Wheel bearing and semi-floating type wheel bearing device having the same

A wheel and bearing technology, applied to the rigid brackets, axles, wheels and other directions of bearing components, can solve the limitations of lightweight and miniaturization, troublesome assembly, and a large number of parts, etc., to achieve lightweight and miniaturization, Easy assembly and high rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

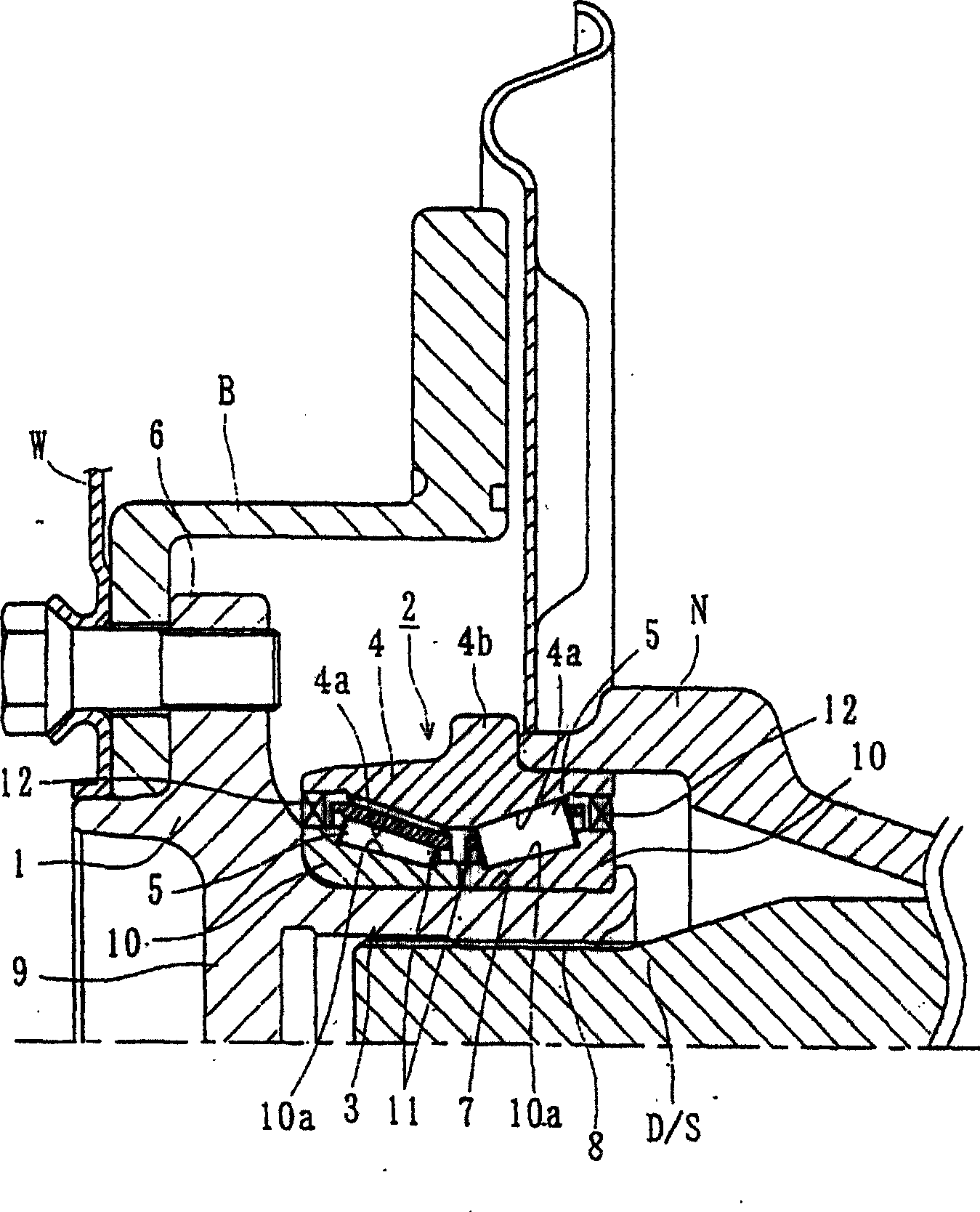

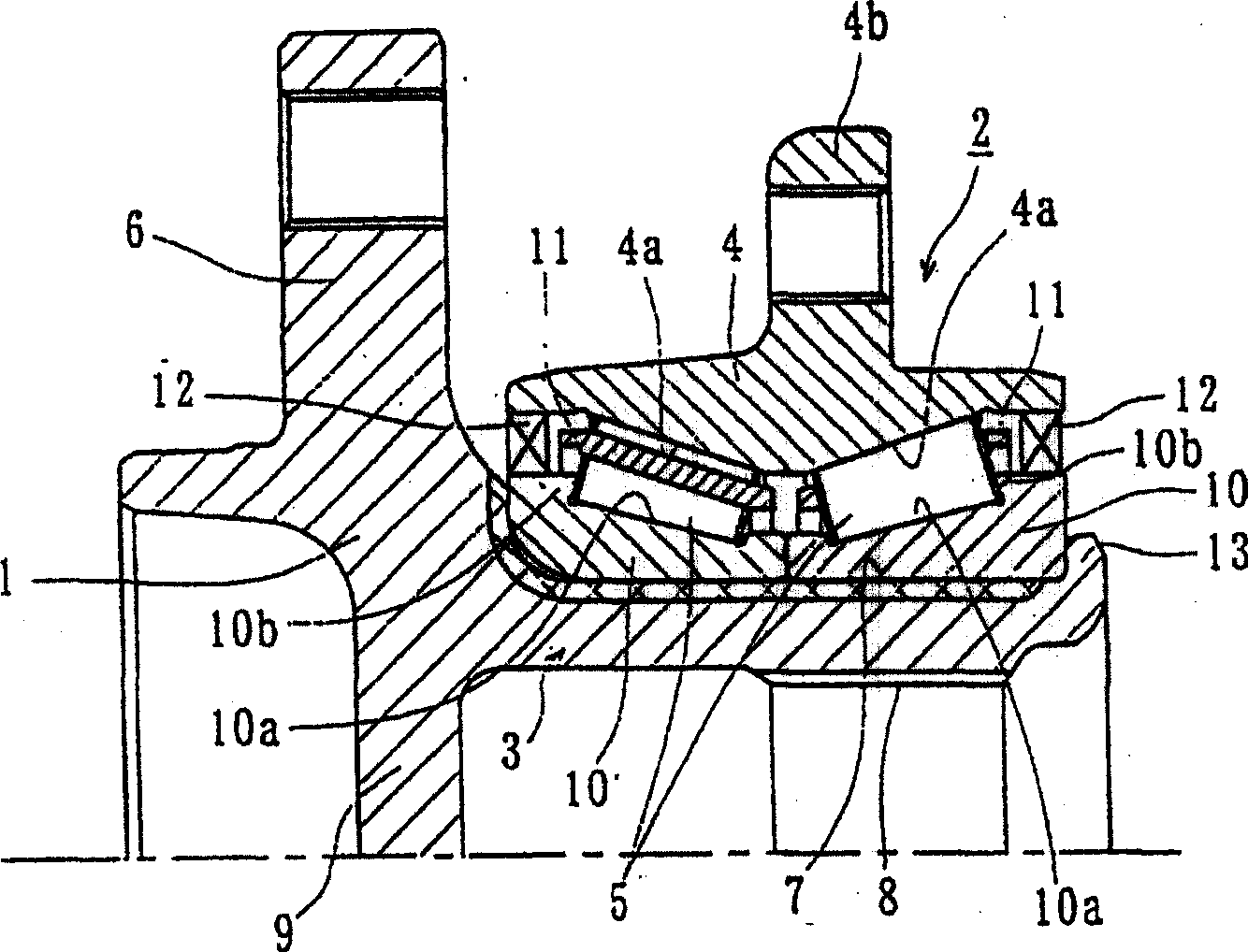

[0065] figure 1 Is a longitudinal sectional view showing the first embodiment of the wheel bearing device of the present invention, figure 2 It is a longitudinal cross-sectional view showing the bearing for the wheel. In addition, in the following description, when mounted on a vehicle, the side closer to the outside of the vehicle is called the outer side (left side of the drawing), and the side closer to the center is called the inner side of the vehicle (right side of the drawing) .

[0066] This wheel bearing device is composed of a hub ring 1 and a multi-row rolling bearing 2 as a unit, and is connected to a drive shaft D / S. The multi-row rolling bearing 2 includes an inner member 3, an outer member 4, and multiple rows of rolling elements (tapered rollers) 5, 5 housed between the two members 3, 4 to roll freely. Here, the inner member 3 refers to the hub ring 1 an...

Embodiment 2

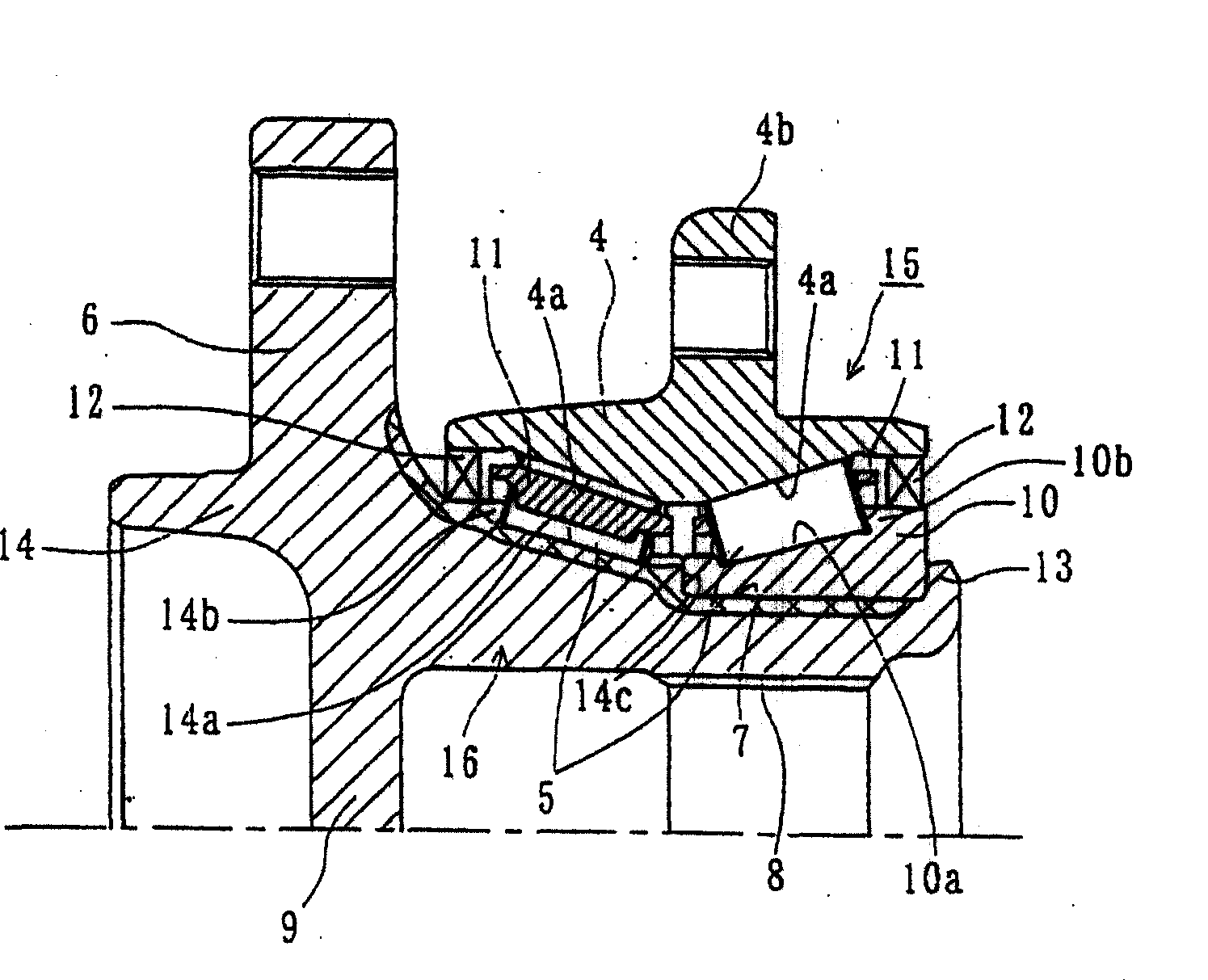

[0073] image 3 It is a longitudinal cross-sectional view showing the second embodiment of the wheel bearing device of the present invention. In this embodiment, only the structure of the hub wheel is different from the above-mentioned embodiment. Therefore, the same components and parts as in the above-mentioned first embodiment are given the same reference numerals, and detailed descriptions thereof are omitted.

[0074] This wheel bearing is formed by unitizing the hub ring 14 and the multi-row rolling bearing 15. The multi-row rolling bearing 15 has an inner member 16, an outer member 4, and a plurality of rows of rolling elements 5, 5 housed between the two members 16, 4 to roll freely. Here, the inner member 16 refers to the hub ring 14 and the inner ring 10 pressed into the hub ring 14. The hub ring 14 has a wheel mounting flange 6 integrated therewith. The wheel mounting flange 6 is used to mount a wheel (not shown) on the outer peripheral end of the vehicle. The hub ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com