High-temperature oxidation resistant and corrosion resistant glass ceramic composite coating and preparation technology thereof

A high-temperature oxidation-resistant, glass-ceramic technology, applied in the field of inorganic high-temperature protective coatings, can solve the problem of glass composition for a long time, and achieve the effects of good resistance to constant temperature oxidation, good thermal expansion coefficient, and good resistance to cyclic oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

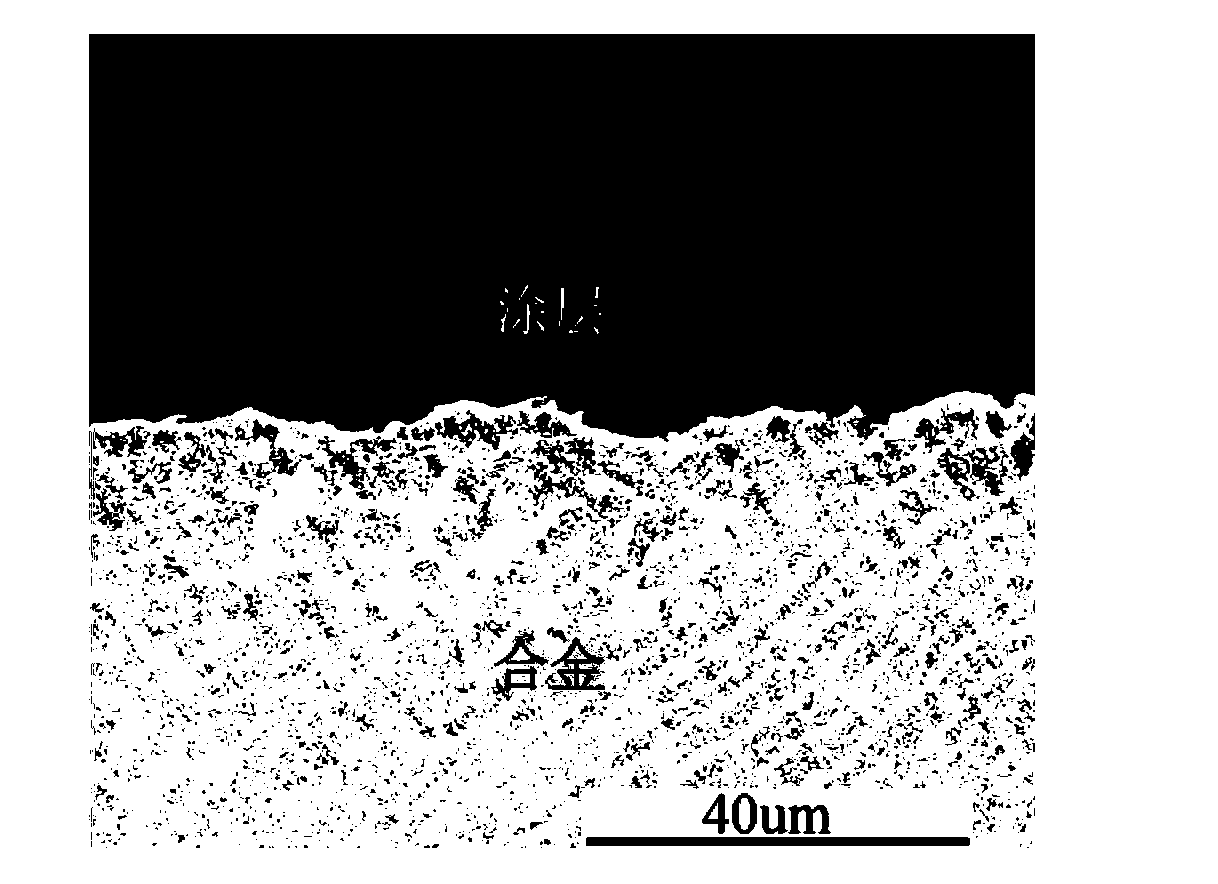

Embodiment 1

[0055] Weigh 200g of potassium silicate water glass with a modulus of 3.9, 20g of alumina powder with a particle size of 1-10μm, 60g of quartz powder with a particle size of 1-10μm, and nano-titanium / titanium oxide mixed powder with a peak particle size of 50nm Powder 8g (in this example, the weight ratio of titanium:titanium oxide is 0.2), pre-mix alumina, quartz, nano-titanium / titanium oxide powder, then add the pre-mixed powder to water glass, and add 10g of distilled water to adjust the coating Viscosity makes the paint suitable for spraying after stirring. During the stirring process, ceramic stirring balls with a particle size of 1 mm were added to increase the stirring and dispersing effect. After stirring for 20 minutes at a speed of 2000 rpm in the stirring disperser, the coating was obtained after filtering through a 300-mesh sieve. The paint is sprayed onto the surface of the sandblasted Ti-47Al-2Cr-2Nb alloy parts by spraying. After the sprayed coating is cured at ...

Embodiment 2

[0058] Weigh 100g of potassium silicate water glass with a modulus of 3.9, 10g of alumina powder with a particle size of 1-10μm, 30g of quartz powder with a particle size of 1-10μm, and nano-titanium / titanium oxide mixed powder with a peak particle size of 50nm Powder 4g (in this example, the weight ratio of titanium: titanium oxide is 0.2), pre-mixed alumina powder, quartz powder, nano-titanium / titanium oxide powder, then added the pre-mixed powder to water glass, and added 4g of distilled water Adjust the paint viscosity to make the paint suitable for spraying after stirring. During the stirring process, ceramic stirring balls with a particle size of 1 mm were added to increase the stirring and dispersing effect. After stirring for 20 minutes at a speed of 1500 rpm in the stirring disperser, the coating was obtained after filtering through a 300-mesh sieve. The paint is sprayed onto the surface of the sandblasted Ti-47Al-2Cr-2Nb alloy parts by spraying. After the sprayed coa...

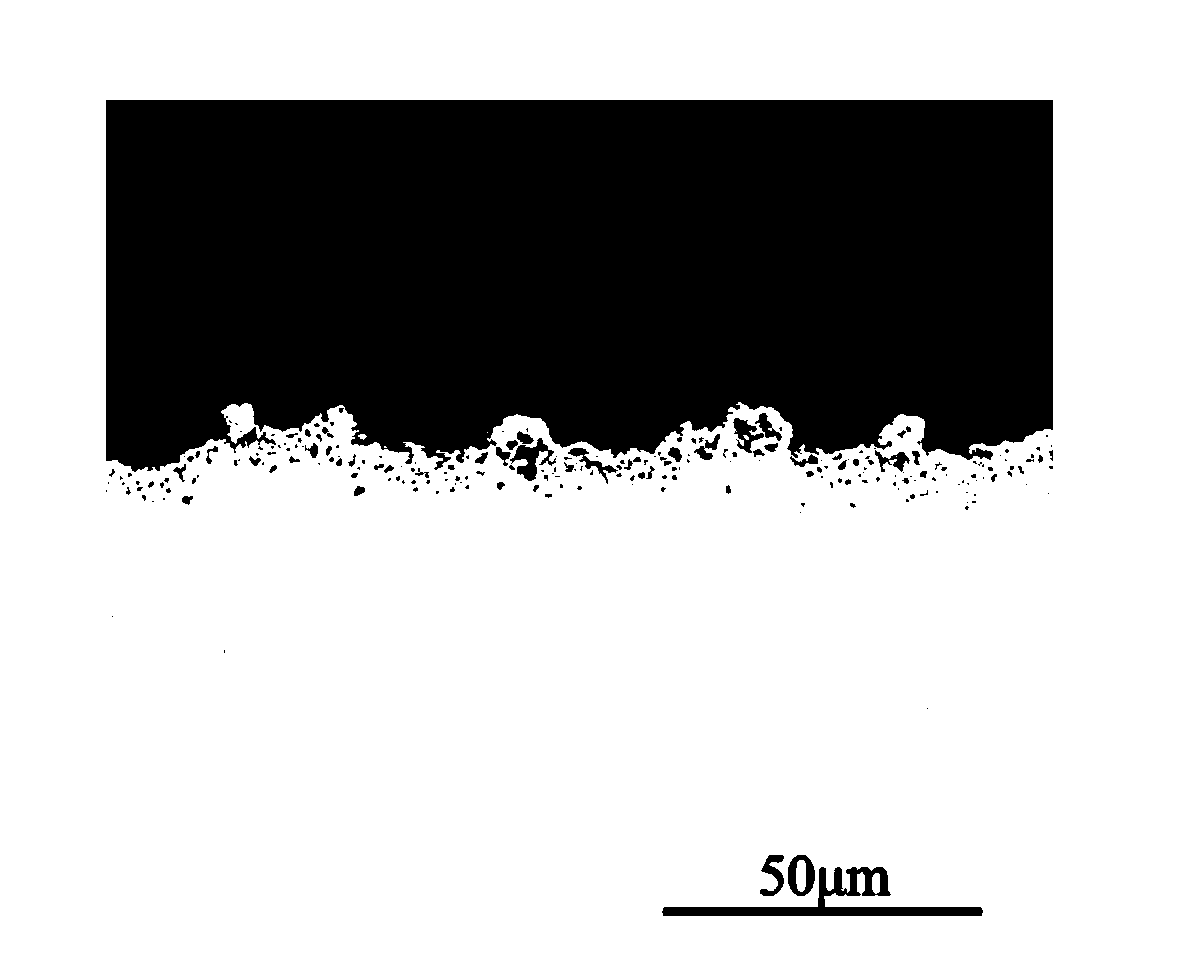

Embodiment 3

[0062] Weigh 150g of potassium silicate water glass with a modulus of 3, 15g of alumina powder with a particle size of 1-10μm, 45g of quartz powder with a particle size of 1-10μm, and nano-titanium / titanium oxide mixed powder with a peak particle size of 70nm Powder 4g (in this example, the weight ratio of titanium: titanium oxide is 0.5), pre-mixed alumina powder, quartz powder, nano-titanium / titanium oxide powder, then added the pre-mixed powder to water glass, and added 5g of distilled water Adjust the paint viscosity to make the paint suitable for spraying after stirring. Add zirconia balls with a particle size of 1 mm to increase the dispersion effect during stirring and dispersing. After stirring for 20 minutes at a speed of 1500 rpm in a stirring dispersing machine, the coating is obtained after filtering through a 200-mesh sieve. The paint is sprayed onto the surface of the sandblasted Ti-6Al-4V alloy parts by spraying. After the sprayed coating is cured at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com