Automobile wheel

A technology for wheels and automobiles, applied in the direction of wheels, web-type wheels, rims, etc., can solve the problems of increased wheel vibration, achieve the effect of suppressing vibration and improving operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

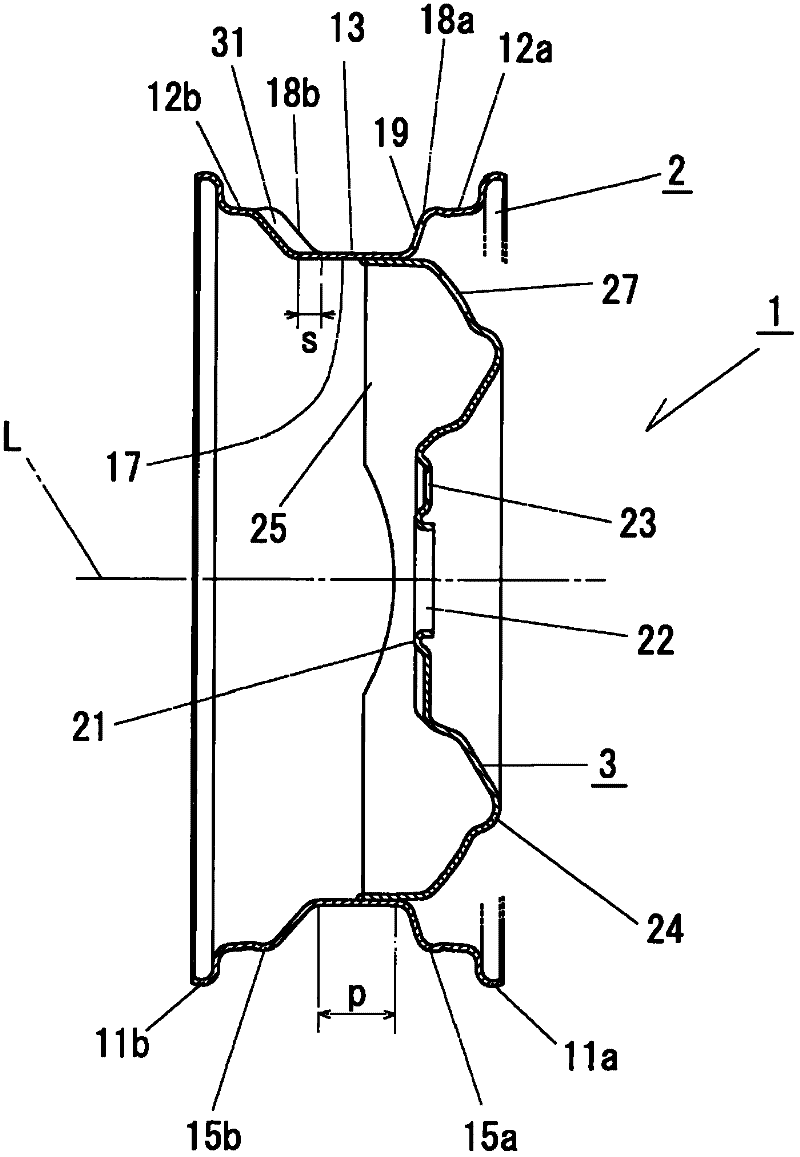

[0037] figure 1 is a longitudinal sectional view showing the automobile wheel 1 of the first embodiment, figure 2 It is a side view. In this automobile wheel 1, the spoke flange portion 25 of the spoke 3 is embedded in the well portion 13 of the rim 2, and the corner weld of the well portion 13 and the spoke flange portion 25 is integrated into a so-called well fitting. Combined structure. Furthermore, the rim 2 and the spokes 3 are formed by forming a steel flat plate, respectively, and the automobile wheel 1 of the first embodiment is a steel wheel with a two-piece structure.

[0038] In addition, in this embodiment, the direction from the back side of the spoke 3 to the design surface side is the front side, and the opposite direction is the back side. In addition, the direction along the wheel radial direction perpendicular to the central axis L of the automobile wheel 1 toward the central axis L is referred to as the inward direction, and the opposite direction is re...

Embodiment 2

[0061] In Example 2, compared with the structure of the above-mentioned Example 1, it is the vehicle wheel 1 of the structure with a narrower rim width. Specifically, it is an automobile wheel 1 of a 13×3.50B type (or a 13×31 / 2J type). In addition, the automobile wheel 1 of the second embodiment has the same configuration as that of the first embodiment except for the rim 2 having a narrow rim width, so the same reference numerals are used for the respective components, and the description thereof is omitted.

[0062] The rim 2 of the second embodiment has a rim width of 3.5 inches, and the width p of the well bottom 17 of the well portion 13 in the front and rear directions is about 22 mm. In addition, the valve 100 with an air pressure detection device has the same structure as that of the above-mentioned first embodiment, and adopts the same dimensions.

[0063] The rim 2 of this embodiment 2, such as Figure 5 , 6 As shown, the well recessed portion 13 provided in the b...

Embodiment 3

[0067] In the automobile wheel 51 of the third embodiment, such as Figures 7 to 9 As shown, it is configured such that a well recessed portion 61 is formed on the front side well wall portion 58 a of the rim 52 . Here, the rim 52 has the same structure as that of the first embodiment except that the well-well portion 58a of the well-well portion 53 is provided with the well-well recessed portion 61 on the front side, so the same components are denoted by the same reference numerals. Its description is omitted. In addition, the spoke 3 has the same structure as that of the above-described first embodiment, and the same components are denoted by the same reference numerals, and the description thereof will be omitted.

[0068] In the above-described rim 52 , the well recessed portion 61 is formed in a portion of the front side well wall portion 58 a of the well portion 53 where the valve hole 59 is formed so as to be recessed toward the front. In addition, the well recessed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com