Bidirectional overrunning clutch, speed control device and automatic speed control system

A technology of overrunning clutches and clutches, applied in the field of clutches, which can solve the problems of high manufacturing precision requirements, limited application places, and low service life, and achieve the effects of large transmission torque, long service life, and reduced cross-sectional size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

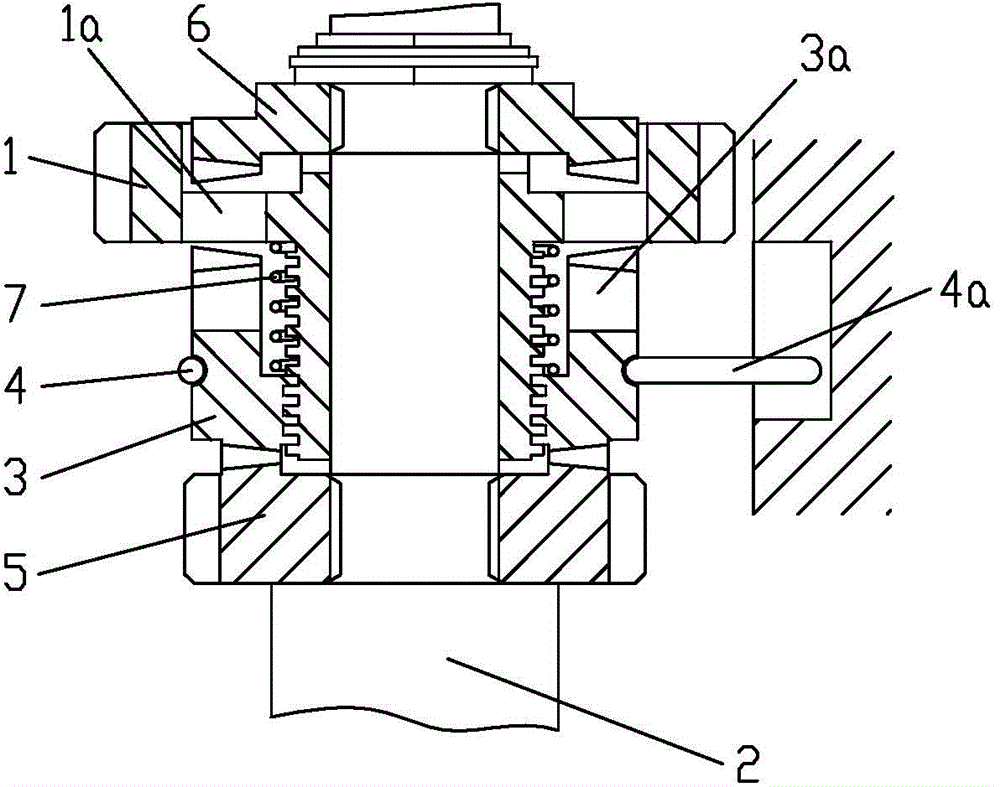

[0036] Example 1 see figure 1 , a two-way overrunning clutch, including a disc-shaped driving part 1 rotatably set on a shaft-shaped follower 2, one end journal of the driving part 1 is fitted with a helical spline sleeve 3 through a helical spline, and the helical spline The sleeve 3 is connected with a brake device that applies frictional resistance thereto; the brake device includes a C-shaped collar 4 with a collar shank 4a, and the C-shaped collar 4 is held on the helical spline sleeve 3 by a C-shaped clamping portion. The ring groove is provided; the C-shaped collar 4 is provided with a U-shaped collar handle 4a, and the U-shaped two free ends of the collar handle 4a are fixedly connected with the C-shaped two free ends of the C-shaped collar 4, and the collar handle 4a is used to prevent the C-shaped collar 4 from rotating synchronously with the helical spline sleeve 3 through the stationary component; the driven part 2 is fixedly connected with the first driven disc 5 ...

Embodiment 2

[0038] Example 2 see figure 2, the structure of the first end meshing clutch is composed of the intermeshing end teeth on the transition plate 8 and the driven member 2, and the transition plate 8 is connected to one end of the helical spline sleeve 3 through a one-way overrunning clutch 8a. Wherein, the intermeshing end teeth on the transition plate 8 and the driven member 2 may be right-angled triangular one-way teeth, isosceles triangles or isosceles trapezoidal two-way teeth.

[0039] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

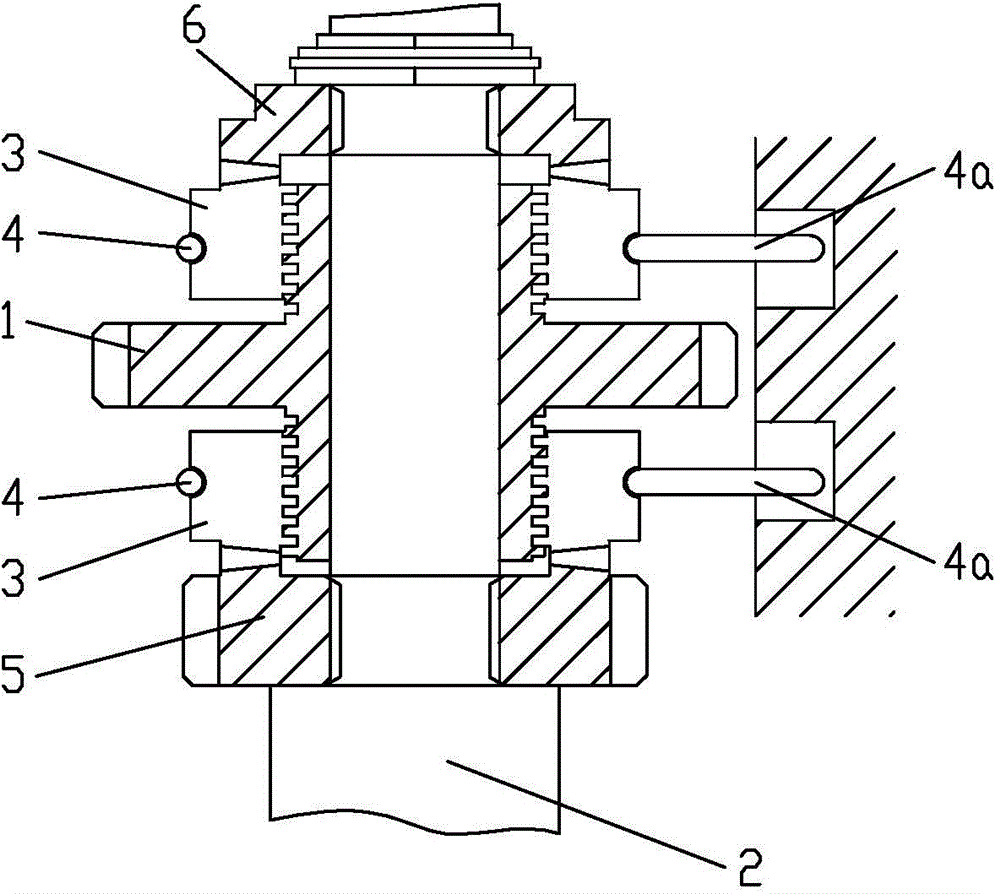

[0040] Embodiment 3 see image 3 , the helical spline sleeve 3 is provided with two fittings on the journals at both ends of the active member 1, the external splines of the journals at both ends of the active member 1 have the same rotation direction, and the two helical spline sleeves 3 are respectively The first end face meshing clutch structure and the second end face meshing clutch structure are formed with the first driven disc 5 and the second driven disc 6 .

[0041] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com