Bearing structural element, supporting base, connector assembly and pipe joint assembly

A technology for bearing structures and structural parts, applied in the directions of rigid brackets, pipes/pipe joints/pipes, connecting components, etc. of bearing components, which can solve the problem that the maximum load of the bottom support structure cannot be provided and the maximum design threshold is the design threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

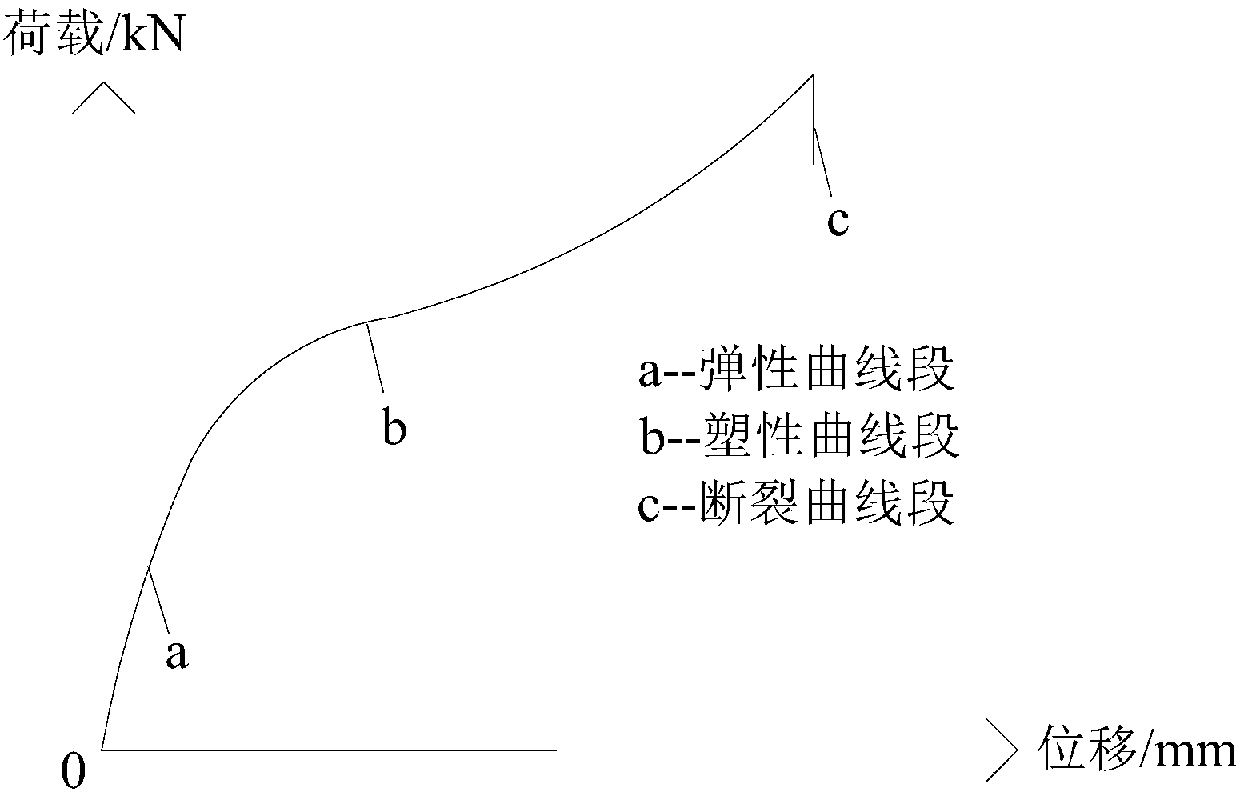

[0122] This embodiment provides a method for designing a load-bearing structural member 1. The maximum reaction force provided by the load-bearing structure 1 under an external load is its own design threshold, that is, when the external load is greater than the design of the load-bearing structural member 1. When the threshold value is reached, the load-bearing structural member 1 deforms, and at the same time, a reaction force of the design threshold value is provided. The relationship between the magnitude of the reaction load and the deformation displacement change of the load-bearing structure 1 is as follows figure 2 The shape of the middle curve c.

[0123] The load-bearing structure 1 of the present invention is an existing material structure. The design threshold refers to the maximum reaction force that the load-bearing structure 1 can provide during the deformation process when the load-bearing structure 1 is subjected to an external load. The force refers to the react...

Embodiment 2

[0133] Such as Figure 2-3 As shown, a load-bearing structural member 1, the maximum reaction force provided by the load-bearing structural member 1 under an external load is its own design threshold, that is, when the external load is less than or equal to the design threshold of the load-bearing structure 1, The load-bearing structure 1 undergoes elastic deformation or / and plastic deformation, and provides a reaction force not greater than the external load; when the external load is greater than the design threshold of the load-bearing structure 1, the load-bearing structure 1 deforms and provides a design Threshold magnitude reaction force.

[0134] The load-bearing structure 1 of the present invention is an existing material structure. The design threshold refers to the maximum reaction force that can be provided in a stable state or deformed when the load-bearing structure 1 is subjected to an external load. The reaction force refers to the reaction force provided by the lo...

Embodiment 3

[0147] This embodiment relates to the selection and testing of metal materials that meet the performance requirements of the load-bearing structure 1.

[0148] 1. Primary selection of materials:

[0149] The selection of the load-bearing structure 1 (referred to as the metal pressure-bearing column in this embodiment) needs to meet two basic conditions:

[0150] 1) The hardness is lower than steel and can be sheared by porous steel plate;

[0151] 2) Have sufficient corrosion resistance in the use environment;

[0152] Comprehensively considering the design requirements for the load and deformation of the shear key cushion and the operating environment in which the shear key cushion is working, the preliminary selected test materials for the shear key metal pressure column include copper, tin bronze, and yellow. The main mechanical properties of copper and zinc, the metal materials used in the test are shown in the following table:

[0153] Table 1 The main mechanical properties of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com