Method for preparing composite coating by adopting multi-stage pack cementation aluminizing in combination with micro-arc oxidation

A technology of micro-arc oxidation and composite coating, which is applied in the direction of coating, superimposed layer plating, surface reaction electrolytic coating, etc. There are reports and other issues to achieve good thermal corrosion resistance, good bonding, and the effect of reducing substrate stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of multi-stage embedded aluminizing combined with composite additive micro-arc oxidation on the surface of niobium alloy includes the following operation steps:

[0031] 1. Pretreatment: The base material is niobium alloy C103, and its chemical composition is: Hf 10.0, Ti 1.30, Zr 0.34, W 0.34, Ta 0.30, C 0.005, N 0.014, O 0.013, Nb balance (wt.%), After polishing step by step, ultrasonically clean with acetone for 12 minutes and blow dry;

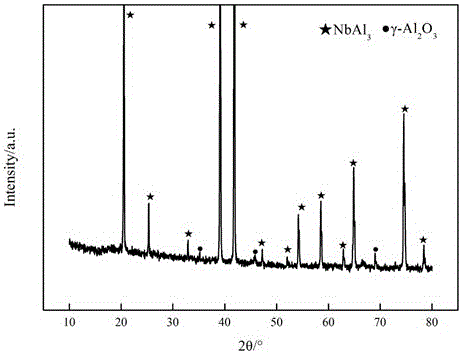

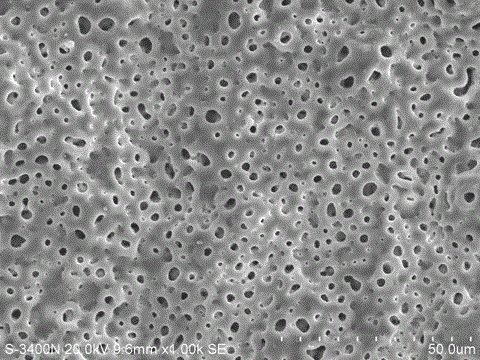

[0032] 2. Multi-stage embedded aluminizing treatment: firstly, the aluminizing agent is prepared according to the following weight percentages: aluminizing agent aluminum powder 10wt%, activator sodium fluoride powder 3wt%, and filler alumina powder 87wt%, and then mixed with a ball mill , Then seal the fully mixed aluminizing agent and the substrate together in a ceramic crucible, and finally place it in a vacuum tube furnace and evacuate to 3.5×10 -2 Pa, at a heating rate of 10°C / min to 120°C for 1 hour, 300°C for ...

Embodiment 2

[0035] 1. Pretreatment: The base material is niobium alloy C103, and its chemical composition is: Hf 10.0, Ti 1.30, Zr 0.34, W 0.34, Ta 0.30, C 0.005, N 0.014, O 0.013, Nb balance (wt.%), After polishing step by step, ultrasonically clean with acetone for 15 minutes and blow dry;

[0036] 2. Multi-stage embedded aluminizing treatment: firstly, the aluminizing agent is prepared according to the following weight percentages: aluminizing agent aluminum powder 11wt%, activator sodium fluoride powder 4wt% and filler alumina powder 85wt%, and then mixed with a ball mill , Then the fully mixed aluminizing agent and the substrate are sealed in a ceramic crucible, and finally placed in a vacuum tube furnace, and evacuated to 1.3×10 -1 Pa, at a heating rate of 10°C / min to 150°C for 1 hour, 350°C for 2 hours, 940°C for 4 hours, and then at a cooling rate of 10°C / min to 400°C and then cooled to room temperature with the furnace to obtain NbAl 3 Aluminized niobium alloy for aluminized layer;

...

Embodiment 3

[0039] 1. Pretreatment: The base material is niobium alloy C103, and its chemical composition is: Hf 10.0, Ti 1.30, Zr 0.34, W 0.34, Ta 0.30, C 0.005, N 0.014, O 0.013, Nb balance (wt.%), After polishing step by step, ultrasonically clean with acetone for 15 minutes and blow dry;

[0040] 2. Multi-stage embedded aluminizing treatment: firstly, the aluminizing agent is prepared according to the following weight percentages: 9wt% of aluminizing agent aluminum powder, 2wt% of activator sodium fluoride powder and 89wt% of filler alumina powder, and then mixing with a ball mill , Then the fully mixed aluminizing agent and the base material are sealed together in a ceramic crucible, and finally placed in a vacuum tube furnace, evacuated to 4.0Pa, and heated to 120°C at a temperature increase rate of 10°C / min and held for 1h, 300°C Insulate for 2h, 940℃ for 3h, then at a cooling rate of 10℃ / min to 400℃, then cool to room temperature with the furnace to obtain NbAl 3 Aluminized niobium a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com