Shot blasting rust removal device for buoy accessories

A technology of attachments and buoys, which is applied to abrasive feeding devices, used abrasive processing devices, metal processing equipment, etc., can solve the problems that the thrown materials cannot be cleaned in time, need manual cleaning, and affect the rust removal effect, etc. Achieve the effect of preventing human handling errors, complete functions, and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

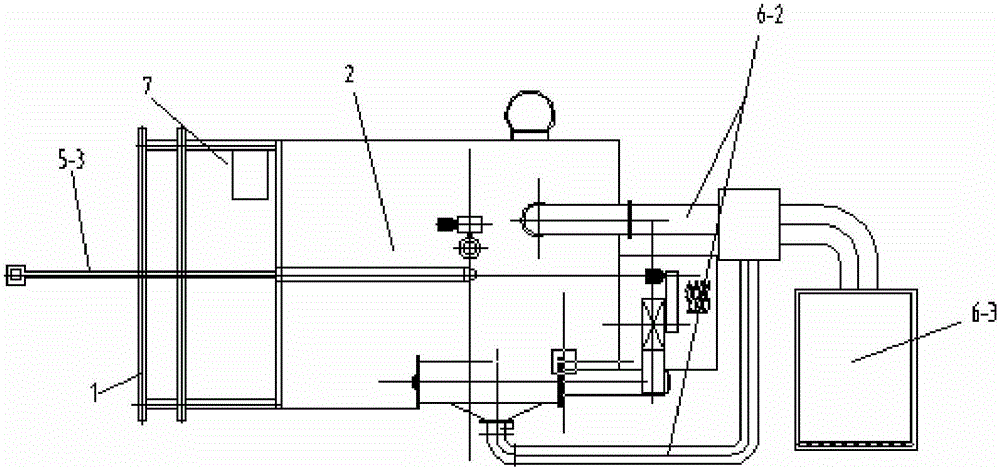

[0027] The following is attached Figures 1 to 4 And embodiment the present invention is described in further detail:

[0028] Such as figure 1 As shown, this embodiment includes a frame 1, a shot blasting cleaning room 2, a shot blasting device assembly 3, a shot sand distribution system 4, a hook system 5, a dust removal system 6 and an electrical control system 7, and its structural characteristics are: The top layer of the frame 1 carries the shot blasting distribution system 4 for the distribution and supply of shot blasting, the shot blasting cleaning room 2 is below the shot blasting distribution system 4, the output port of the shot blasting distribution system 4 and the shot blasting machine assembly for shot blasting work processing 3, the input port of shot blasting distribution system 4 is connected with a pipeline extending downward, and the end of the pipeline is provided with a shot blasting conveyor for sucking materials from the outside, and the output port o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com