Pitching transferring integrated waist structure of human-like robot

A robot and humanoid technology, applied in the field of robotics, can solve the problems that the pitch angle range cannot be compared with the range of motion of the human waist, and the control difficulty of humanoid robots, etc., and achieve the effect of large reduction ratio, small size, and improved driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

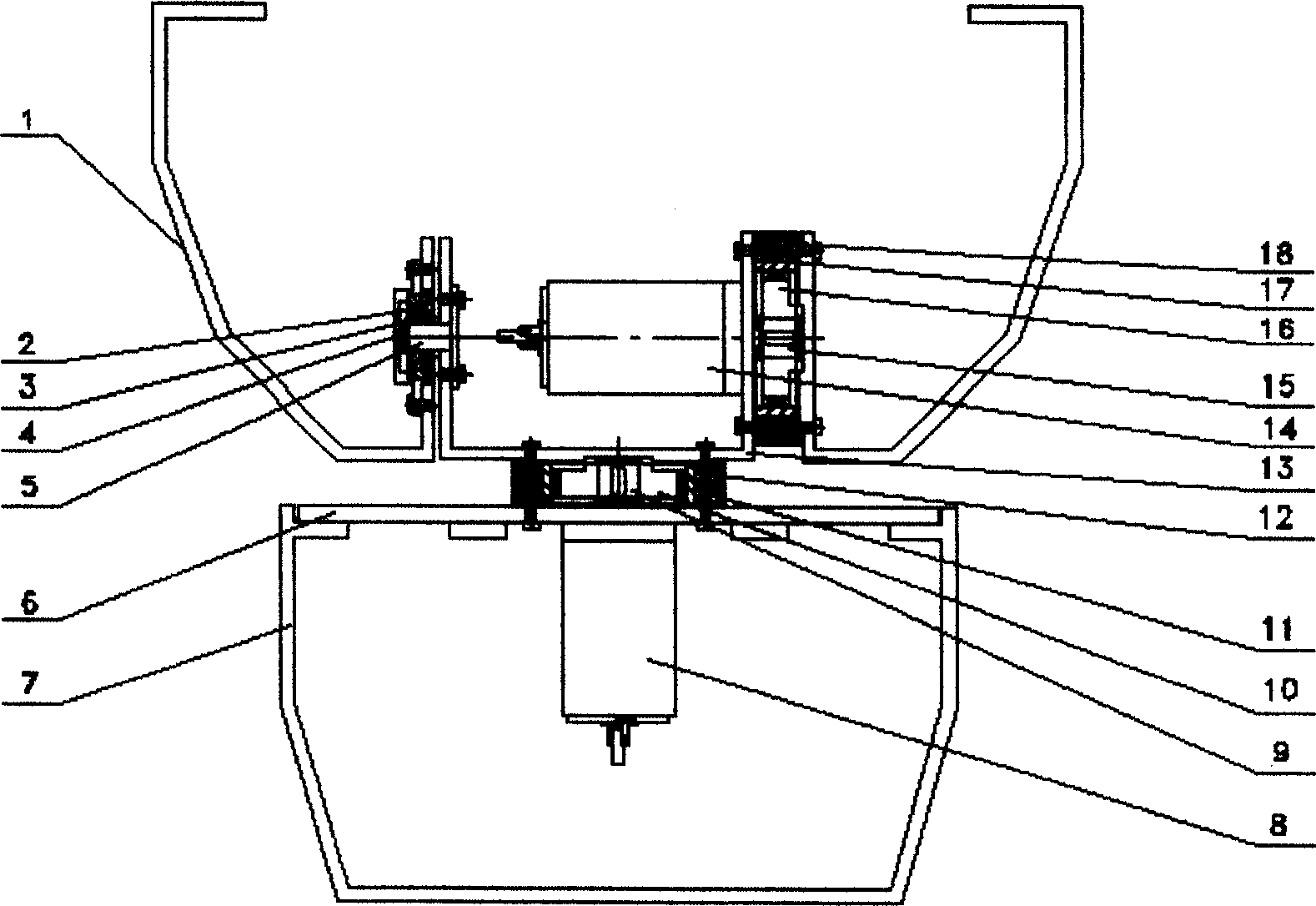

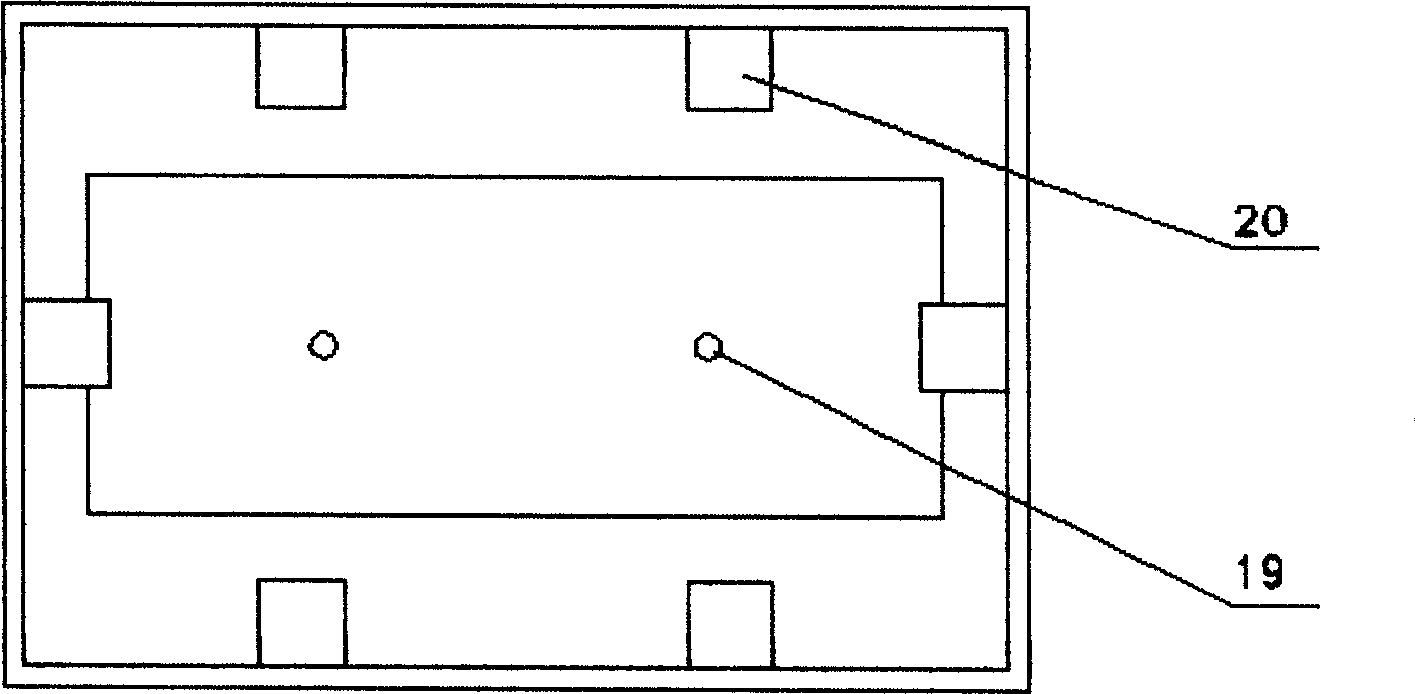

[0010] Such as figure 1 with figure 2 As shown, the present invention includes: chest plate 1, angular contact ball bearing 2, snap ring 3, end cover 4, end cover shaft 5, abdominal cavity cover plate 6, abdominal cavity plate 7, relay drive motor 8, first harmonic reducer 9 (including the input shaft sleeve 10 of the first harmonic reducer, the static rigid wheel 11 of the first harmonic reducer, the dynamic rigid wheel 12 of the first harmonic reducer), the abdominal plate 13, the pitch drive motor 14, the second harmonic Reducer 15 (comprising second harmonic reducer input shaft sleeve 16, second harmonic reducer static wheel 17, second harmonic reducer dynamic wheel 18).

[0011] The angular contact ball bearing 2 is arranged in the end cover 4, and is axially fixed with the end cover shaft 5 through the snap ring 3, and the left part of the chest cavity plate 1 is connected with the left part of the connecting plate 13 by the end cover shaft 5; the second harmonic decel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com