Cold pad-batch dyeing device for open-width knitted fabrics

A dyeing device and technology for knitted fabrics, applied in the processing of textile materials, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of increased consumption, inconsistent colors, complicated operations, etc., to prevent fabric deviation and joint printing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

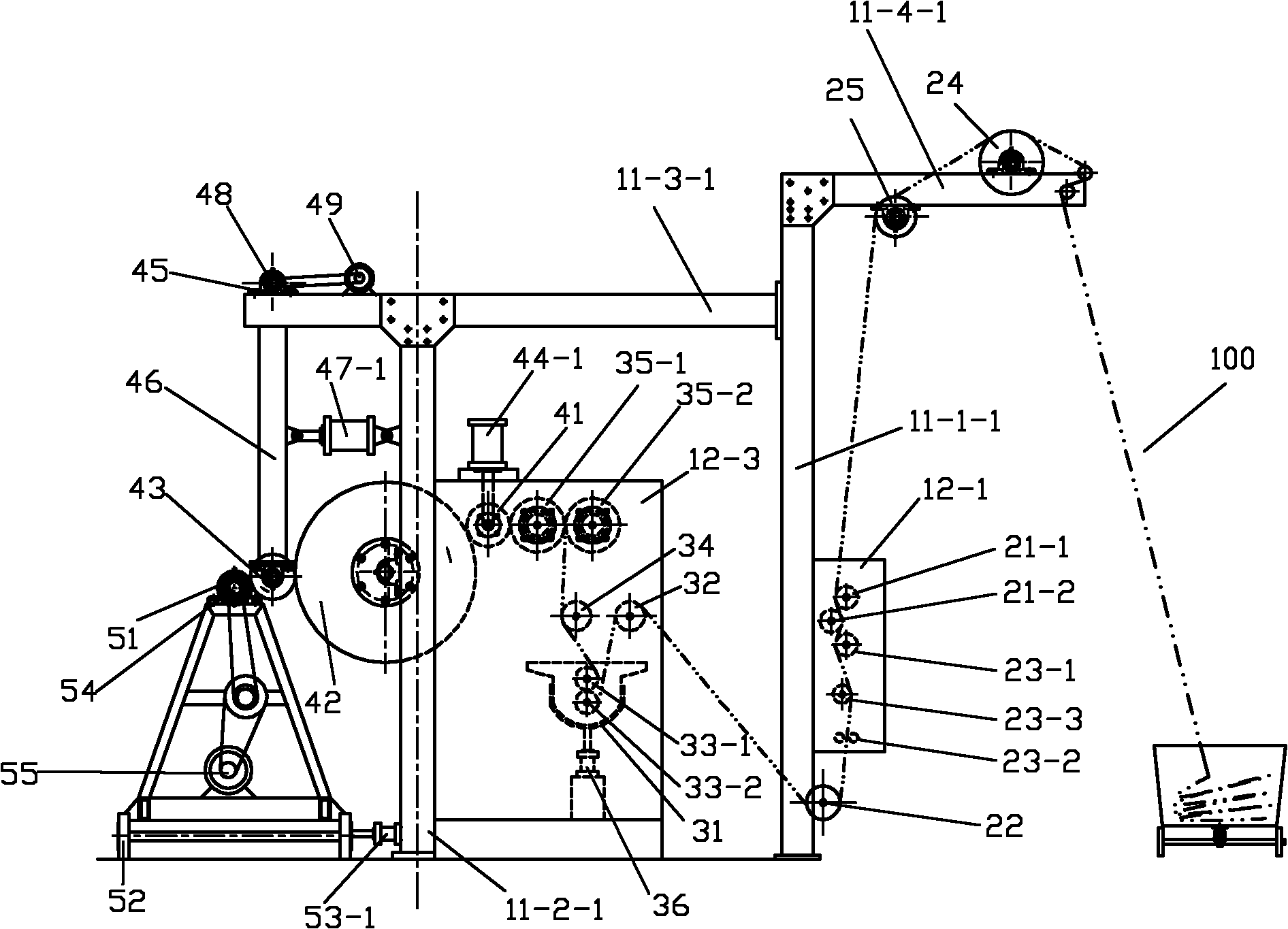

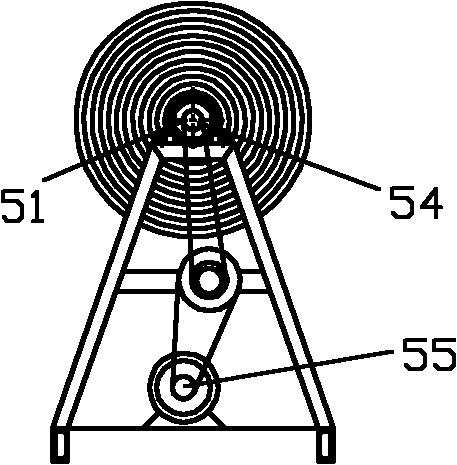

[0023] (Example 1) see figure 1 The cold pile dyeing device of the open-width open-width knitted fabric of the present embodiment includes a frame 1, a cloth feeding device 2, a dyeing liquid device 3, a wet state cloth feeding device 4, a cloth rolling device 5, a liquid supply device and Control circuit. The cloth feeding device 2, the dyeing liquid squeezing device 3, the cloth feeding device 4 and the cloth rolling device 5 are arranged sequentially on the fabric traveling route in a wet state. The various cloth guide rollers of each component are arranged according to the front and rear directions, and their respective axes are parallel to each other.

[0024] The frame component 1 includes a main frame body 11 and a box assembly 12 .

[0025] The main frame body 11 includes 2 right vertical beams 11-1, 2 left vertical beams 11-2, 2 horizontally arranged front and rear beams 11-3, and 2 horizontal beams 11-3 fixed on the 2 horizontal beams 11-2. 3. Two connecting beams...

Embodiment 2

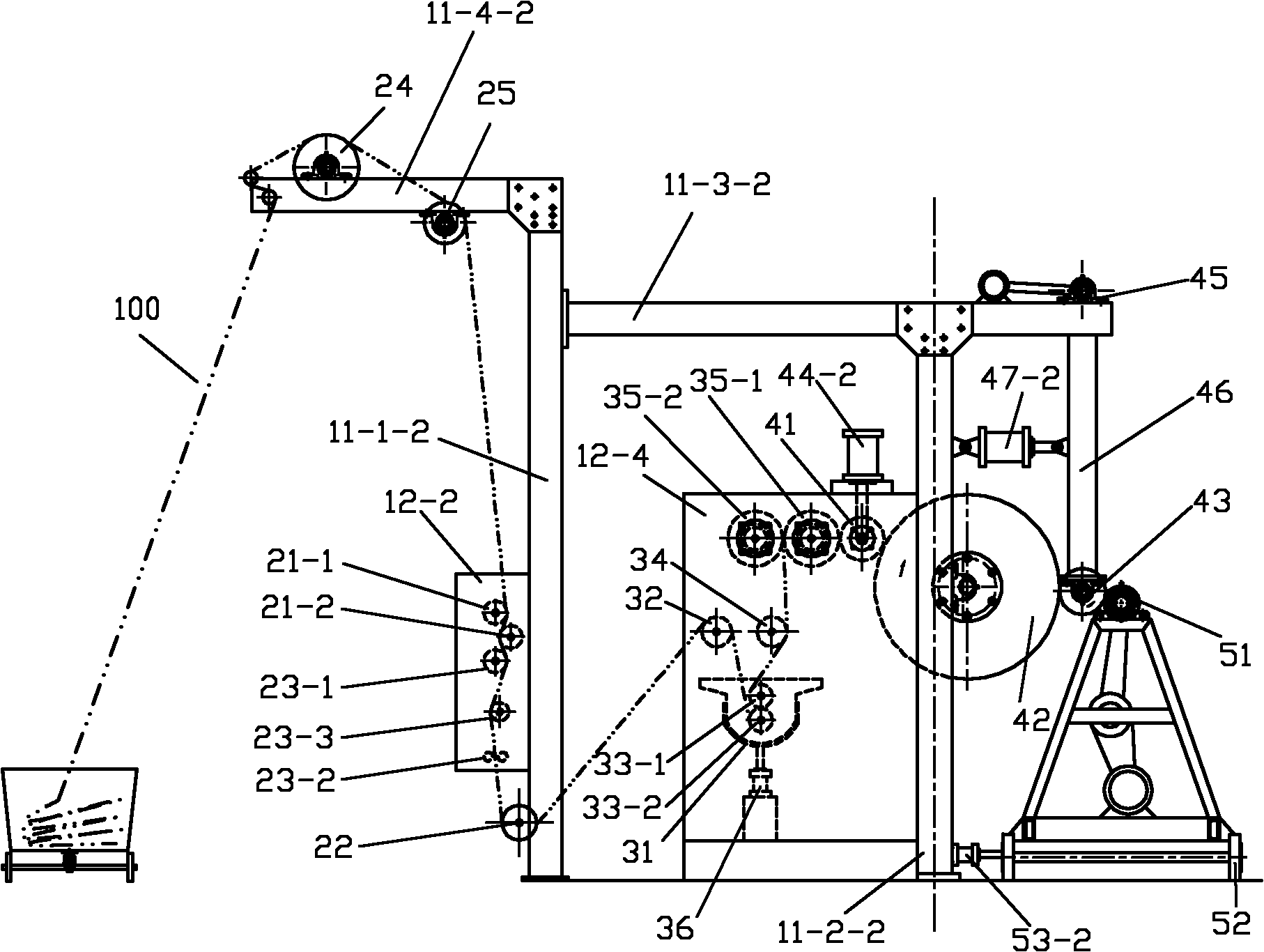

[0042] (Example 2) see Figure 4 and Figure 5 , the rest are the same as in Example 1, except that the immersion roller group 33 has 4 immersion rollers; The bearing assembly is connected to the left front box 12-3 and the left rear box 12-4 in rotation; the front and rear ends of the other three immersion rollers are respectively connected to the left front box 12-3 and the left rear through their respective bearing assemblies. on the box body 12-4, and can slide up and down in the up and down direction; among the four immersion rollers, the upper immersion roller is positioned on the lower immersion roller by its own weight. Rolls; the fabric surrounds the 4 dipping rollers from top to bottom in turn, and after passing through the dipping rollers, it is dipped with printing and dyeing solution for many times, which greatly increases the printing and dyeing speed to 60 m / min, and greatly improves the efficiency of cold-batch dyeing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com