Silicon steel plate for motor stator

A motor stator and silicon steel sheet technology, applied in the field of motor parts, can solve the problems of increasing the size of the silicon steel sheet 9, increasing the difficulty of winding the coil C, and reducing the gap, so as to improve the motor driving torque, shorten the development time and The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

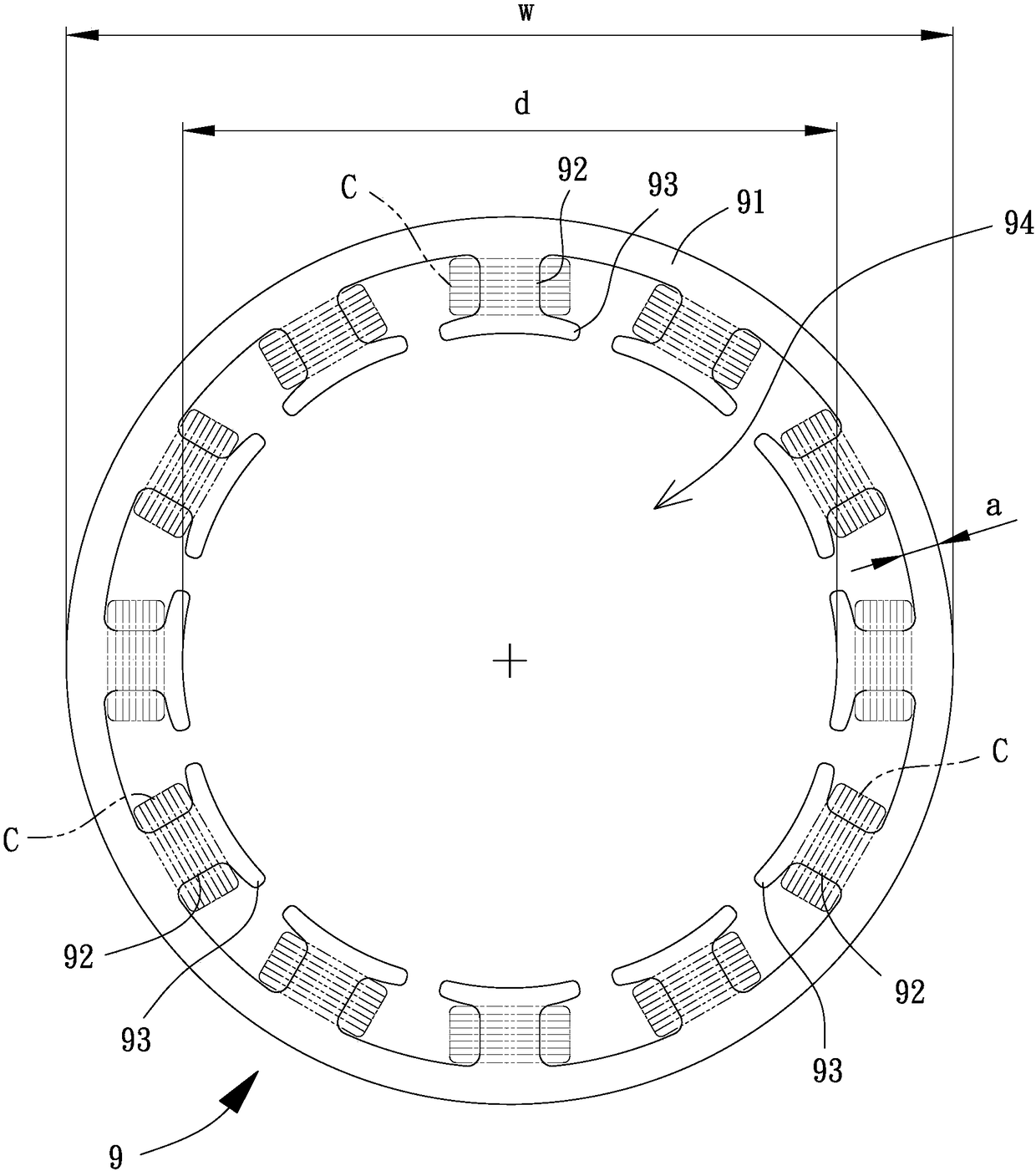

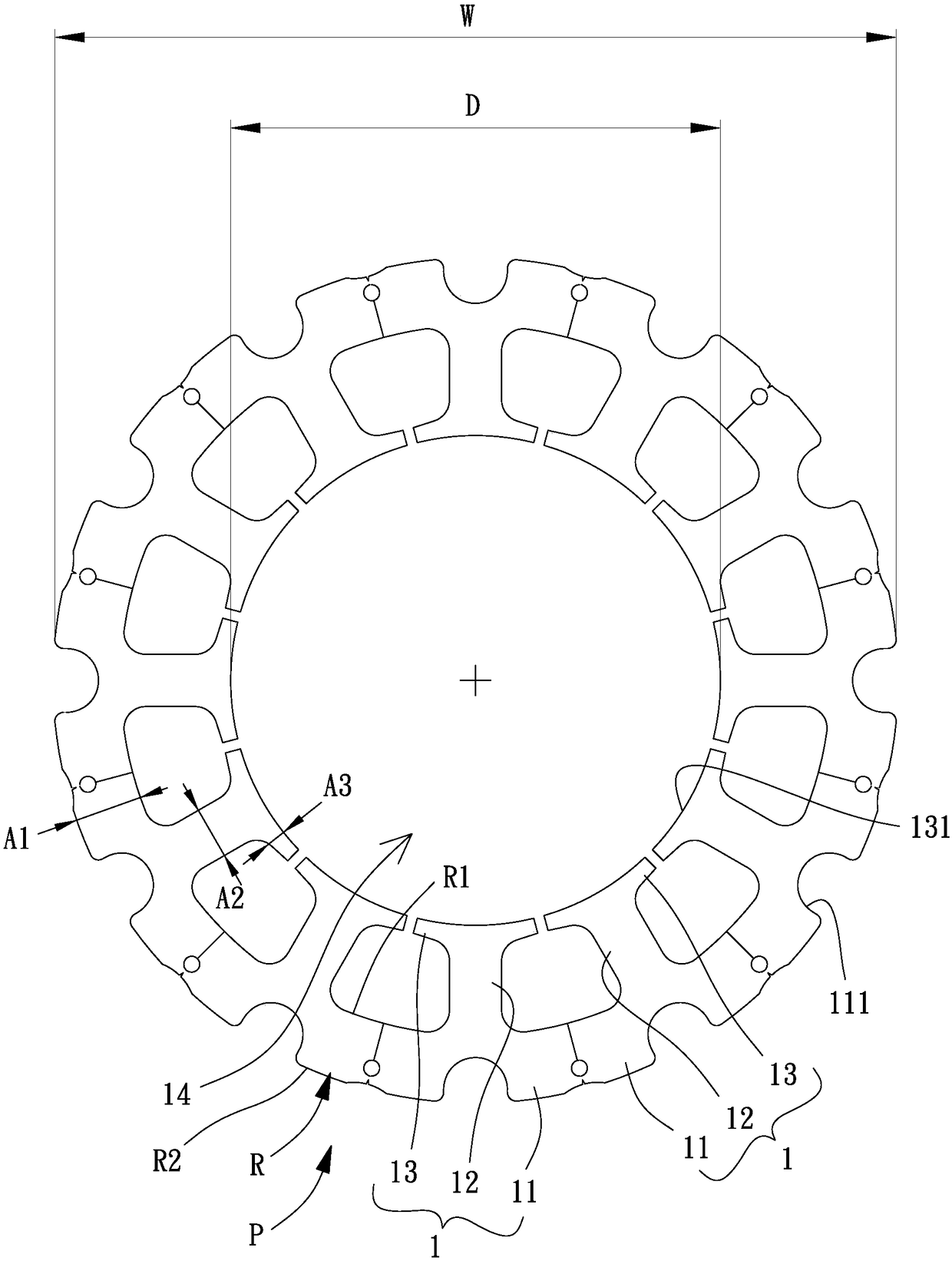

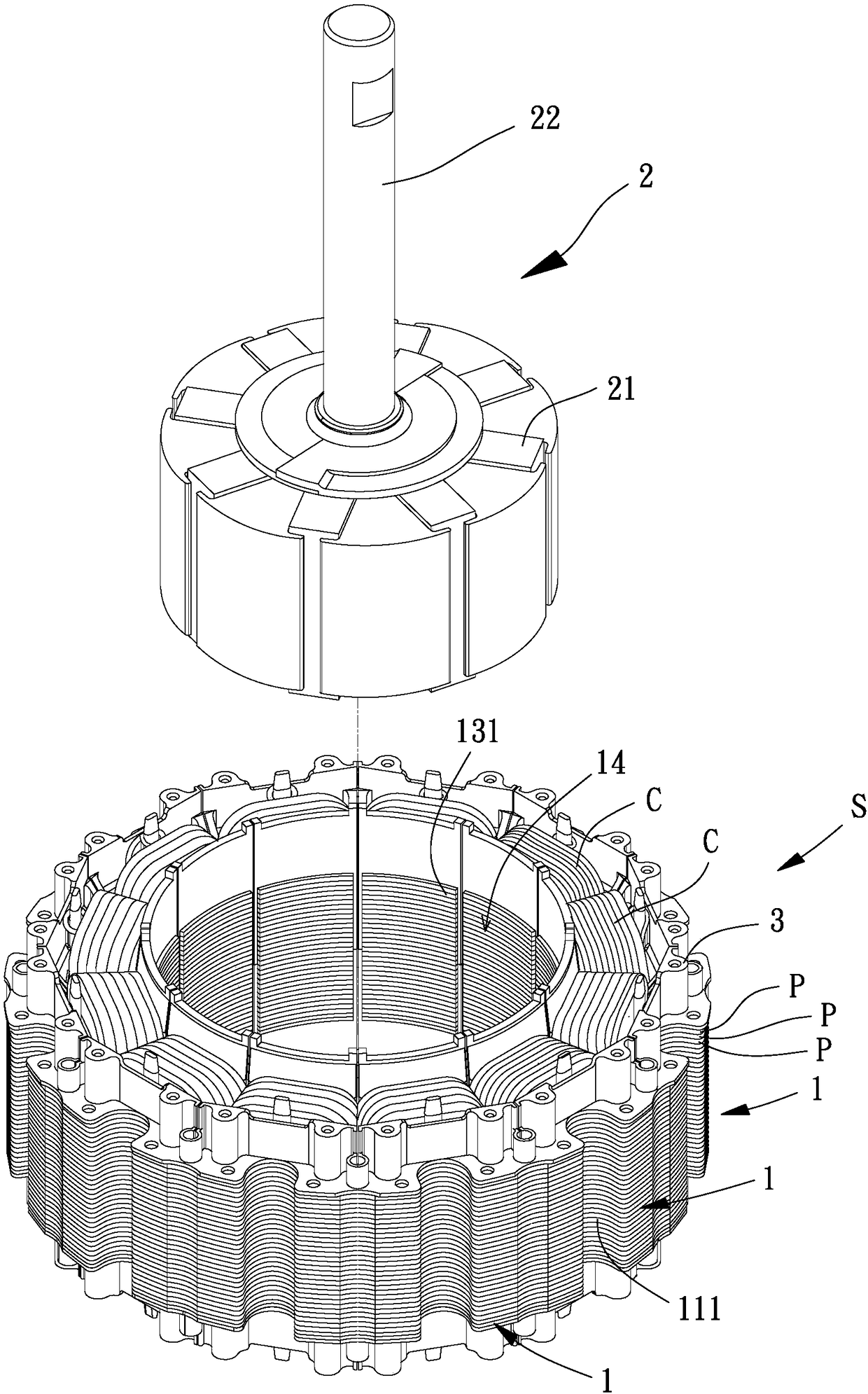

[0050] Please refer to figure 2 , 3 , which is the first embodiment of the silicon steel sheet P for the motor stator of the present invention, the silicon steel sheet P for the motor stator includes a plurality of connected magnetic pole units 1, each magnetic pole unit 1 has a yoke portion 11, a pole column part 12 and a pole shoe part 13; the yoke part 11, the pole part 12 and the pole shoe part 13 of each magnetic pole unit 1 can be integrally formed and connected, or assembled and connected by any method or structure, and the present invention is not limited .

[0051] In detail, the plurality of pole units 1 are connected by yoke parts 11 to form a yoke ring R; the number of pole parts 12 of the silicon steel sheet P can be a multiple of three, preferably at least twelve; each magnetic pole The pole part 12 of the unit 1 can expand the magnetic conduction area by the inner surface 131 of the connected pole shoe part 13, and form an accommodating hole 14 surrounded by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com