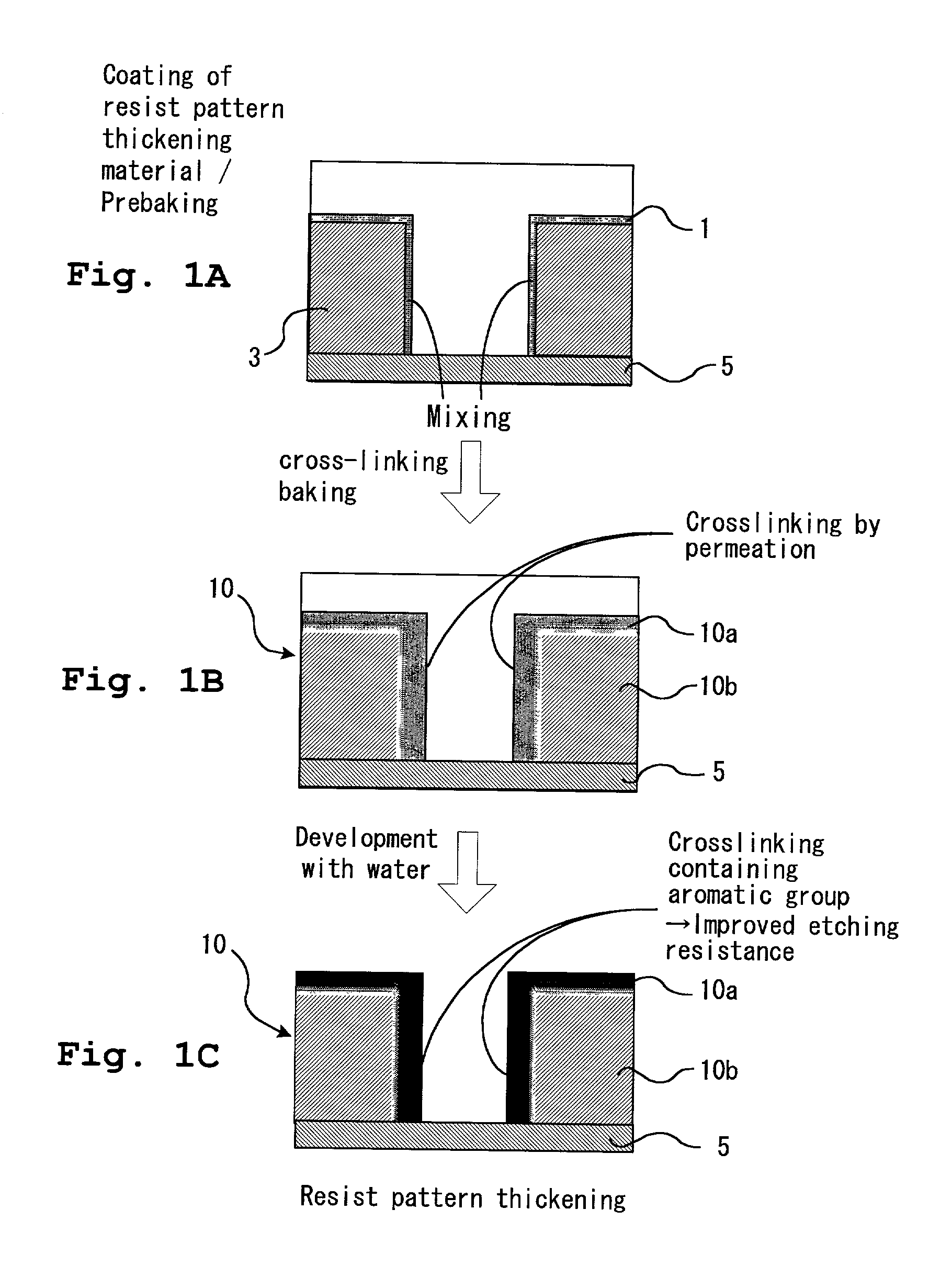

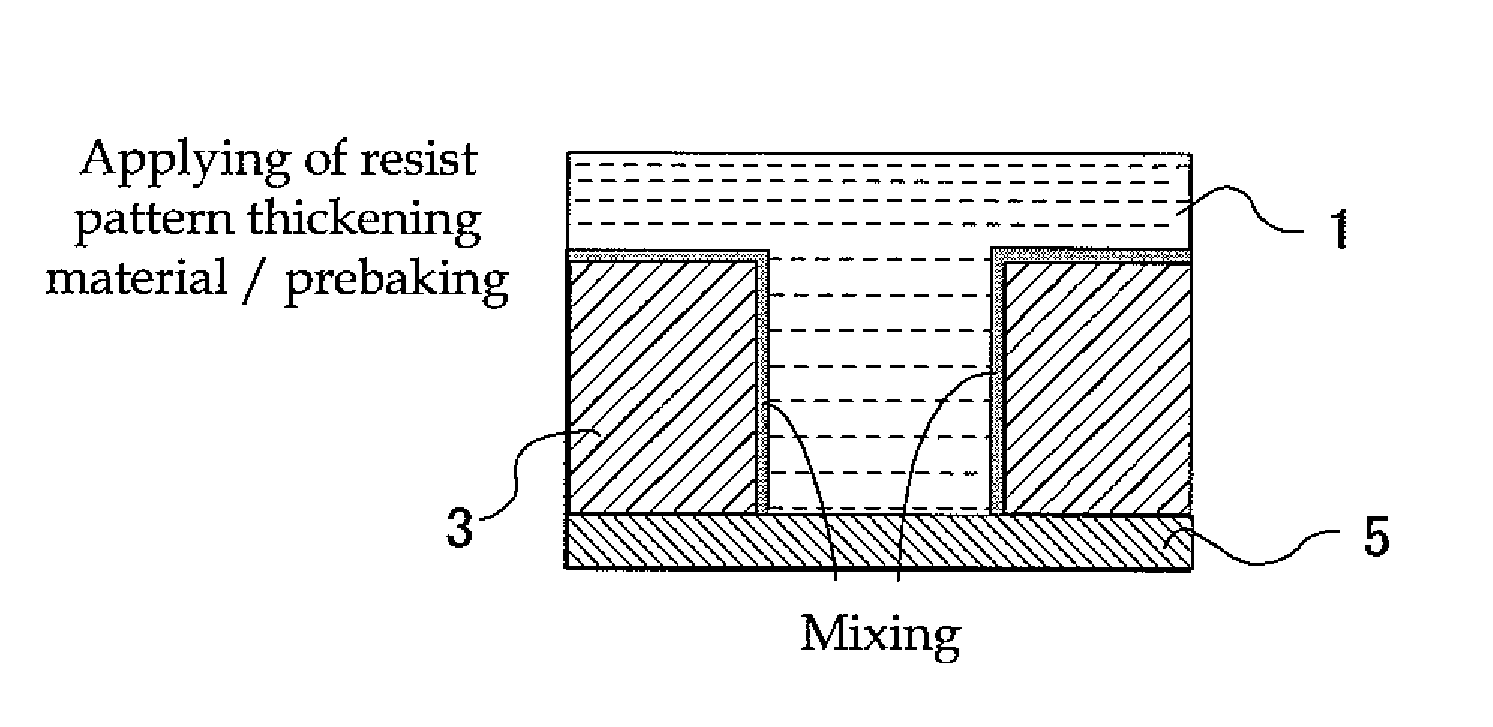

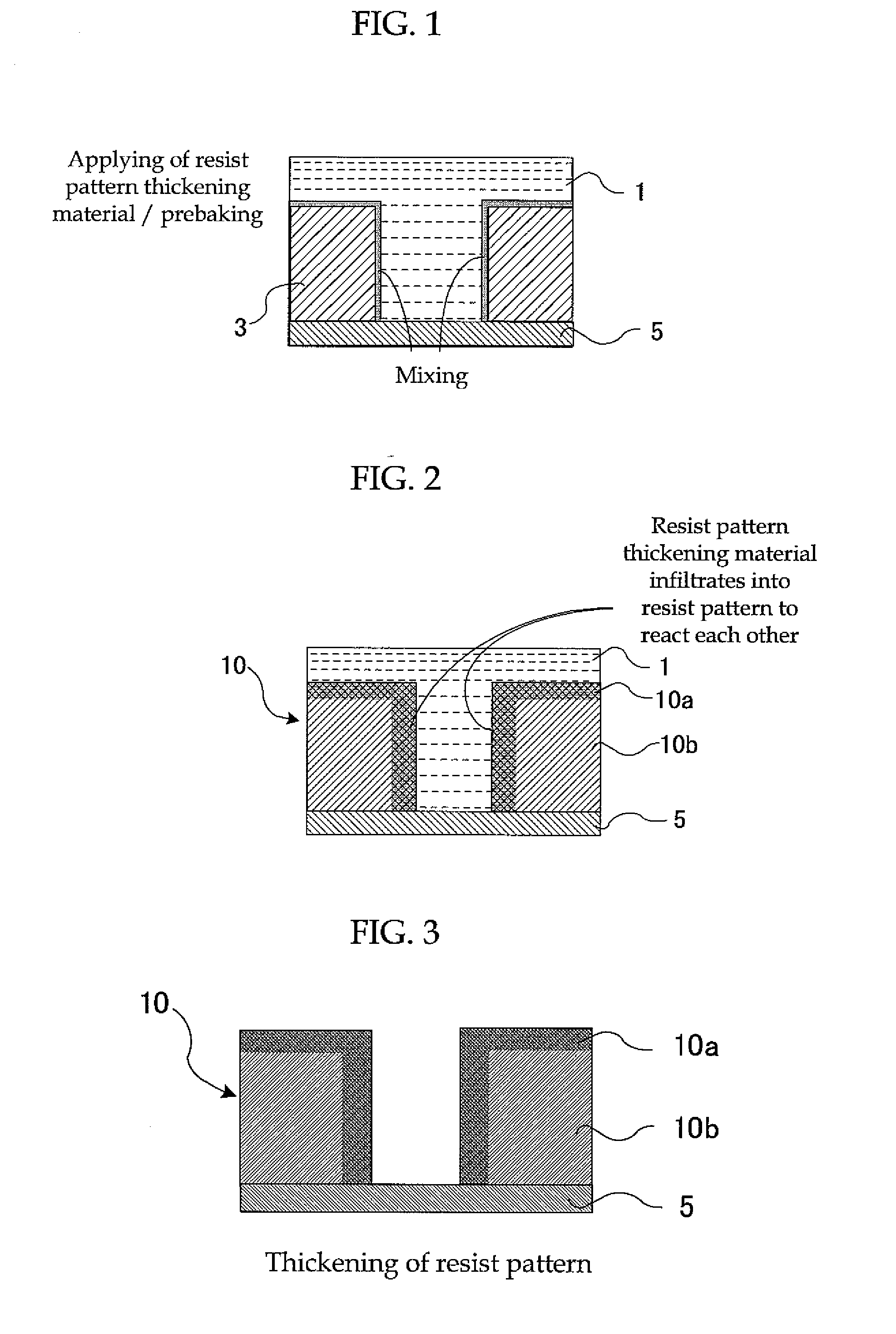

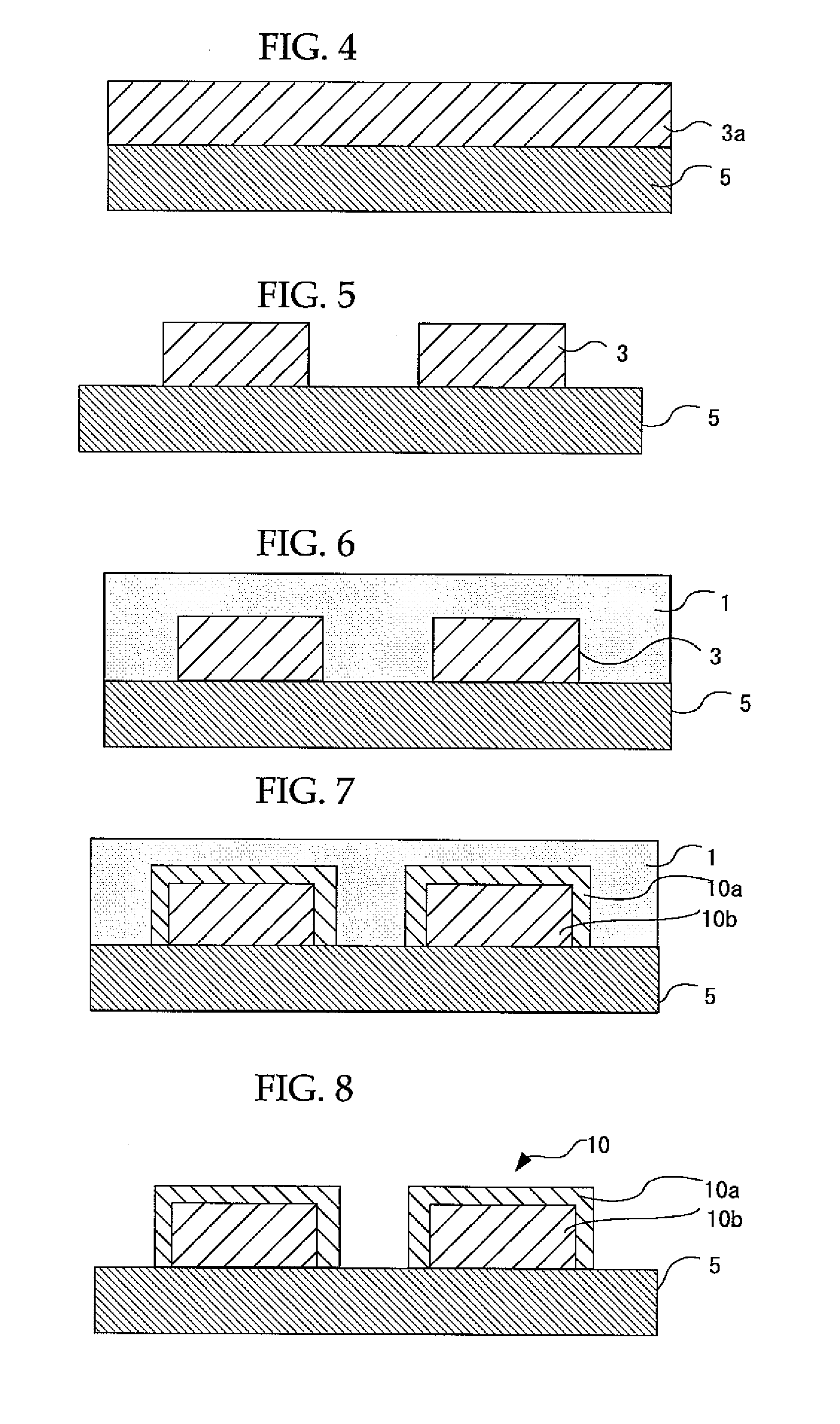

Resist pattern thickening material, resist pattern and forming method thereof, and semiconductor device and manufacturing method thereof

InactiveUS20030102285A1Excellent etch resistanceExquisite patternConstruction of head windingsDecorative surface effectsResistWater soluble

A resist pattern thickening material comprises a resin, a crosslinking agent and a water-soluble aromatic compound. A resist pattern comprises an upperlayer on an underlayer resist pattern with an etching rate (Å / s) ratio of the underlayer resist pattern to the upper layer under the same condition of 1.1 or more, or comprises an upperlayer containing an aromatic compound on an underlayer resist pattern. A method for forming a resist pattern comprises applying a resist pattern thickening material after forming an underlayer resist pattern, on the surface of the pattern. A semiconductor device comprises a pattern formed by the resist pattern. A method for manufacturing the semiconductor device comprises applying after forming an underlayer resist pattern on an underlying layer, the thickening material to the surface of the pattern to thicken the pattern, and patterning the underlying layer by etching using the pattern as a mask.

Owner:FUJITSU LTD

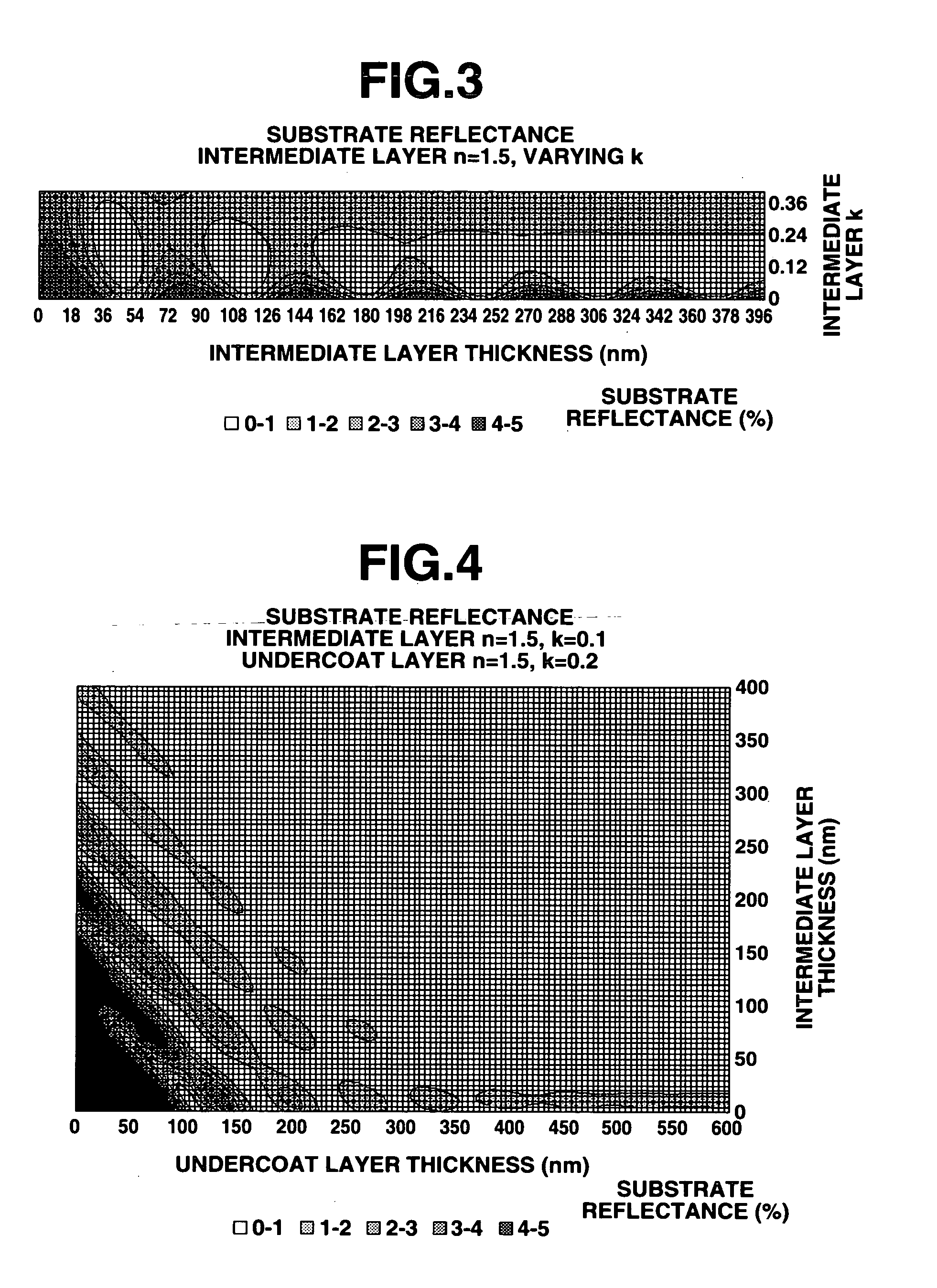

Photoresist undercoat-forming material and patterning process

ActiveUS20070275325A1Satisfactory antireflective effectImprove corrosion resistancePhotosensitive materialsPhotosensitive material processingResistGlycylxylidide

A material comprising a specific bisphenol compound of formula (1) is useful in forming a photoresist undercoat wherein R1 and R2 are H, alkyl, aryl or alkenyl, R3 and R4 are H, alkyl, alkenyl, aryl, acetal, acyl or glycidyl, R5 and R6 are alkyl having a ring structure, or R5 and R6 bond together to form a ring. The undercoat-forming material has an extinction coefficient sufficient to provide an antireflective effect at a thickness of at least 200 nm, and a high etching resistance as demonstrated by slow etching rates with CF4 / CHF3 and Cl2 / BCl3 gases for substrate processing.

Owner:SHIN ETSU CHEM IND CO LTD

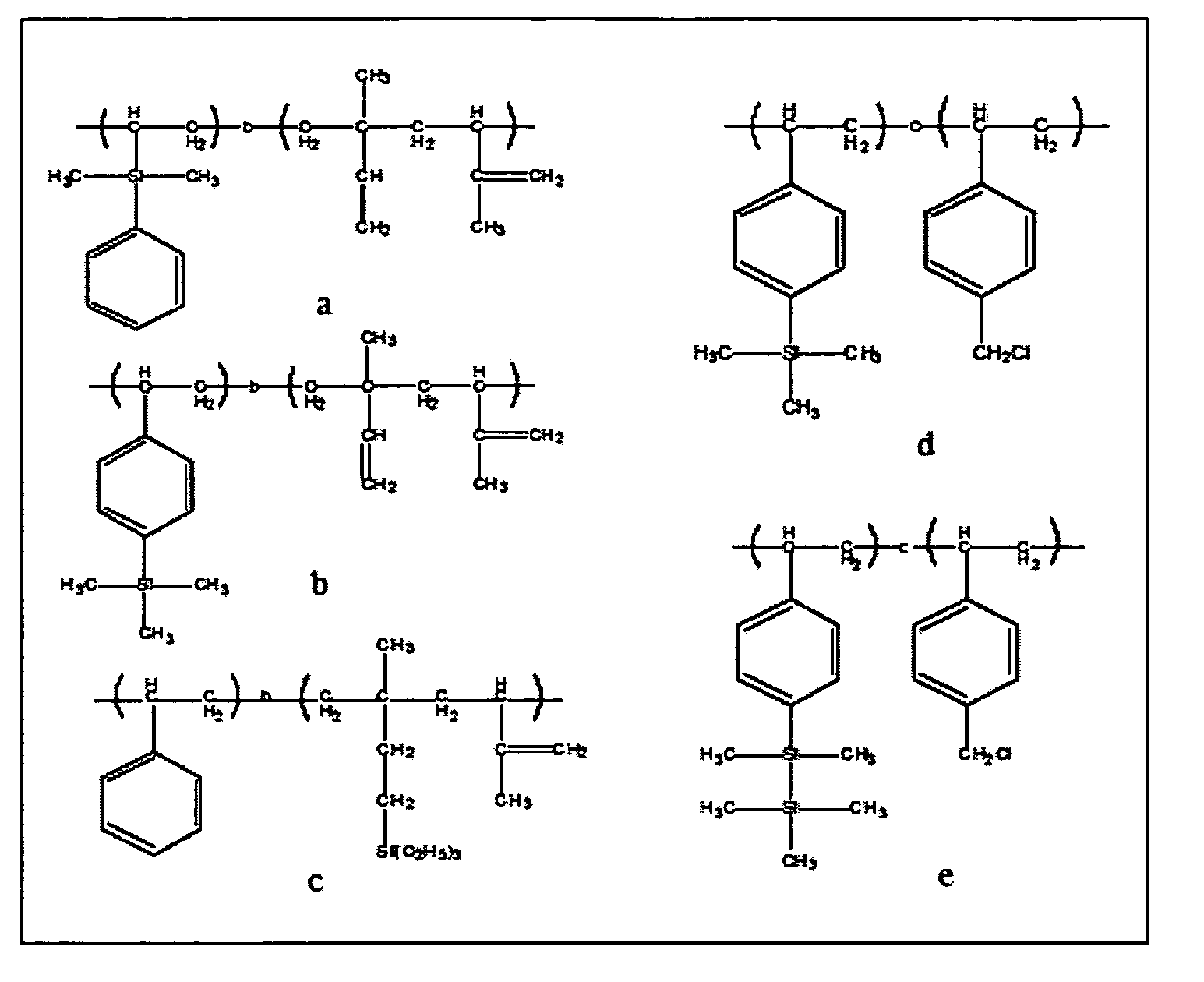

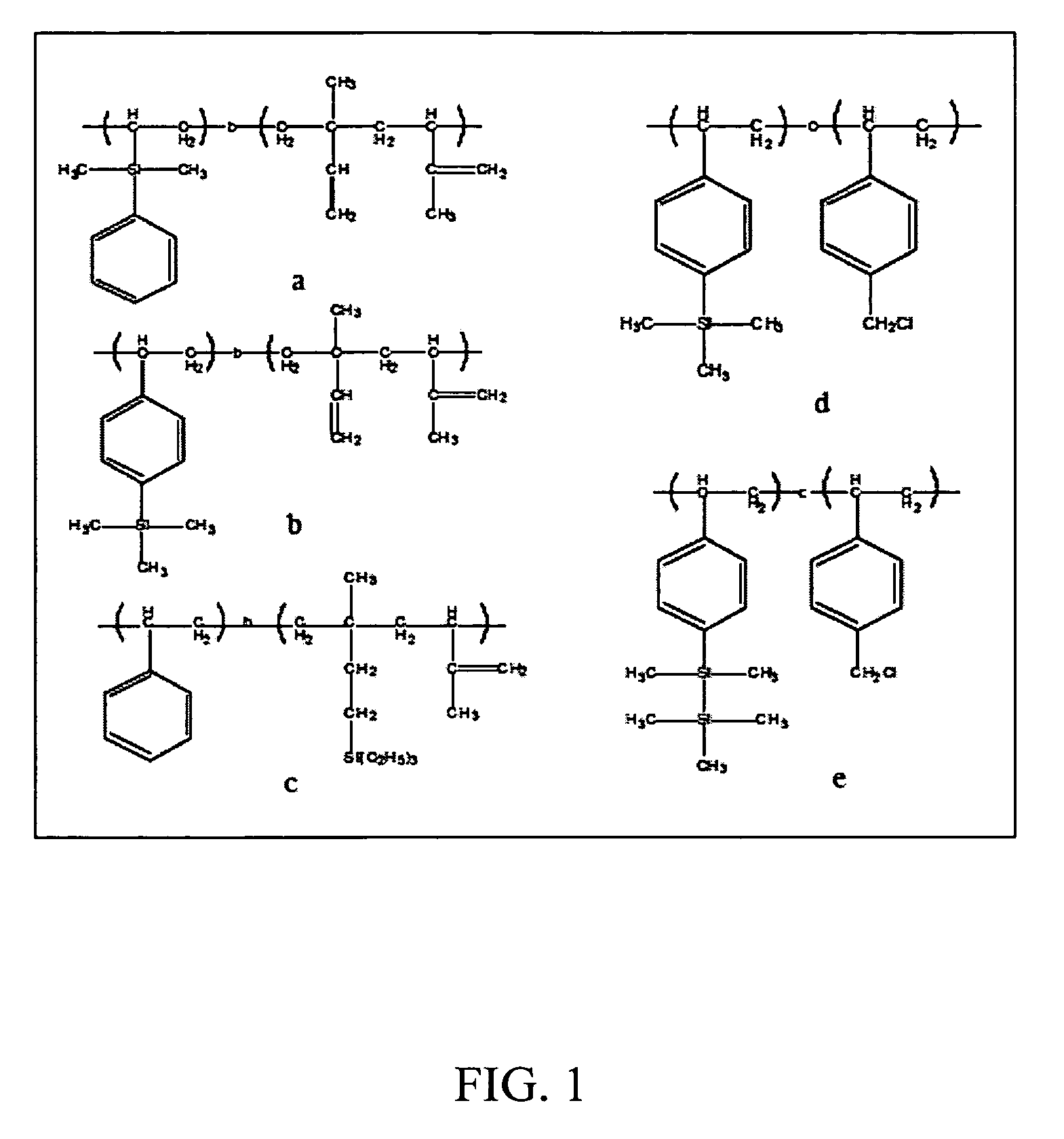

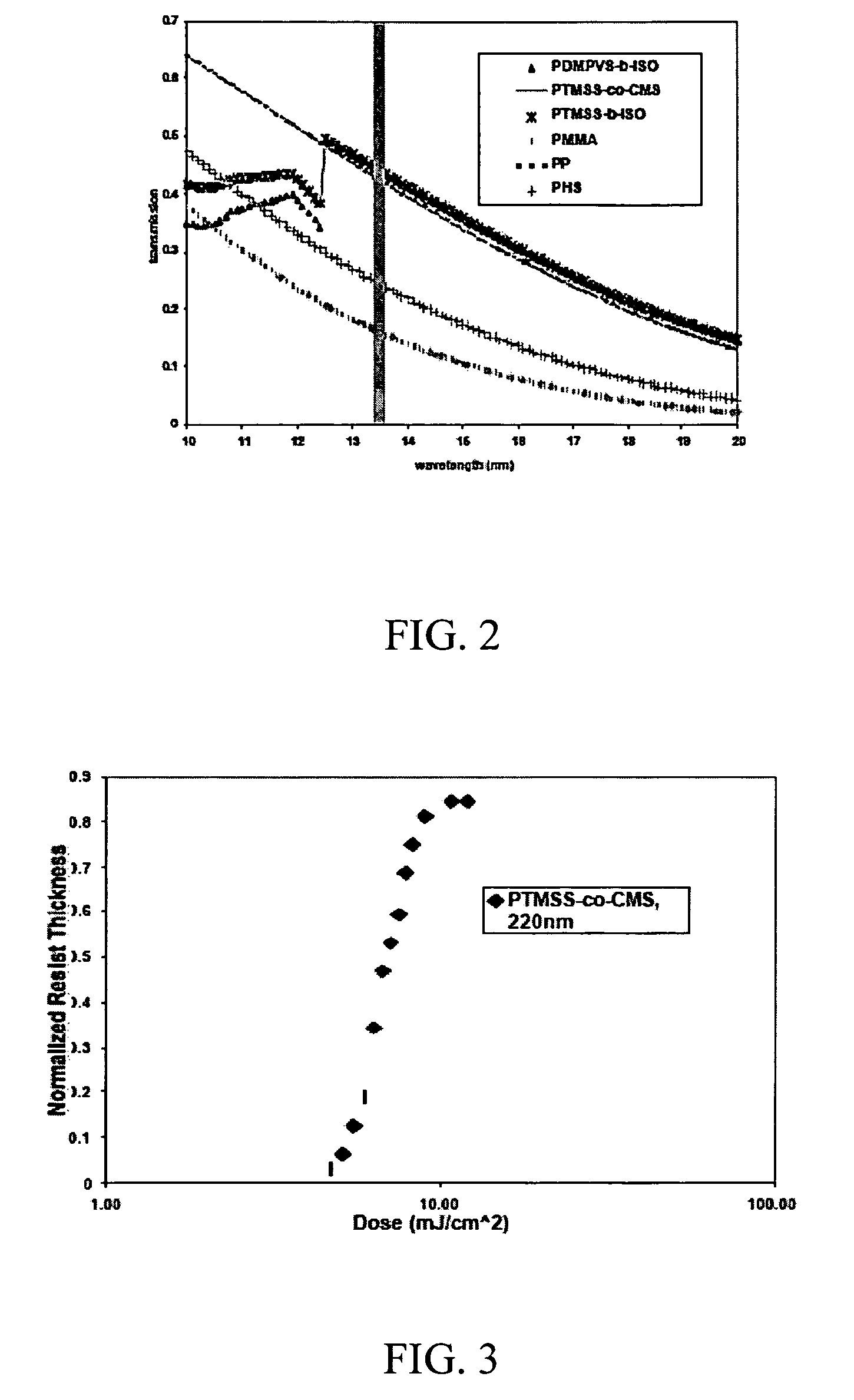

Organoelement resists for EUV lithography and methods of making the same

ActiveUS7326514B2Simple methodReduce etch ratePhotosensitive materialsRadiation applicationsLithography processUltraviolet

Resist compositions containing silicon, boron, or both silicon and boron may be used with ultra-violet lithography processes and extreme ultra-violet (EUV) lithography processes to increase the reactive ion etch resistance of the resist compositions, improve transmission of the resist materials, and to dope substrates.

Owner:WISCONSIN MADISON UNIV OF +2

Biphenyl derivative, resist bottom layer material, bottom layer forming method, and patterning process

ActiveUS20120252218A1Excellent etch resistanceImprove heat resistanceOrganic chemistryPhotomechanical apparatusResistBiphenyl derivatives

A biphenyl derivative having formula (1) is provided wherein Ar1 and Ar2 denote a benzene or naphthalene ring, and x and z each are 0 or 1. A material comprising the biphenyl derivative or a polymer comprising recurring units of the biphenyl derivative is spin coated and heat treated to form a resist bottom layer having improved properties, optimum values of n and k, step coverage, etch resistance, heat resistance, solvent resistance, and minimized outgassing.

Owner:SHIN ETSU CHEM IND CO LTD

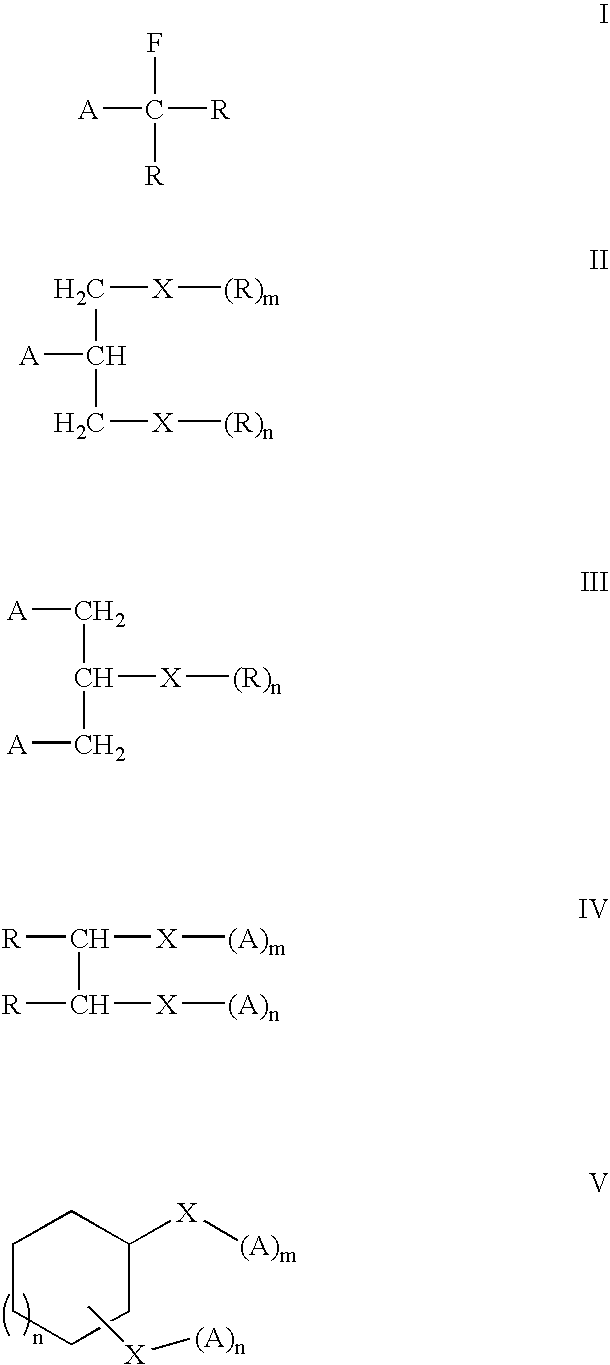

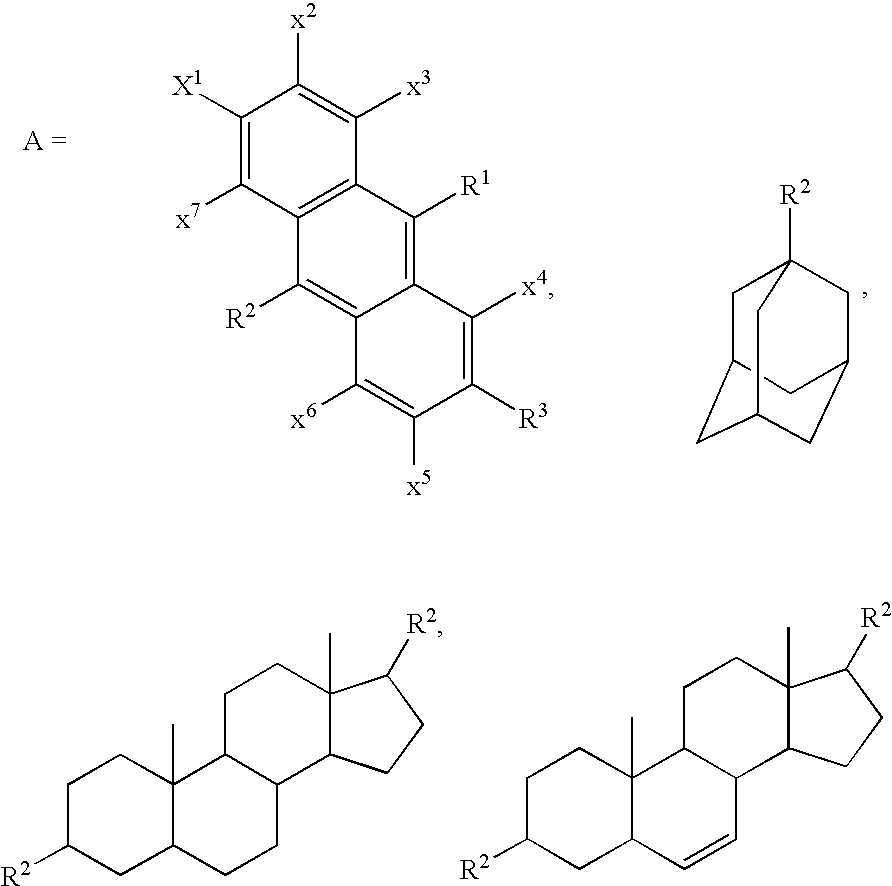

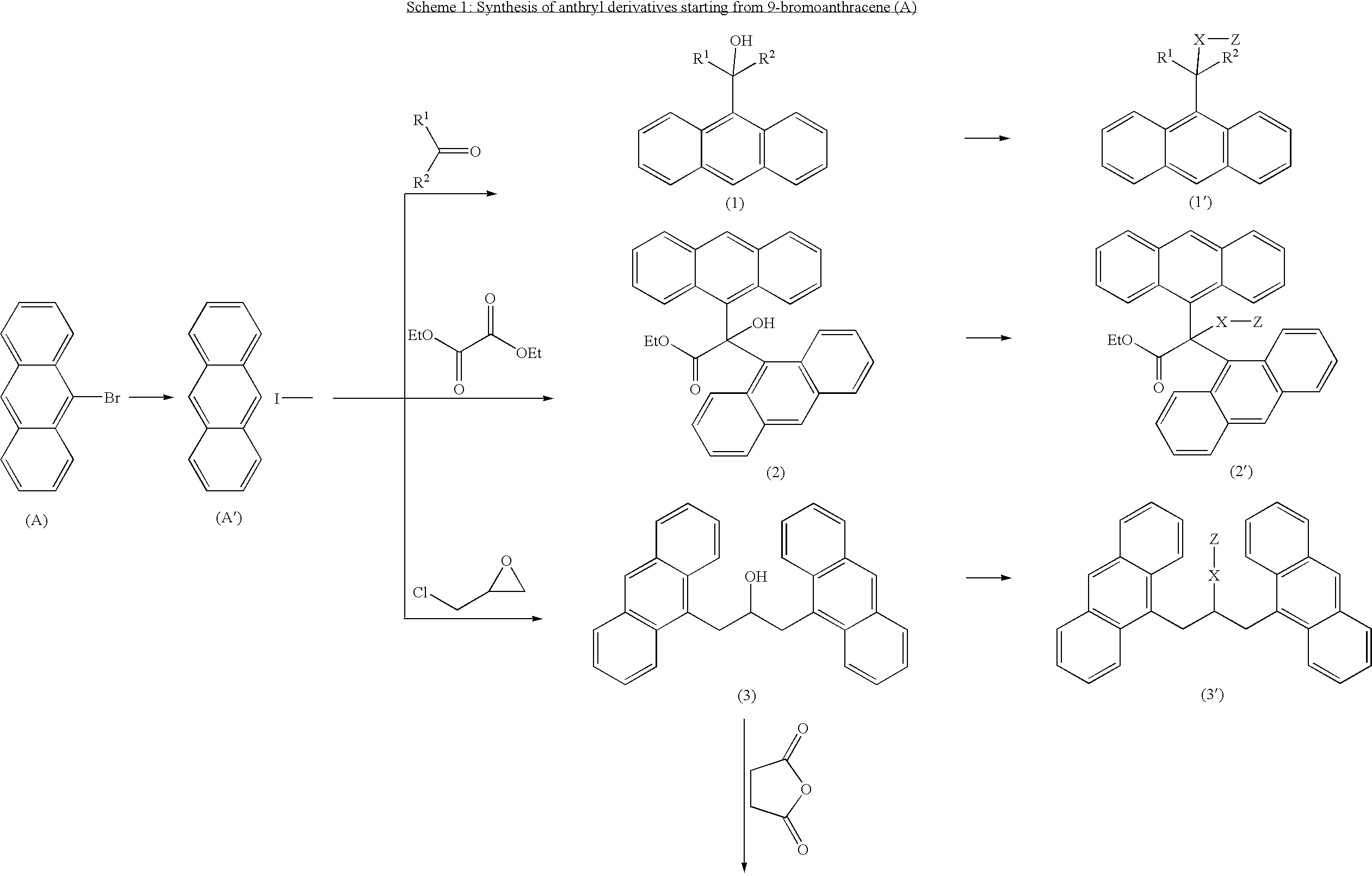

Polycarbocyclic derivatives for modification of resist, optical and etch resistance properties

InactiveUS20050026068A1Suitable absorption propertyExcellent etch resistanceEsterified saccharide compoundsSugar derivativesResistCarbon chain

Mixed carbocycle derivatives containing at least two carbocycles per molecule from the group of anthracenes, adamantanes and steroids with functionalized carbon chains are synthesized and used as modifiers of resist properties and especially etch resistance enhancement and absorption characteristics. These derivatives are characterized by formulas I-V, where A and R may be an anthryl- and / or an adamantyl- and / or a steroid moiety. Methods for the preparation of the above compounds are disclosed.

Owner:GOGOLIDES EVANGELOS +5

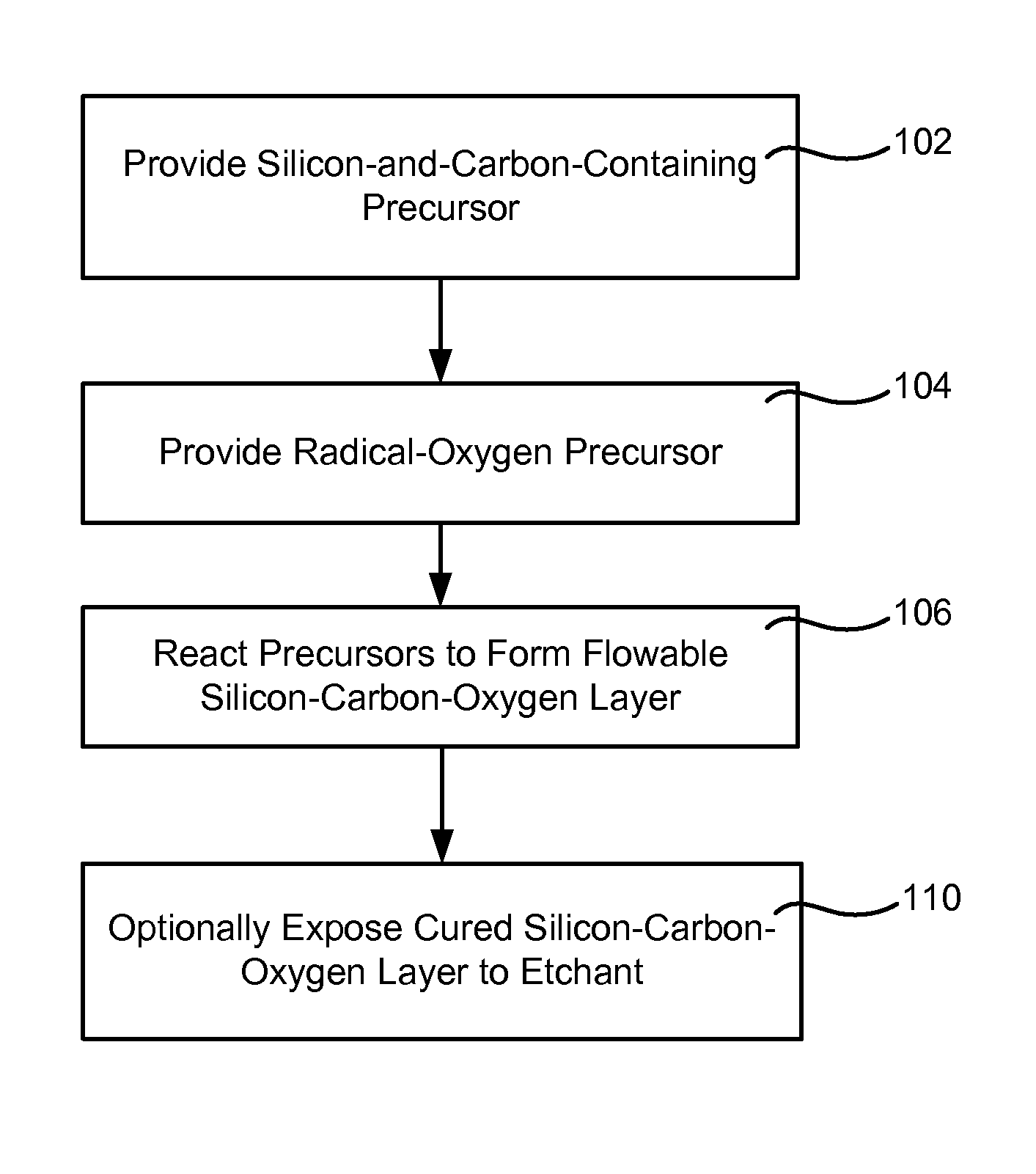

Flowable silicon-carbon-oxygen layers for semiconductor processing

ActiveUS20140302688A1Excellent etch resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilicon oxide

Methods are described for forming a dielectric layer on a patterned substrate. The methods may include combining a silicon-and-carbon-containing precursor and a radical oxygen precursor in a plasma free substrate processing region within a chemical vapor deposition chamber. The silicon-and-carbon-containing precursor and the radical oxygen precursor react in to deposit a flowable silicon-carbon-oxygen layer on the patterned substrate. The resulting film possesses a low wet etch rate ratio relative to thermal silicon oxide and other standard dielectrics.

Owner:APPLIED MATERIALS INC

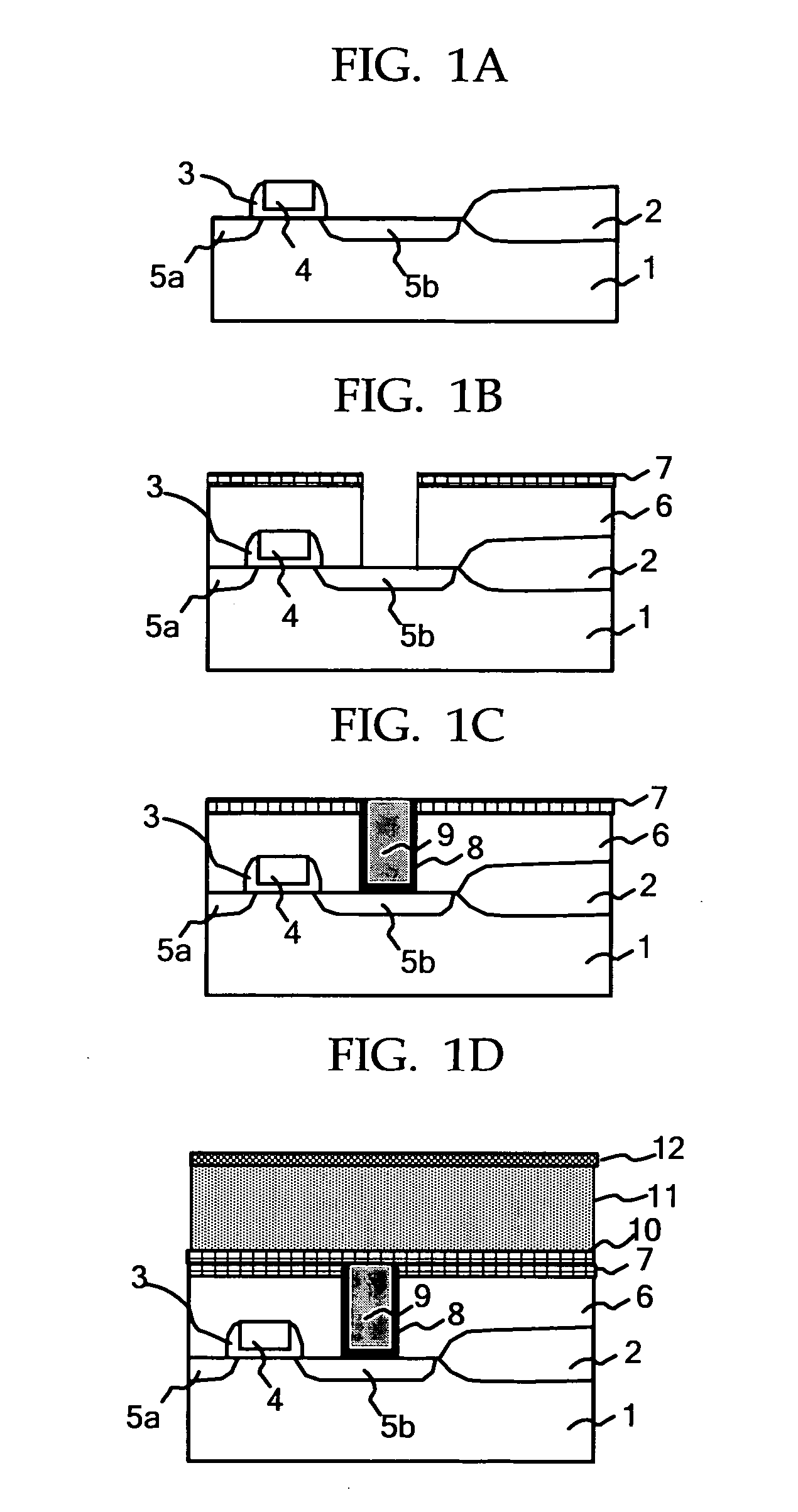

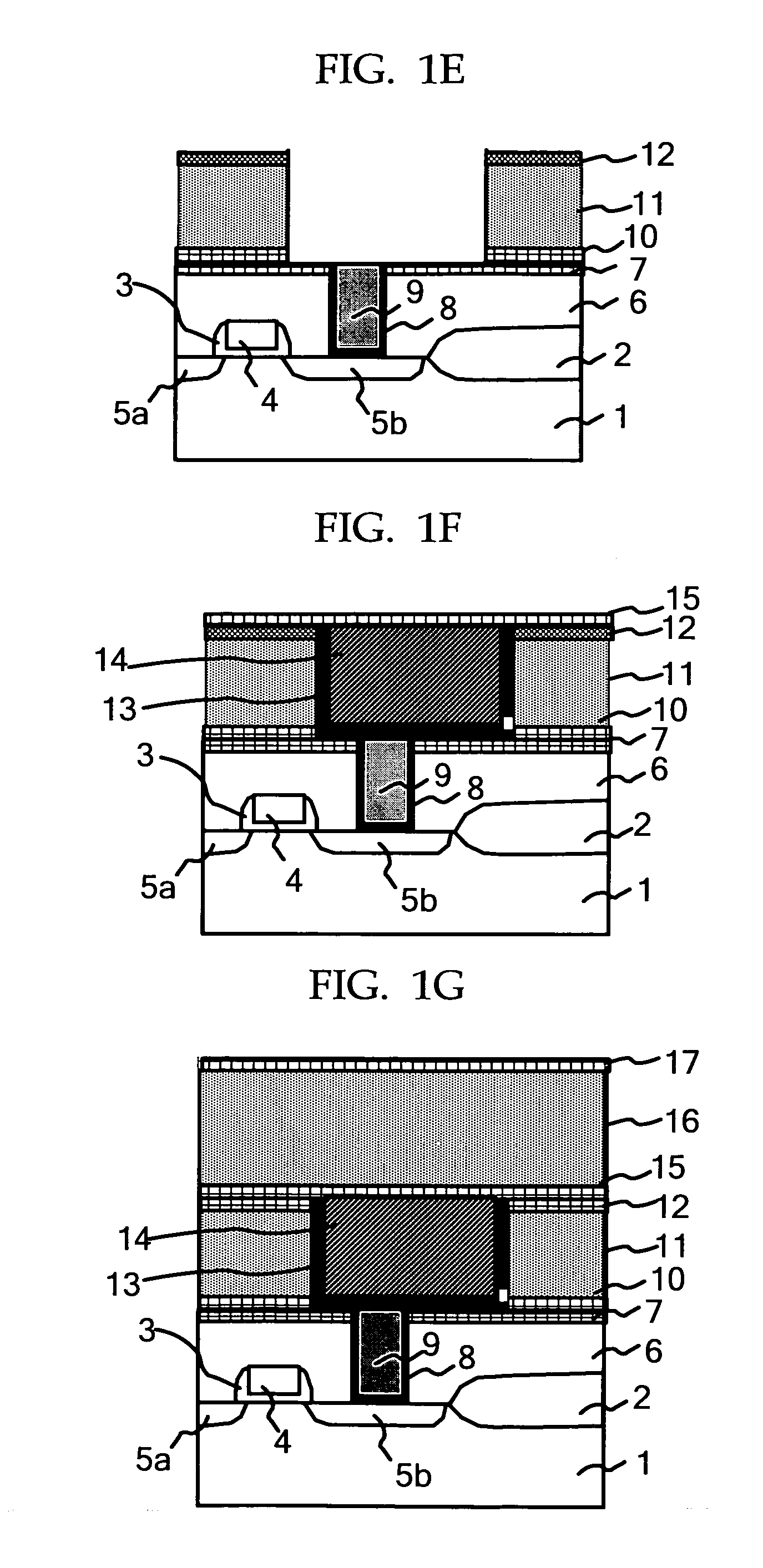

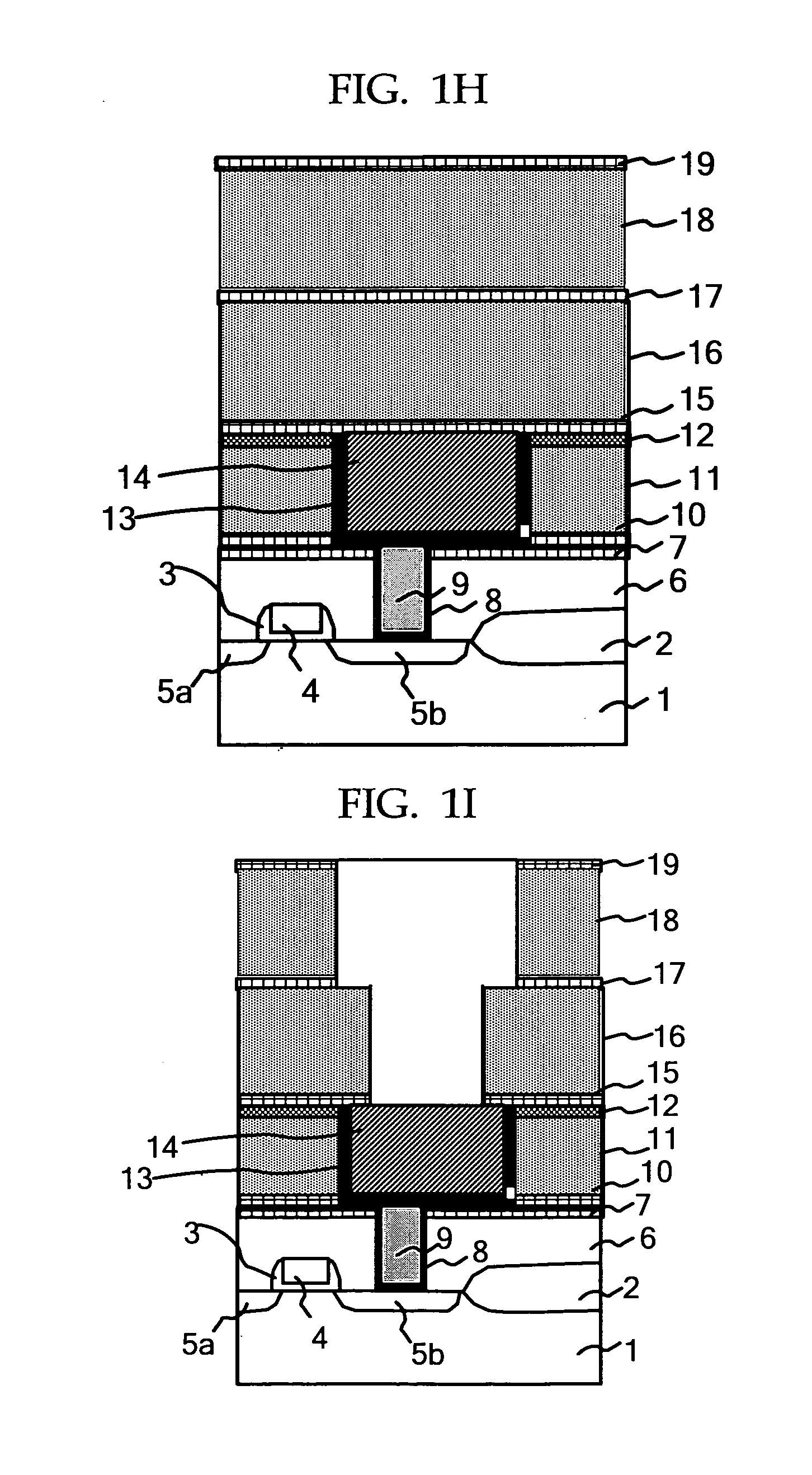

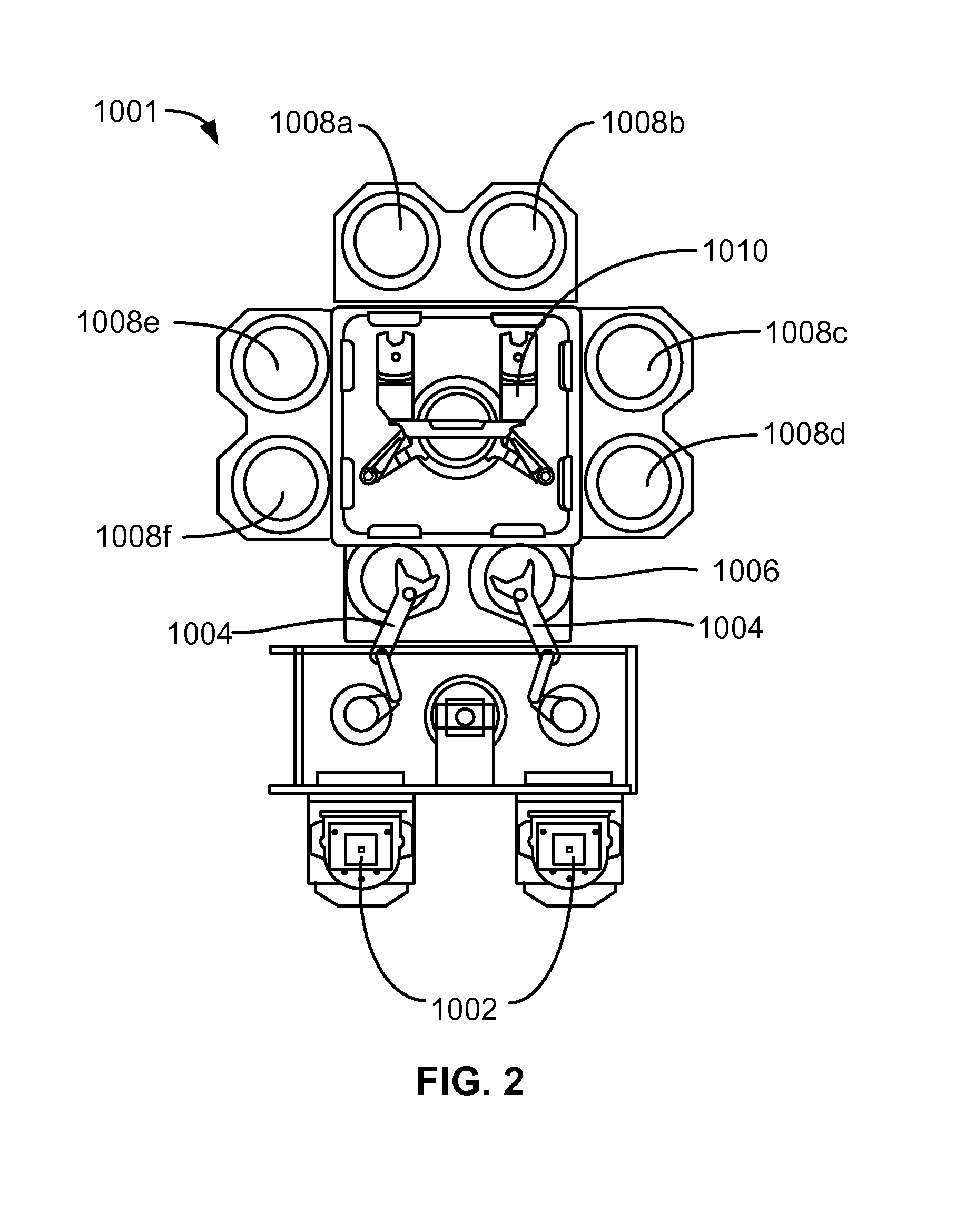

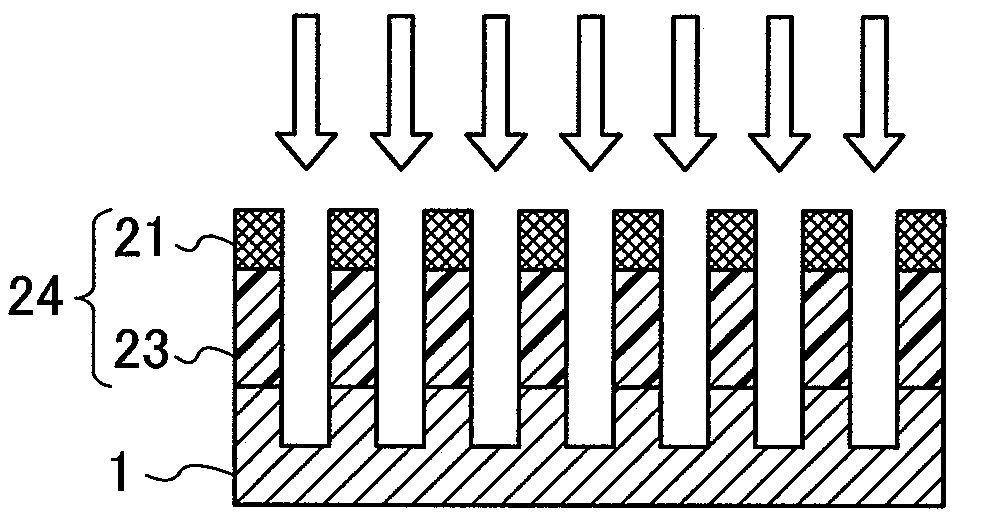

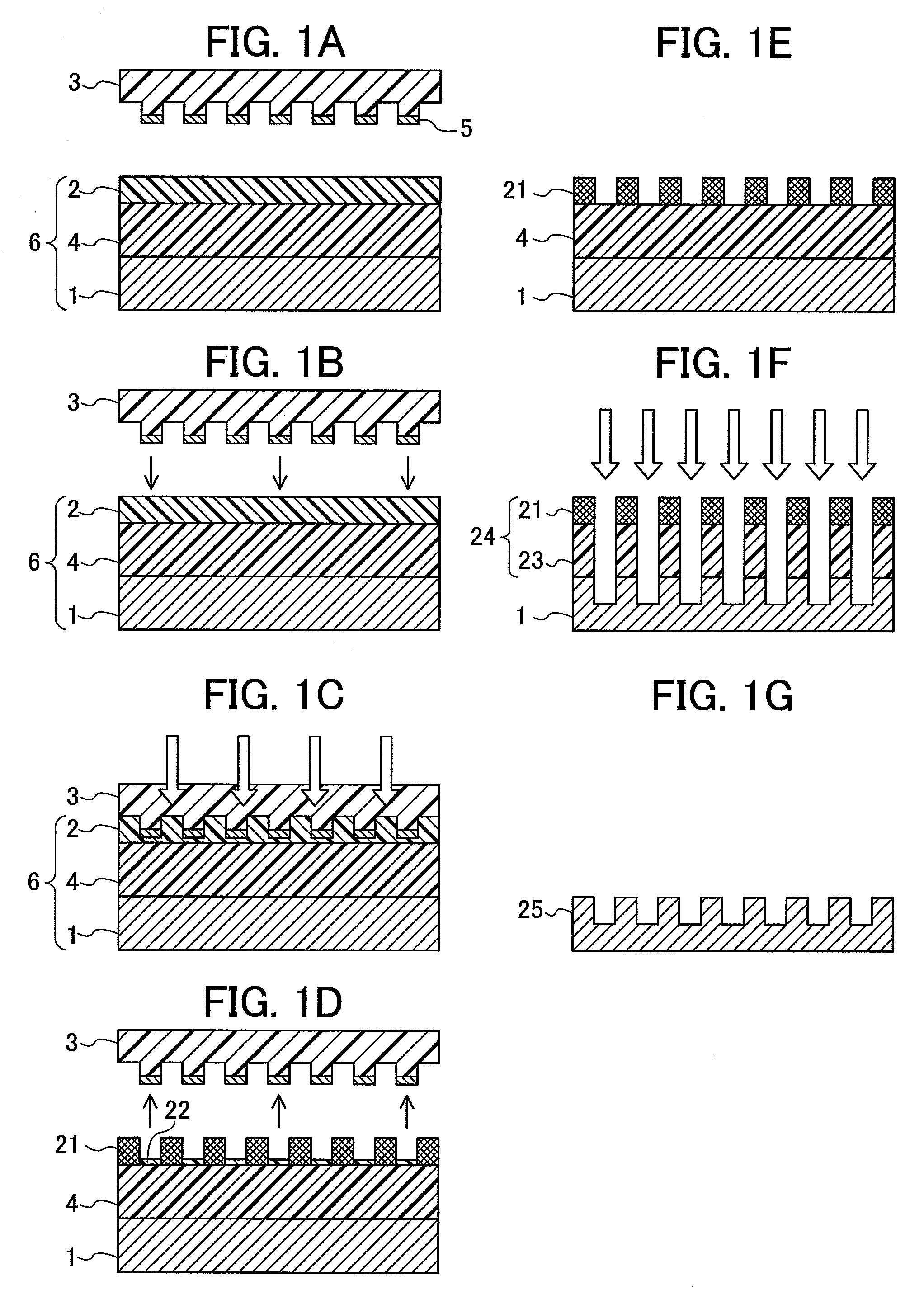

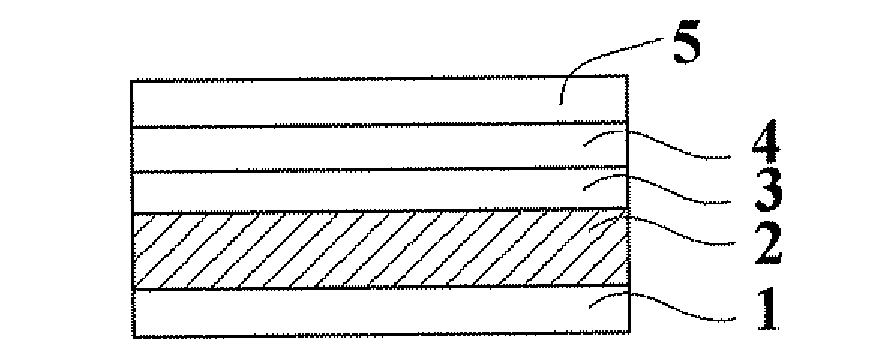

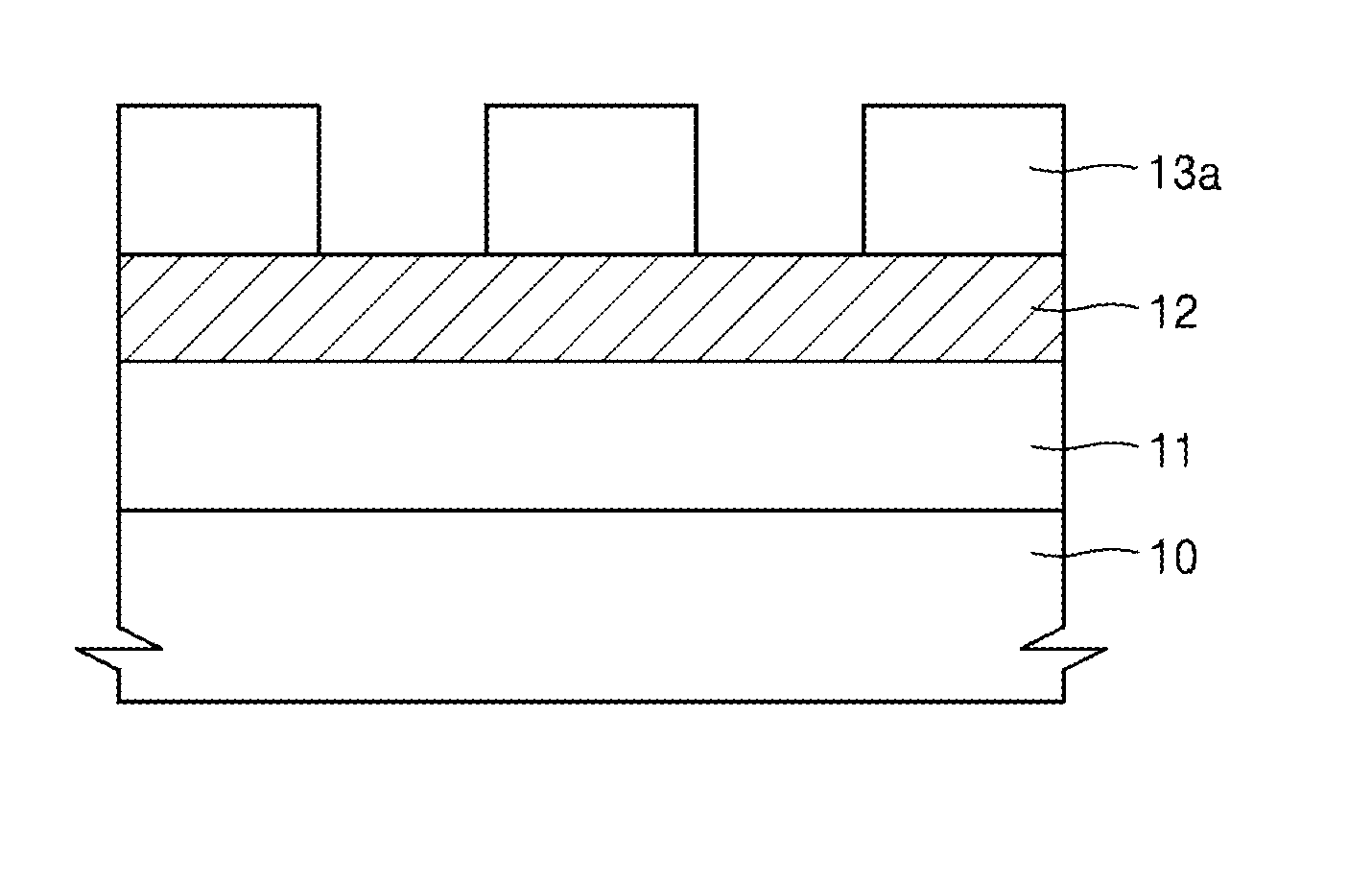

Method of forming resist pattern by nanoimprint lithography

ActiveUS20090189317A1Excellent etch resistanceImprove the immunityNanoinformaticsPhotomechanical apparatusResistOrganic layer

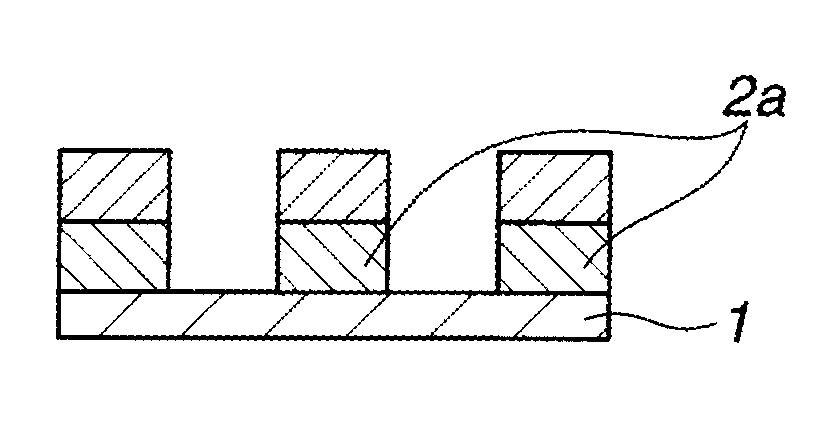

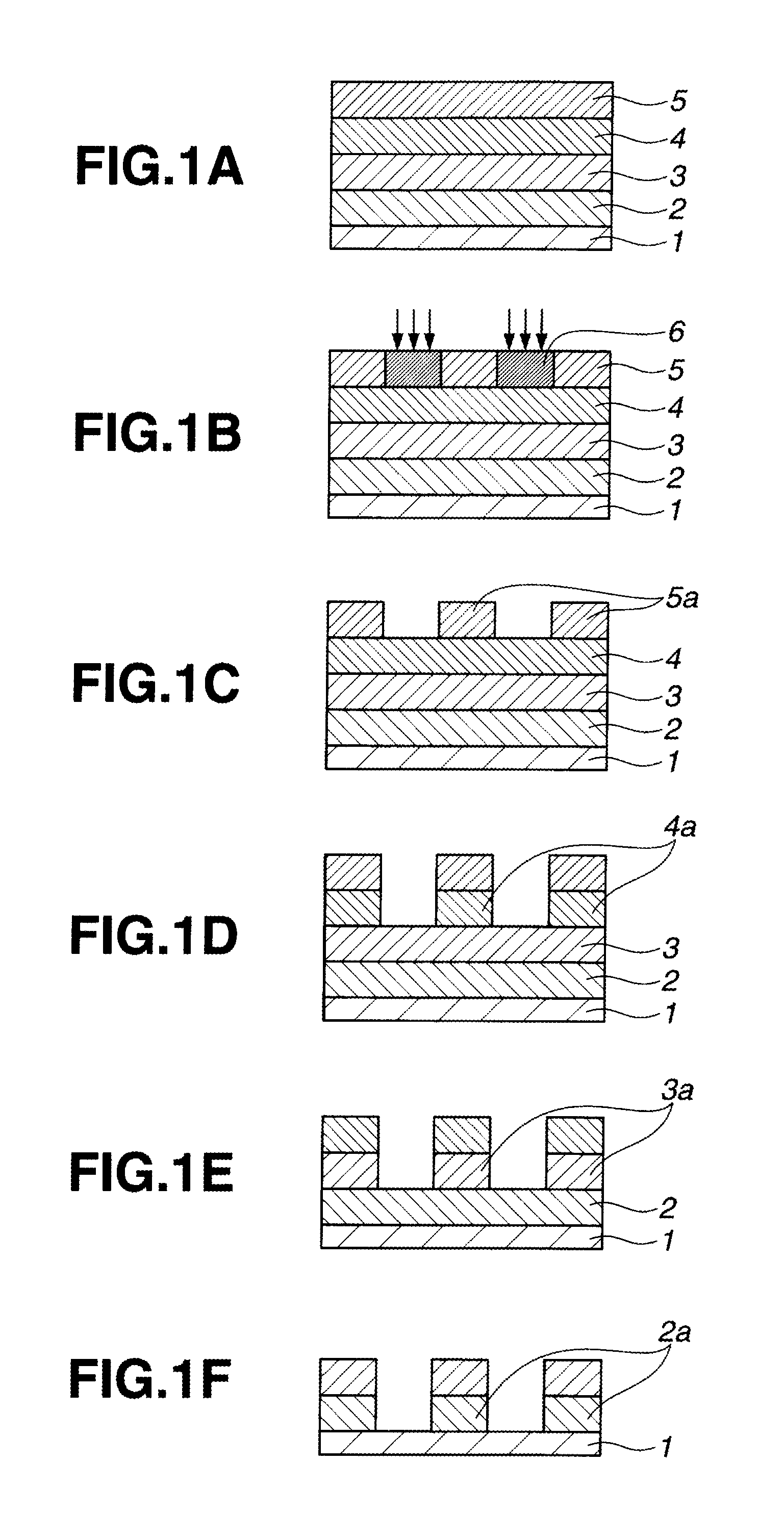

A method of forming a resist pattern of high aspect ratio excelling in etching resistance by the use of nanoimprint lithography. The method of forming a resist pattern by nanoimprint lithography comprises the steps of disposing organic layer (4) on support (1); providing resist layer (2) on the organic layer (4) with the use of chemical amplification type negative resist composition containing silsesquioxane resin (A); pressing light transmission allowing mold (3) with partial light shielding portion (5) against the resist layer (2) and thereafter carrying out exposure from the upside of the mold (3); and detaching the mold (3).

Owner:TOKYO OHKA KOGYO CO LTD

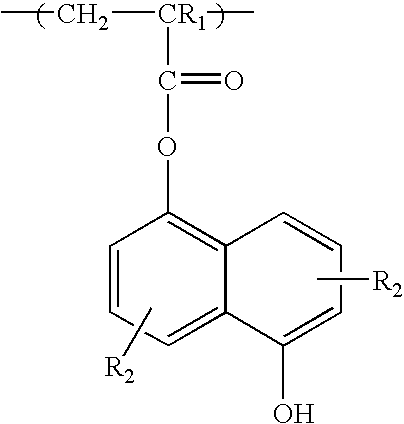

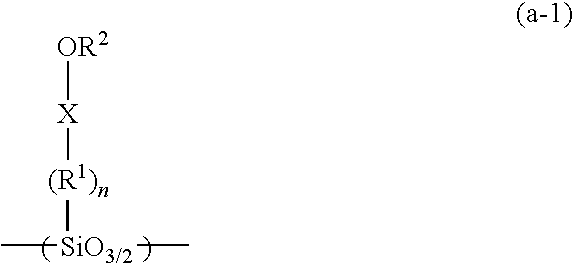

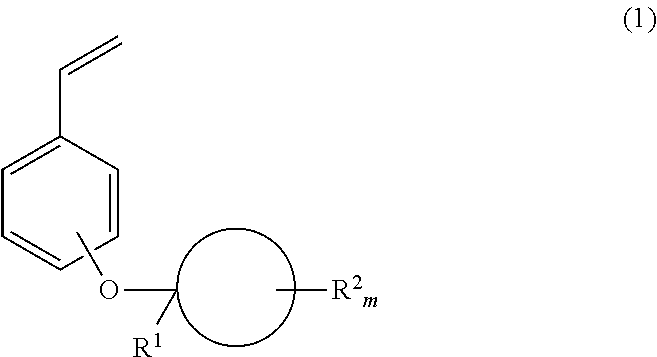

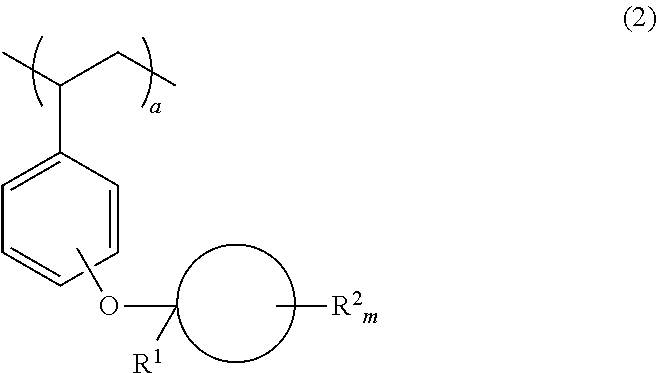

Bottom resist layer composition and patterning process using the same

ActiveUS20080038662A1High resolutionPrecise patternDecorative surface effectsSemiconductor/solid-state device manufacturingResistLength wave

There is disclosed a bottom resist layer composition for a multilayer-resist film used in lithography comprising, at least, a polymer comprising a repeating unit represented by the following general formula (1). Thereby, there can be provided a bottom resist layer composition that exhibits optimum n value and k value on exposure to shorter wavelengths, excellent etching resistance under conditions for etching substrates, and is promising for forming a bottom resist layer used for a multilayer-resist process such as a silicon-containing bilayer resist process or a trilayer resist process using a silicon-containing intermediate resist layer.

Owner:SHIN ETSU CHEM IND CO LTD

Resist underlayer film composition and patterning process using the same

ActiveUS20130087529A1Reduce reflectivityExcellent etch resistanceOrganic chemistryDecorative surface effectsResistHeat resistance

There is disclosed A resist underlayer film composition, the resist underlayer film composition contains a truxene compound having a substituted or an unsubstituted naphthol group as shown by the following general formula (1). There can be provided a resist underlayer film composition to form a resist underlayer film being capable of reducing reflectance and having high etching resistance, heat resistance.

Owner:SHIN ETSU CHEM IND CO LTD

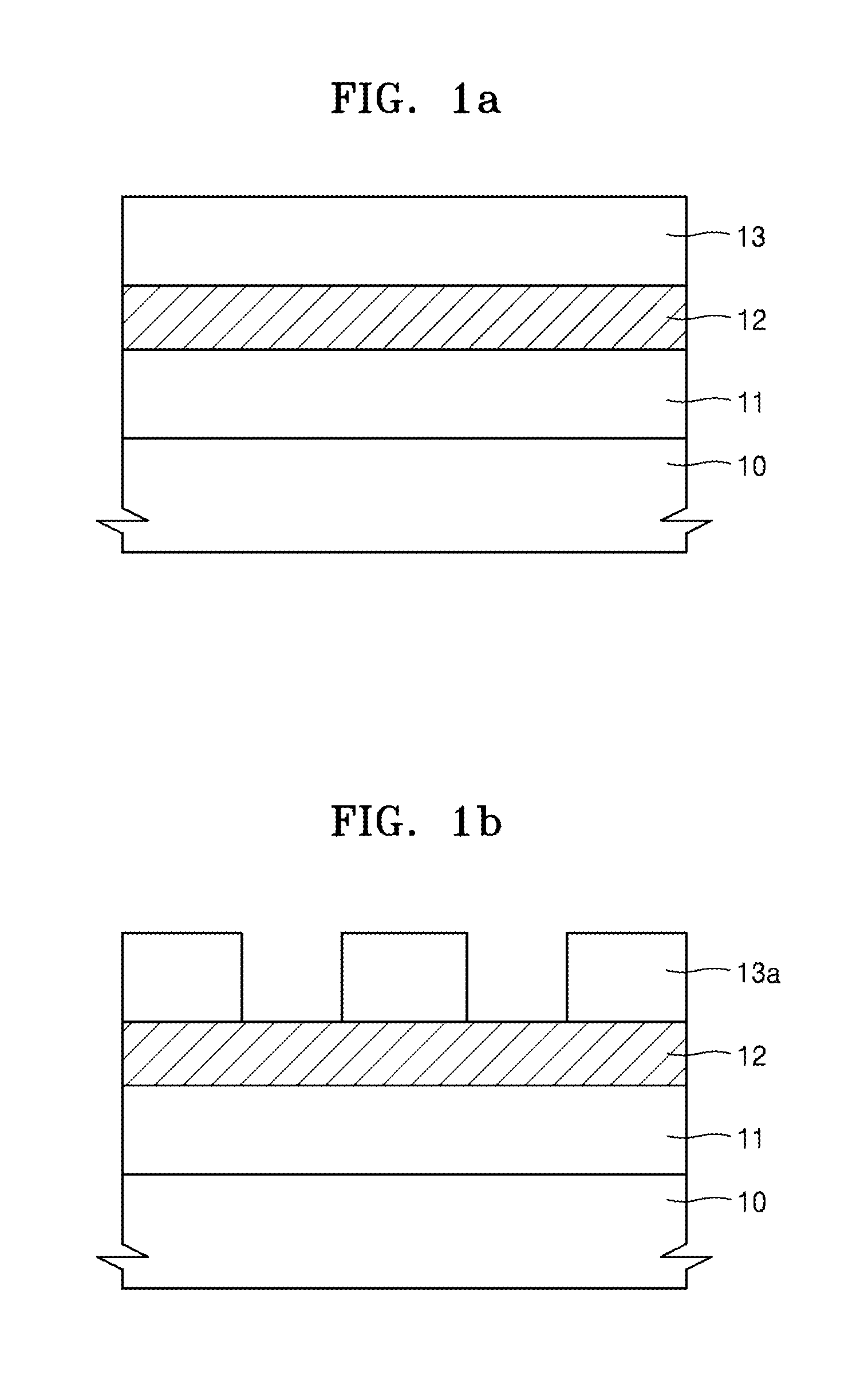

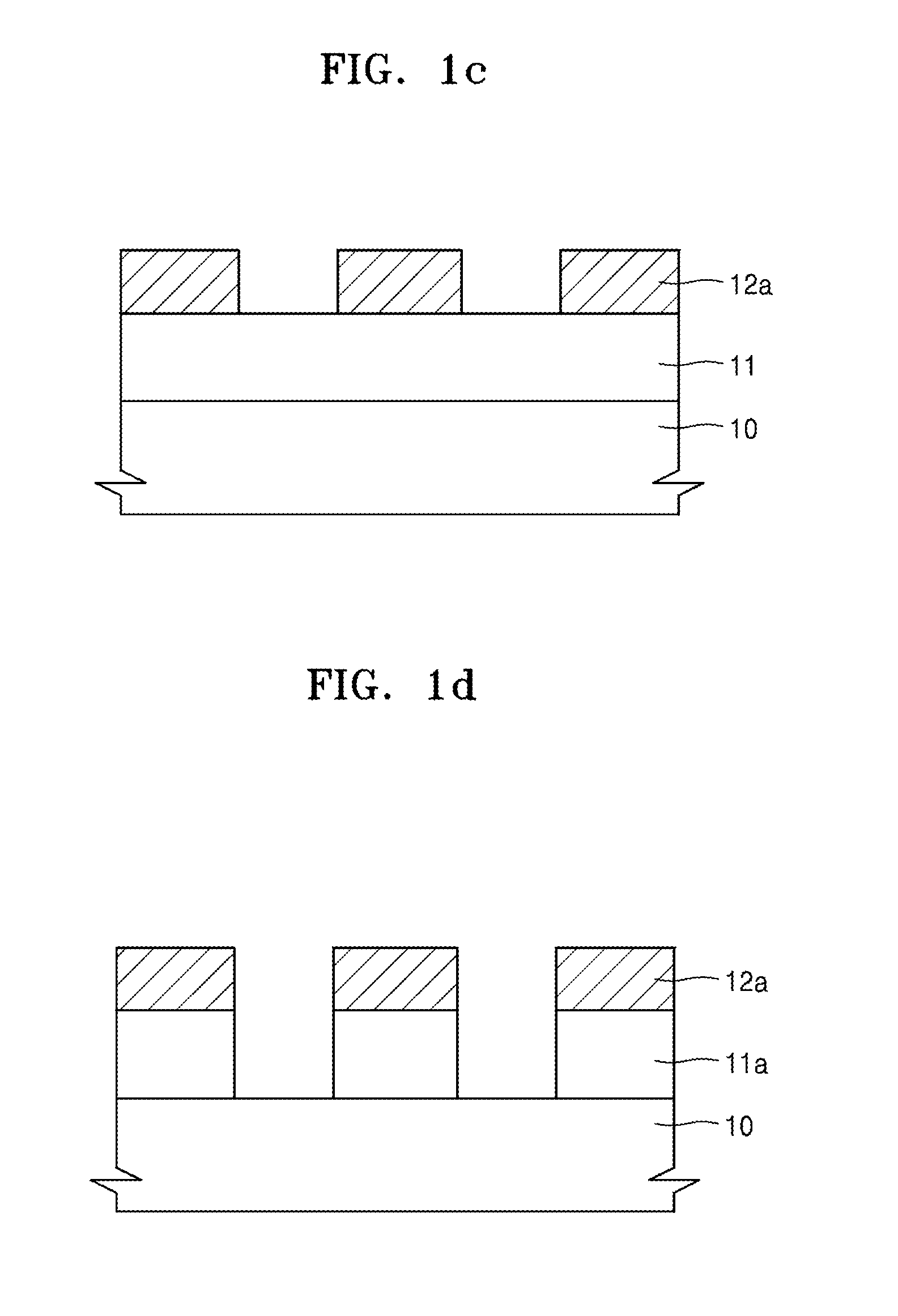

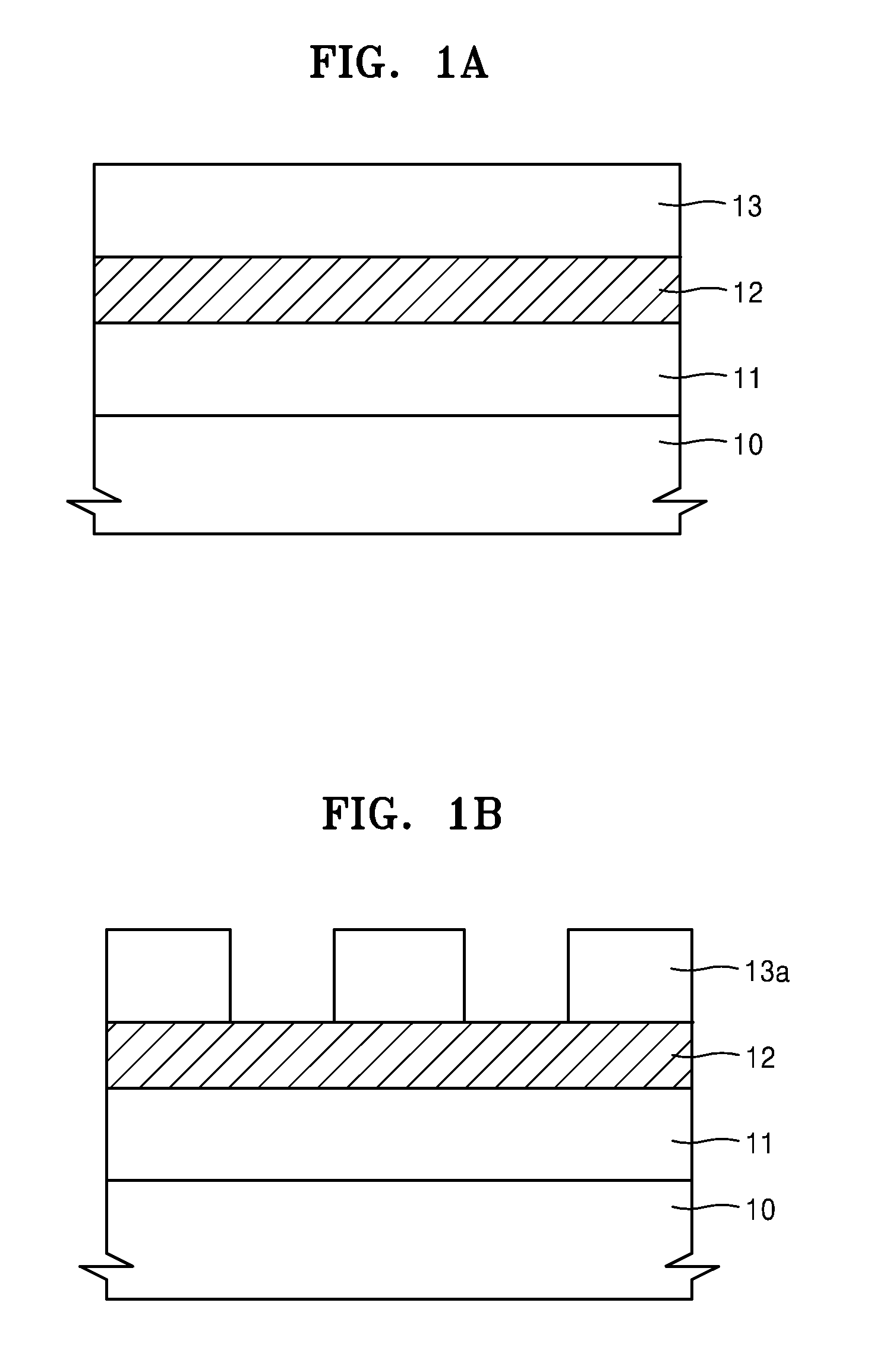

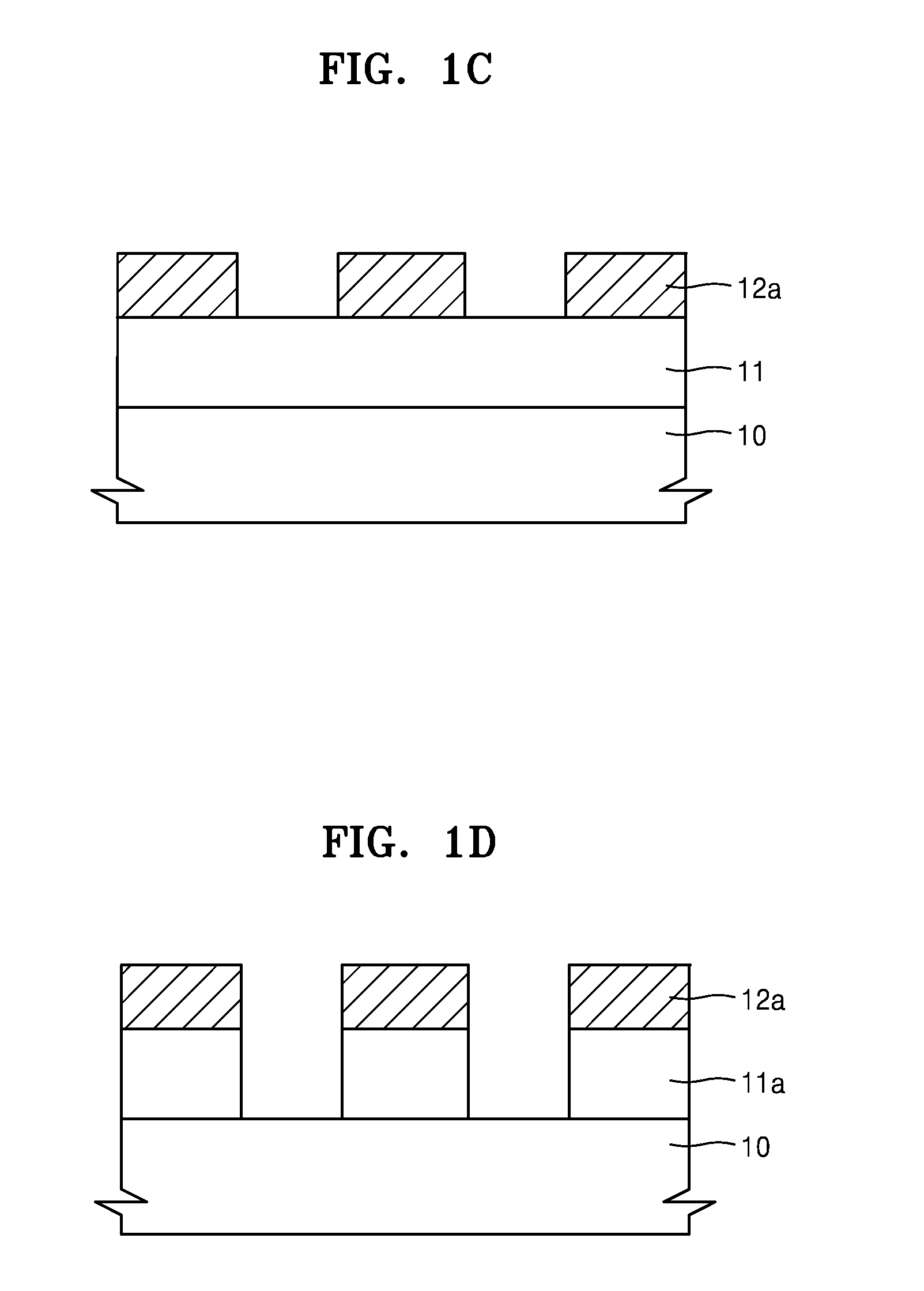

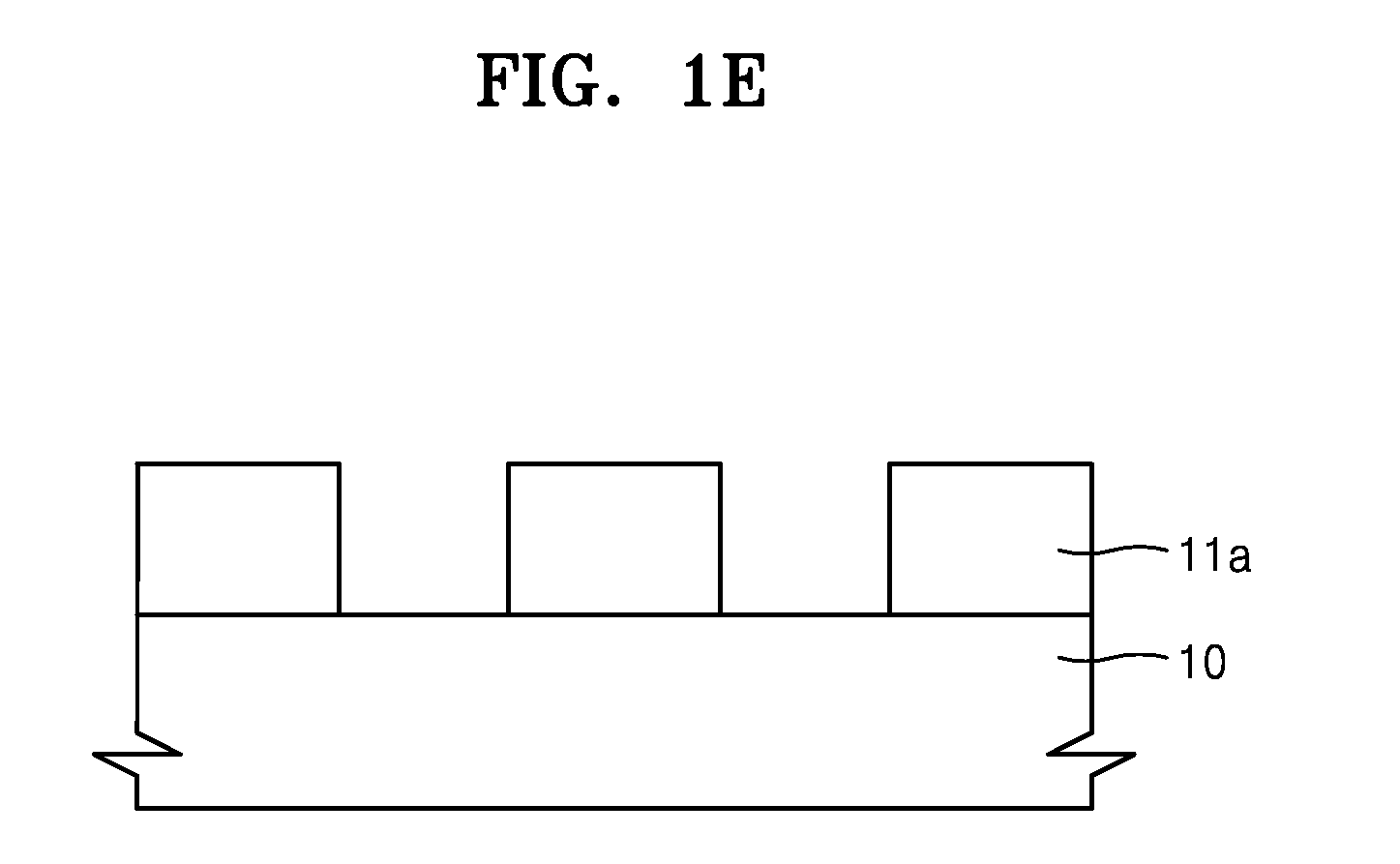

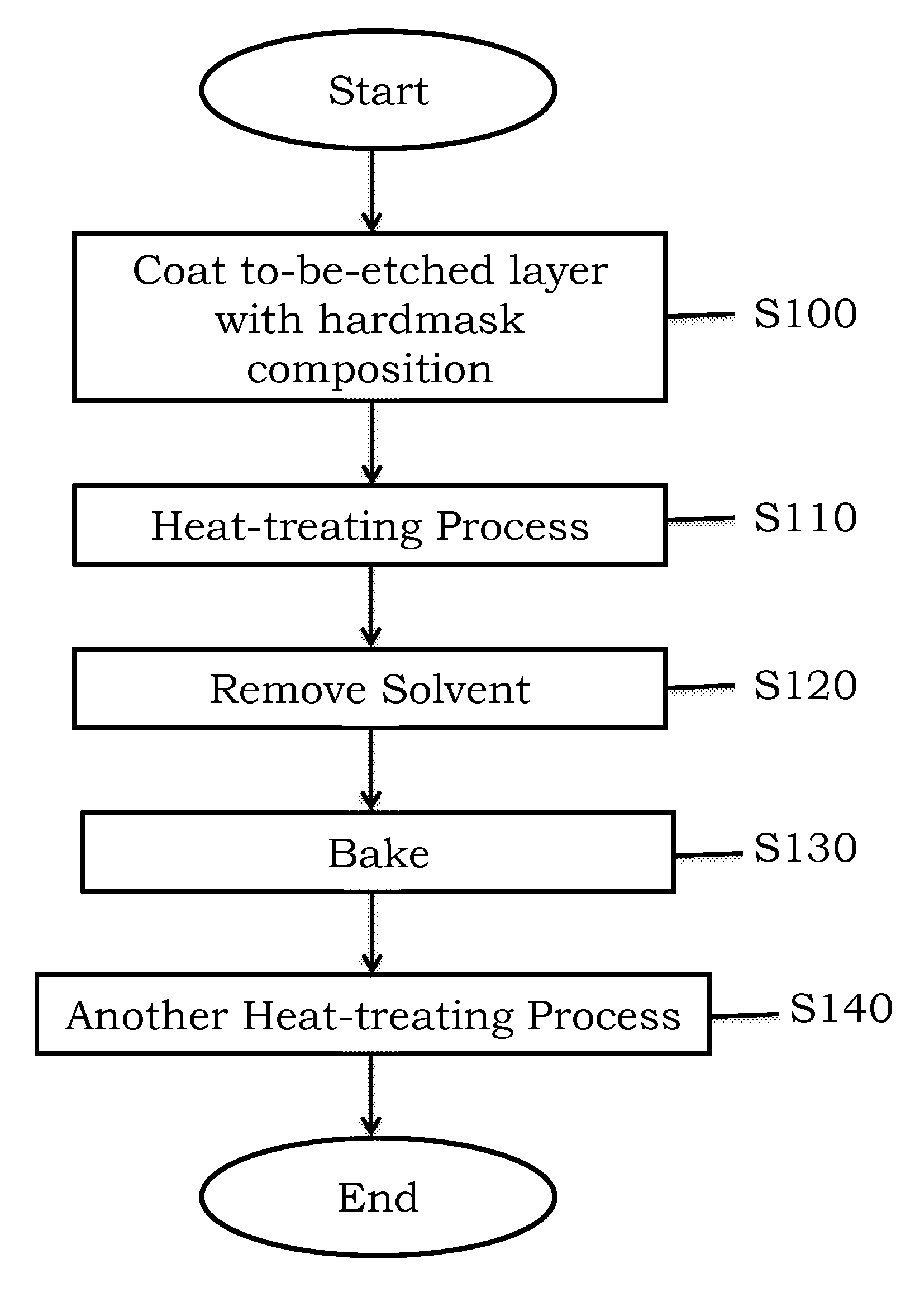

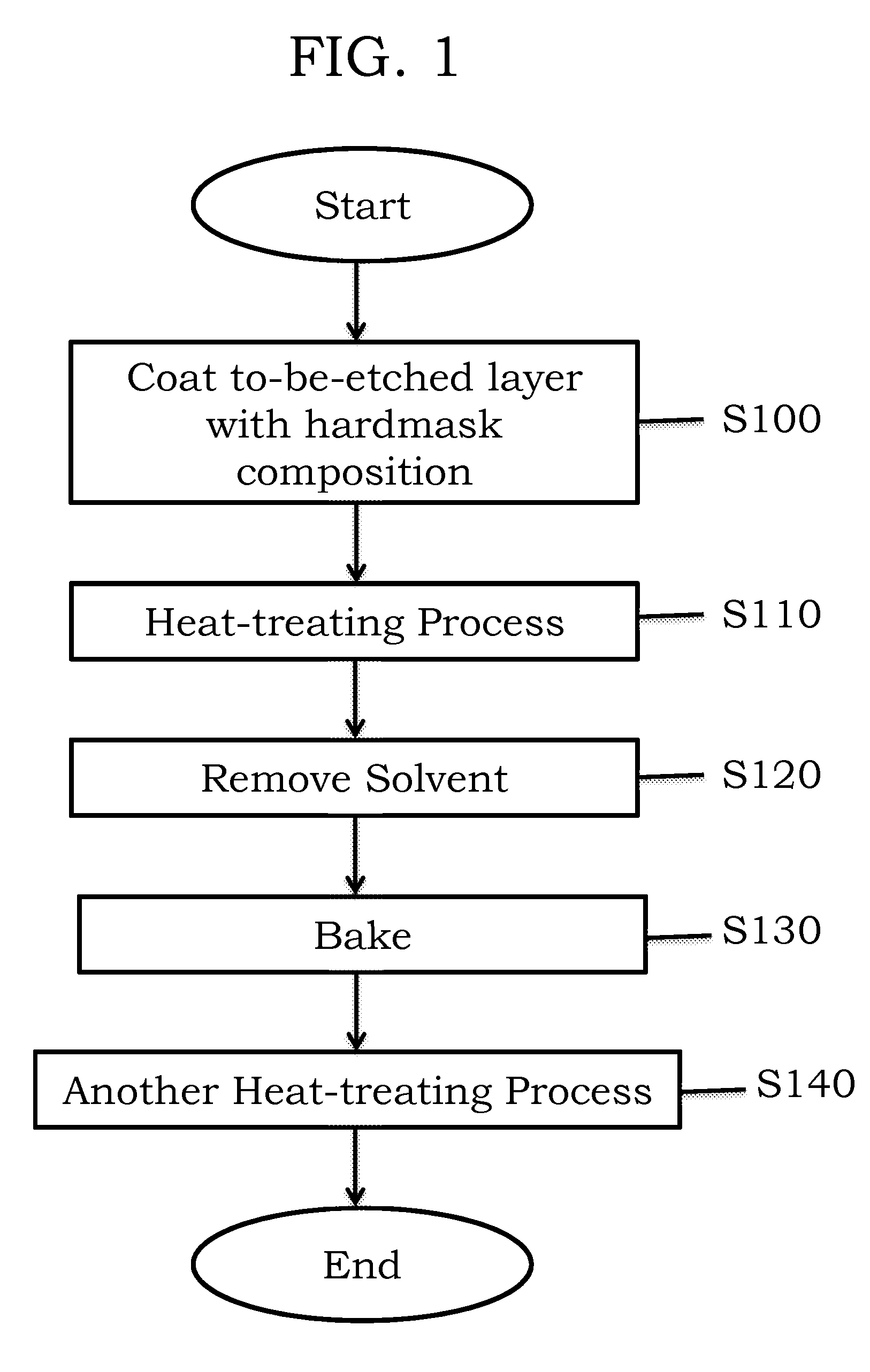

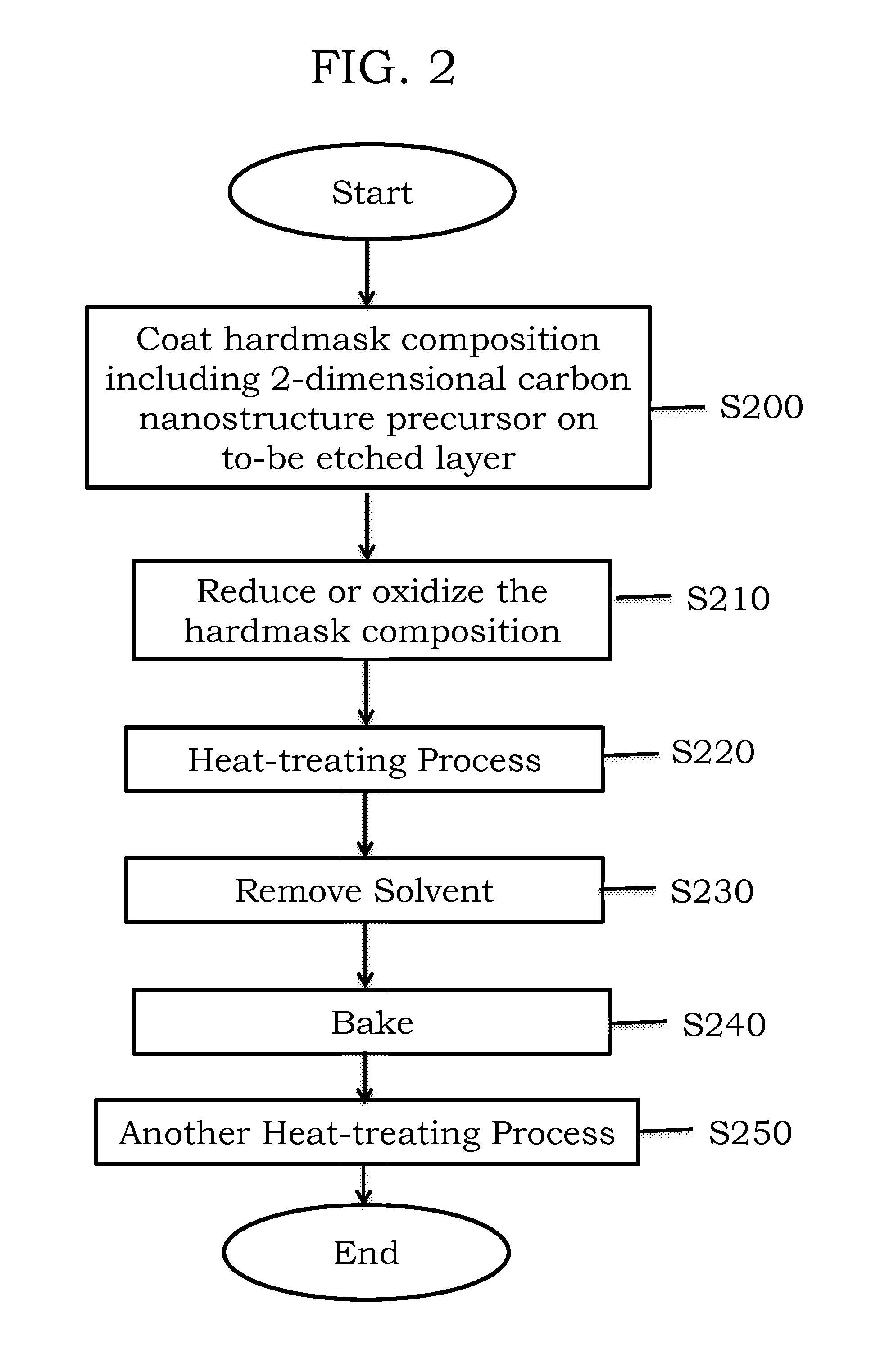

Hardmask composition and method of forming pattern using the hardmask composition

InactiveUS20160005625A1Excellent etch resistanceSemiconductor/solid-state device manufacturingAnti-corrosive paintsPolymer scienceHexagonal boron nitride

A hardmask composition includes a first material including one of an aromatic ring-containing monomer and a polymer containing a repeating unit including an aromatic ring-containing monomer, a second material including at least one of a hexagonal boron nitride and a precursor thereof, a chalcogenide-based material and a precursor thereof, and a two-dimensional carbon nanostructure and a precursor thereof, the two-dimensional carbon nanostructure containing about 0.01 atom % to about 40 atom % of oxygen, and a solvent.

Owner:SAMSUNG ELECTRONICS CO LTD

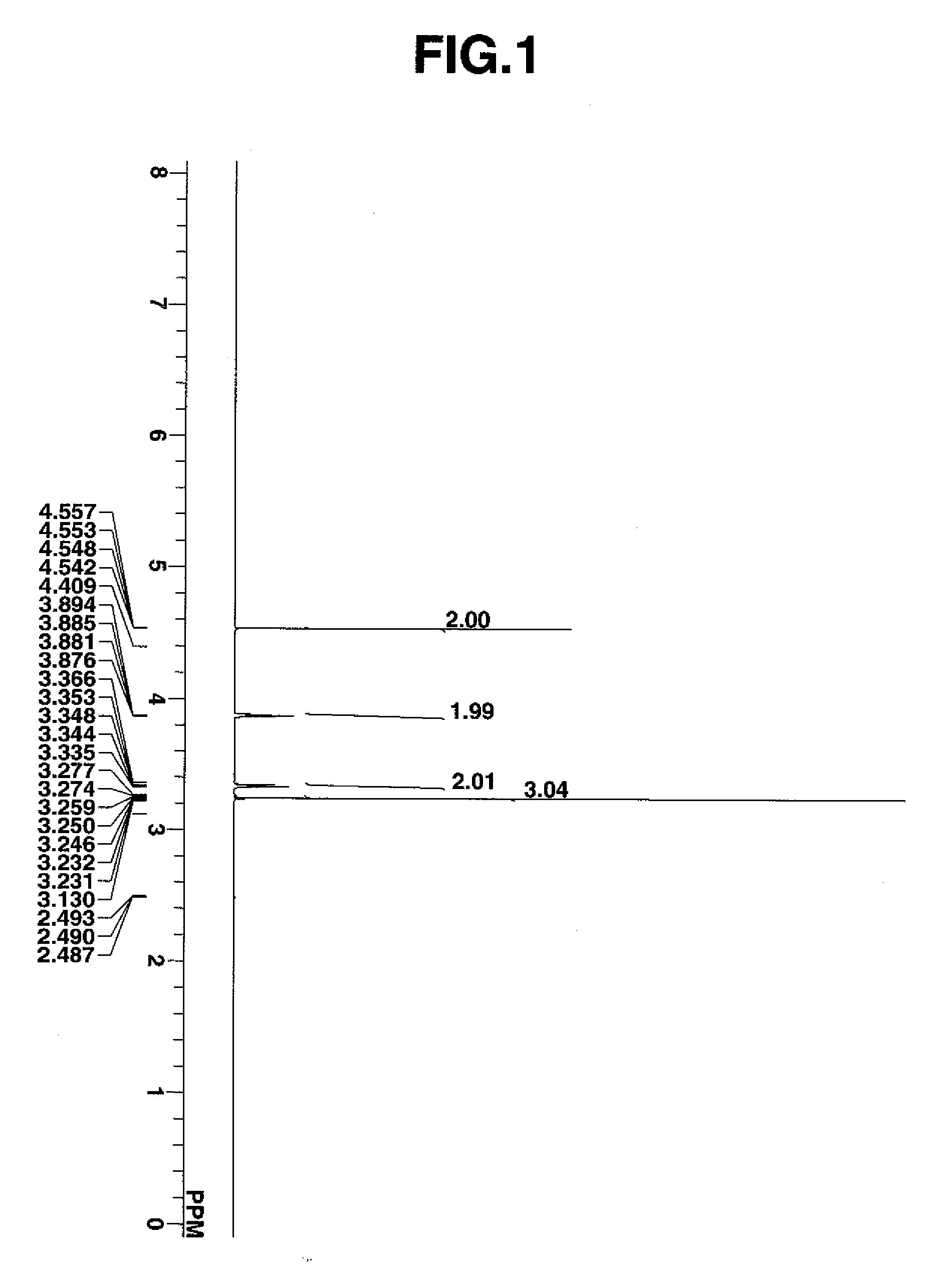

Monomer, polymer, positive resist composition and patterning process

ActiveUS20130288180A1Increase contrastMinimized swell in alkaline developer sufficientOrganic chemistryPhotosensitive materialsResistMonomer

A polymer for use in resist compositions is obtained from a monomer having formula (1) wherein R1 is methyl, ethyl, propyl, vinyl or ethynyl, the circle designates C3-C12 cycloalkyl, a combination wherein R1 is ethyl and the circle is cyclohexyl being excluded, R2 is H or C1-C4 alkyl, and m is 1 to 4.

Owner:SHIN ETSU CHEM IND CO LTD

Hardmask composition and method of forming patterning by using the hardmask composition

ActiveUS20160027645A1Excellent etch resistanceWater-repelling agents additionSemiconductor/solid-state device manufacturingSolventMaterials science

Example embodiments relate to a hardmask composition and / or a method of forming a fine pattern by using the hardmask composition, wherein the hardmask composition includes at least one of a two-dimensional layered nanostructure and a precursor thereof, and a solvent, and an amount of the at least one of a two-dimensional layered nanostructure and the precursor is about 0.01 part to about 40 parts by weight based on 100 parts by weight of the hardmask composition.

Owner:SAMSUNG ELECTRONICS CO LTD

Hardmask composition and method of forming pattern using the hardmask composition

ActiveUS20160291472A1Excellent etch resistanceGrapheneSemiconductor/solid-state device manufacturingGraphitePolymer chemistry

Owner:SAMSUNG ELECTRONICS CO LTD

Hardmask composition and method of forming pattern by using the hardmask composition

ActiveUS20150348794A1Excellent etch resistanceWater-repelling agents additionSemiconductor/solid-state device manufacturingOxygenSolvent

A hardmask composition may include a solvent and a 2-dimensional carbon nanostructure containing about 0.01 atom % to about 40 atom % of oxygen or a 2-dimensional carbon nanostructure precursor thereof. A content of oxygen in the 2-dimensional carbon nanostructure precursor may be lower than about 0.01 atom % or greater than about 40 atom %. The hardmask composition may be used to form a fine pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

Photoacid generator, copolymer, chemically amplified resist composition, and method of forming pattern using the chemically amplified resist composition

ActiveUS20100143843A1Increase roughnessExcellent etch resistanceOrganic chemistryOrganic compound preparationPhotoacidPhotoacid generator

Disclosed are a photoacid generator, a copolymer, a chemically amplified resist composition, and a method of forming a pattern using the chemically amplified resist composition. The photoacid is connected with a main chain of the copolymer, whereby the photoacid is equally dispersed within a resist layer, and characteristics of line edge roughness of a resist pattern is improved.

Owner:SK MATERIALS PERFORMANCE CO LTD

Resist pattern thickening material, method for forming resist pattern, semiconductor device and method for manufacturing the same

ActiveUS20080073322A1Less dependencyResist pattern is excellent particularly in etch resistanceDecorative surface effectsSolid-state devicesResistEngineering

The present invention provides a resist pattern thickening material, which can utilize ArF excimer laser light; which, when applied over a resist pattern to be thickened, e.g., in form of lines and spaces pattern, can thicken the resist pattern to be thickened regardless of the size of the resist pattern to be thickened; and which is suited for forming a fine space pattern or the like, exceeding exposure limits. The present invention also provides a process for forming a resist pattern and a process for manufacturing a semiconductor device, wherein the resist pattern thickening material of the present invention is suitably utilized.

Owner:FUJITSU LTD

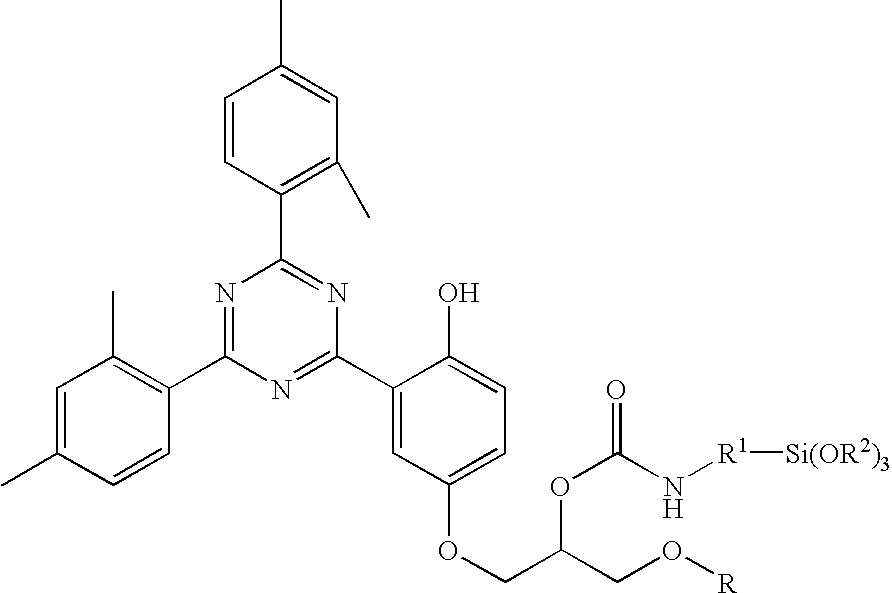

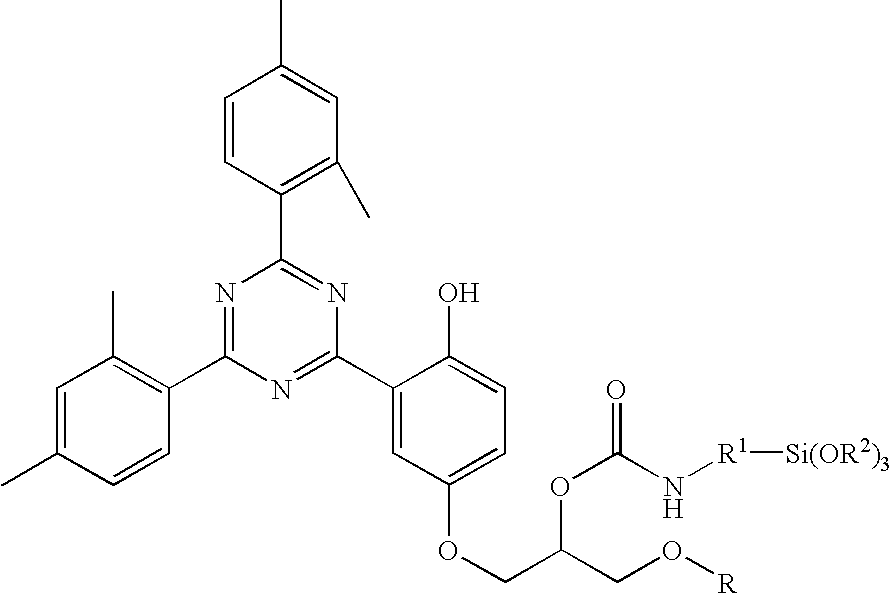

Silane-modified UV absorbers and coatings

InactiveUS20060074153A1Better originalImproved environmental etch resistanceSilicon organic compoundsUltravioletUv absorber

Including a triazine UV light absorber having a silane group in a coating improves scratch and mar resistance after weathering.

Owner:BASF CORP

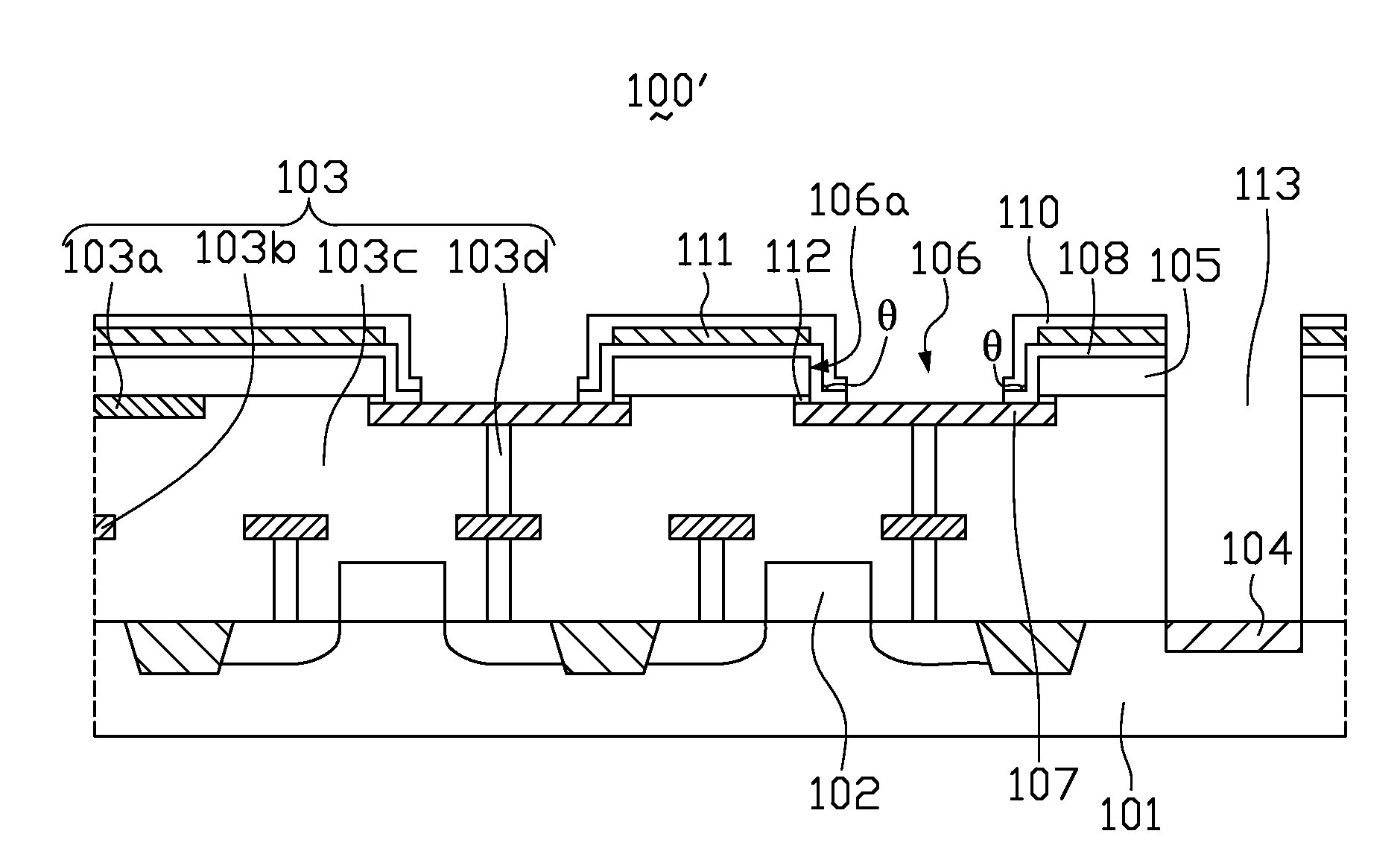

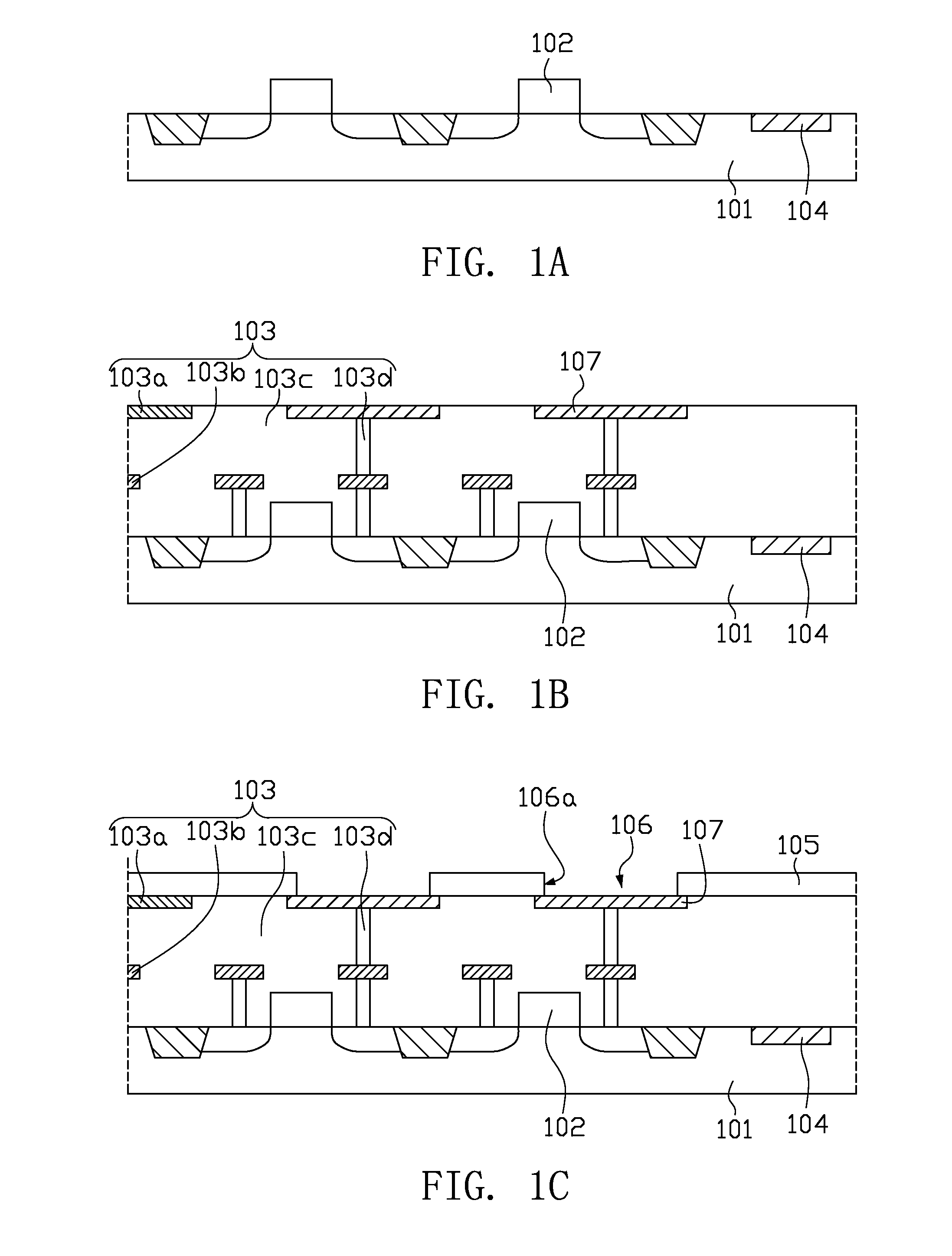

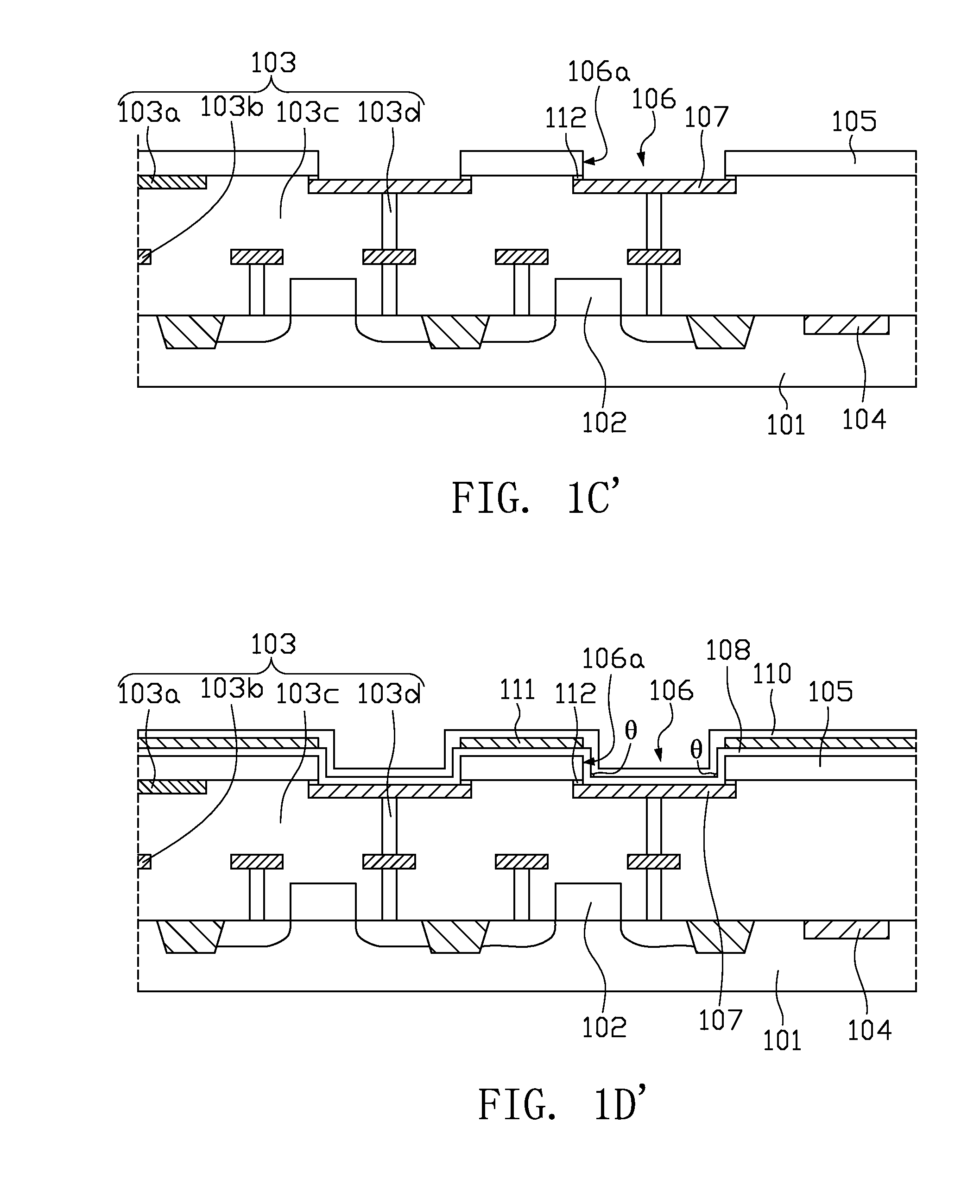

Bond pad structure and fabricating method thereof

ActiveUS20130093104A1Excellent etch resistanceAvoid undercutSemiconductor/solid-state device detailsSolid-state devicesIsolation layerInterconnection

A bond pad structure comprises an interconnection structure and an isolation layer. The dielectric layer has an opening and a metal pad. The isolation layer is disposed on the interconnection structure and extends into the opening until it is in contact with the metal pad, whereby the sidewalls of the opening is blanketed by the isolation layer, and a portion of the metal pad is exposed from the opening.

Owner:MARLIN SEMICON LTD

Naphthalene derivative, resist bottom layer material, resist bottom layer forming method, and patterning process

ActiveUS20110311920A1Excellent etch resistanceImprove heat resistanceOrganic chemistryOrganic compound preparationResistBenzene

A naphthalene derivative having formula (1) is provided wherein cyclic structures Ar1 and Ar2 denote a benzene or naphthalene ring, X is a single bond or C1-C10 alkylene, m is 0 or 1, and n is such a natural number as to provide a molecular weight of up to 100,000. A material comprising the naphthalene derivative or a polymer comprising the naphthalene derivative is spin coated to form a resist bottom layer having improved properties. A pattern forming process in which a resist bottom layer formed by spin coating is combined with an inorganic hard mask formed by CVD is available.

Owner:SHIN ETSU CHEM IND CO LTD

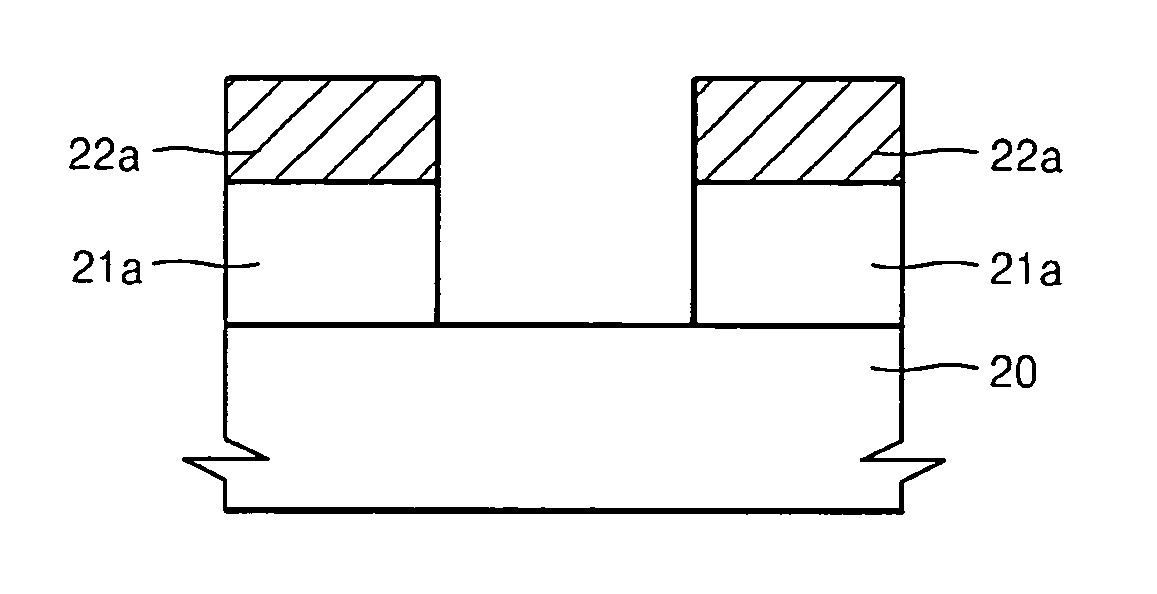

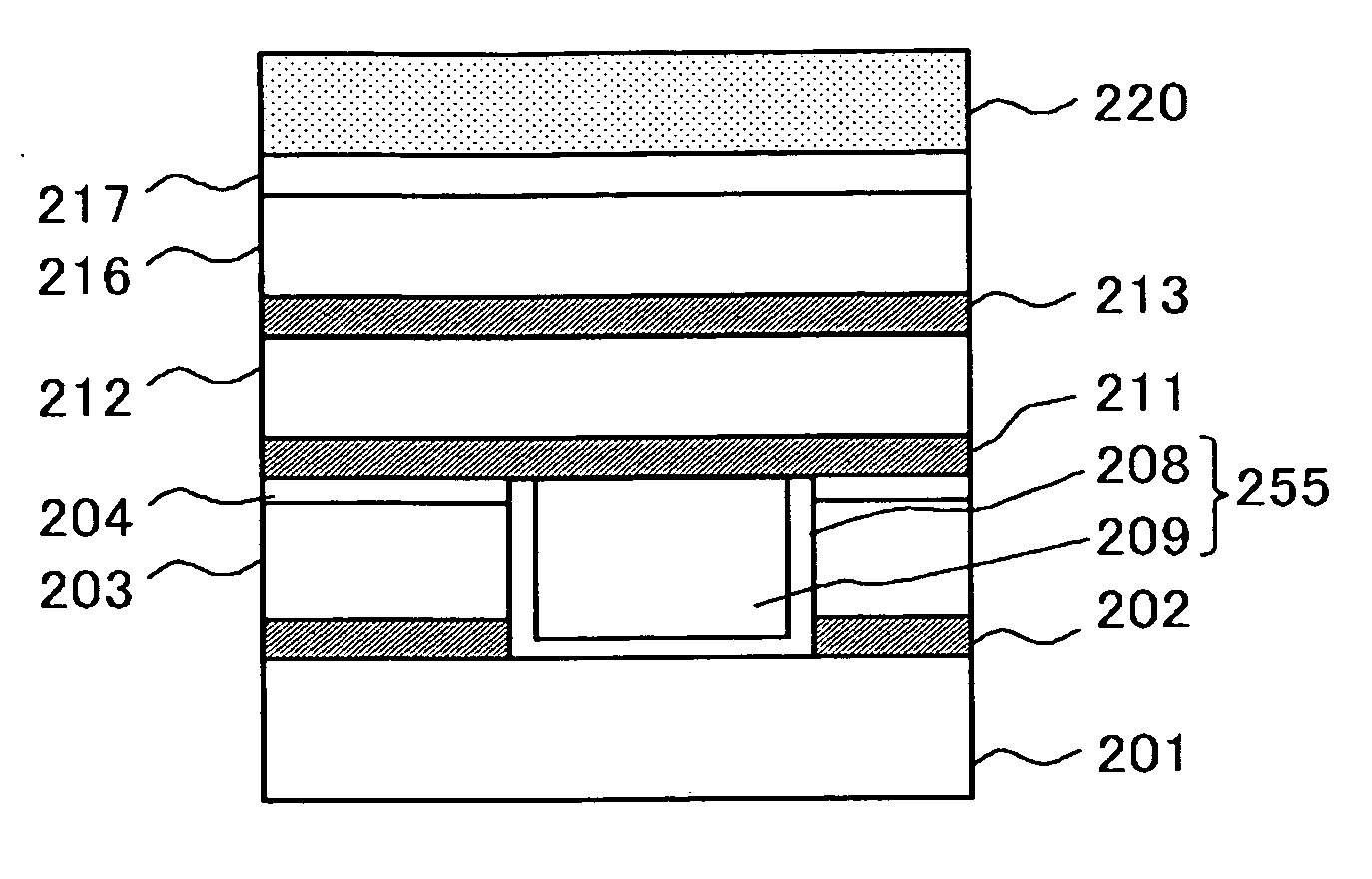

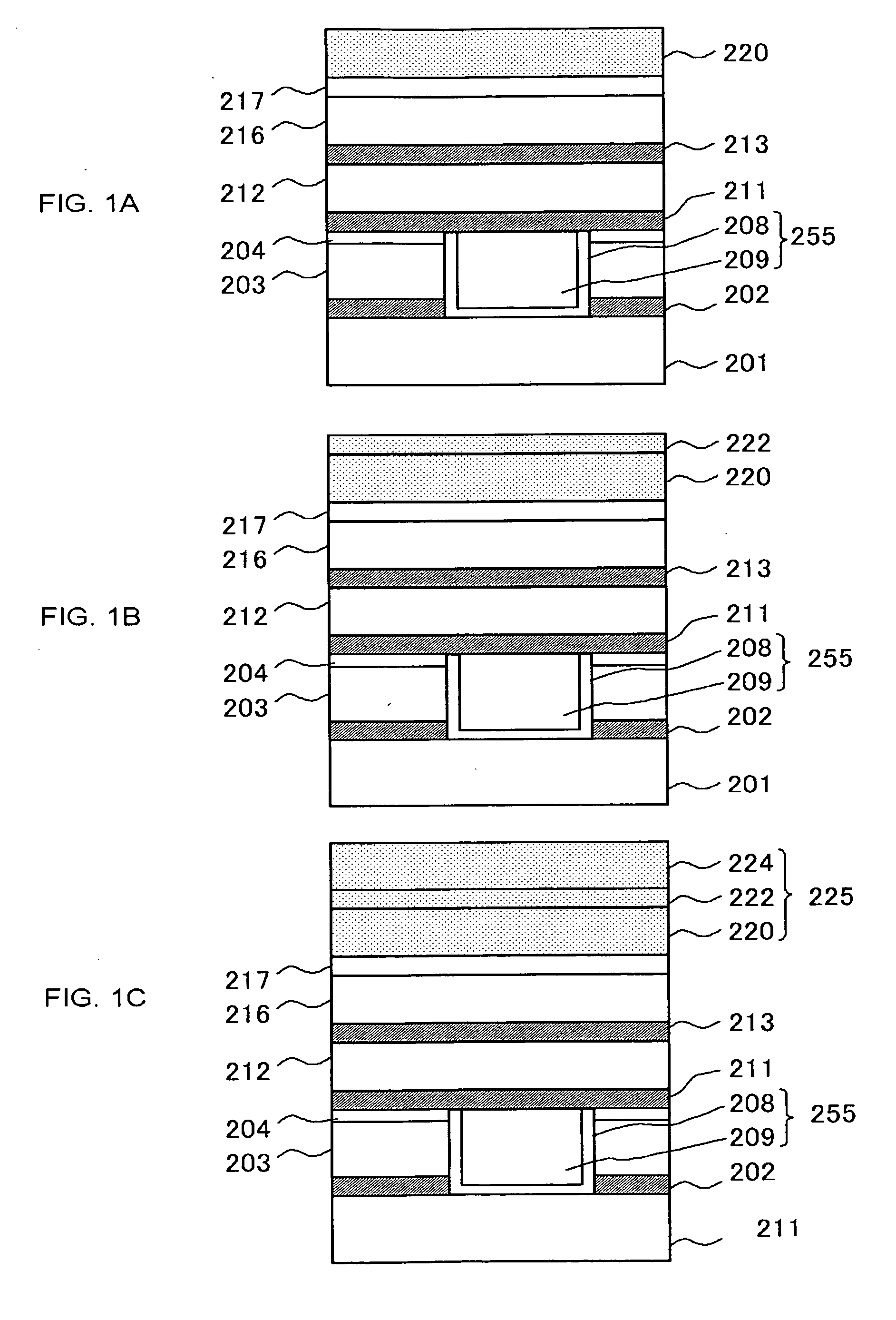

Method of fabricating a semiconductor device

ActiveUS20060216946A1Increasing ash resistancePrevent the intermediate film from degradingSemiconductor/solid-state device manufacturingChemical vapor depositionSemiconductor

An intermediate film 222 in a three-layered resist film 225 is formed by the chemical vapor deposition process at a temperature not higher than 300° C., using Si(OR1)(OR2)(OR3)(OR4) , where each of R1, R2, R3 and R4 independently represents a carbon-containing group or a hydrogen atom, excluding the case where all of R1 to R4 are hydrogen atoms.

Owner:RENESAS ELECTRONICS CORP

Multilayer photoresist systems

ActiveUS7582412B2Excellent etch resistanceUndesired reflectionPhotosensitive materialsRadiation applicationsAnthraceneResist

Multilayer photoresist systems are provided. In particular aspects, the invention relates to underlayer composition for an overcoated photoresist, particularly an overcoated silicon-containing photoresist. Preferred underlayer compositions comprise one or more resins or other components that impart etch-resistant and antireflective properties, such as one or more resins that contain phenyl or other etch-resistant groups and anthracene or other moieties that are effective anti-reflective chromophores for photoresist exposure radiation.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Hardmask composition and associated methods

ActiveUS20080118875A1Excellent etch resistanceGood storage stabilityPhotosensitive materialsSemiconductor/solid-state device manufacturingCopolymerMultiple bonds

A hardmask composition includes a solvent and an organosilicon copolymer. The organosilicon copolymer may be represented by Formula A:(SiO1.5—Y—SiO1.5)x(R3SiO1.5)y (A)wherein x and y may satisfy the following relations: x is about 0.05 to about 0.9, y is about 0.05 to about 0.9, and x+y=1, R3 may be a C1-C12 alkyl group, and Y may be a linking group including a substituted or unsubstituted, linear or branched C1-C20 alkyl group, a C1-C20 group containing a chain that includes an aromatic ring, a heterocyclic ring, a urea group or an isocyanurate group, or a C2-C20 group containing one or more multiple bonds.

Owner:CHEIL IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com