Packaging body for film roll

A film roll and package technology, which can be used in packaging, transportation and packaging, household refrigeration devices, etc., can solve problems such as film roll wrinkles, and achieve the effect of reducing chain defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, one embodiment of the present invention will be described based on the drawings. In addition, in this specification, when expressing a numerical range as A-B, it considers that the numerical range includes the value of the lower limit A and the upper limit B.

[0033] 〔The composition of the package body of the film roll〕

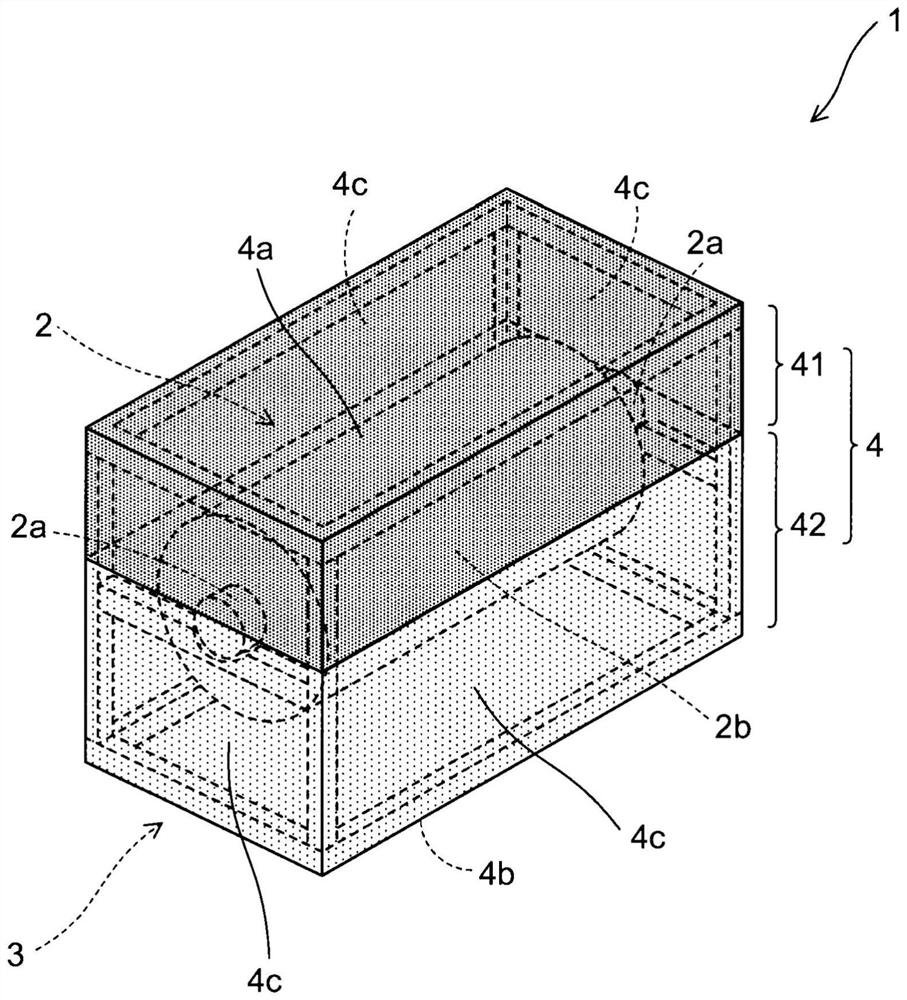

[0034] figure 1 It is a perspective view which shows the schematic structure of the package body (it abbreviates simply as a package body hereafter) 1 of the film roll of this embodiment. The package body 1 includes a film roll 2 , a holder 3 , and a cover member 4 . It should be noted that, in figure 1 In , the covering member 4 is hatched for the purpose of clarifying the covering member 4 (hatching is also indicated in other drawings as necessary).

[0035] figure 2 It is a perspective view showing the film roll 2 and the holder 3 before packaging with the covering member 4, image 3 It is a perspective view showing the appea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com