Support, electronic device, and method for manufacturing the same

一种电子设备、制造方法的技术,应用在电气设备外壳/柜子/抽屉、电气元件、电数字数据处理等方向,能够解决橡胶垫脚剥落、橡胶垫脚与框架底面粘接减弱、橡胶垫脚作业繁杂等问题,达到易于安装、不易脱落的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

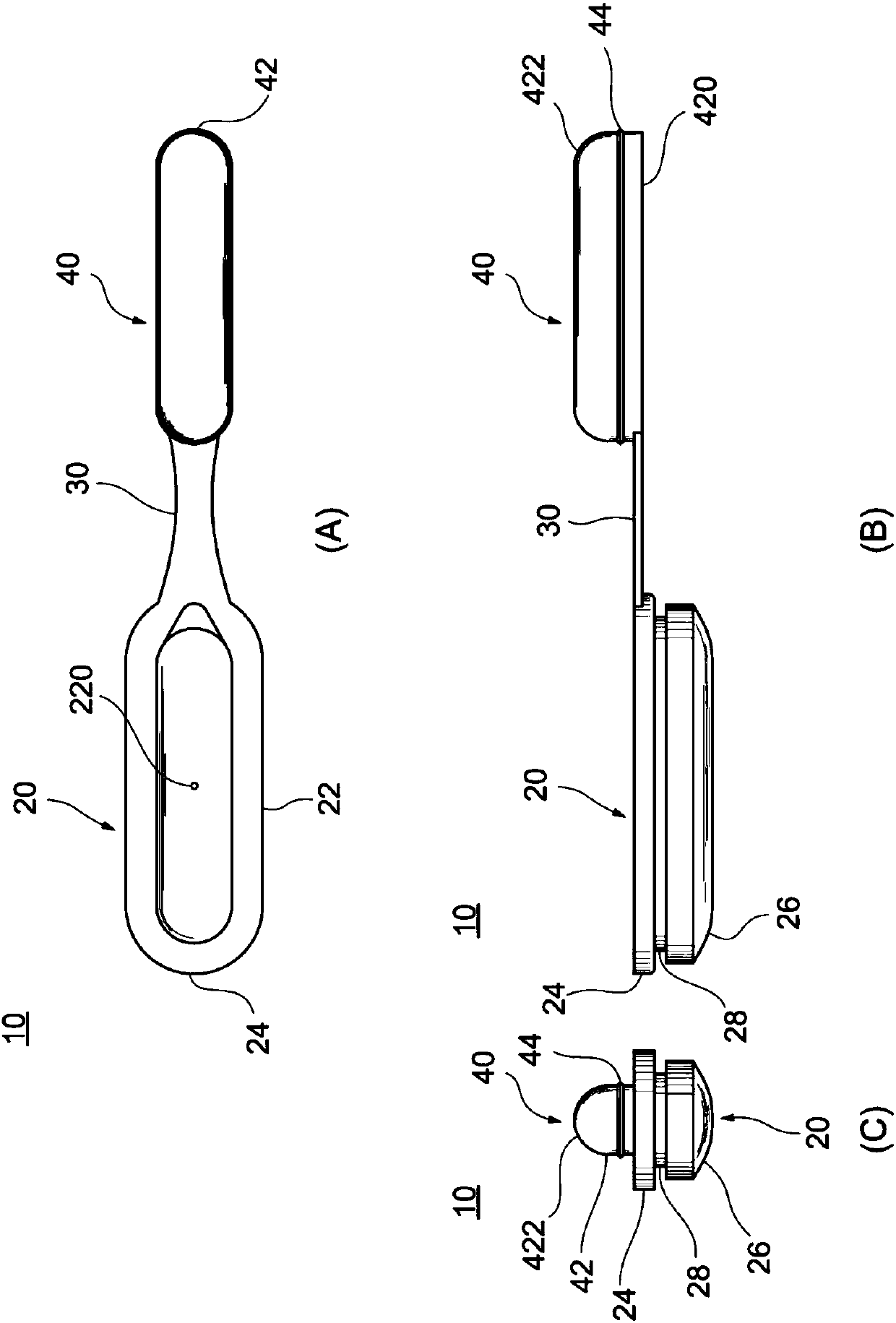

[0027] Such as figure 1 As shown, the notebook computer 1 has a main body 2 and a cover body 3 , wherein the cover body 3 is hinged to the rear end of the main body 2 and can be opened and closed relative to the main body 2 . On the surface of the cover body 3 facing the main body 2, for example, a liquid crystal display 4 displaying various information is provided.

[0028] The main body 2 has a flat box-like frame 5 . The frame 5 is constituted by attaching the upper surface cover 6 and the bottom surface cover 7 to face each other. A substrate, CPU, memory, HDD, SDD, battery, and the like (hereinafter, also referred to as “internal components such as a substrate”) are accommodated inside the frame 5 . Input mechanisms such as a keyboard 8 and a touch panel 9 are provided on the upper cover 6 side of the frame 5 .

[0029] Such as figure 2 As shown, supports 100 , 102 , 104 , and 106 (hereinafter collectively referred to as “supports 10 ”) are respectively attached to t...

no. 2 approach

[0057] Next, use Figure 7 and Figure 8 10 A of support bodies concerning 2nd Embodiment of this invention are demonstrated. The support body 10A differs from the support body 10 of the first embodiment in that the concave portion of the first member and the convex portion of the second member have different shapes. The rest of the structure of the support body 10A is substantially the same as the structure of the support body 10 , and hereinafter, the same reference numerals and names are assigned and descriptions thereof are omitted.

[0058] Such as Figure 7 As shown, the shape of the second member 40A of the support body 10A is different from that of the concave portion 22 of the first member 20, and the upper surface 422A of the convex portion 42A is in a shape that is concave toward the inner side of the center except for both ends in the longitudinal direction (as opposed to this, in the In the support body 10 of the first embodiment, as image 3 As shown, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com