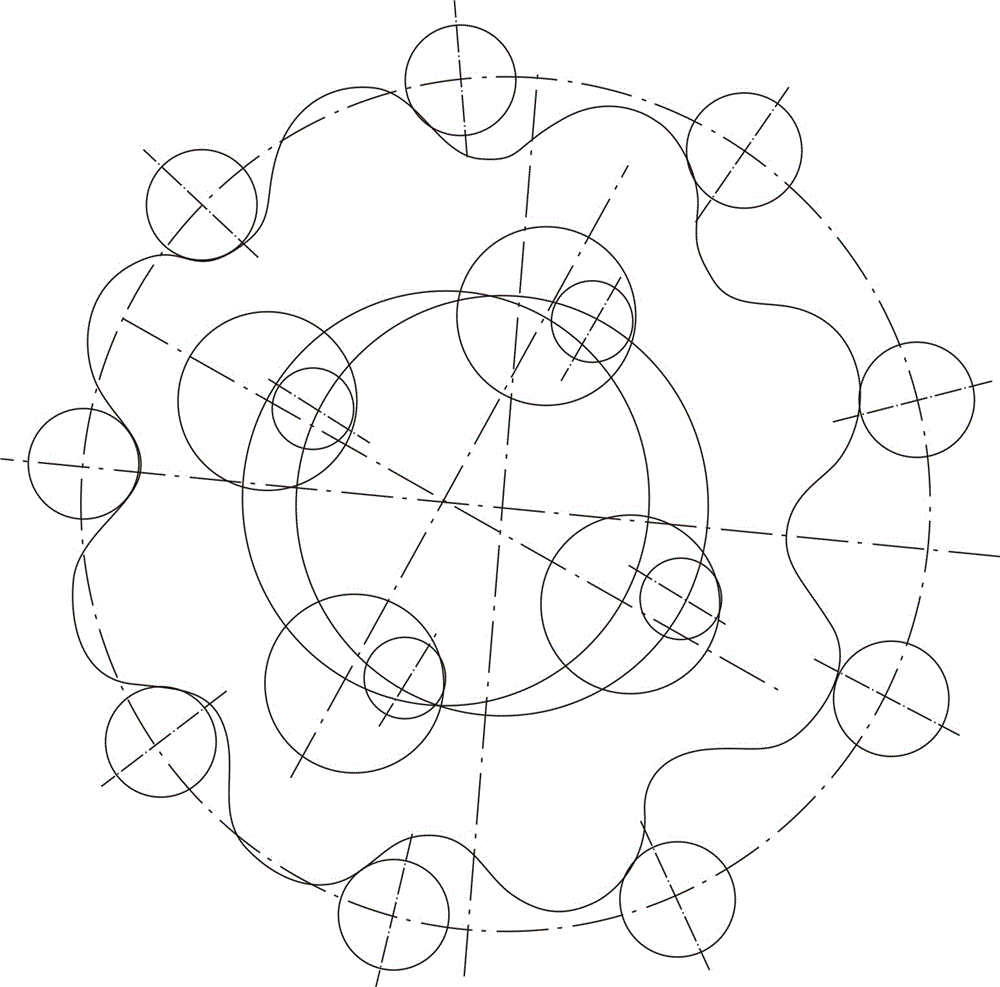

Reduction gear with combination of gear change structure and eccentric cycloidal roller pin gear change structure

A variable speed structure and eccentric swing technology, applied in gear transmission, gear vibration/noise attenuation, transmission, etc., can solve the problem of complex structure and assembly process of cycloidal pinwheel reducer, reduced mechanical stability, increased wear of parts, etc. problem, to achieve the effect of compact structure, large overlapping coefficient and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

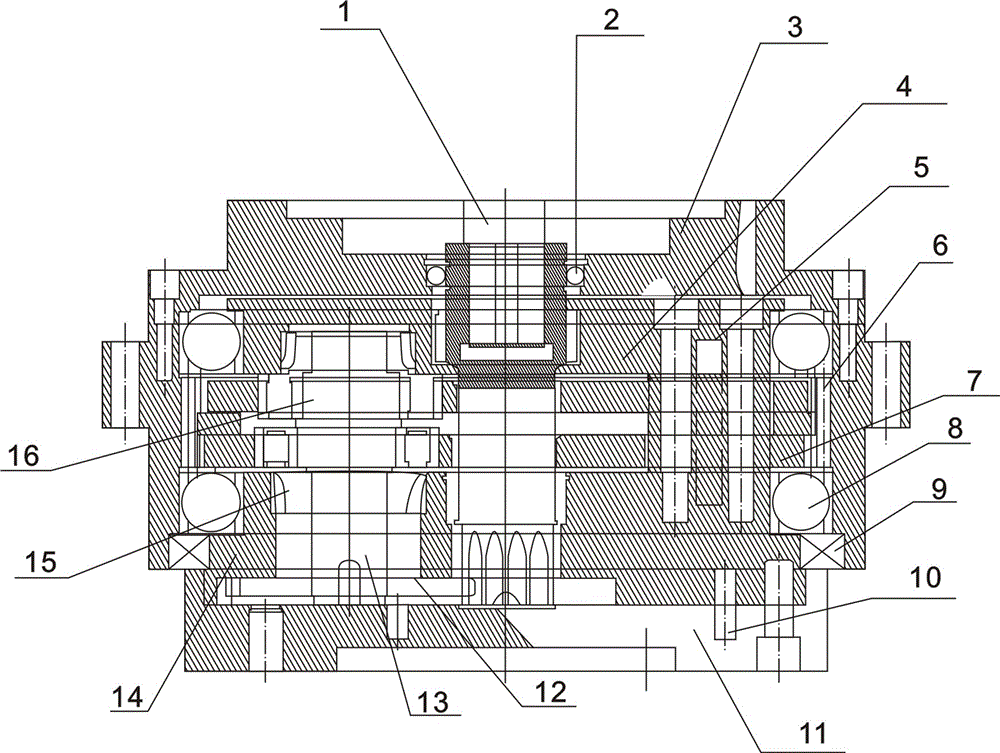

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] The entire transmission device of the new speed reduction device can be divided into three parts: input part, deceleration part and output part. First, the sun gear on the 1-input shaft drives three 12-planetary gears as the first-stage deceleration, and a pair of 180° double eccentric structures are designed on the three planetary gears 12-, and each section of eccentric cylinder is equipped with two The 16-bearing IV called the rotating arm drives two 7-cycloidal wheels to rotate, the eccentric cycloidal wheel is connected with the 4-bearing cover, and the 14-bearing sleeve is connected by bolts (4-bearing cover, 14-bearing sleeve outer shell and 8-Bearing II has a limited position and stabilizing effect on the internal cycloidal wheel, which greatly improves the stability of the internal mechanical movement and reduces noise) and through the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com