Winching device

A winch and equipment technology, applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as electrical and electronic component failures, and achieve simple and reliable mechanical synchronization without torque surges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

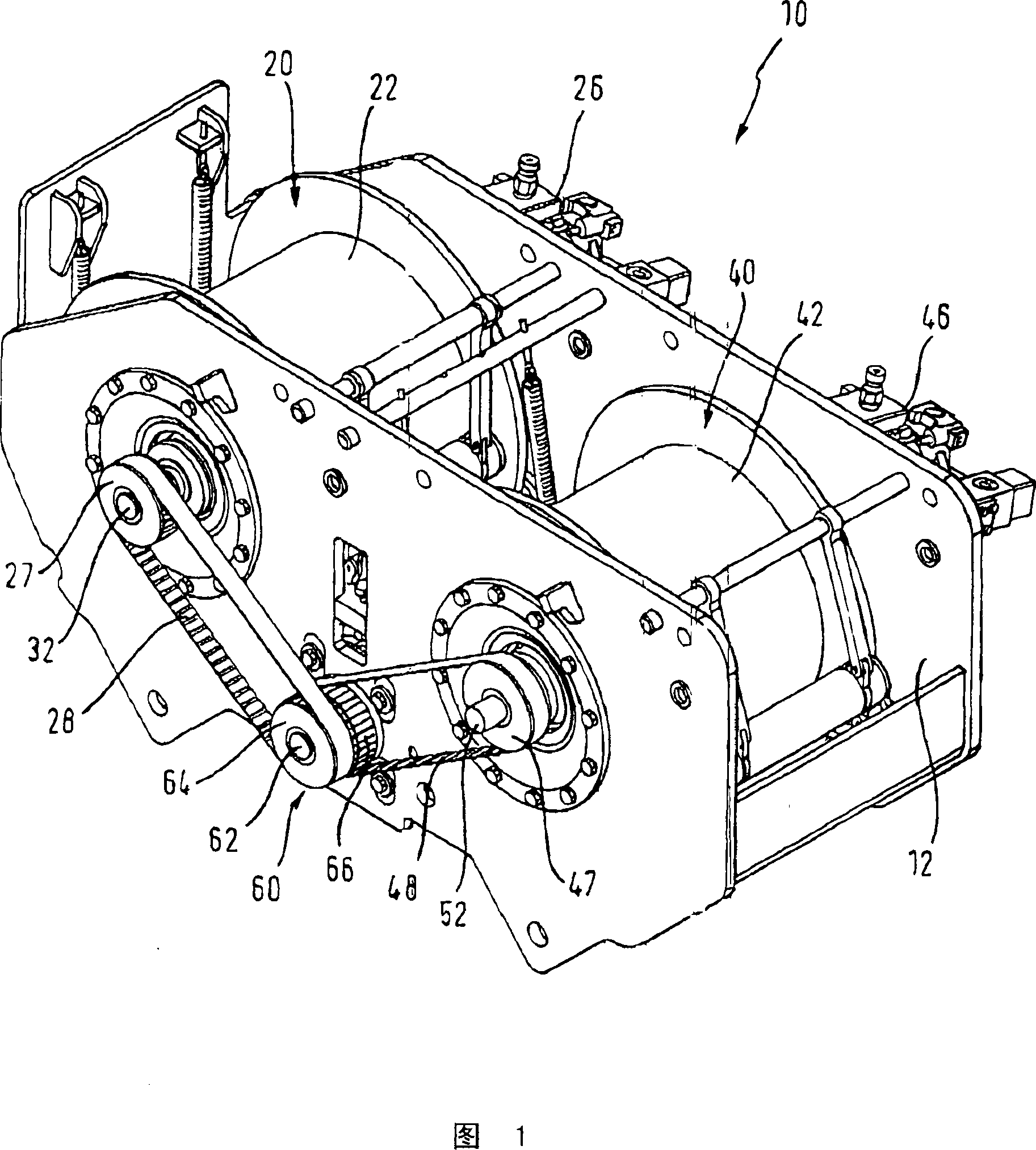

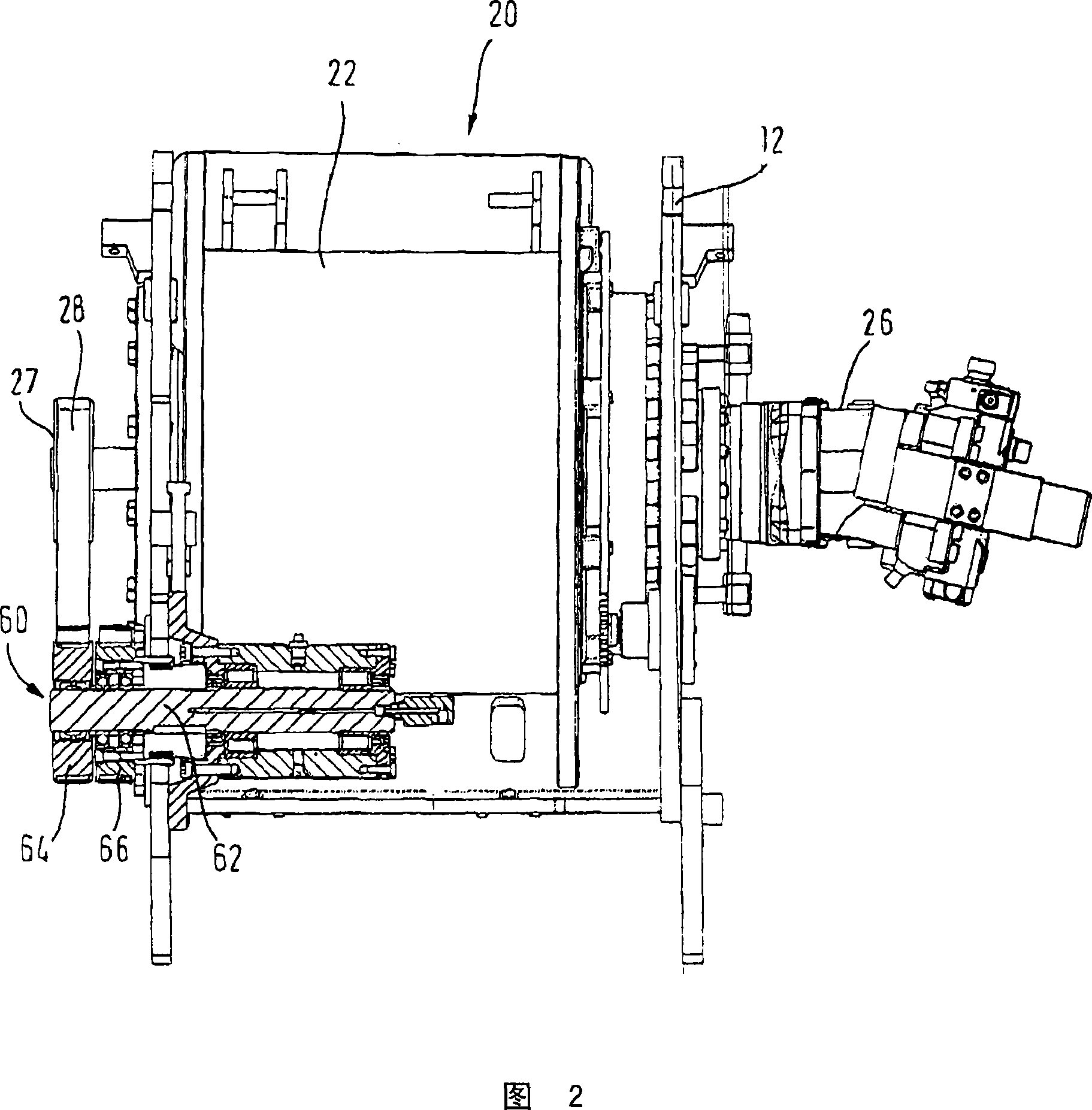

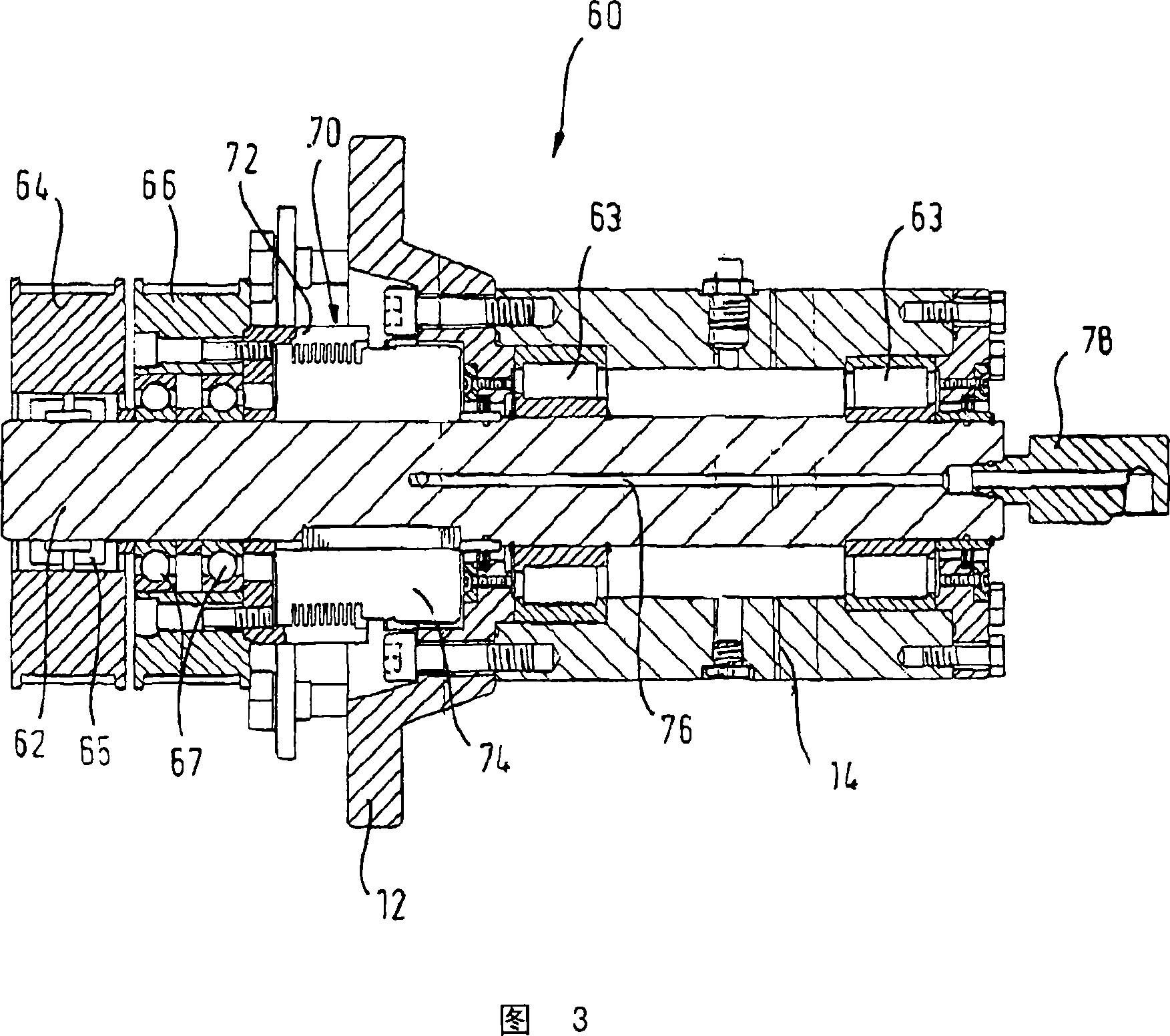

[0024] According to Figures 1 and 2, the winch device 10 of the present invention has a box-shaped, open-top housing 12 in which a first winch 20 and a second winch 40 are positioned in a parallel, side-by-side manner, a first winch drum 22 and a second winch drum Cartridge 42 is pivotally mounted in housing 12 . A synchronization device 60 with a differential shaft 62 is positioned intermediate the two capstans 20 , 40 . The first synchronous wheel 64 and the second synchronous wheel 66 are located on a differential shaft 62 protruding from one side of the housing 12 .

[0025] A first synchronous wheel 64 connected for rotation with the differential shaft 62 is connected in rotation with the first drive wheel 27 through a belt-shaped, toothed drive belt 28 . The first drive wheel 27 is connected for rotation on an extension shaft 32 driven by the first hydraulic drive 26 of the first winch 20 . In the same way, the second extension shaft 52 of the second winch 40 is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com