Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Guaranteed meshing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

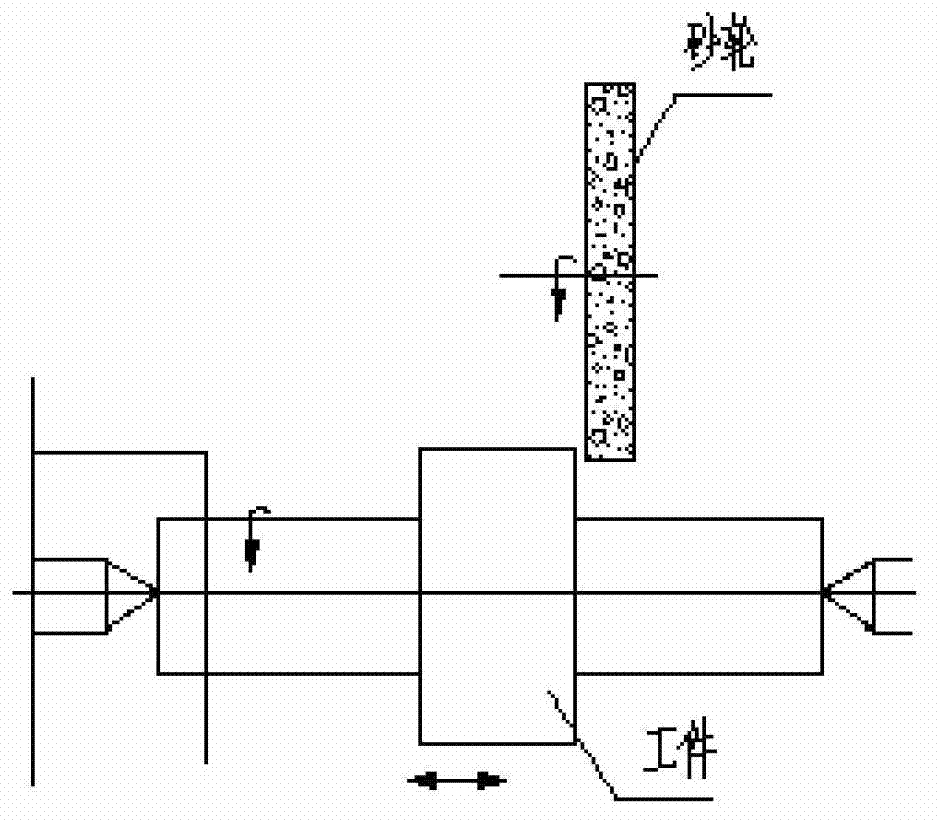

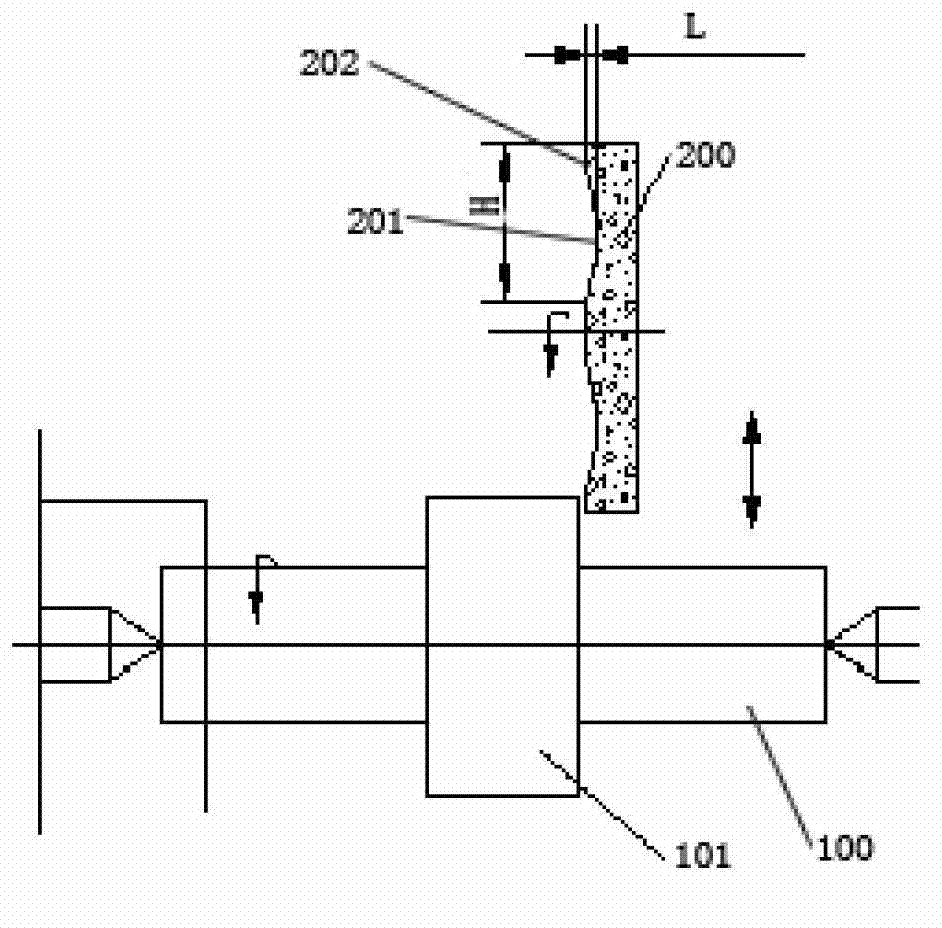

Machining method of high-accuracy cutter shaft of rotary shear

ActiveCN102825515AGuaranteed beatGuaranteed meshing accuracyPlane surface grinding machinesCircular discResonance

The invention discloses a machining method of a high-accuracy cutter shaft of a rotary shear. The machining method is sequentially performed according to the following steps of: 1, forging a blank and normalizing; 2, performing rough turning; 3, performing hardening and tempering, i.e., performing quenching and high-temperature tempering treatment on the cutter shift; 4, performing semi-fine turning; 5, performing semi-fine milling; 6, performing fine turning; and 7, performing fine milling, i.e., milling a main outer circle and a taper of the cutter shaft, and meanwhile, arranging a groove in a middle part of an axial end face of a milling grinding wheel, wherein a part which is clamped between the groove and the circumferential surface of the grinding wheel is a milling part of the grinding wheel, so that the milling part of the grinding wheel in a rotation process is used for milling an end face of a cutter shaft shoulder which is kept in the rotation process after being clamped on a machine tool, and the grinding wheel does reciprocating motion in the radial direction of the cutter shaft in a milling process. According to the machining method, a contact area of the grinding wheel and the shaft shoulder can be reduced, jumping of a grinding wheel and aggravation of jumping of the shaft by resonance of an end face of the shaft shoulder and the grinding wheel in a milling process are prevented, and the milling accuracy of the axial end face is guaranteed to be within 0.005 mum.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

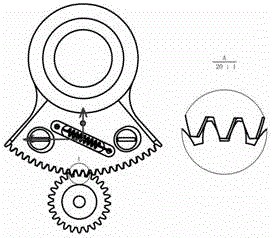

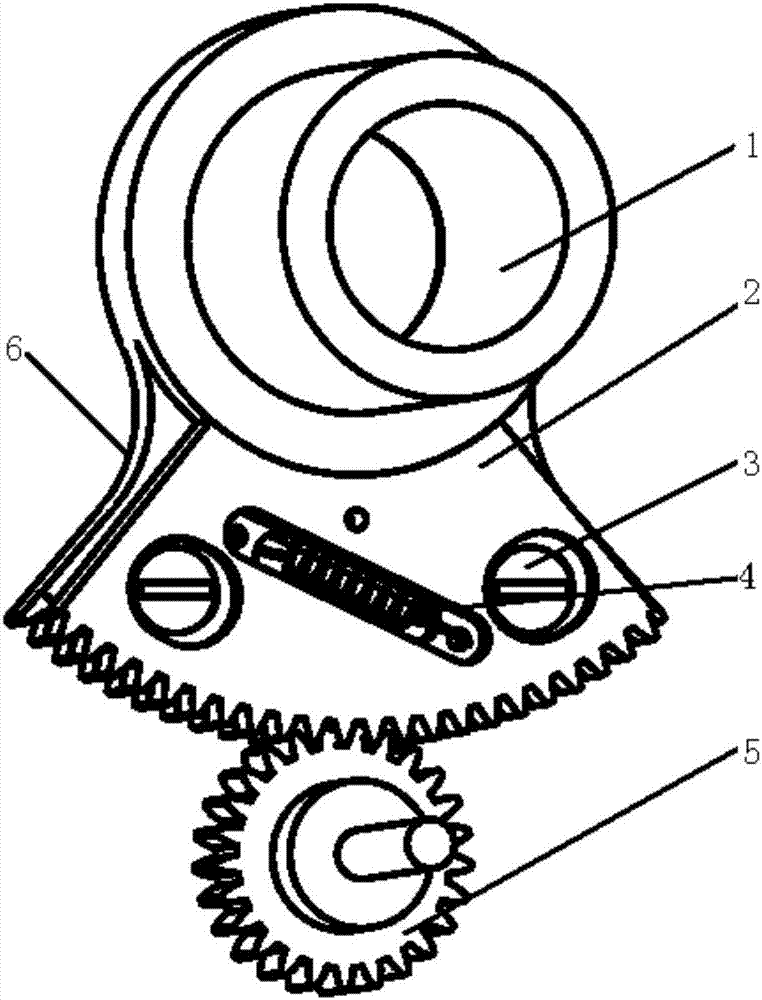

Method for automatically eliminating limited angle gear backlash

InactiveCN104565333AImprove machining accuracyImprove assembly accuracyGearing detailsGear wheelEngineering

The invention discloses a method for automatically eliminating limited angle gear backlash, and aims to provide a compact limited angle gear backlash eliminating mechanism which is simple and compact in structure and capable of realizing gear transmission without backlash, improving gear transmission precision, reducing cost and improving assembling capacity. The technical scheme for implementing the method includes that one of a driving gear and a driven gear which are engaged with each other is divided into a main sector gear and an auxiliary sector gear, a fixed main gear working portion and the loaded auxiliary gear are sectored, a bottom arc of a small end sector of the loaded auxiliary gear fits with a cylindrical surface of a gear rotating shaft cylinder, inclined hole grooves (7) are formed in sectors of the fixed main gear and the loaded auxiliary gear, and gear tension springs (4) keeping a tension state are mounted in the inclined hole grooves, the fixed main gear and the loaded auxiliary gear are connected together by loading the sector of the auxiliary gear through the gear tension springs, and the fixed main gear and the loaded auxiliary gear are mutually staggered to form a certain circumference angle and engaged with the driven gear in opposite directions.

Owner:SOUTH WEST INST OF TECHN PHYSICS

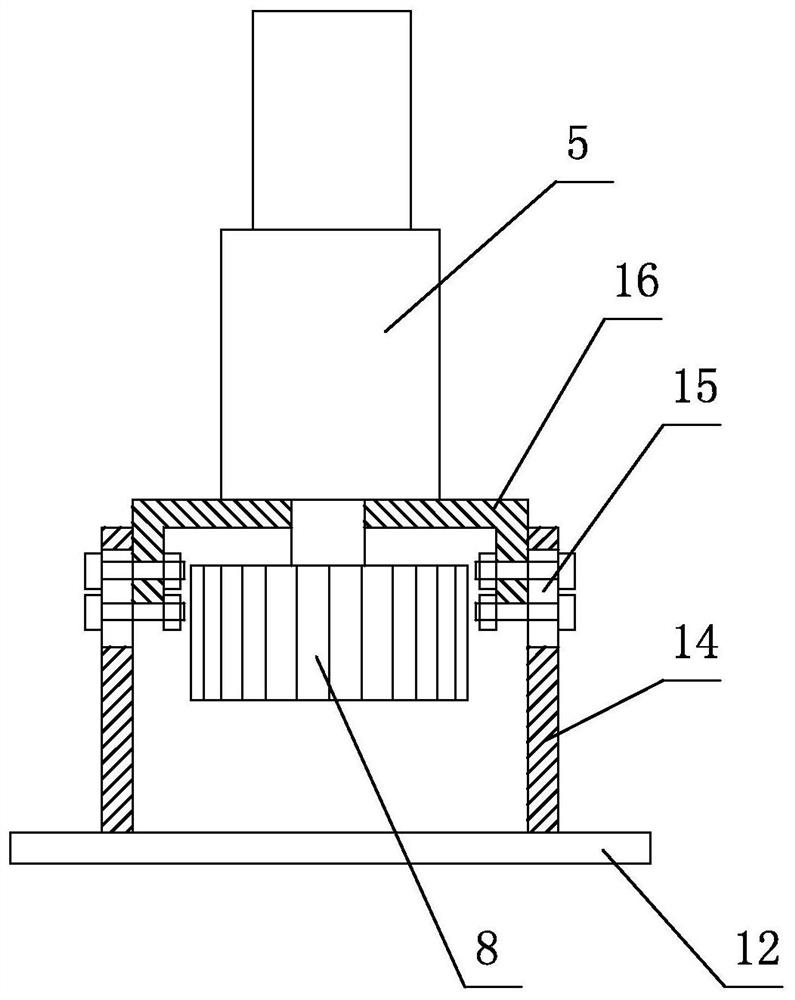

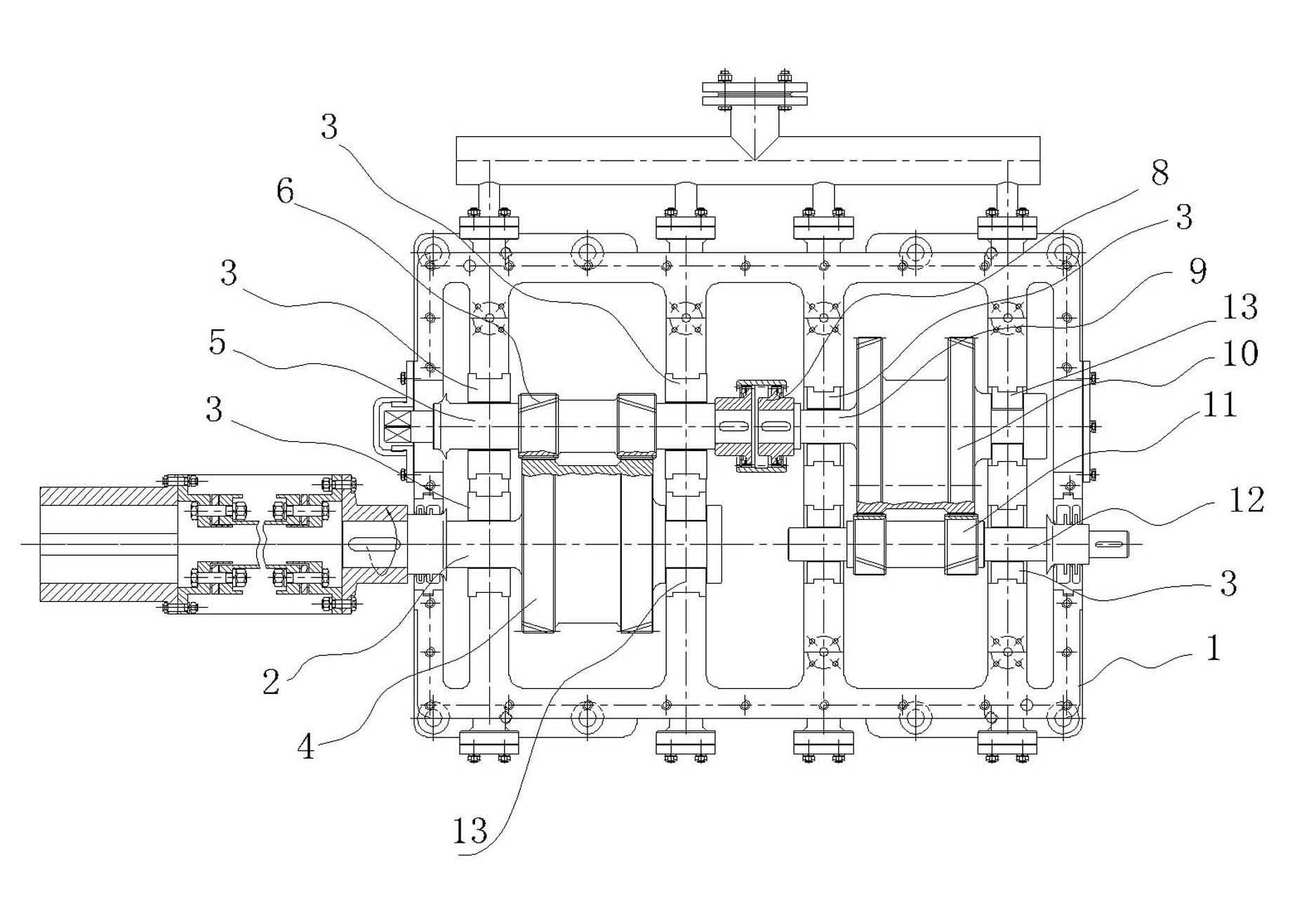

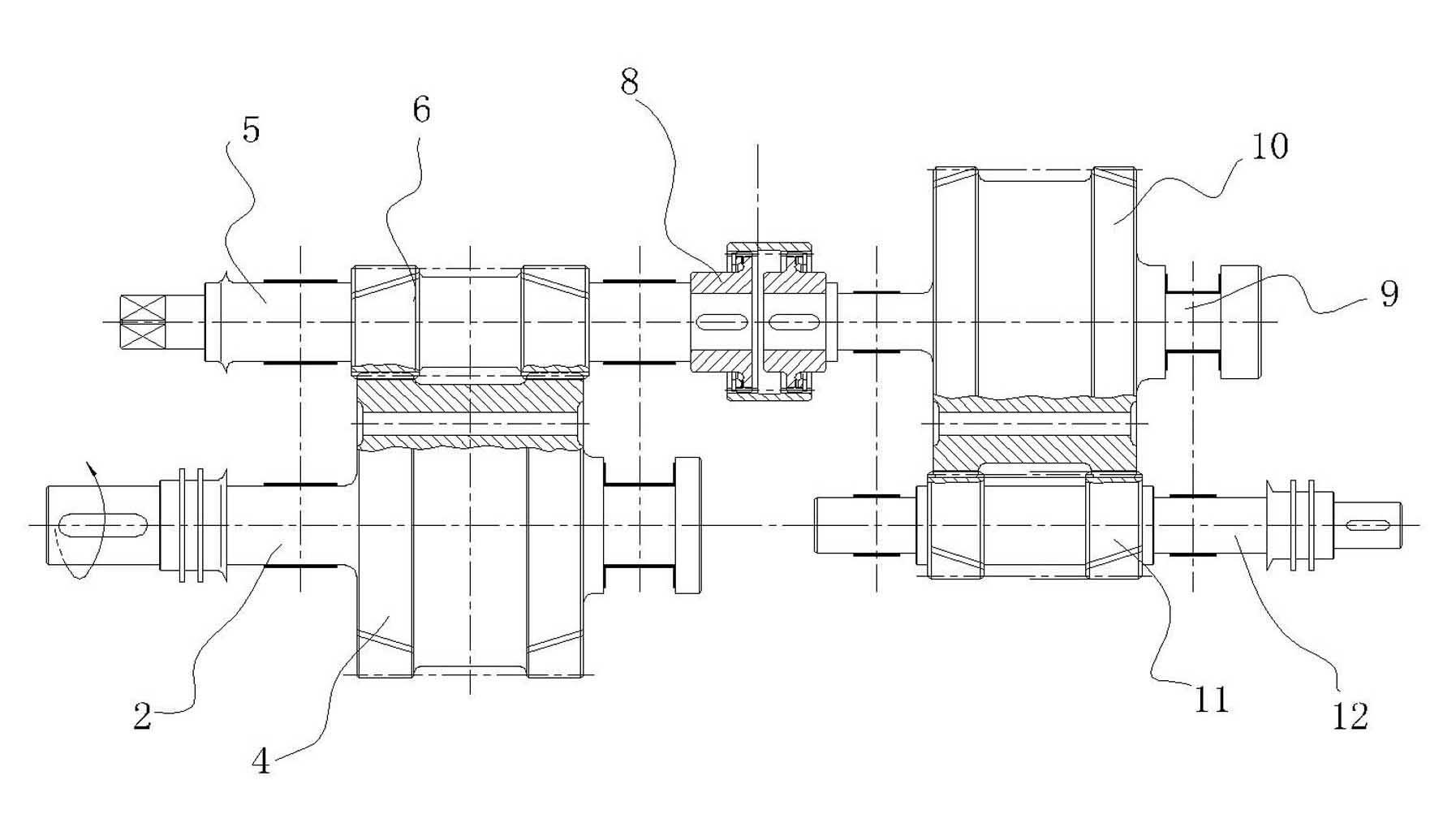

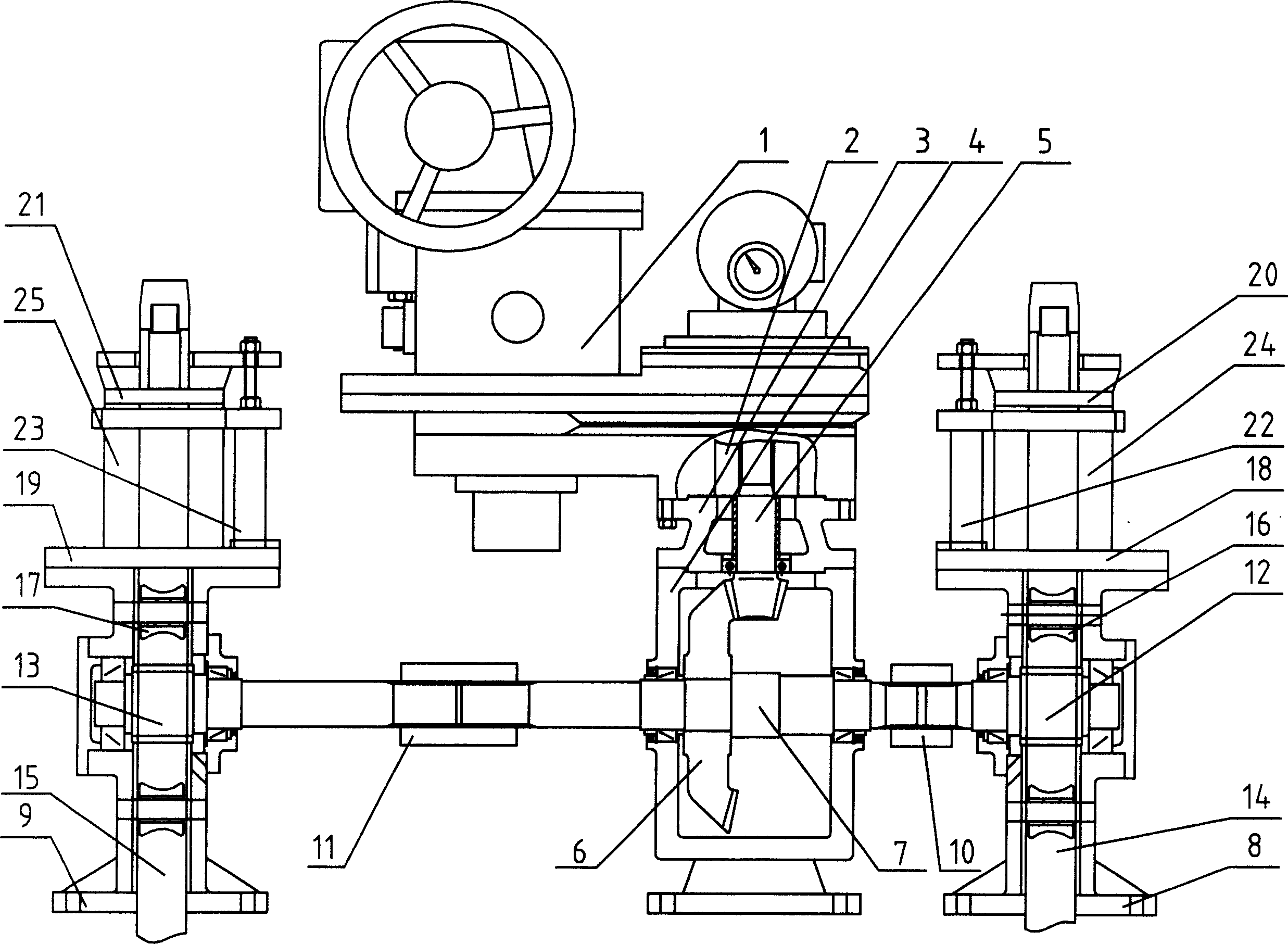

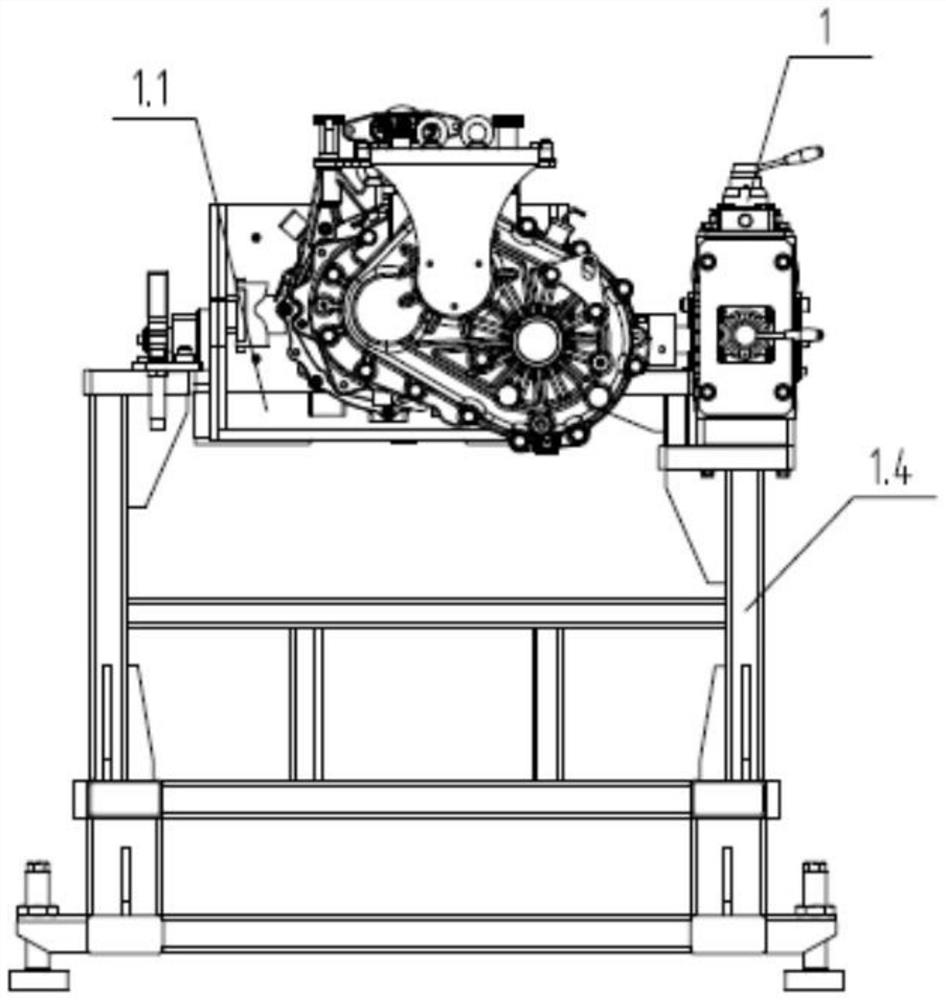

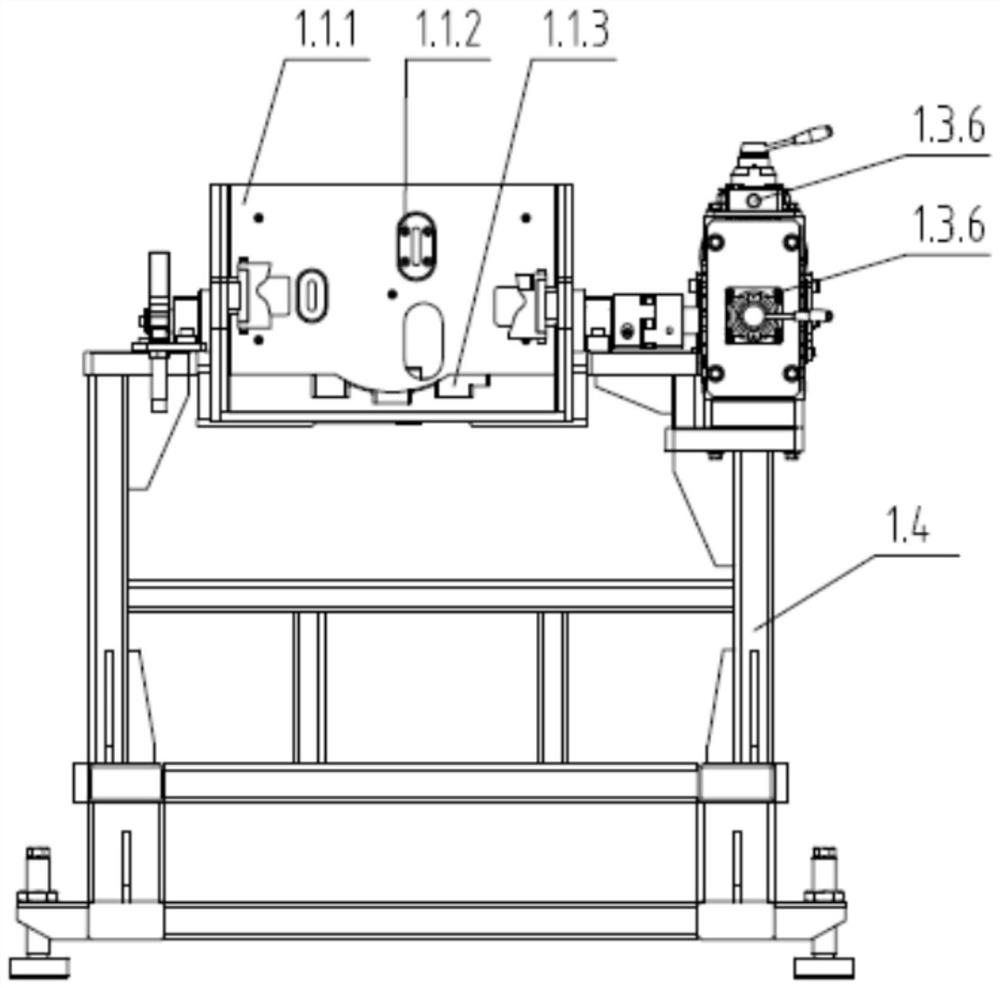

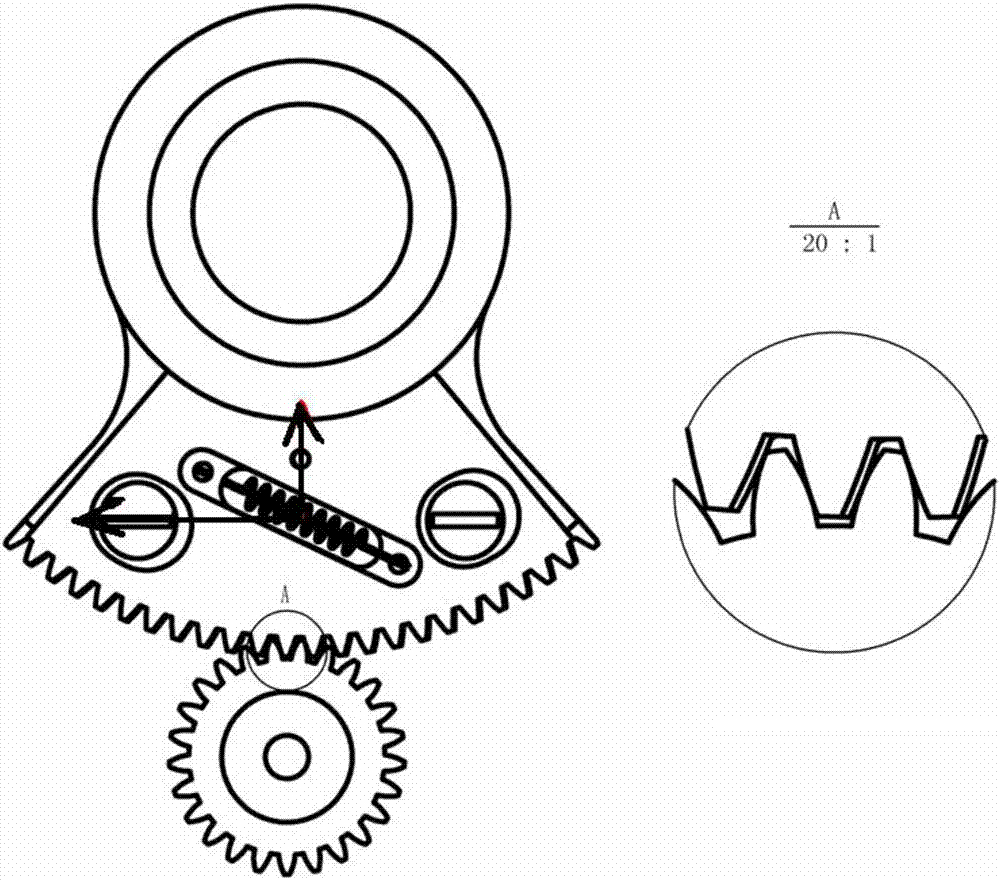

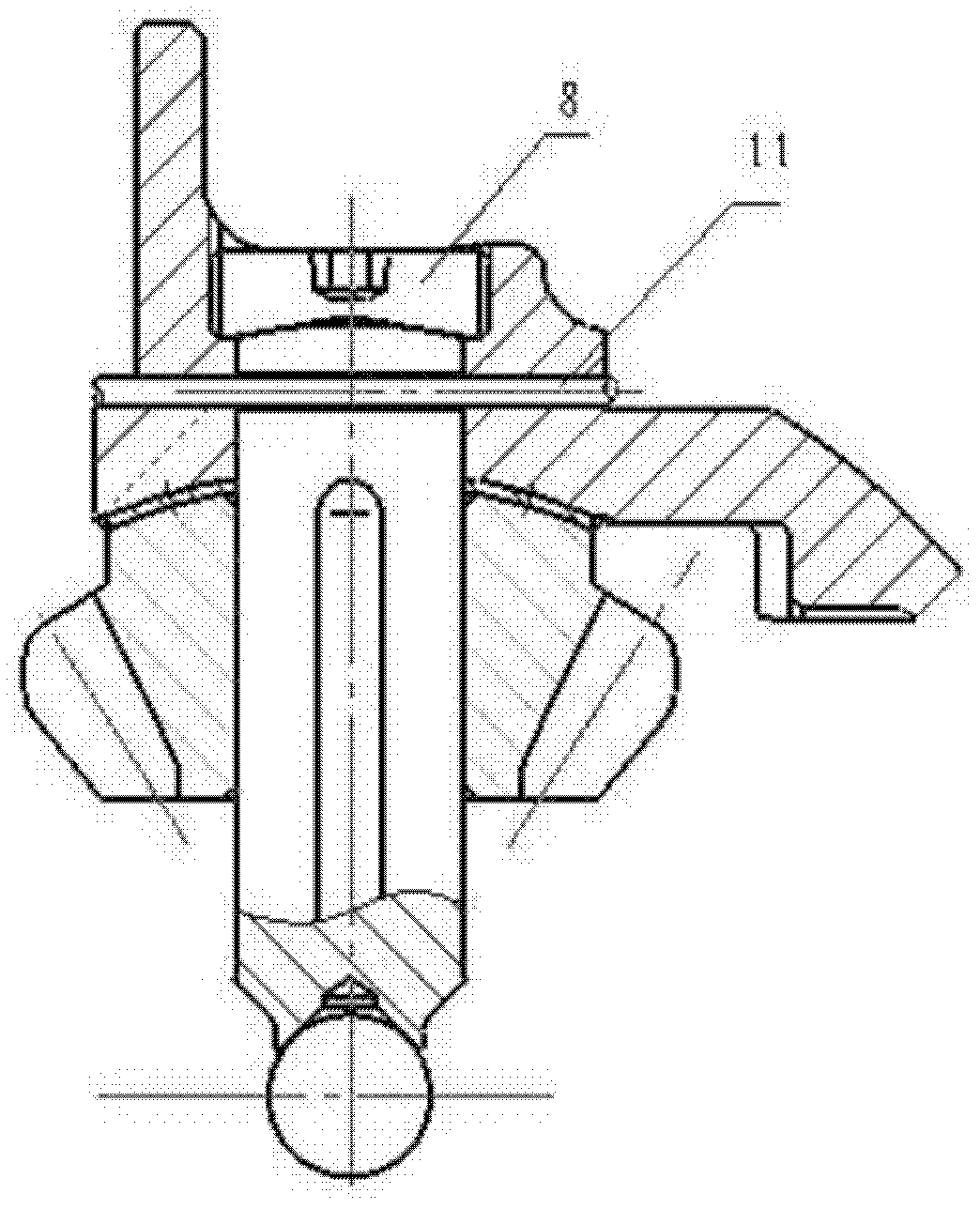

Mechanical enclosed test bench of bevel gear

ActiveCN107621366AGuaranteed meshing accuracyEasy to installMachine gearing/transmission testingBall bearingEngineering

The invention discloses a mechanical enclosed test bench of a bevel gear. The test bench comprises a bevel gear box including a tested bevel gear group, an accompanied tested bevel gear group, and a shaft. The tested bevel gear group consists of a first tested bevel gear and a second tested bevel gear that are engaged and are perpendicular to each other. The accompanied tested bevel gear group includes a first accompanied tested bevel gear and a second accompanied tested bevel gear that are engaged and are perpendicular to each other; the first tested bevel gear and the first accompanied tested bevel gear are installed on the shaft. An angular contact ball bearing is installed between the first tested bevel gear and the first accompanied tested bevel gear on the shaft; and cylindrical roller bearings are installed at the two ends of the shaft. A first adjusting assembly for adjusting the axial position of the first tested bevel gear is arranged at the shaft. The test bench having a simple structure is installed conveniently; the performances are stable; the bearing capability of the shaft is large; and the engaging precision of the bevel gear is high; and the test bench is capableof testing the transmission performance of the bevel gear at a high speed.

Owner:CENT SOUTH UNIV

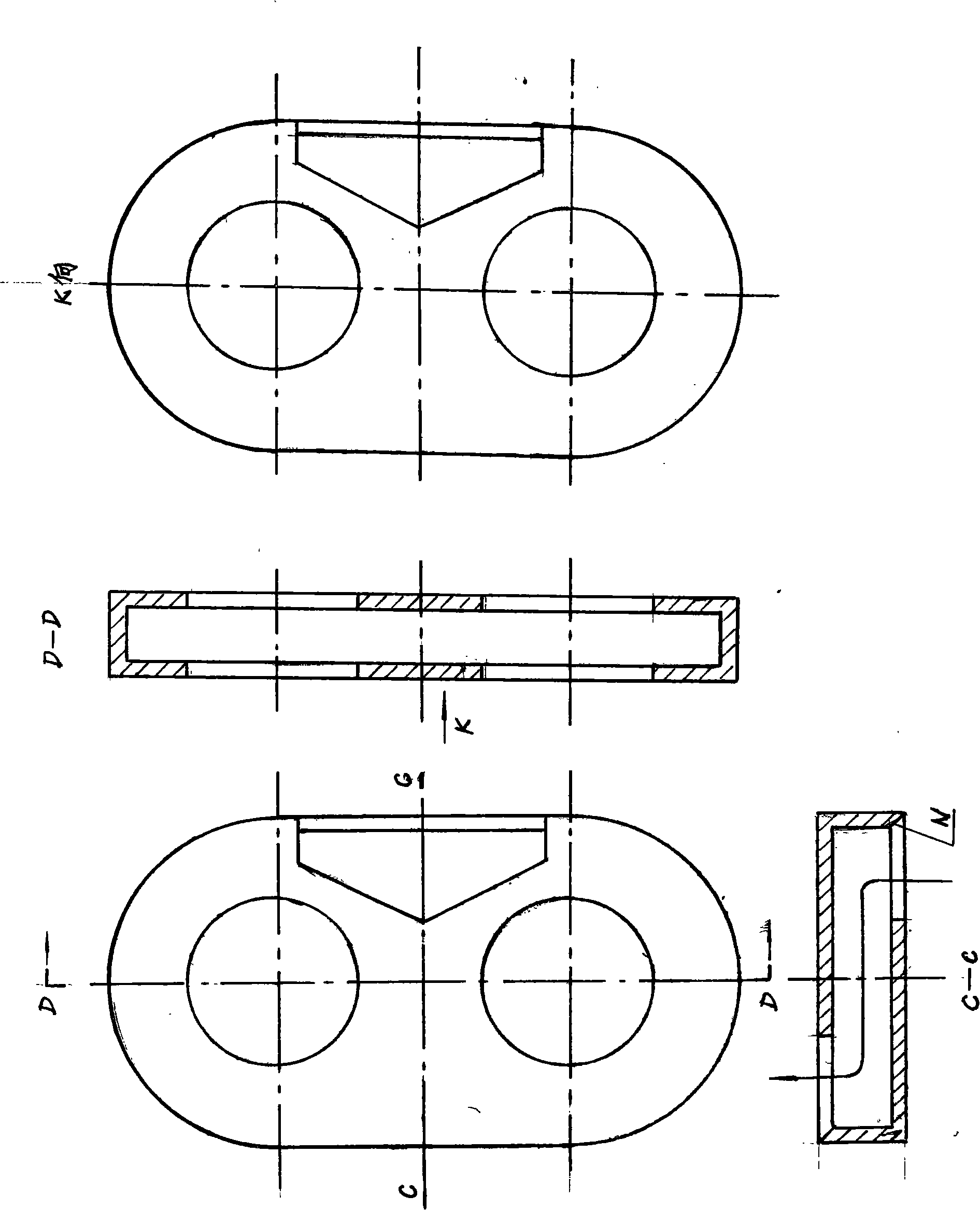

Multilevel inner series dual supercharging double-circular-arc gear pump

InactiveCN101251107AEasy to installEasy maintenanceRotary piston pumpsRotary/oscillating piston combinationsGear grindingGear pump

The invention provides a multistage internal serial dual pressurizing double-circular-arc gear pump which is a graduate innovation and turns the prior interstage external serial pressurizing into interstage serial pressurizing with the renovated pump still having gradual thinning of tooth thickness and dual pressurizing. After internal serial pressurizing, the prior interstage separating plate has a new function and acts as an internal channel; the outside of a pump casing is provided with a cooling water jacket; both ends of a hole arranged inside the casing are provided with end plates used in a bearing seat; a supporting axle is in mesh transmission with a multistage double-circular-arc gear pair arranged on the axle; because no external bearing seat is adopted, the overall structure of the invention is simplified. Moreover, two parallel shafts are formed into an assembly; a shaft seat plate, a multistage gear pair and a serial clapboard, etc. are assembled into a big component in advance; then, the component is moved inside the inner hole of the pump casing, thereby realizing convenient assembly and disassembly. The gear pump has the advantages that: the inner hole is taken as installation benchmark, which ensures high installation precision and is suitable for high-speed operation; the positive displacement pump has high efficiency and is energy-saving; dual pressurizing is obtained through multistate series connection and tooth thickness gradual thinning; mass flow is obtained through small tooth number, big module and high speed; the gear pump, which has a simple structure, high reliability, excellent manufacturability, easy manufacture and no gear grinding of a gear, can be made by an ordinary machine making factory. The pump can be used to convey liquid, gas and high-temperature medium with certain corrosivity; moreover, the pump has excellent self-priming performance and is insensitive to pollution.

Owner:赵明

Face tooth grinding fixture

InactiveCN102248229AGuaranteed meshing accuracyExtended service lifeGear-cutting machinesGear teethLine of actionEngineering

The invention relates to a face tooth grinding fixture characterized by comprising a bottom support plate, wherein a dividing device is installed on the bottom support plate, a positioning sleeve is fixedly installed on the dividing device, the positioning sleeve and the dividing device are coaxially installed, a clamping device is arranged at the upper end of the positioning sleeve, an inclined surface is formed on the bottom surface of the bottom support plate, and the angle of the inclined surface is equal to the included angle between the root of the processed face tooth and the theoretical line of action. The face tooth grinding fixture has a simple and compact structure, low manufacturing cost and convenience in operation, can realize grinding of the face tooth only by a common tool grinder without needing extra special equipment, provides a means for grinding the face tooth, meets the requirement on the roughness of the face tooth surface, improves the tooth form accuracy, ensures the accuracy of mesh of the face tooth, prolongs the service life of the face tooth and reduces waste.

Owner:WUXI RL PRECISION MACHINERY

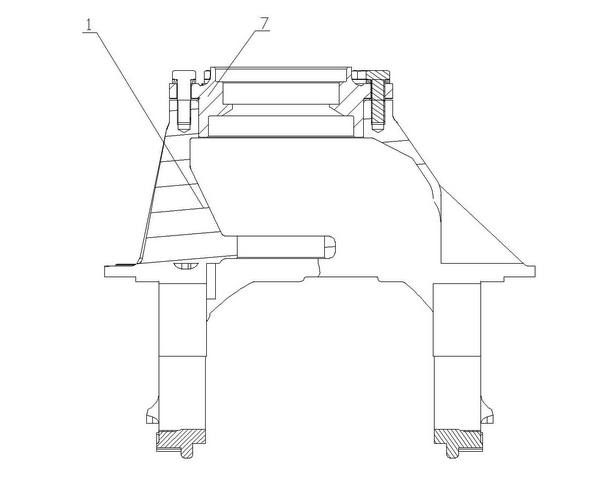

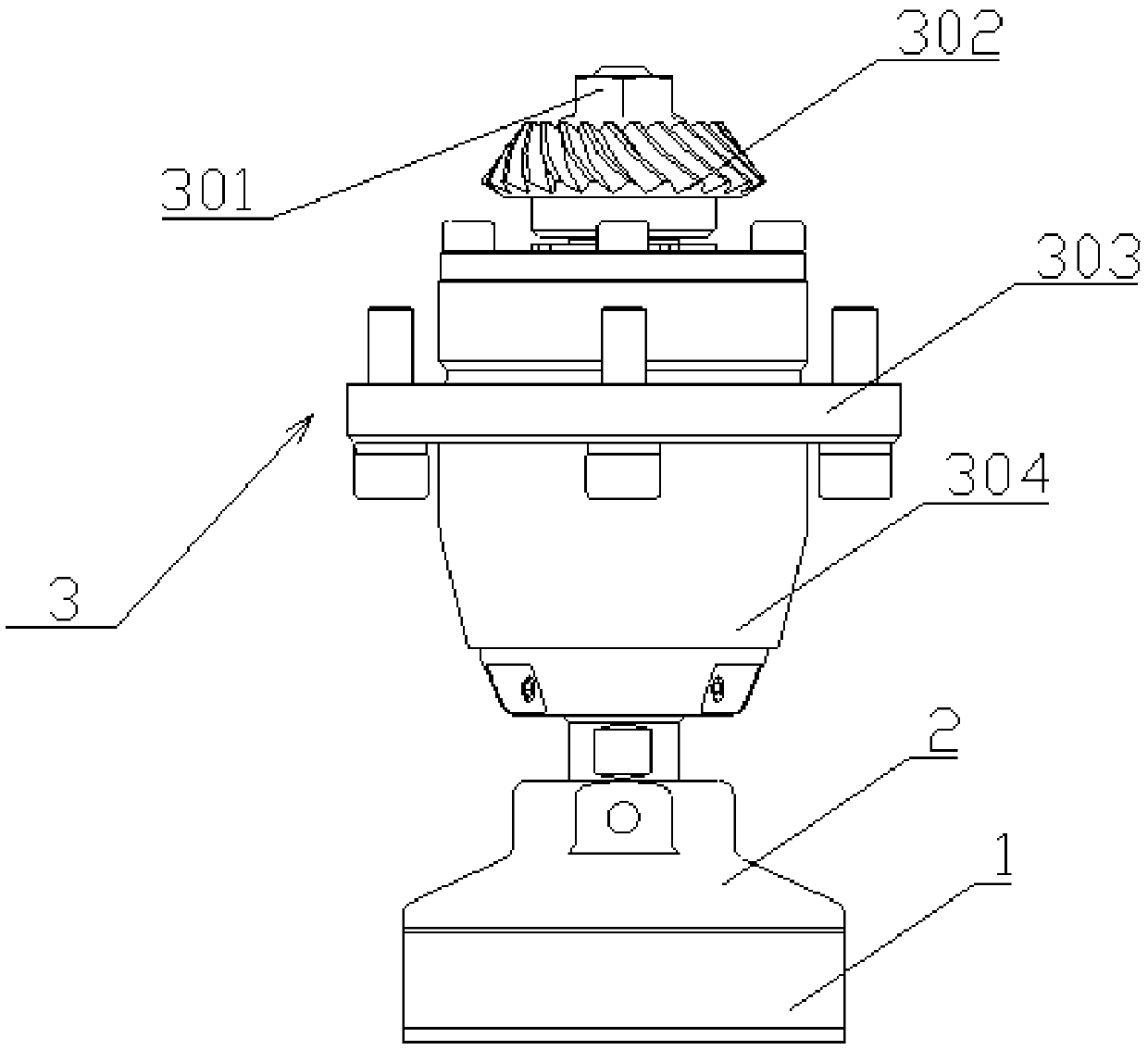

Main speed reducer housing for light car axle

InactiveCN102518785AGuaranteed installation accuracyInfluence of installation accuracyGearboxesGearing detailsReduction driveGear wheel

The invention discloses a main speed reducer housing for a light car axle, wherein a step for mounting a bearing is directly cast on the speed reducer housing; the bearing is directly assembled on the speed reducer housing; a driving bevel gear is directly assembled in a bearing hole; a through hole formed in a mounting surface of the speed reducer housing is directly connected with an axle housing; and reinforced ribs are arranged at the corresponding positions of the front bearing and the rear bearing both used for assembling the driving bevel gear, as well as the bearing of a differential gear. The main speed reducer housing for the light car axle effectively improves the engagement precision of the driving bevel gear; as the guide bearing is not adopted to support the driving bevel gear, the space is saved, the space base is provided for the wide tooth surface design of the gear, and the design concept of the high power density of the speed reducer is finally realized; through the reasonable arrangement and the optimized calculation of the supporting ribs, the basic wall thickness of the speed reducer housing can achieve the minimum degree of 4mm without influencing the service life of the gear, and realize the light scale design; and bearing burning and gear early failure are avoided through the verification of the rack and the road experiment, the matched requirements for the whole vehicle are satisfied.

Owner:DONGFENG DANA AXLE

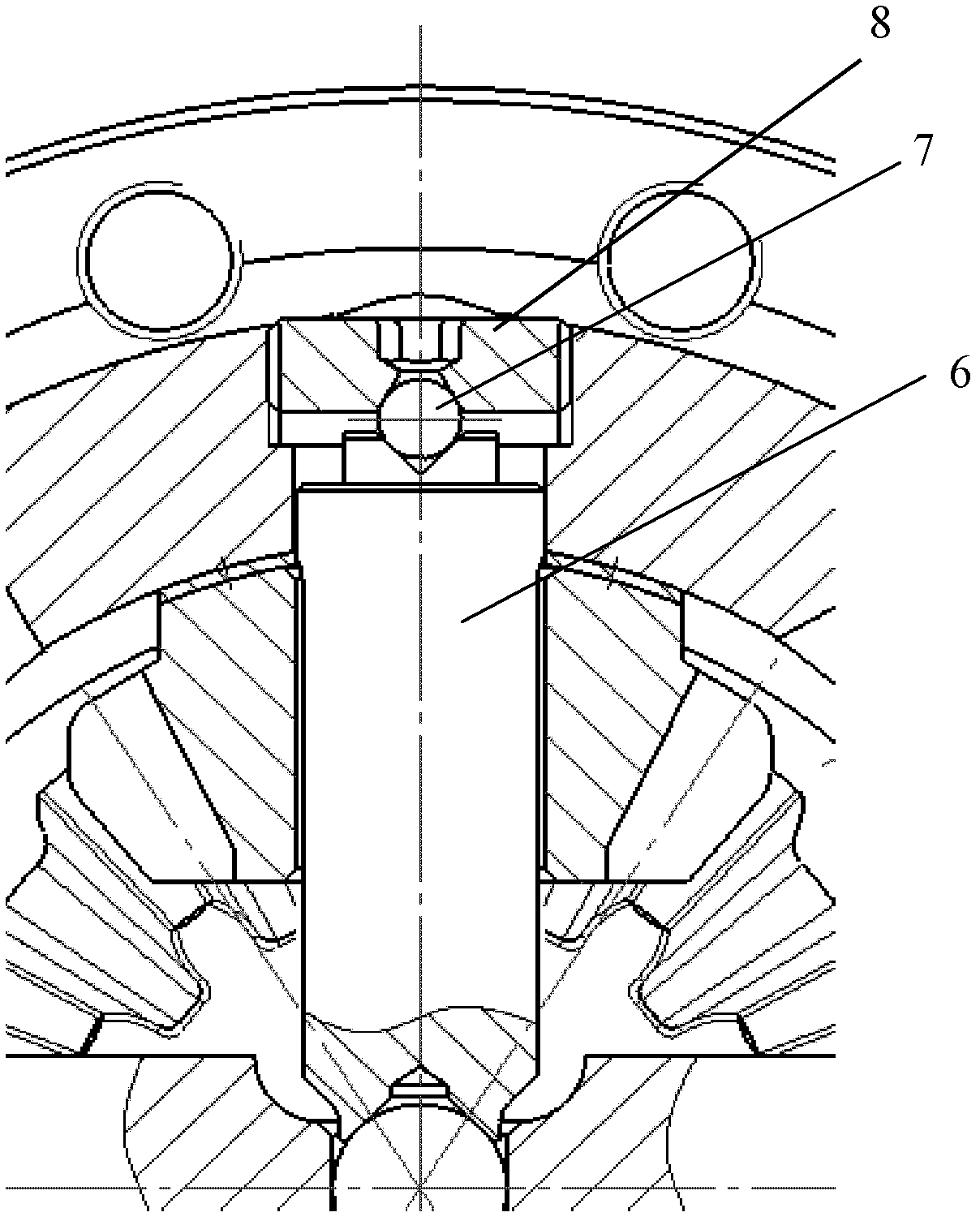

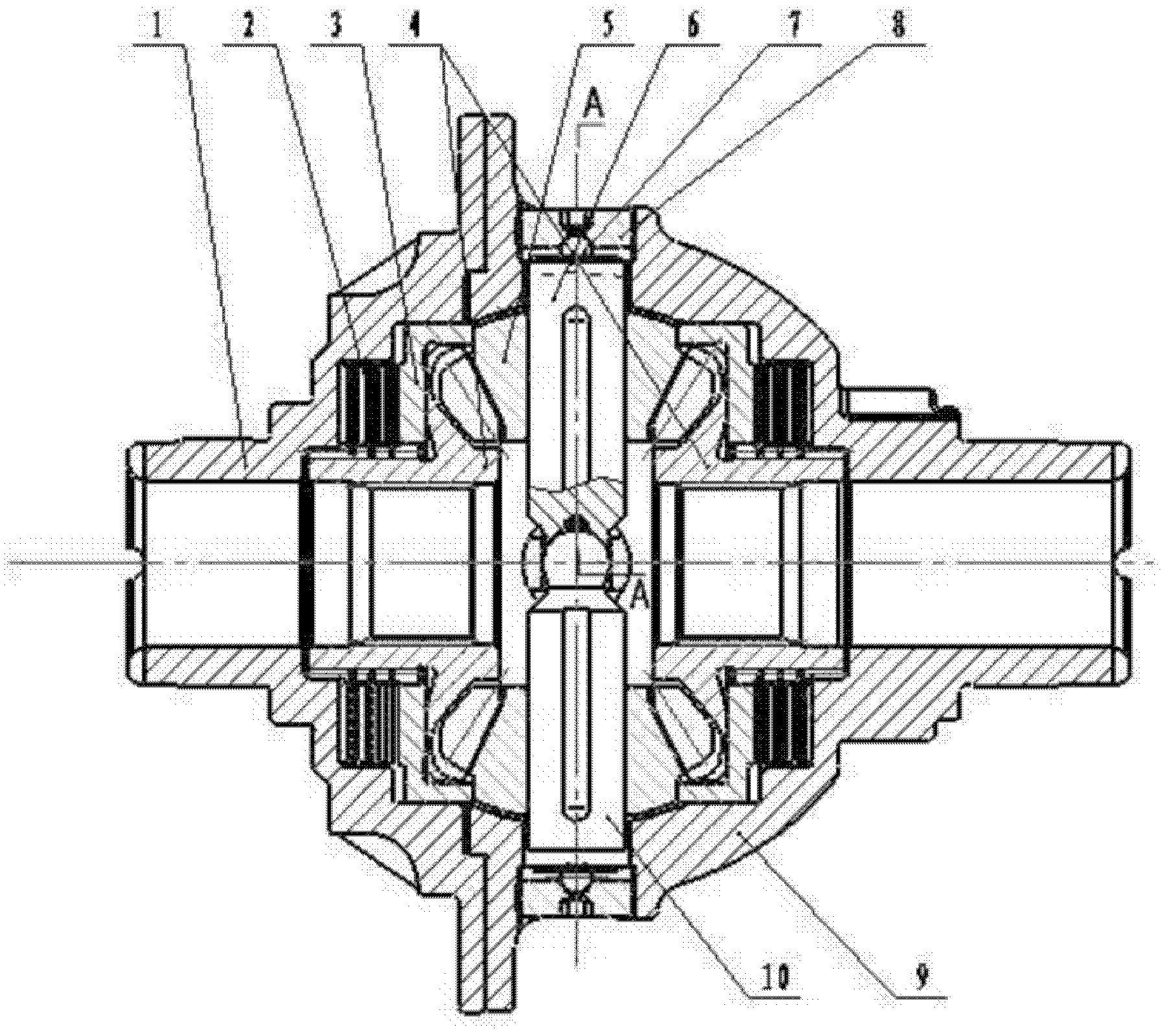

Swing type limited slip differential

ActiveCN102518772ADriving safetyGuaranteed meshing accuracyDifferential gearingsControl devicesLimited-slip differentialGear wheel

The invention provides a swing type limited slip differential, which comprises a shell, two differential gears distributed on the left and right, two planet gears distributed up and down between the differential gears, friction plates and pressure plates. The swing type limited slip differential is characterized in that: each planet gear is provided with a gear shaft; one of the two contacted gear shafts has a ball at the front end, and the other of the two contacted gear shafts has a recessed inner taper hole at the front end; the center of the ball is positioned at conic nodes of the planet gears; gaps are formed between the pressure plates and the shell; and the tail of each gear shaft is mounted on the shell and can do trace swing in the same plane as the axis of each differential gear. When a bevel gear pair is meshed, the conic nodes are overlapped, and the meshing accuracy is ensured; and after driving torque is lost or reduced because wheels on one side slip, automatic adjustment is carried out through an internal mechanism, larger driving torque of wheels on the other side is instantly regulated, and the driving torque on the two sides is redistributed to ensure driving safety when a vehicle slips or turns a corner.

Owner:天津天海同步科技有限公司

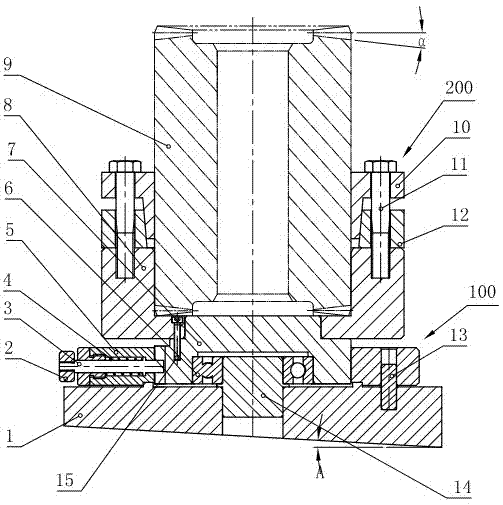

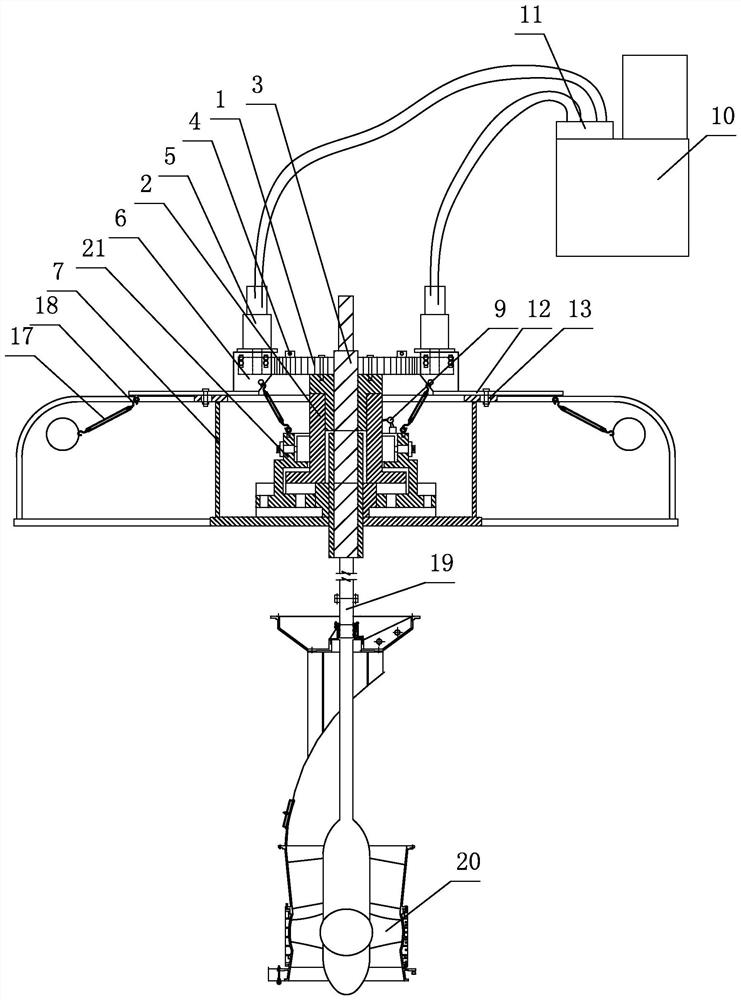

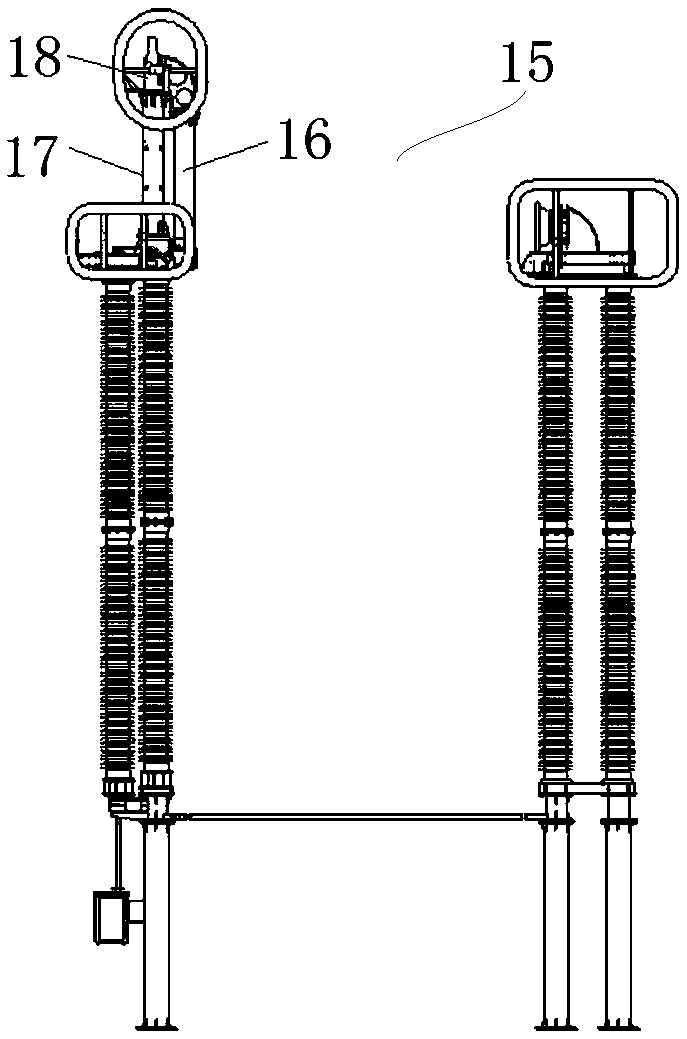

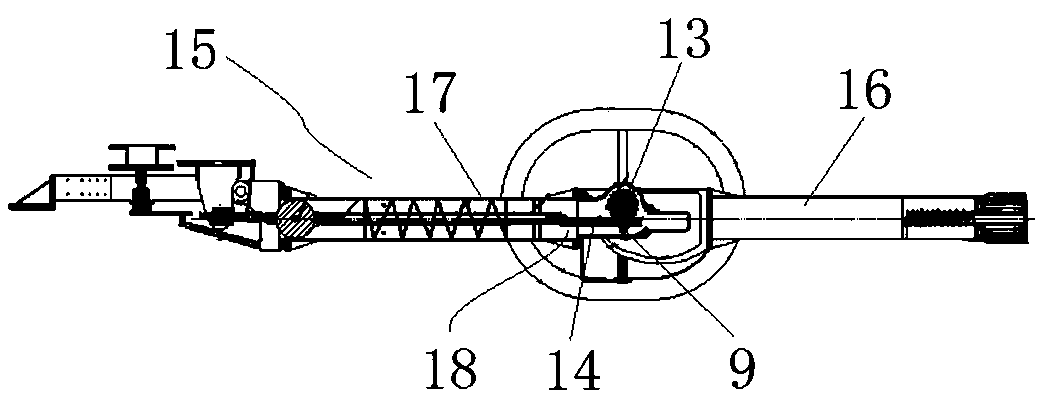

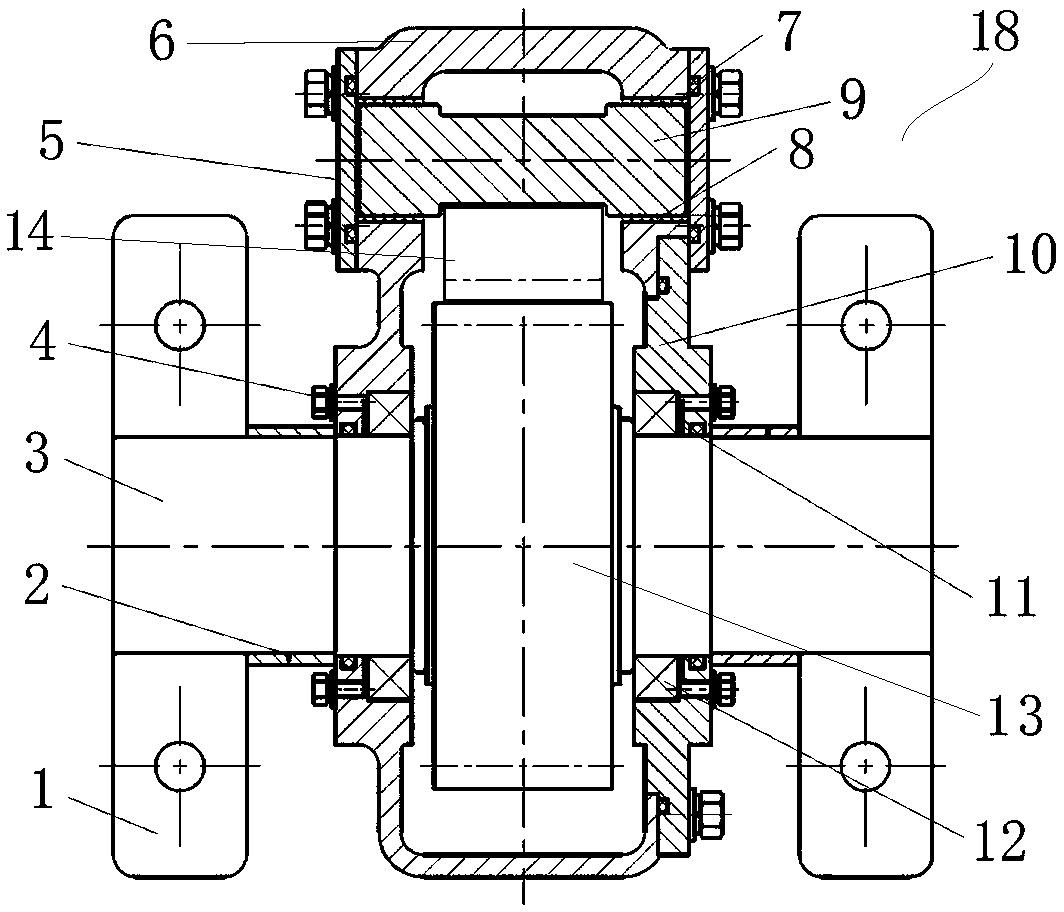

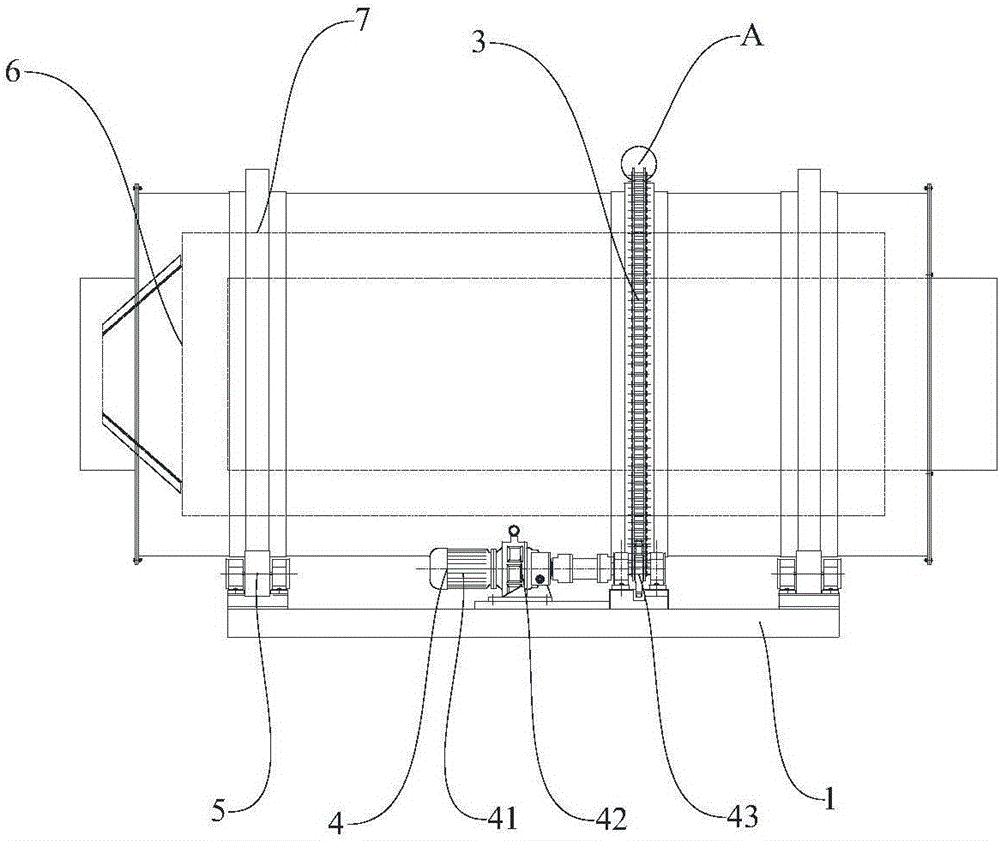

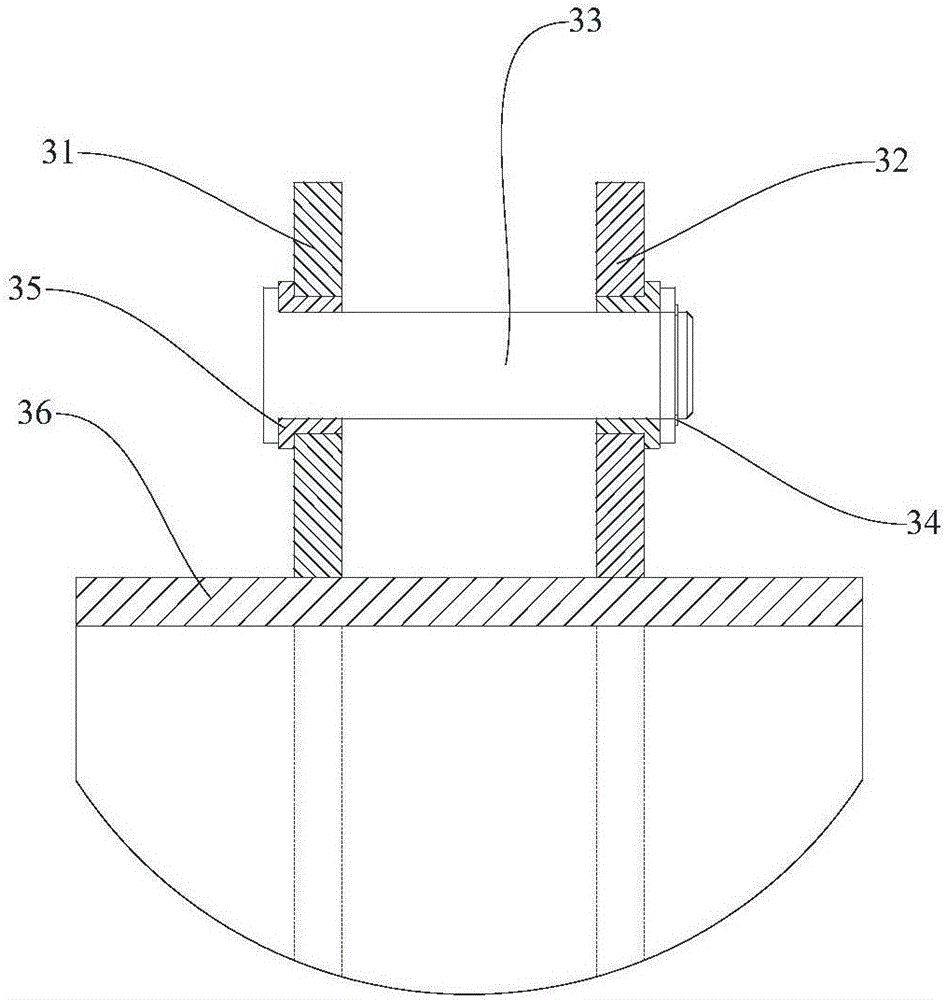

Hydraulic turning overhauling device and method for large vertical axial-flow pump unit

PendingCN111810434AForce balanceEven by forcePump componentsElectric/magnetic position measurementsHydraulic motorAxial-flow pump

The invention discloses a hydraulic turning overhauling device and method for a large vertical axial-flow pump unit. The device comprises a gear disk, two hydraulic motors and a detecting instrument;the gear disk is mounted on a thrust bearing through bolts; a motor spindle penetrates through the center of the gear disk; lifting rings are arranged on the upper surface of the gear disk; the two hydraulic motors are arranged symmetrically with the motor spindle used as the center; the two hydraulic motors work synchronously; the hydraulic motors are mounted on a motor casing through adjustablesupporting seats; the adjustable supporting seats are used for adjusting the horizontal positions, the vertical positions and the inclination angles of the hydraulic motors; pinions driven by the hydraulic motors are in meshing connection with the gear disk; and the detecting instrument is used for detecting the motor spindle or a pump shaft. The power is sufficient, the stress balance of the geardisk can be guaranteed, the horizontal positions, the vertical positions and the inclination angles of the hydraulic motors are adjusted through the adjustable supporting seats, the meshing precisionof the pinions and the gear disk is guaranteed, and safe and stable operation of a water pump is guaranteed.

Owner:南水北调东线山东干线有限责任公司

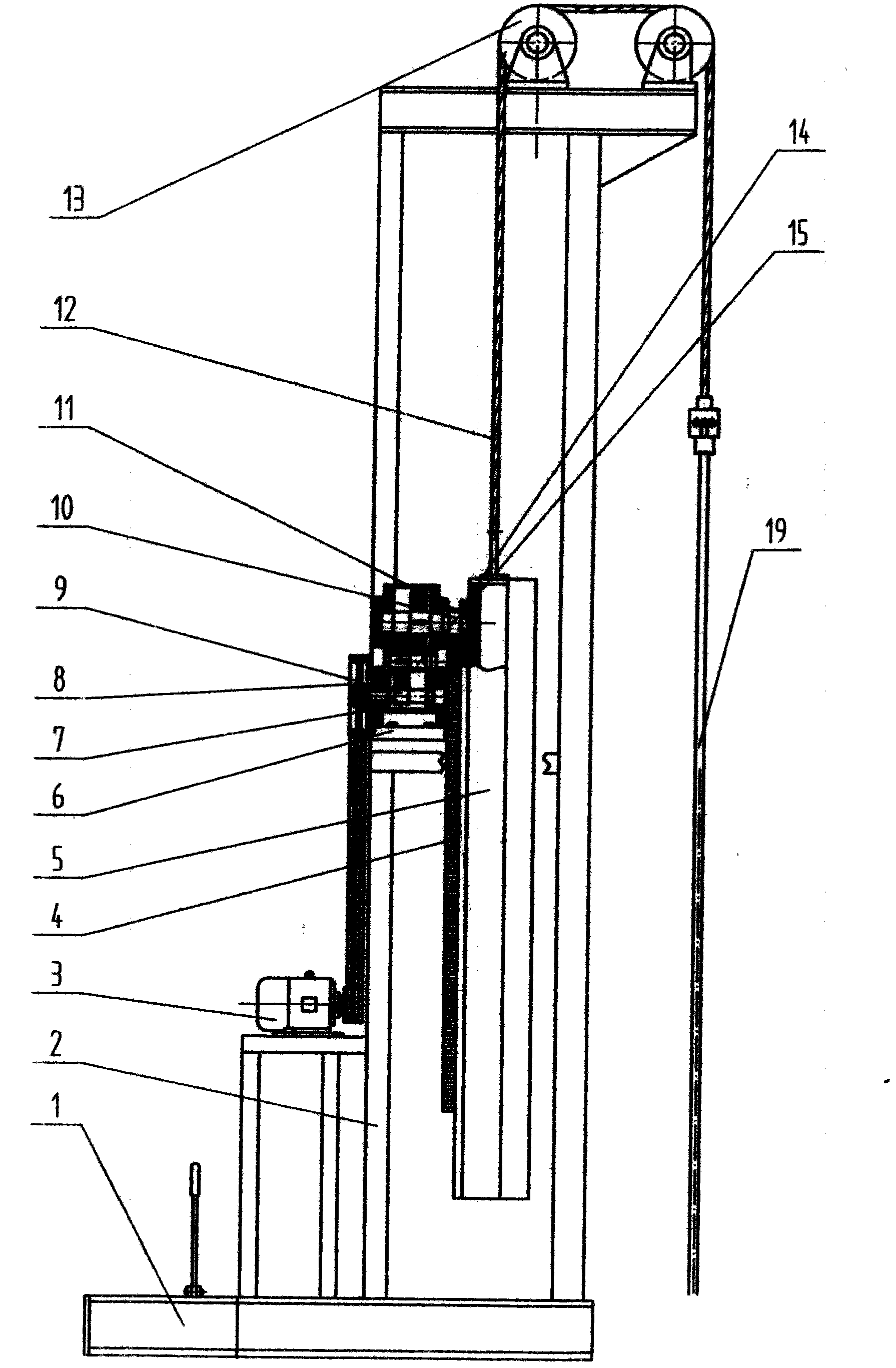

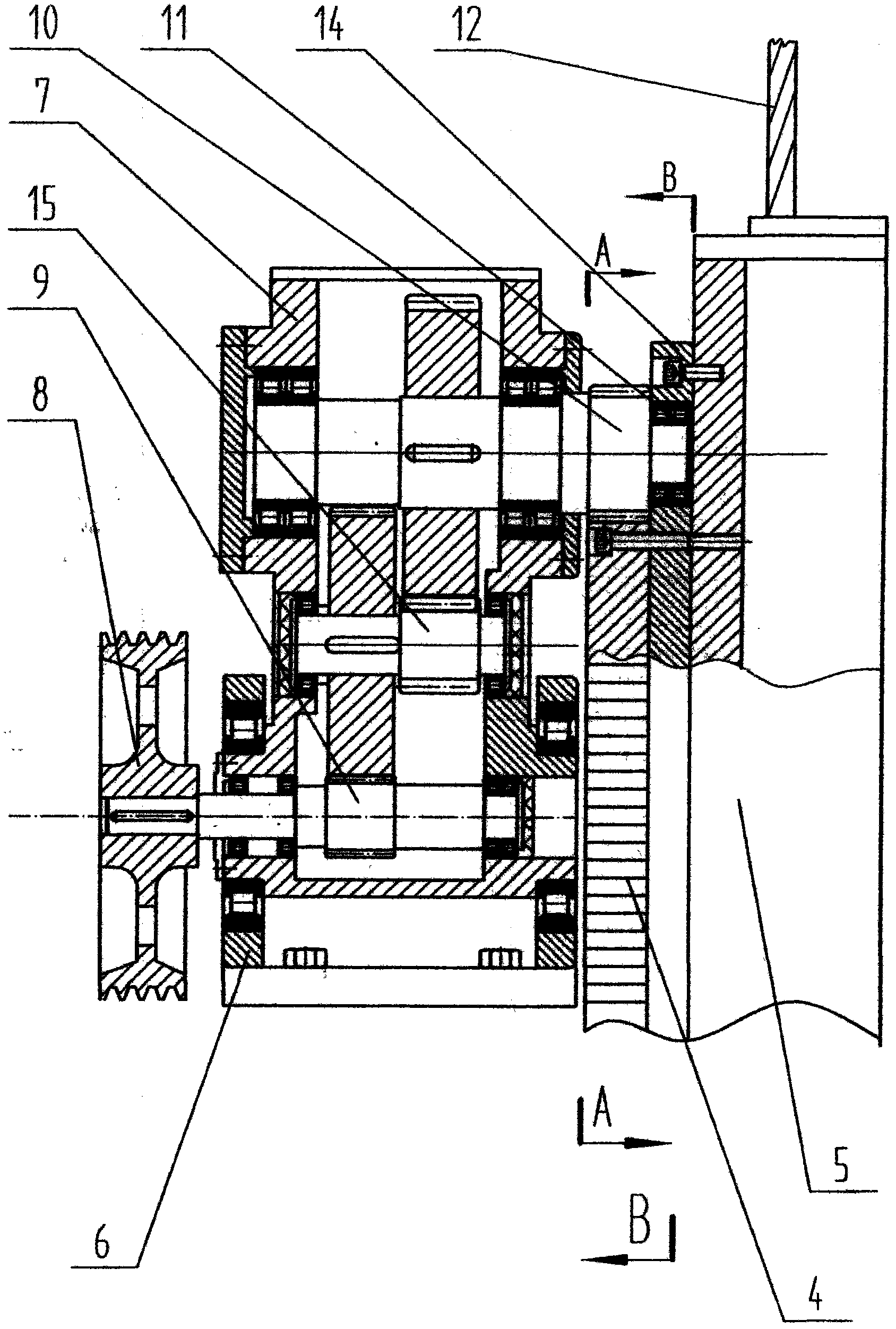

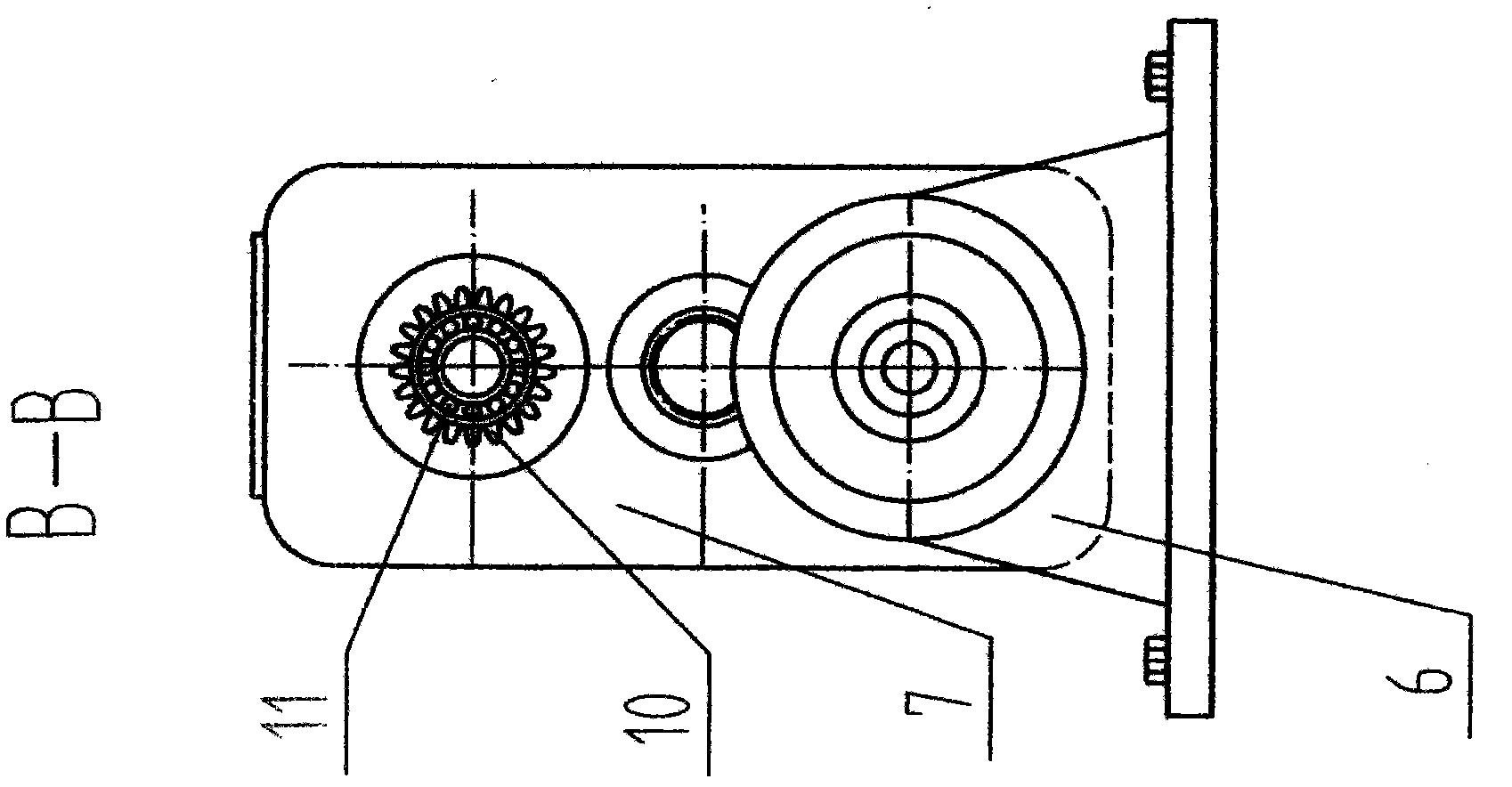

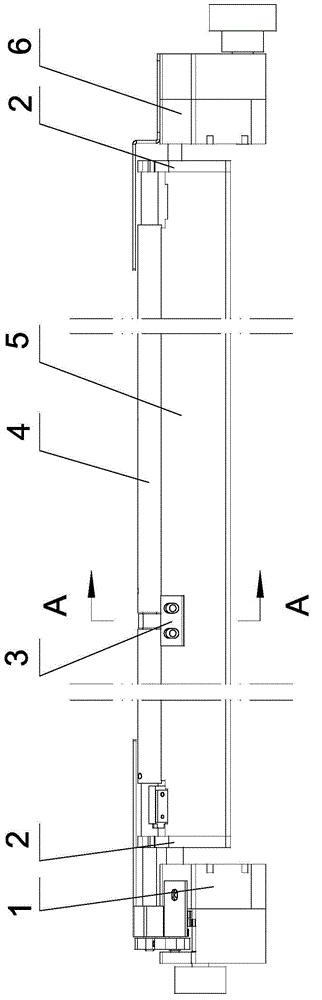

Planet gear ring oil pumping unit

InactiveCN102828726AGuaranteed meshing accuracyGuaranteed bearing capacityFluid removalFriction gearingsGear wheelRack and pinion

The invention discloses a planet gear ring oil pumping unit comprising a rack, a motor, a support, a gear box, a sun wheel gear shaft, a planet gear shaft, speed reduction gears, an annular rack and a rope suspending system. The planet gear ring oil pumping unit disclosed by the invention is characterized in that the middle part of the rack is provided with a support, the support is provided with the gear box, the gear box is provided with the sun wheel gear shaft, the speed reduction gear shaft and the planet gear shaft, and the speed reduction gear shaft and the planet gear shaft are respectively provided with one speed reduction gear. The planet gear shaft is meshed with the annular rack and does linear movement, and the two ends of the rack are semi-circular long rings, so that the oil pumping unit operates to an annular gear surface and enters into a guide ring, a planet gear is meshed with a semi-circular gear and moves from the left side of the rack to the right side of the rack under the action of the guide ring, the annular rack starts to operate in an inverted manner at the moment, reciprocation of the rack is realized, the rope suspending system at the top of the rack is driven, and the aim of pumping oil is achieved. The planet gear ring oil pumping unit disclosed by the invention has the characteristics of simple structure, reliable operation, high efficiency, stable reversing, economical efficiency and durability.

Owner:陈建武

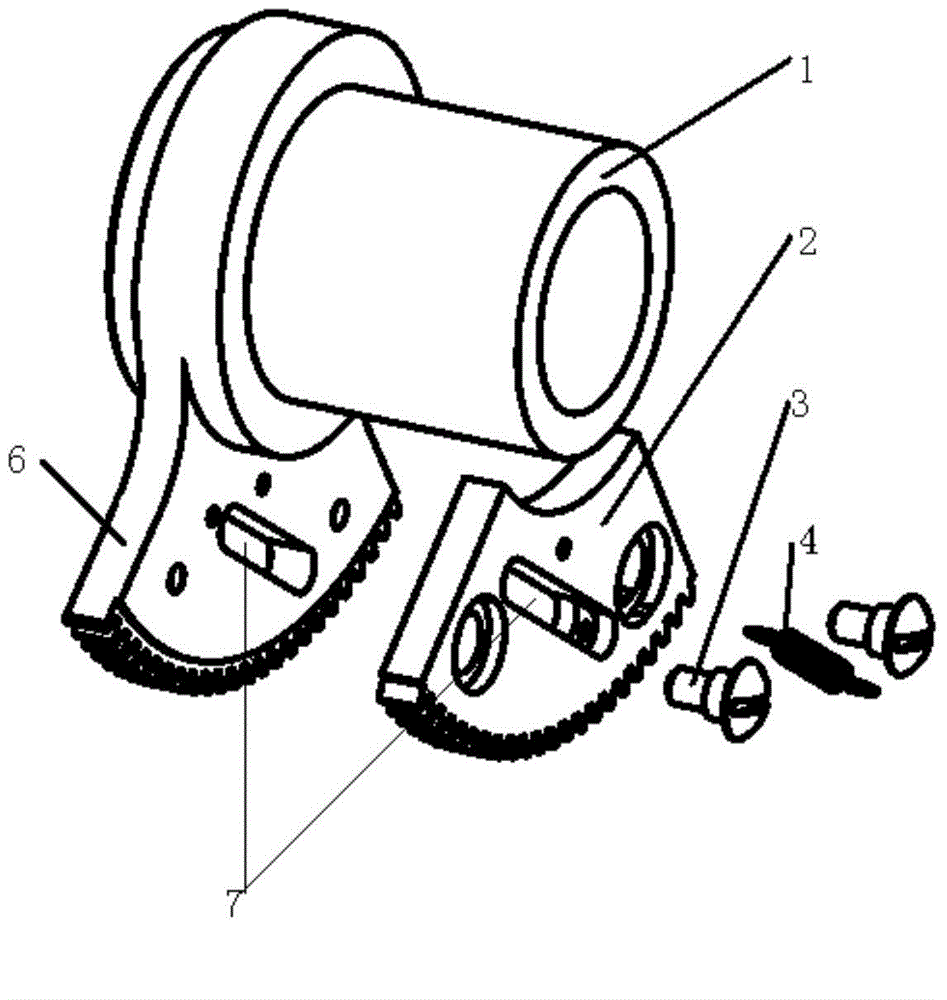

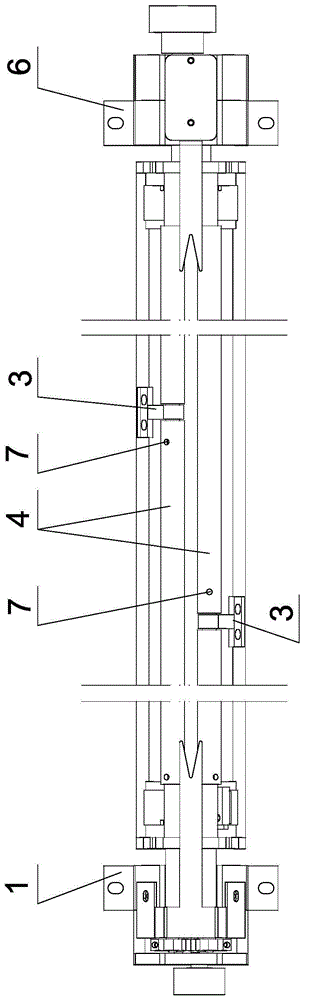

Roller device of computerized flat knitting machine

ActiveCN104963076AExtended service lifeGuaranteed accuracyWeft knittingEngineeringMechanical engineering

The invention relates to a roller device of a computerized flat knitting machine and aims to tract fabric by two rollers of the device after the two rollers are open and can still rotate. Traction force can be adjusted via adjustments of a gap between the two rollers; and when the rollers open and close, transmission gear engaging precision can be guaranteed, so transmission gear abrasion can be reduced, interference to a base plate can be avoided and service life of the transmission gear can be prolonged. The technical scheme is that the roller device of the computerized flat knitting machine comprises a left carrying rack, a right carrying rack and two rollers. The roller device is characterized in that the left and right ends of each roller are rotationally positioned on the left and right carrying rack individually via two swinging blocks; a driving assembly driving the two rollers to rotate is installed on the left carrying rack; and an opening-closing assembly driving the two swinging blocks to swing to enable the two rollers to close and open is installed on the right carrying rack.

Owner:浙江万事兴机械有限公司

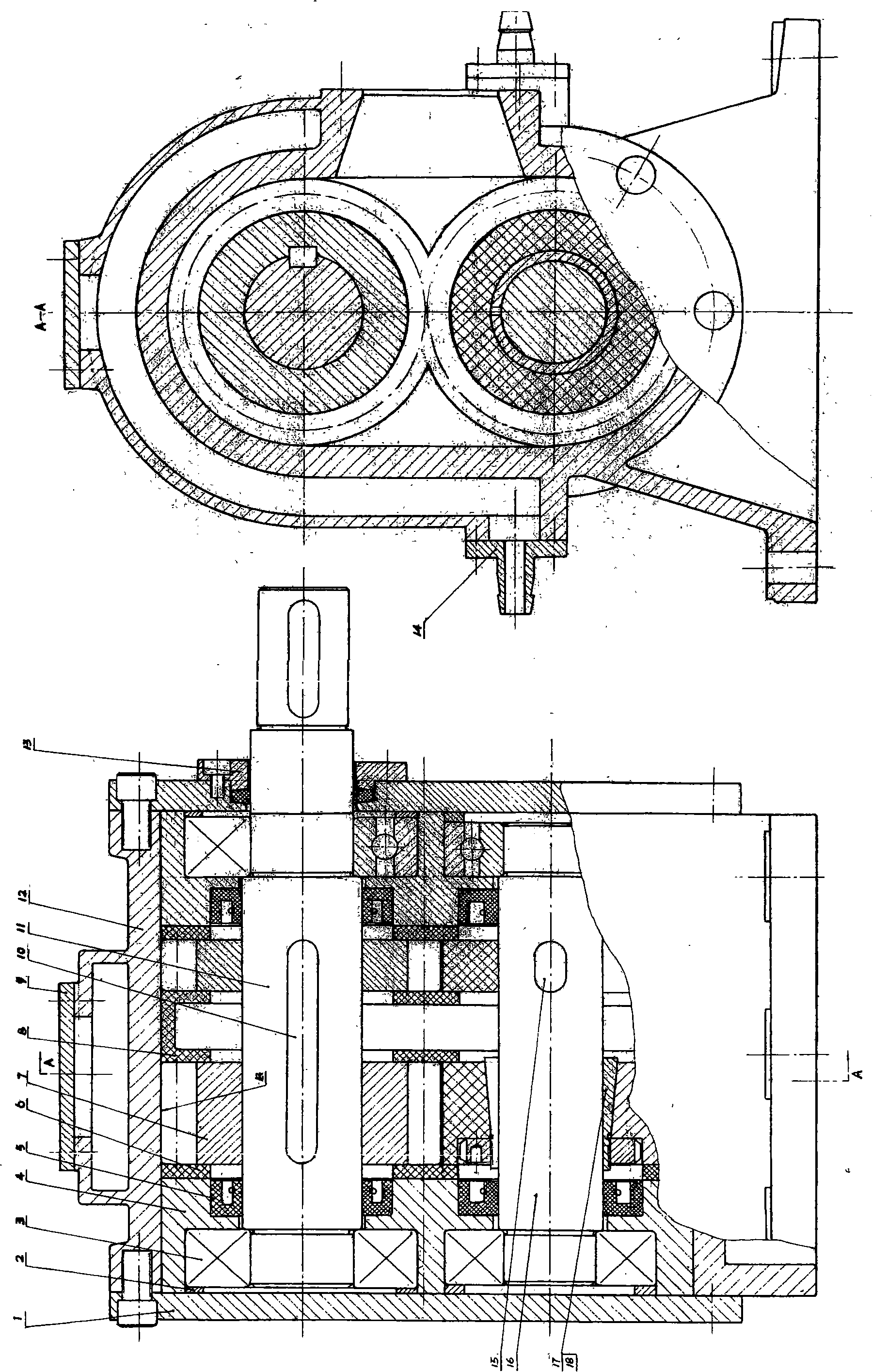

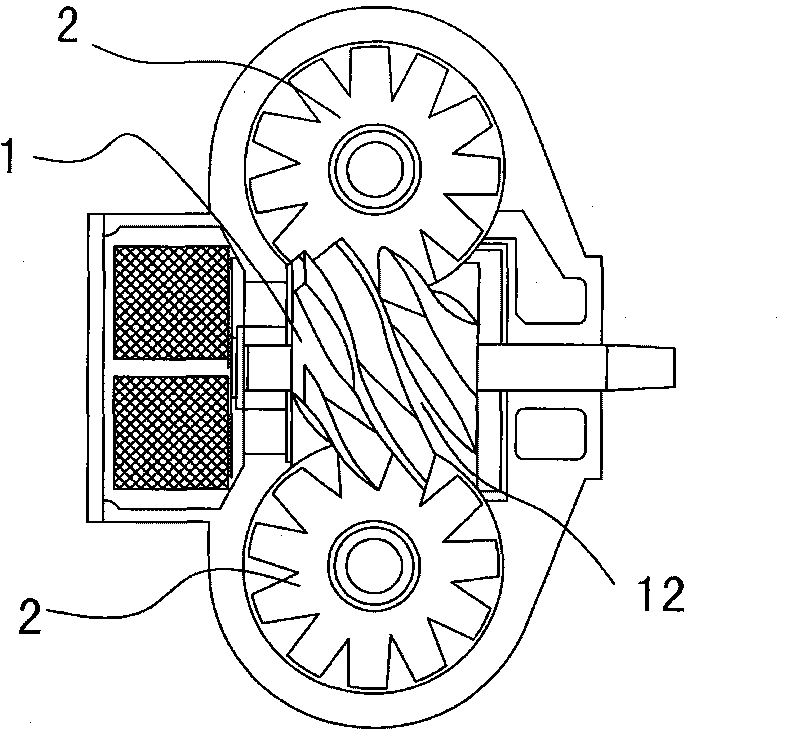

Speed increasing box for compressor

InactiveCN102086919AReduce volumeCompact structureRotary bearingsToothed gearingsShock waveEngineering

The invention relates to a speed increasing box for a compressor, and the speed increasing box is applied to an experiment table of a transonic speed axial flow compressor. The speed increasing box for the compressor comprises a box body, wherein the box body is internally provided with a two-stage gear transmission structure; the two-stage gear transmission structure comprises a primary input gear shaft, a primary output gear shaft, a secondary input gear shaft, a secondary output gear shaft; the primary output gear shaft is connected with the secondary input gear shaft; the primary output gear shaft and the secondary input gear shaft are positioned on the same main shaft; and the primary input gear shaft and the secondary output gear shaft are positioned at the same side of the main shaft. The speed increasing box for the compressor provided by the invention has the advantages of compact structure, greater speed increasing ratio and reasonable design, and can not generate shock stall and buffeting; and the technical problems in the prior art that the occupation area of the speed increasing box structure is large, the speed revolving of transonic speed input can not be satisfied by the speed increasing ratio, and the shock stall and buffeting can be easily generated are solved.

Owner:杭州南方通达齿轮有限公司

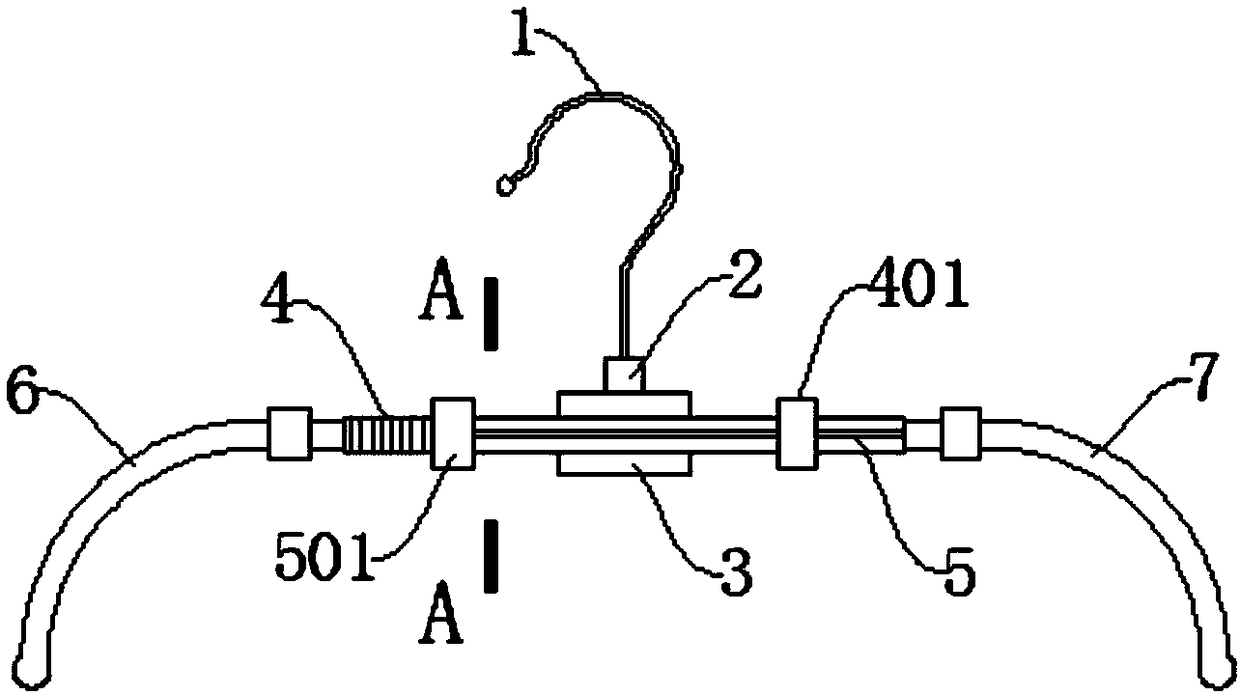

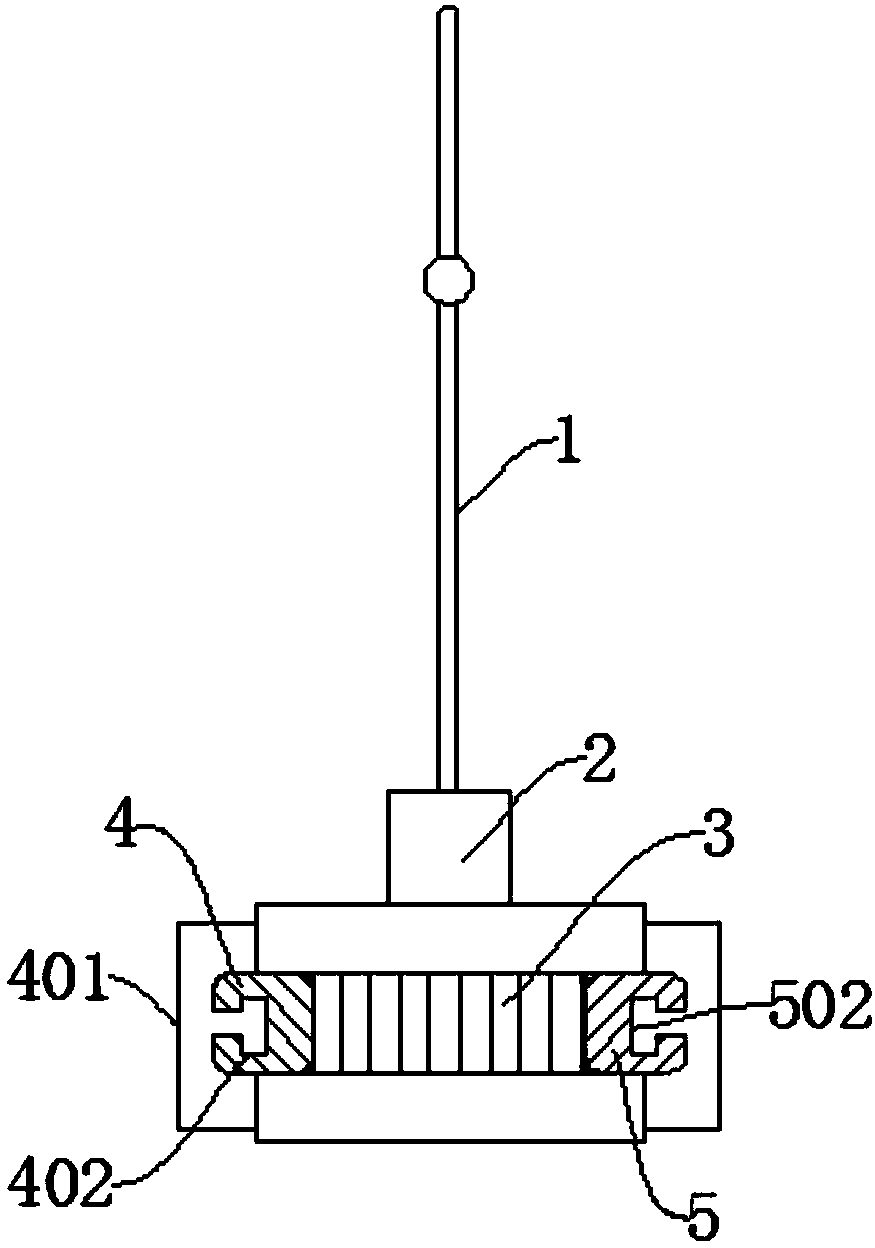

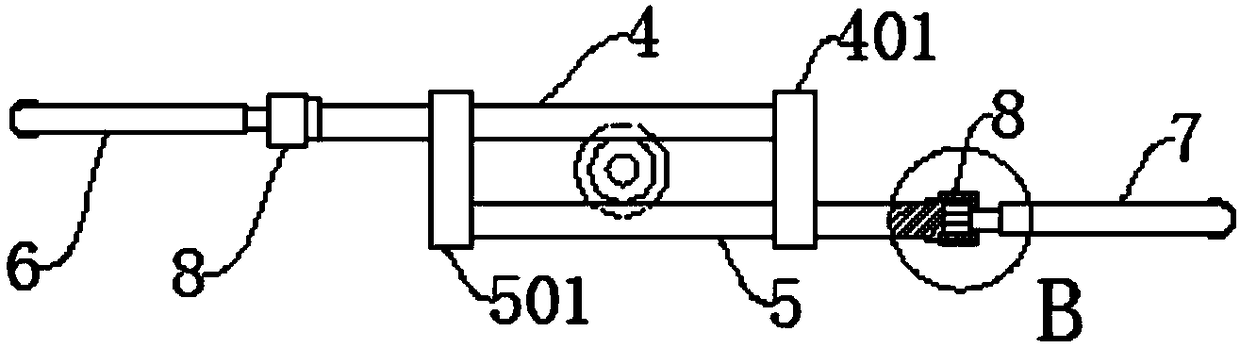

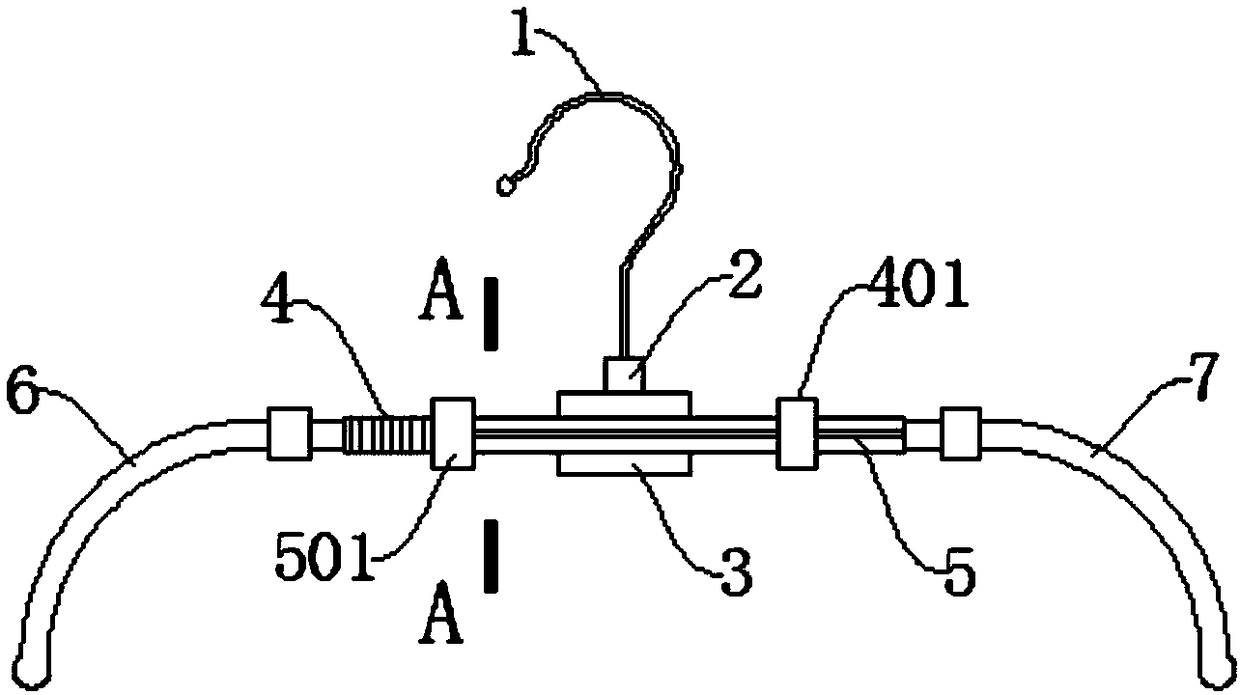

Use method of telescopic clothes hanger

The invention discloses a use method of a telescopic clothes hanger. When the telescopic clothes hanger is used, a hook is rotated anticlockwise, a connecting shaft drives a gear to rotate anticlockwise, a first rack and a second rack are driven by the gear to move to the two sides, a tensile spring generates reverse acting force when the first rack and the second rack are pulled open, when the first rack and the second rack are driven by the gear to move to proper positions, a locking screw is screwed down, when the clothes hanger needs to be folded up, the locking screw is unscrewed, and under the effect of the reverse acting force of the tensile spring, the first rack and the second rack move to the hook to reset. The telescopic clothes hanger has the advantages that when the clothes hanger is unfolded, a user needs to manually rotate the hook anticlockwise, the connecting shaft drives the gear to rotate anticlockwise, the first rack and the second rack are driven by the gear to move to the two sides, the tensile spring generates reverse acting force when the first rack and the second rack are pulled open, when the clothes hanger needs to be folded up, the user needs to unscrewthe locking screw without manually rotating the hook, the first rack and the second rack move to the hook to reset under the effect of the reverse acting force of the tensile spring, operation is convenient, and the telescopic clothes hanger is convenient to operate, simple and easy to use.

Owner:胡融

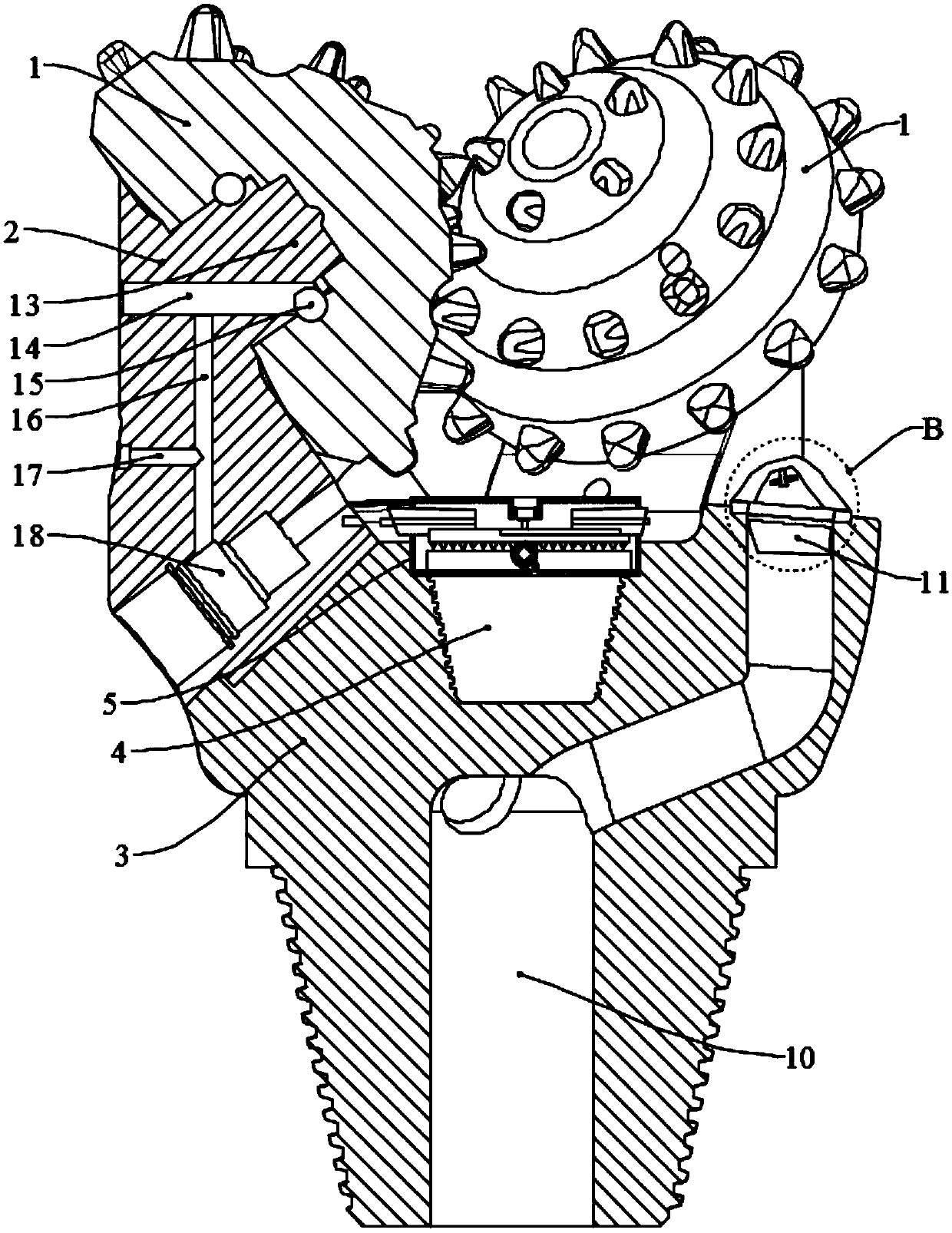

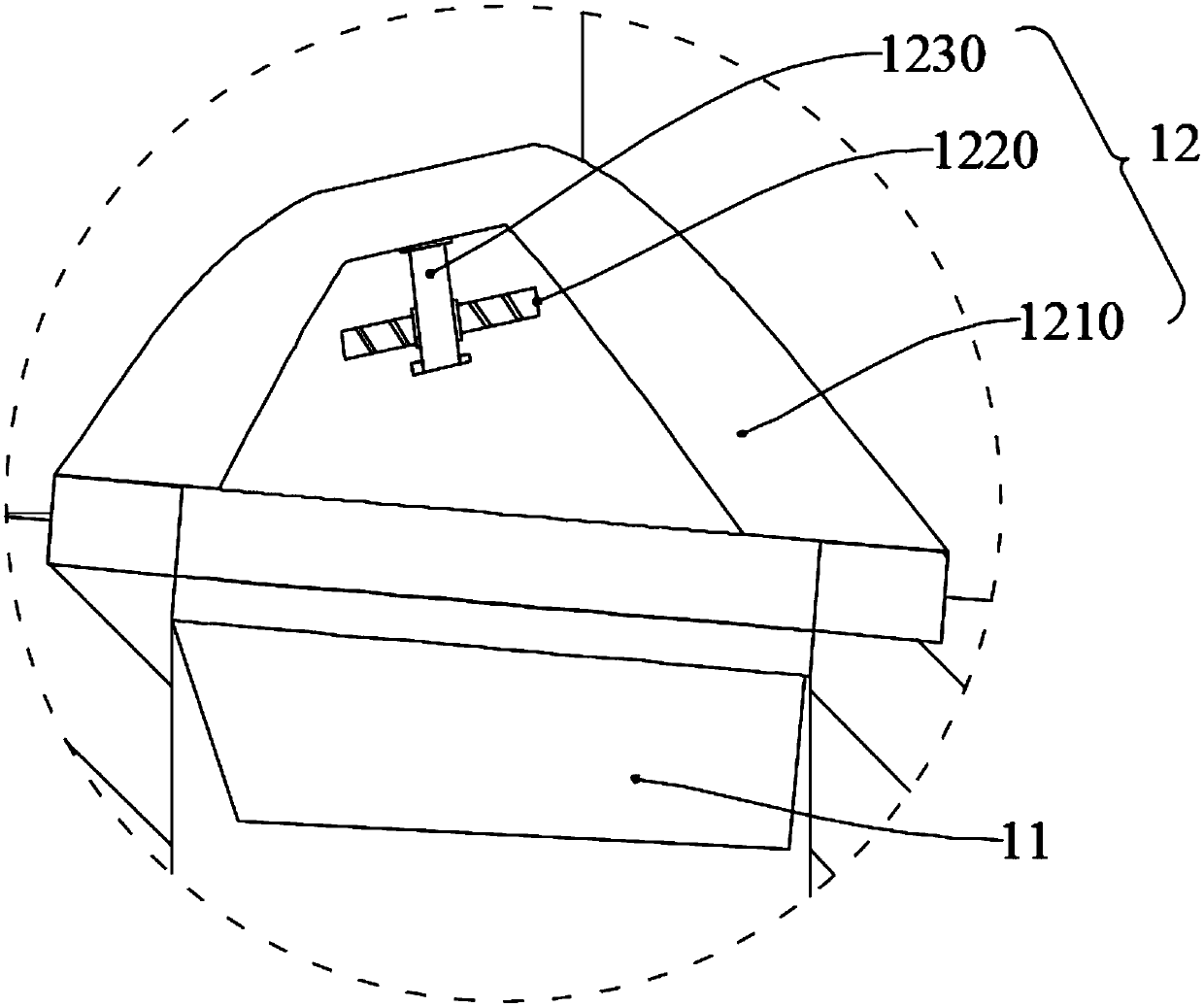

Split-type cone drill bit

The invention discloses a split-type cone drill bit, belongs to the technical field of geological drilling devices, and aims at solving the problems of the integrated connection of cone legs and coneseat of the cone drill bit, heavy integrated weight of a cone, high labor intensity of a worker when a single cone is replaced, and the inconvenient replacement of the cone. The cone drill bit comprises a cone seat, the upper ends of the cone seat is provided with three cone legs which are annularly distributed, and cones are rotatably connected with any cone leg; the cone legs are slidably connected with the cone seat, a placing groove is formed in the middle of the cone seat, first inner threads are arranged on the inner wall of the lower end of the placing groove, pressing units which are used for tightly pressing the cone legs are arranged in the middle of the cone seat, and connecting ends which are mutually matched to the first inner threads are connected with the lower ends of the pressing units.

Owner:CANGZHOU GREAT DRILL

Double hanging point gate opening and closing device capable of fast closing gate

InactiveCN1752351ATo achieve the purpose of quick closureGuaranteed lifeBarrages/weirsCouplingDrive shaft

The present invention relates to a double hanging point quickly-closed gate opening and closing equipment. Said equipment includes the following several portions: driving control mechanism, connecting flange, driving gear box, hanging point supporting frames, large spiral bevel gear and small spiral bevel gear, coupler, rack connected with gate, buffer frame and buffer. Said invention also provides the concrete connection mode of all the above-mentioned portions.

Owner:TIANJIN SPEED REDUCER

Telescopic clothes hanger

The invention discloses a telescopic clothes hanger which comprises a hook and a first supporting arm and a second supporting arm. The bottom of the hook is provided with a connecting shaft. A gear isfixedly connected with the lower side of the connecting shaft. A first rack and a second rack which are meshed with the gear are arranged outside the gear and are in parallel. The head portion of thefirst rack is provided with a first slide sleeve. The head portion of the second rack is provided with a second slide sleeve. The first slide sleeve and the second slide sleeve are symmetrically arranged on the two sides of the gear. The telescopic clothes hanger has the advantages that by forward and backward rotating the hook, the distance between the first supporting arm and the second supporting arm can be adjusted, and therefore the requirement for airing clothes with different sizes is met by means of the clothes hanger, operation is simple and use is convenient.

Owner:胡融

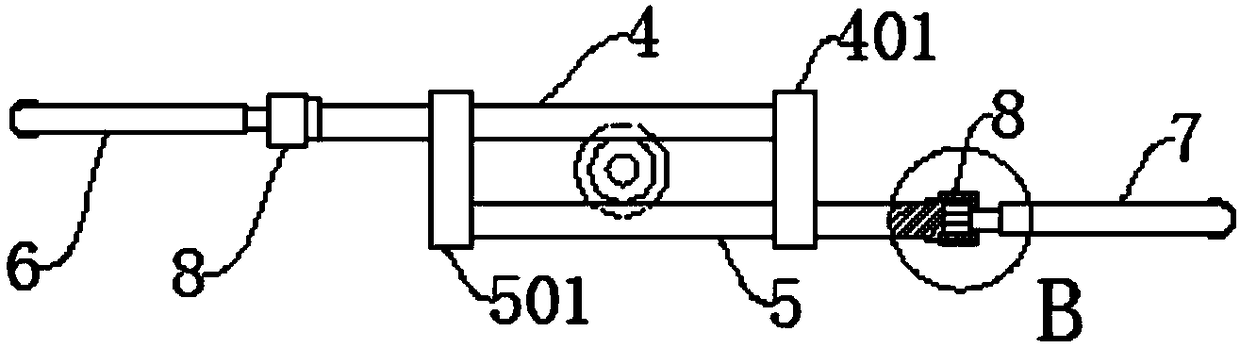

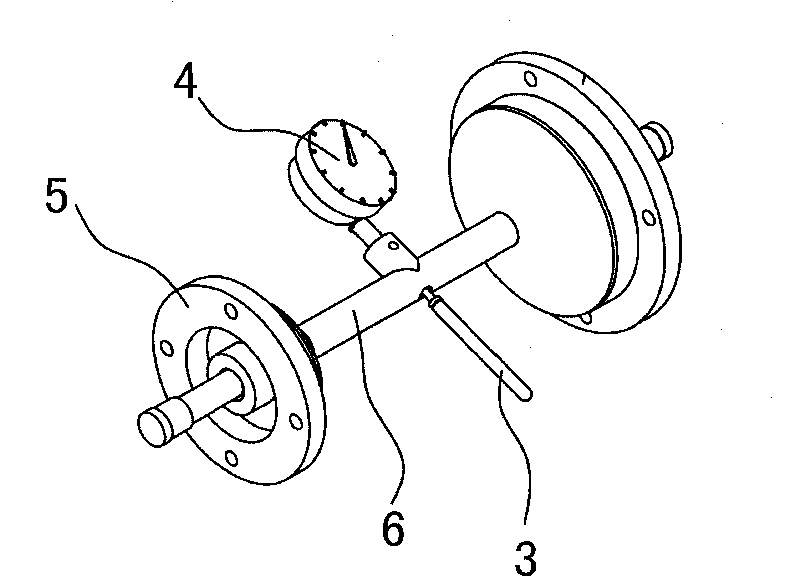

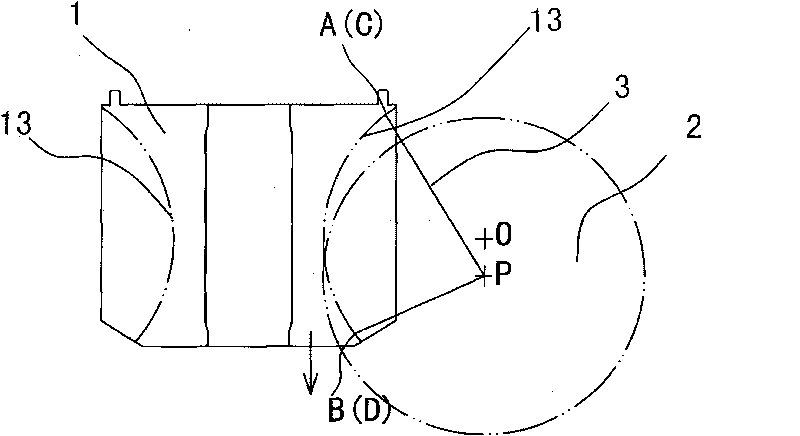

Method for adjusting star wheel-rotor engagement accuracy of single screw rod type refrigerating compressor

ActiveCN101725530AIncrease or decrease thicknessAvoid wear and tearRotary piston pumpsRotary piston liquid enginesRefrigeration compressorEngineering

The invention relates to a method for adjusting star wheel-rotor engagement accuracy of a single screw rod type refrigerating compressor. The method has the following steps that: (1) a main shaft is arranged in a machine casing, and a circular gasket is prearranged; (2) a centering tooling is arranged in the machine casing position in which a star wheel is arranged; (3) a screw rod rotor rotates, the end of a centering needle is adjusted to one end of a rotor groove, and a reading of a dialgage at the time is recorded as a; the screw rod rotor reversely rotates, the end of the centering needle is adjusted to the other end of the rotor groove, and a reading of the dialgage at the time is recorded as b; the tolerance range is set to be 0+ / -delta, and the difference between b and a is compared with 0+ / -delta; (4) if the difference between b and a exceeds the tolerance range, the thickness of the circular gasket between the fixed mating surfaces is increased or decreased, and the step (3) is repeated, until the difference between b and a is controlled within the tolerance range. The invention solves the problems that the traditional star wheel-rotor engagement has complicated debugging process, the assembly efficiency of the products is low, and the assembled star wheel-rotor engagement is still low.

Owner:MCQUAY AIR CONDITIONING & REFRIGERATION SUZHOU

Conductive disconnecting link of disconnecting switch, gear box of conductive disconnecting link and gear box body

ActiveCN108054046AGuaranteed meshing accuracyGuaranteed opening and closing operationAir-break switch detailsGear wheelEngineering

The invention relates to a conductive disconnecting link of a disconnecting switch, a gear box of the conductive disconnecting link and a gear box body. The conductive disconnecting link of the disconnecting switch comprises an upper conductive tube, a lower conductive tube and a gear box which is connected with the upper conductive tube and the lower conductive tube; the gear box comprises a gearbox body; a gear shaft for assembling a gear is arranged in the gear box body by means of bearing transmission; a rack matched with the gear is arranged in the gear box body; the gear box body comprises a box body unit; end cover mounting holes which are used for exposing the meshing portions of the gear and located in at least one side of the gear shaft are formed in the box body unit; the end cover mounting holes are provided with end covers; and the corresponding ends of the gear shaft are rotationally arranged on the end coves. According to the gear box body, the box body unit and the endcovers are installed in a matched manner; the end cover mounting holes can expose the meshing portions of the gear; and when the end covers are arranged on the box body unit, the meshing conditions of the gear and the rack can be observed through the end cover mounting holes, and therefore, the meshing accuracy of the gear and the rack can be ensured.

Owner:HENAN PINGGAO ELECTRIC +3

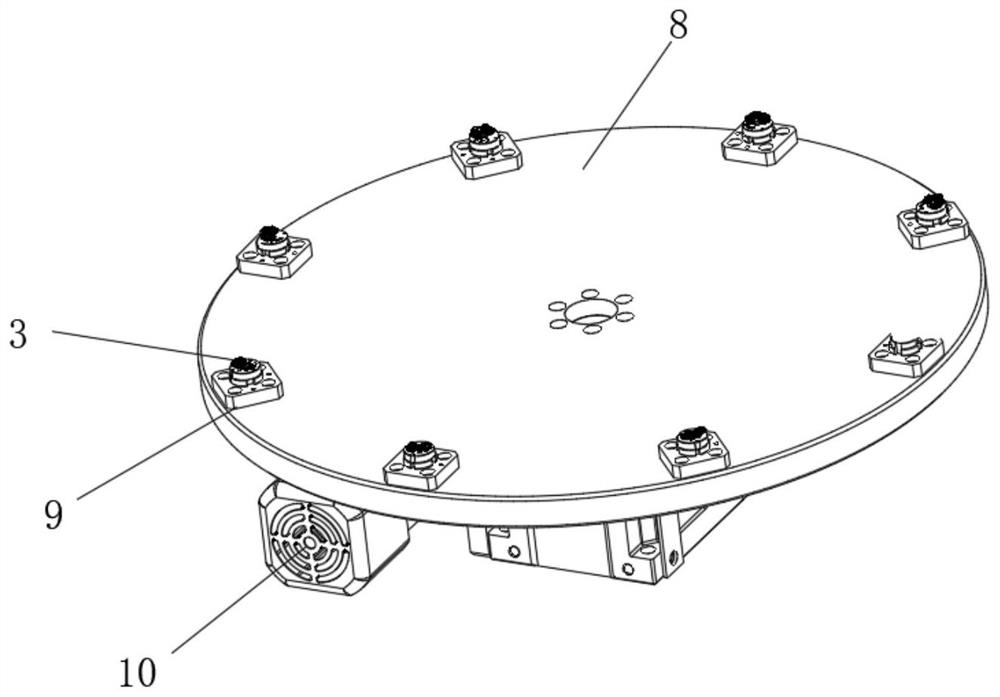

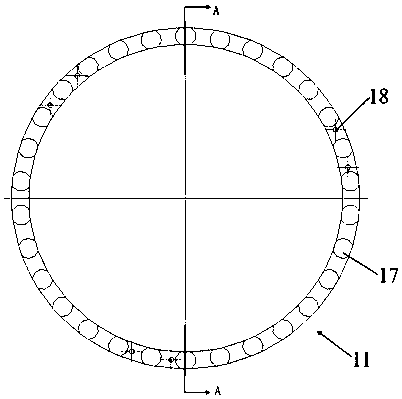

Cog rotary dryer

InactiveCN106225472AExtended service lifeReduce energy consumptionDrying solid materialsElectric machineryEngineering

The invention discloses a cog rotary dryer. The cog rotary dryer comprises a transmission assembly and a driving assembly, wherein the transmission assembly comprises a first cog locating wheel, a second cog locating wheel and a plurality of pillars; the first cog locating wheel and the second cog locating wheel extend in the circumferential direction of a barrel body and are fixed to the barrel body; the first cog locating wheel and the second cog locating wheel are spaced at equal intervals in the radial direction; the pillars extend in the radial direction; one ends of the pillars are detachably connected with the first cog locating wheel; the other ends of the pillars are detachably connected with the second cog locating wheel; the plurality of pillars are spaced at equal intervals in the circumferential direction of the barrel body; the driving assembly comprises a motor, a gear motor and a driving gear; and the driving gear meshes with the circumferential wall of the pillar between the first cog locating wheel and the second cog locating wheel. According to the cog rotary dryer provided by the embodiment of the invention, the transmission efficiency can reach 95% to 98%, the energy consumption can be reduced, and the service life is prolonged.

Owner:江苏火焰山干燥技术有限公司

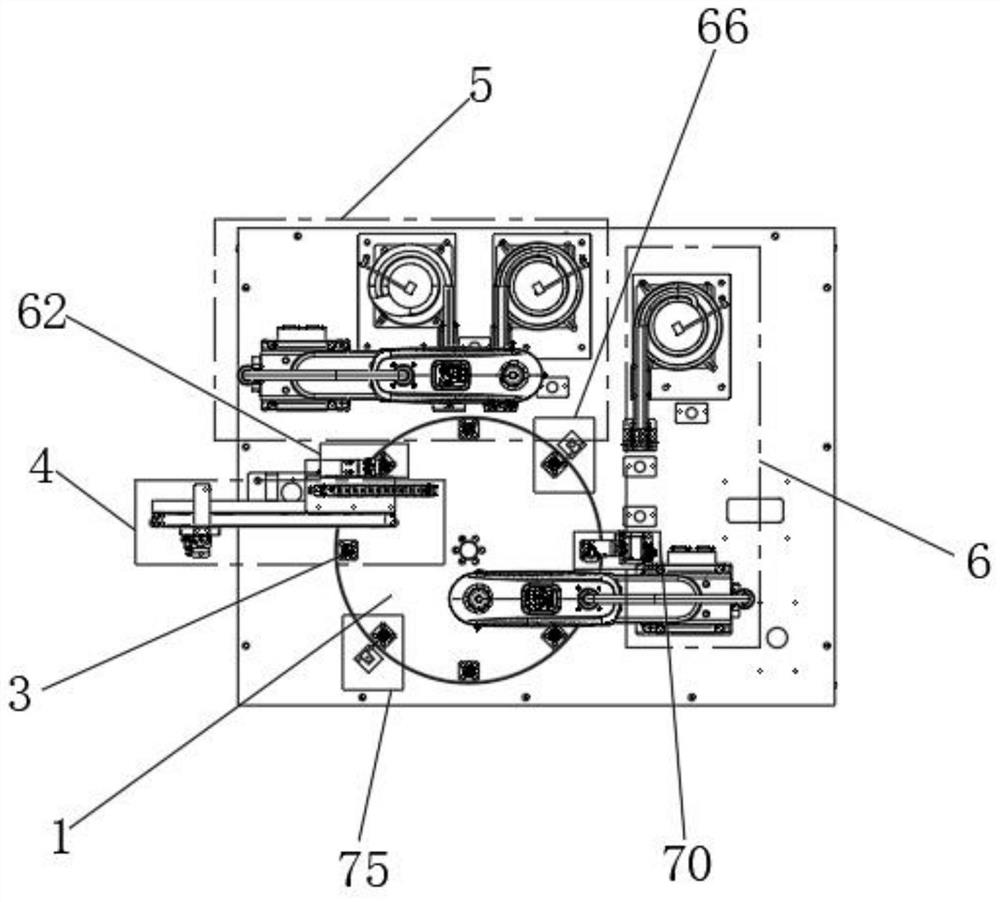

Internet of Things intelligent gas meter electromechanical valve gearbox gear set assembling system and method

PendingCN113770717AGuaranteed accuracyGuarantee stabilityAssembly machinesMetal working apparatusGear wheelControl engineering

The invention discloses an Internet of Things intelligent gas meter electromechanical valve gearbox gear set assembling system. The Internet of Things intelligent gas meter electromechanical valve gearbox gear set assembling system comprises a gearbox cover body conveying system; and the Internet of Things intelligent gas meter electromechanical valve gearbox gear set assembling system further comprises a gearbox cover body feeding system, a lower-layer gear assembling system and an upper-layer gear assembling system which are sequentially arranged in the gearbox cover body conveying direction. The gearbox cover body conveying system is used for automatically conveying gearbox cover bodies, the gearbox cover body conveying system is filled with the cover bodies through the gearbox cover body feeding system, and the lower-layer gear assembling system and the upper-layer gear assembling system are used for gear assembling of lower-layer gears and upper-layer gears correspondingly. After assembly, the lower-layer gears and the upper-layer gears are meshed with each other to form gearbox gear sets, the assembly cost is low, and the efficiency is high.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

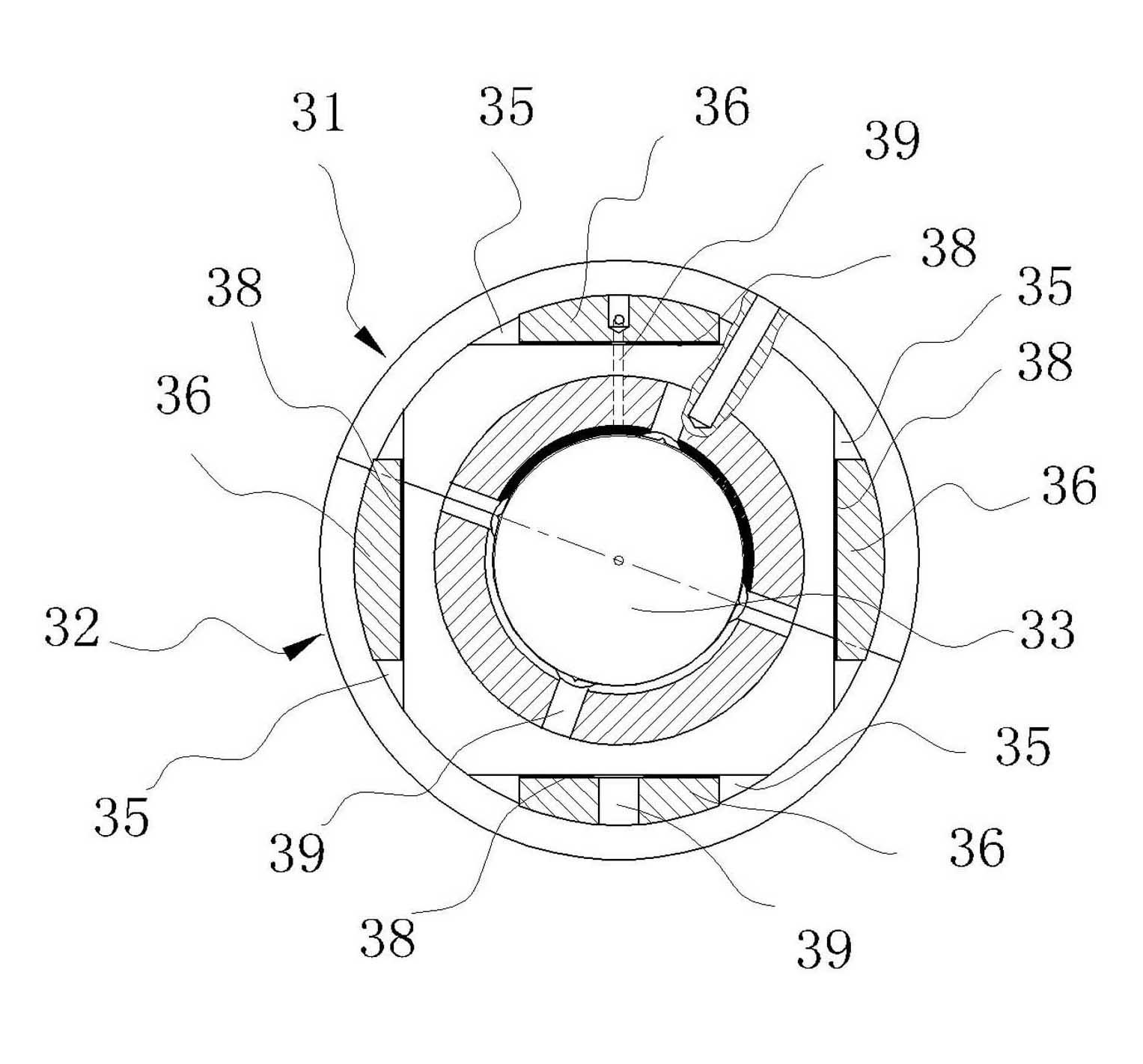

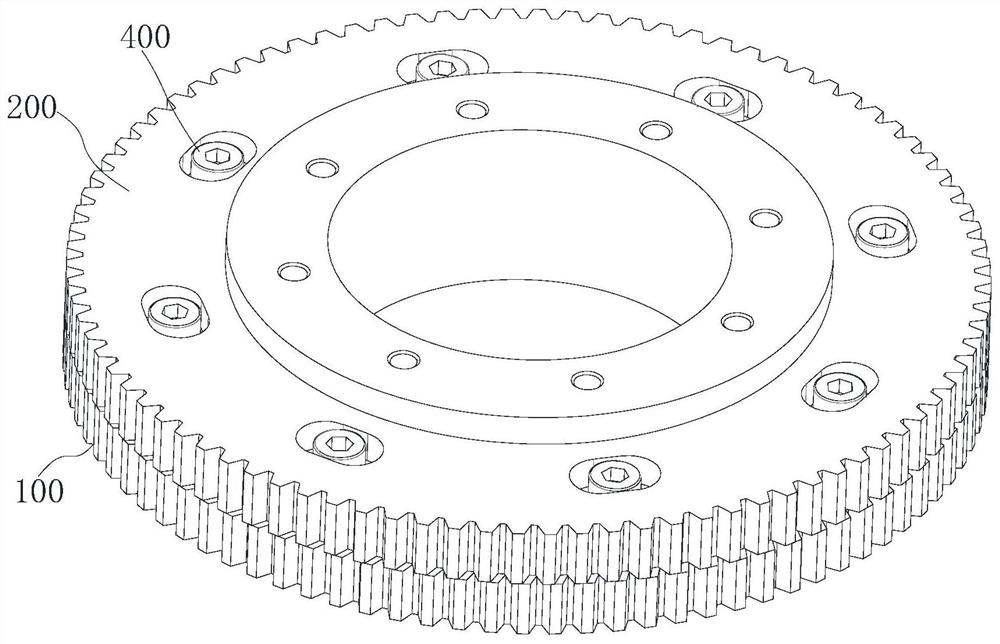

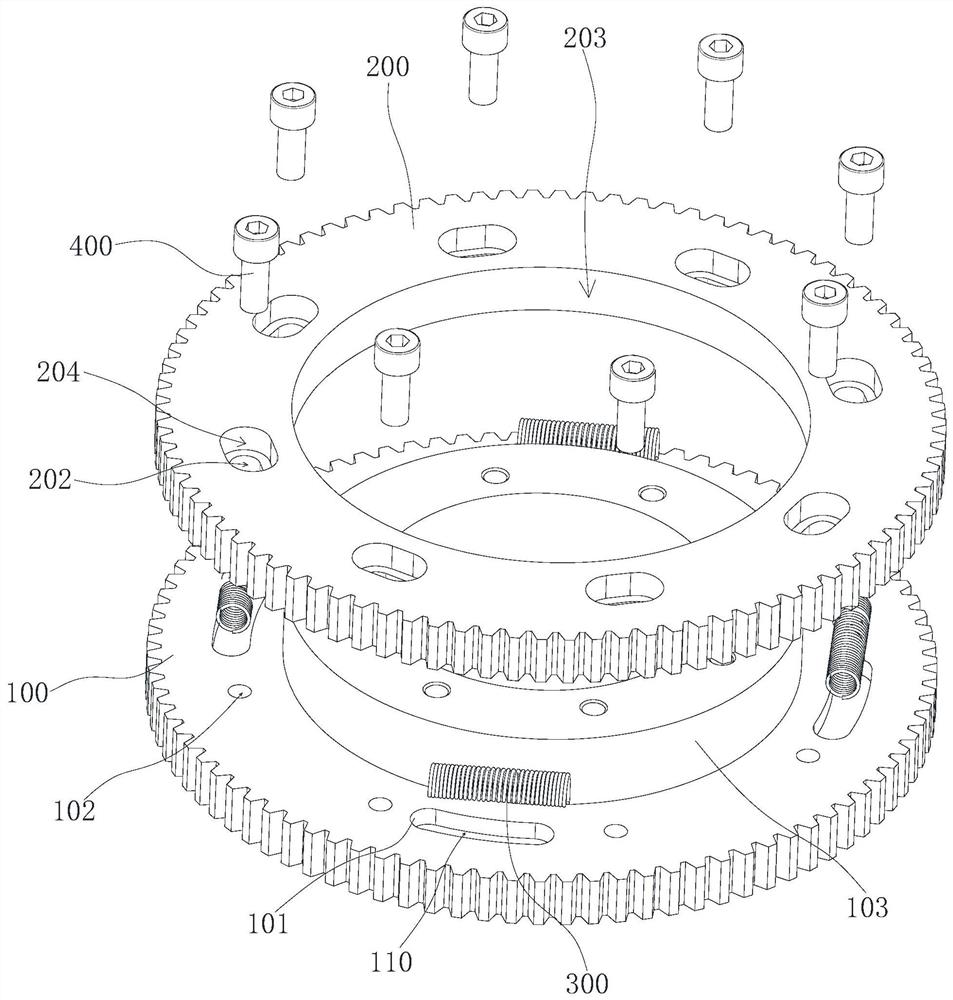

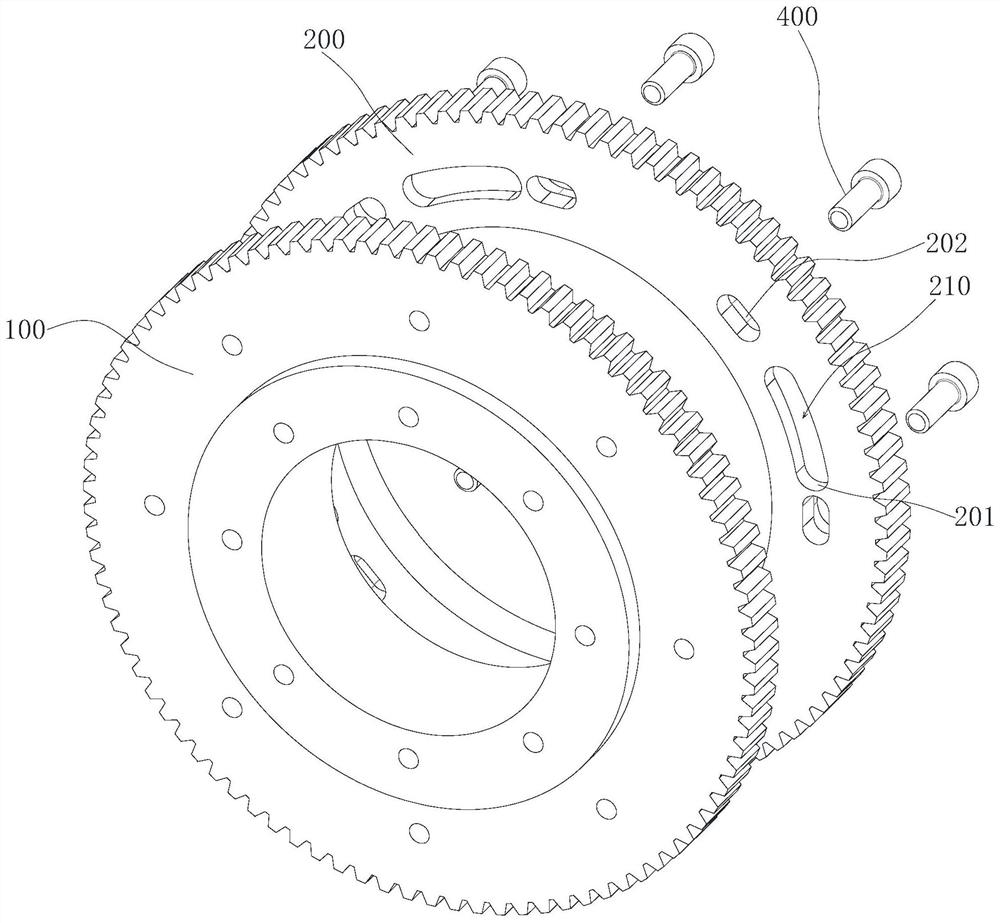

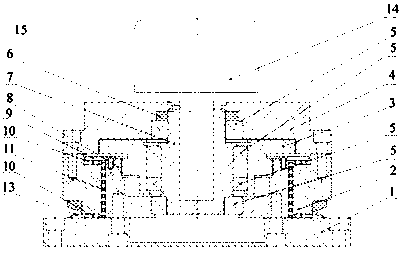

Clearance-eliminating planar enveloping ring surface worm wheel structure, worm wheel clearance-eliminating method and processing method

PendingCN111750069AGuaranteed meshing accuracyEliminate backlashPortable liftingWorm wheelsMechanical driveGear tooth

The invention belongs to the technical field of mechanical transmission parts, and in particular relates to a clearance-eliminating planar enveloping ring surface worm wheel structure, a worm wheel clearance-eliminating method and a processing method. The clearance-eliminating planar enveloping ring surface worm wheel structure comprises a first worm wheel and a second worm wheel same in tooth profile parameter, the first worm wheel is rotatably connected to the second worm wheel, at least one first limiting part is arranged on the inner side of the first worm wheel, a second limiting part corresponding to the first limiting part is arranged on the inner side of the second worm wheel, a compression elastic part is arranged between the first limiting part and the second limiting part corresponding to each other, a plurality of waist-shaped holes are formed in the second worm wheel, and threaded holes corresponding to the waist-shaped holes are formed in the first worm wheel; the compression elastic part extrudes the first worm wheel and the second worm wheel to dislocate; gear teeth of the first worm wheel are attached to a threaded surface of a screw on the same side, and gear teeth of the second worm wheel are attached to a threaded surface of the screw on the other side; and lock screws penetrate the corresponding waist-shaped holes and are connected to the corresponding threaded holes.

Owner:纳密智能科技(东莞)有限公司

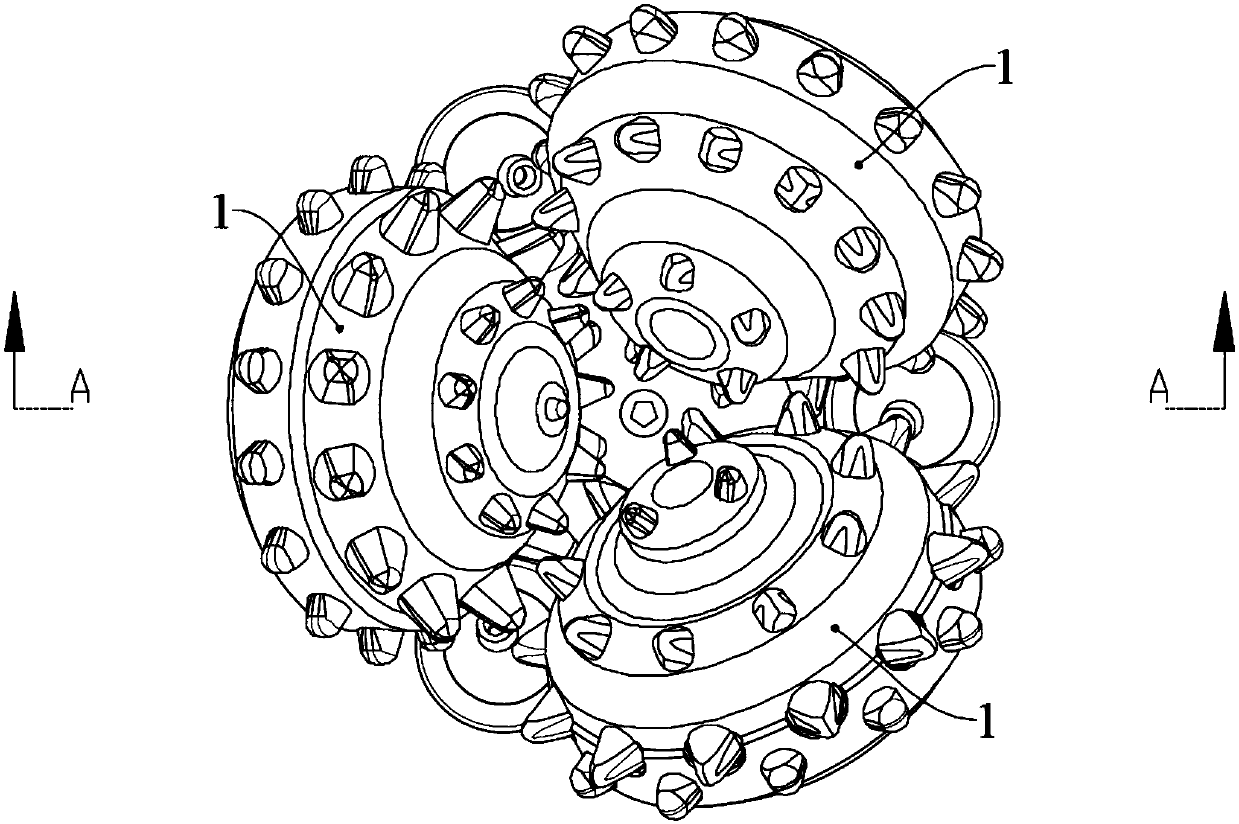

An oil-free scroll air compressor

ActiveCN103437998BPrevent thermal deformationGuaranteed meshing accuracyRotary piston pumpsRotary piston liquid enginesOil freeAir compressor

The invention discloses an oil-free vortex air compressor. The oil-free vortex air compressor is characterized in that the air compressor comprises a dynamic scroll arranged in a shell and driven by a motor and a static scroll fixed on the shell, the dynamic scroll and the static scroll are respectively provided with mutually engaged scroll teeth which divide the interiors of the dynamic scroll and the static scroll into a plurality of compression chambers with a volume changing with movement of the scroll teeth, the static scroll is provided with one or more than one air vents and an air inlet, and the air vents are communicated with the compression chambers. The oil-free vortex air compressor has the advantages of a simple structure, convenience in installation and usage and a good popularization value.

Owner:FOSHAN GUANGSHUN ELECTRICAL EQUIP +1

Tool for assembling driving motor and speed reducer

ActiveCN111922680AAvoid radial forceEasy to assembleWork holdersMetal working apparatusReduction driveElectric machinery

The invention discloses a tool for assembling a driving motor and a speed reducer. The tool comprises a driving motor turnover trolley, a driving motor combined assembly positioning plate, a speed reducer lifting appliance and a spline shaft hook wrench. Manual intervention is adopted for confirmation, the problem that a spline matching pair of the driving motor and the speed reducer is difficultto accurately center and synchronously mesh in place in the assembling process is solved, the driving motor turnover trolley is adopted, the spline matching pair of the driving motor and the speed reducer is preassembled in the vertical state and locked in the horizontal state, assembling operation of an operator is facilitated, meanwhile, extra radial acting force generated in the assembling process of a spline shaft of the driving motor and a spline sleeve of the speed reducer is avoided, and the meshing precision of the spline shaft of the driving motor and the spline sleeve of the speed reducer under the mass production condition is ensured.

Owner:HEFEI JUYI POWER SYST CO LTD

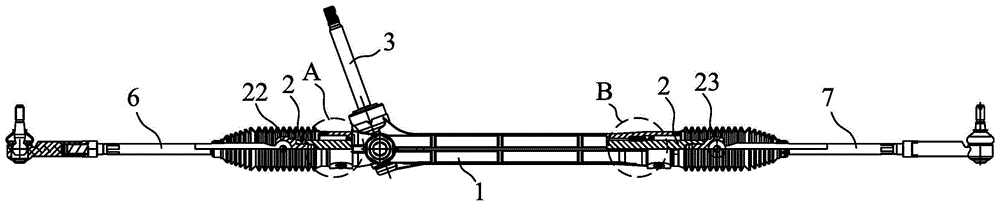

Rack and pinion steering gear

ActiveCN105365880AGuaranteed meshing accuracyAvoid percussionMechanical steering gearsEngineeringRack and pinion

In order to solve the problem that the rack and pinion steering gear in the prior art easily produces abnormal sound in the use process, the invention provides a rack and pinion steering gear. The rack and pinion steering gear comprises a shell, a rack, a pinion shaft and a positioning ring, wherein the positioning ring is fixed in the shell; a positioning hole is formed in the positioning ring; the rack is arranged in the shell and simultaneously penetrates through the positioning ring; the rack and the positioning hole are in transition fit, so that the rack can move relative to the positioning ring in the axial direction of the shell, and the positioning ring fixes the rack at the periphery of the rack; the pinion shaft is arranged on the shell in a rotatable manner, and the axial direction of the pinion shaft is tilted relative to the axial direction of the shell; and the pinion shaft is meshed with the rack, and the rotating of the pinion shaft drives the rack to move in the axial direction of the shell. The rack and pinion steering gear provided by the invention can effectively reduce metal hitting sound made between the pinion shaft and the rack teeth of the rack when the pinion shaft rotates and is favorable to improving the quality of the whole vehicle.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

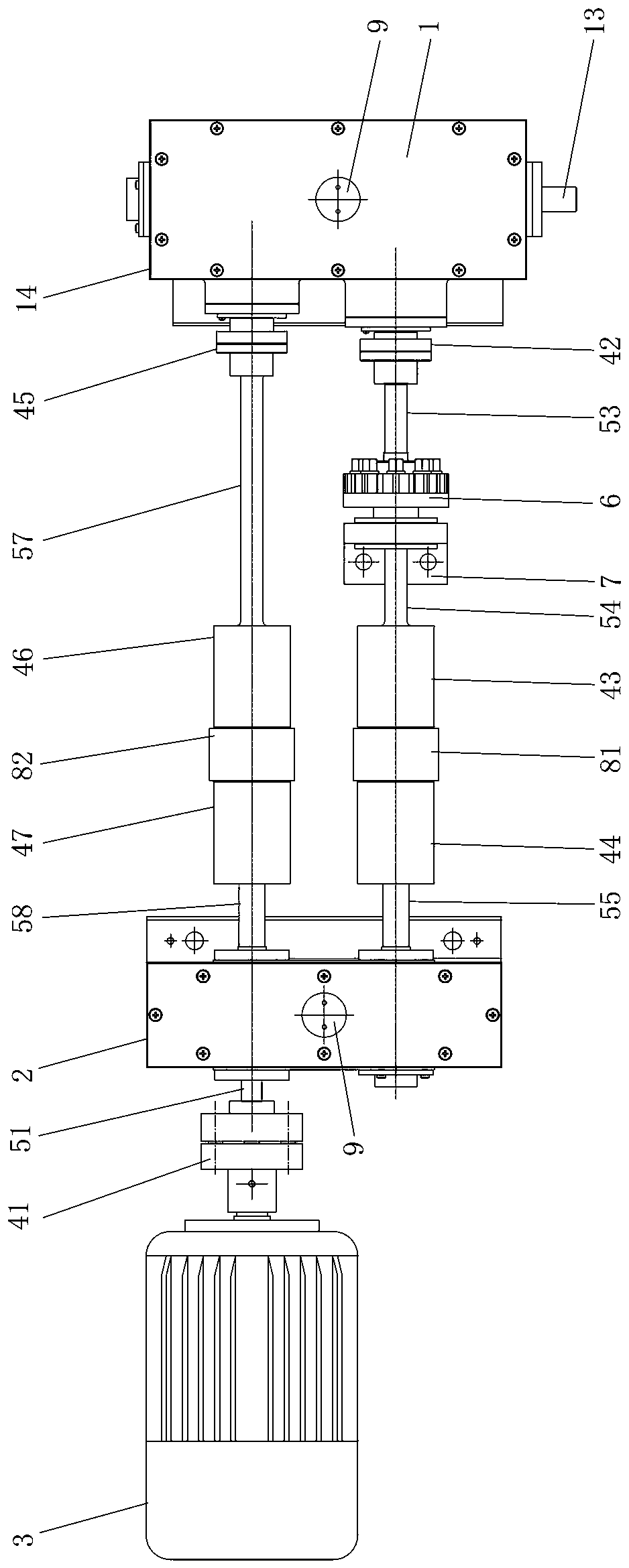

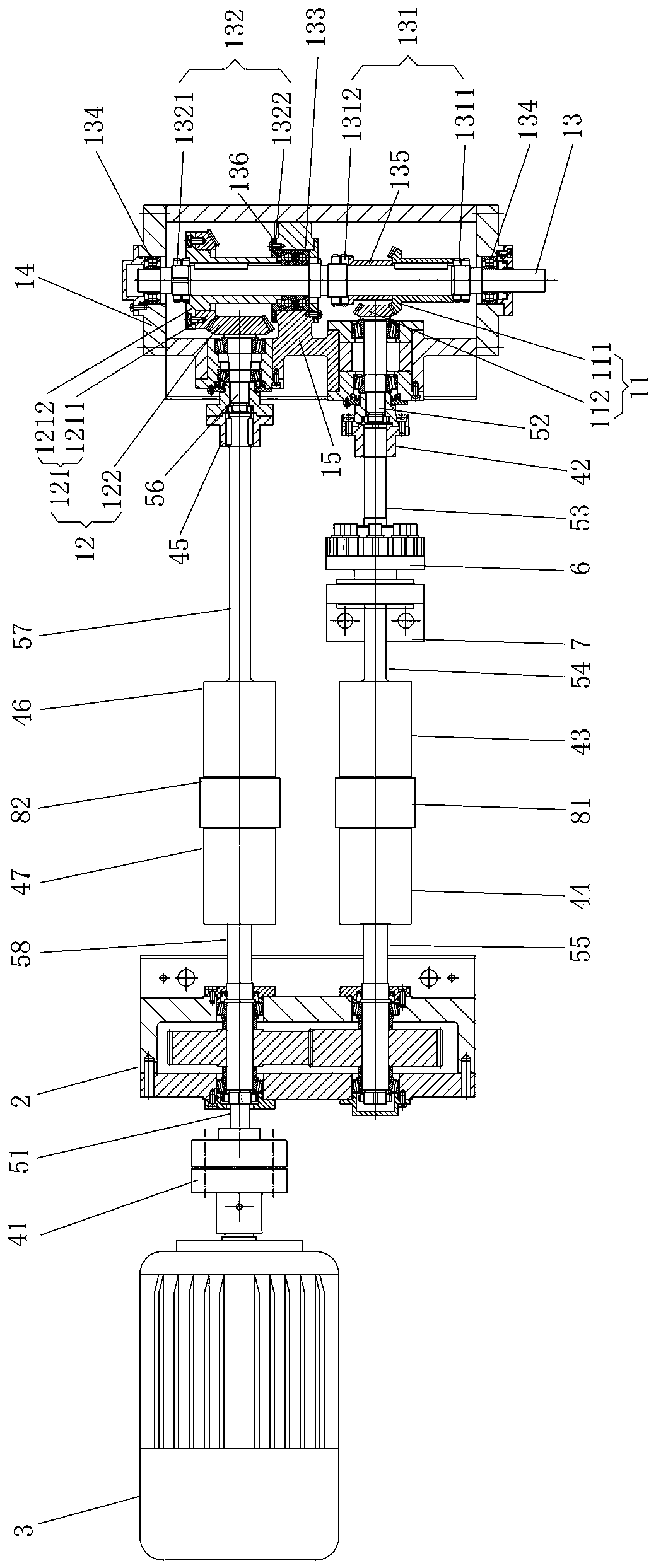

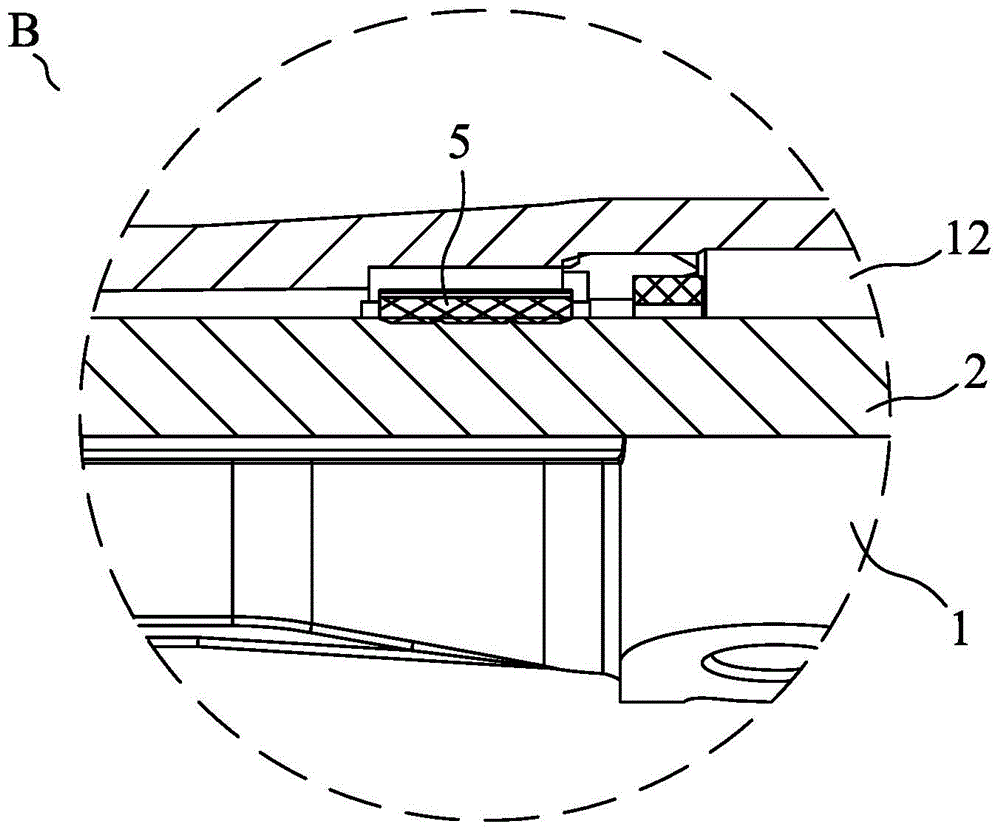

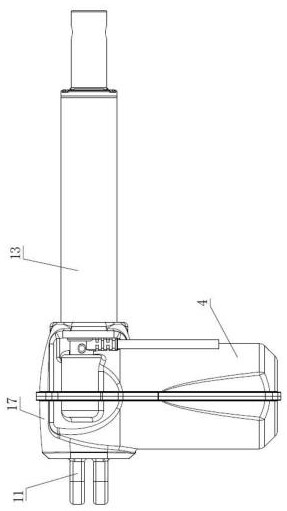

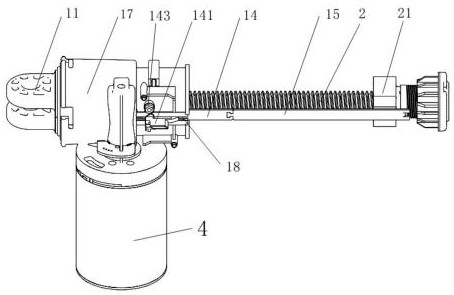

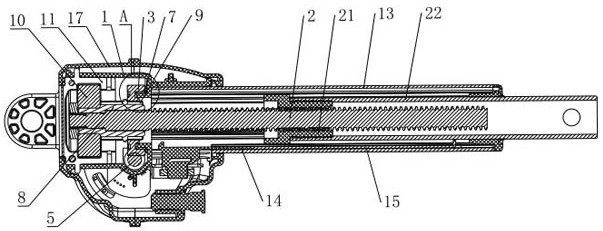

Linear actuator

ActiveCN112128335AGuaranteed meshing accuracyImprove transmission efficiencyGearingMechanical energy handlingElectric machineryDrive motor

The invention discloses a linear actuator. The linear actuator comprises a main shell, a lead screw, a worm wheel, a driving motor and a worm, wherein a mounting circumferential surface is arranged onthe contour surface of the worm wheel between a hole of a core part, sleeved on the lead screw, of the worm wheel and gear teeth, meshed with the worm, of an outer ring; a centering circumferential surface matched with the mounting circumferential surface is arranged on the main shell; the worm wheel is positioned and mounted on the main shell through the mounting circumferential surface and thecentering circumferential surface; the extending end of the worm is arranged in a supporting hole of the main shell, and the distance between the center line of the supporting hole in the main shell and the center line of the centering circumferential surface is consistent with the design center distance between the worm wheel and the worm; a gap is formed between the worm wheel and the lead screwat the driving position, so that the worm wheel can be only centered on the main shell through the mounting circumferential surface and the centering circumferential surface; a rear mounting chamberis formed in the rear part of the main shell, a rear connecting piece which is screwed and fixed in a rotating mode is arranged in the rear mounting chamber, and a bearing supported at the rear end ofthe lead screw is mounted on the rear connecting piece; and the lead screw , the worm wheel and the worm are positioned on the main shell, so that the mutual meshing precision is improved.

Owner:CHANGZHOU KAIDI ELECTRICAL INC

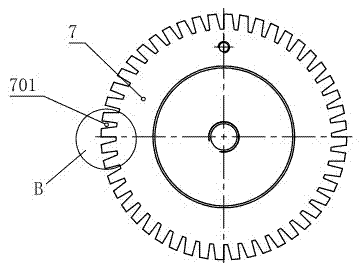

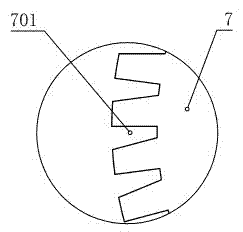

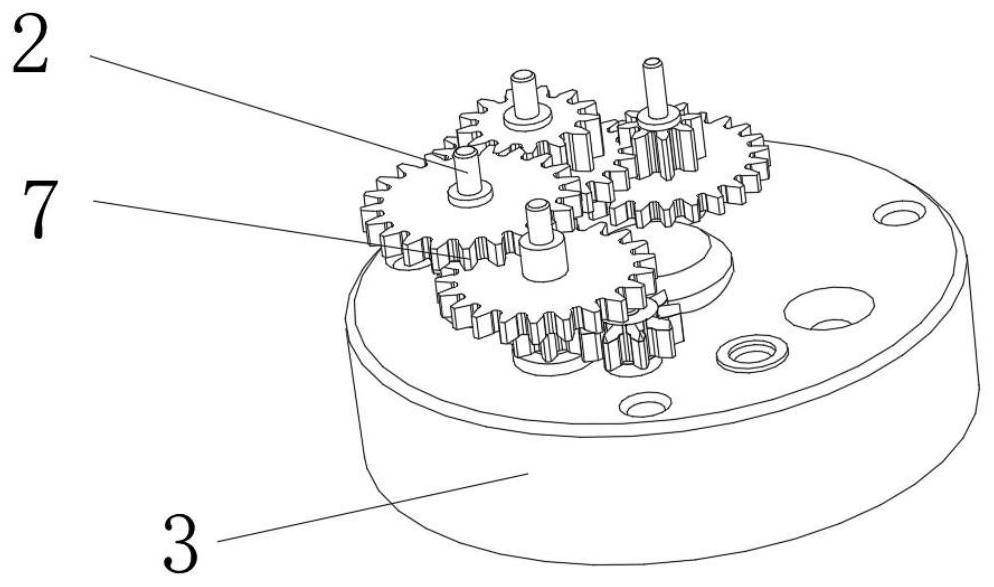

The Method of Automatically Eliminating Backlash of Angle-Limited Gears

InactiveCN104565333BGuaranteed meshing accuracyNo backlashGearing detailsGear wheelGear transmission

The invention discloses a method for automatically eliminating limited angle gear backlash, and aims to provide a compact limited angle gear backlash eliminating mechanism which is simple and compact in structure and capable of realizing gear transmission without backlash, improving gear transmission precision, reducing cost and improving assembling capacity. The technical scheme for implementing the method includes that one of a driving gear and a driven gear which are engaged with each other is divided into a main sector gear and an auxiliary sector gear, a fixed main gear working portion and the loaded auxiliary gear are sectored, a bottom arc of a small end sector of the loaded auxiliary gear fits with a cylindrical surface of a gear rotating shaft cylinder, inclined hole grooves (7) are formed in sectors of the fixed main gear and the loaded auxiliary gear, and gear tension springs (4) keeping a tension state are mounted in the inclined hole grooves, the fixed main gear and the loaded auxiliary gear are connected together by loading the sector of the auxiliary gear through the gear tension springs, and the fixed main gear and the loaded auxiliary gear are mutually staggered to form a certain circumference angle and engaged with the driven gear in opposite directions.

Owner:SOUTH WEST INST OF TECHN PHYSICS

Polishing wheel device

PendingCN111469037AEven by forceImprove flatnessPolishing machinesGrinding drivesPolishingEngineering

The invention belongs to the technical field of glass polishing, and discloses a polishing wheel device. The polishing wheel device comprises a polishing wheel, a rotating seat and a transmission assembly which are connected in succession. When glass is polished, a drive device drives the transmission assembly to rotate, then the rotating seat is driven to rotate, and therefore the polishing wheelrotates at a high speed to polish the surface of the glass. Compared with a traditional disc type brush polishing device, the surface of the polishing wheel is much level, the glass stress is even when the polishing wheel is in contact with the glass, and therefore the surface planeness of the glass is higher, and the polishing effect is better; in addition, the polishing wheel is small in size and high in rotating speed, the polishing efficiency is high, compared with a brush, the rigidity and bouncing performance of the polishing wheel are better, and the problem that scratches and other defects are generated on the glass surface due to traditional polishing devices is solved; and meanwhile, the flexibility of the polishing wheel is high, and the polishing wheel can be suitable for 3D curved polishing.

Owner:湖南安冠智能科技有限公司 +1

Swing type limited slip differential

ActiveCN102518772BDriving safetyGuaranteed meshing accuracyDifferential gearingsControl devicesLimited-slip differentialEngineering

The invention provides a swing type limited slip differential, which comprises a shell, two differential gears distributed on the left and right, two planet gears distributed up and down between the differential gears, friction plates and pressure plates. The swing type limited slip differential is characterized in that: each planet gear is provided with a gear shaft; one of the two contacted gear shafts has a ball at the front end, and the other of the two contacted gear shafts has a recessed inner taper hole at the front end; the center of the ball is positioned at conic nodes of the planet gears; gaps are formed between the pressure plates and the shell; and the tail of each gear shaft is mounted on the shell and can do trace swing in the same plane as the axis of each differential gear. When a bevel gear pair is meshed, the conic nodes are overlapped, and the meshing accuracy is ensured; and after driving torque is lost or reduced because wheels on one side slip, automatic adjustment is carried out through an internal mechanism, larger driving torque of wheels on the other side is instantly regulated, and the driving torque on the two sides is redistributed to ensure driving safety when a vehicle slips or turns a corner.

Owner:天津天海同步科技有限公司

High-precision heavy-load thick roller shaft system for speed reducer

PendingCN109356999AImprove axial stiffnessImprove radial stiffnessGearing detailsReduction driveReducer

The invention discloses a high-precision heavy-load thick roller shaft system for a speed reducer. The high-precision heavy-load thick roller shaft system for the speed reducer comprises a motor; a motor shaft is assembled in a deep hole of an input shaft; a step wheel is assembled out of the input shaft, and a bearing is arranged between the two; an output shaft is assembled out of the step wheel; a bearing is arranged between the output shaft and the input shaft; a main body is assembled out of the output shaft; an input end cover is assembled above the main body and the step wheel; a bearing and a sealing cover are arranged between the input end cover and the input shaft; the input end cover and the main body are fastened through screws; an output disc is arranged under the output shaftand the main body, and is connected with the bottom of the output shaft through screw fastening pieces; an outer oil seal sleeve is arranged in a clamping groove on the outer wall at the lower end ofthe main body; a radial thick roller shaft system is arranged between the output shaft and the main body; axial thick roller shaft systems are arranged on the upper and lower end surfaces of the mainbody; a cover disc is assembled above the axial thick roller shaft system on the upper end; and the cover disc is fixed on the top surface of the output shaft. The high-precision heavy-load thick roller shaft system for the speed reducer can improve the load and the impact resistance of the speed reducer to the greatest extent, and prolongs the anticipant life of the speed reducer.

Owner:中核新科(天津)科技有限公司

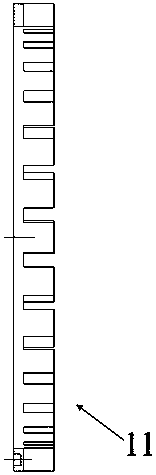

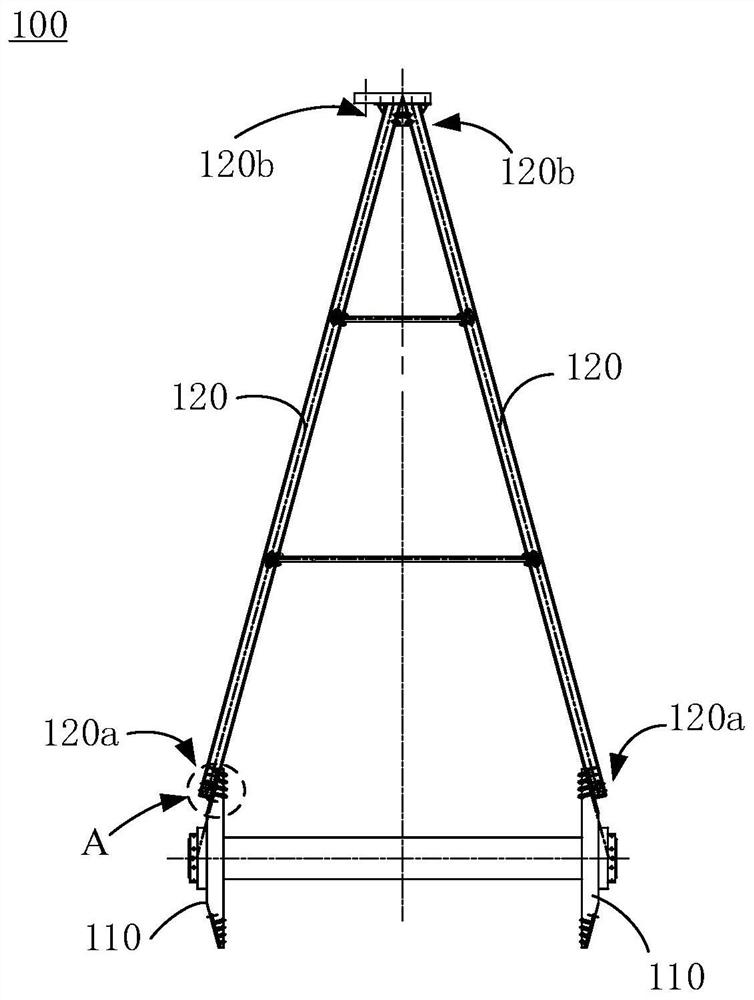

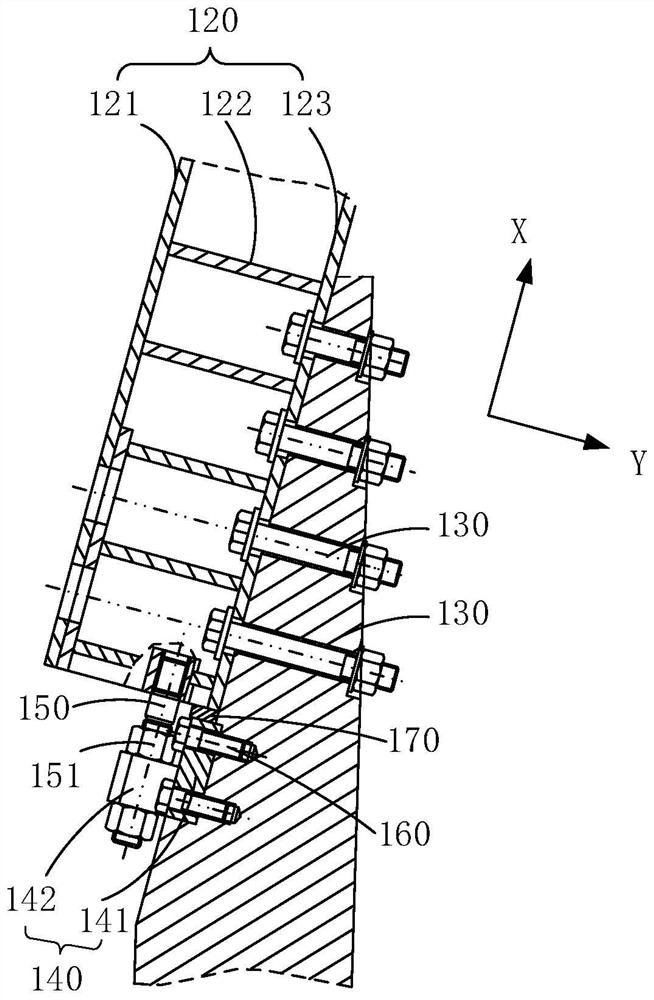

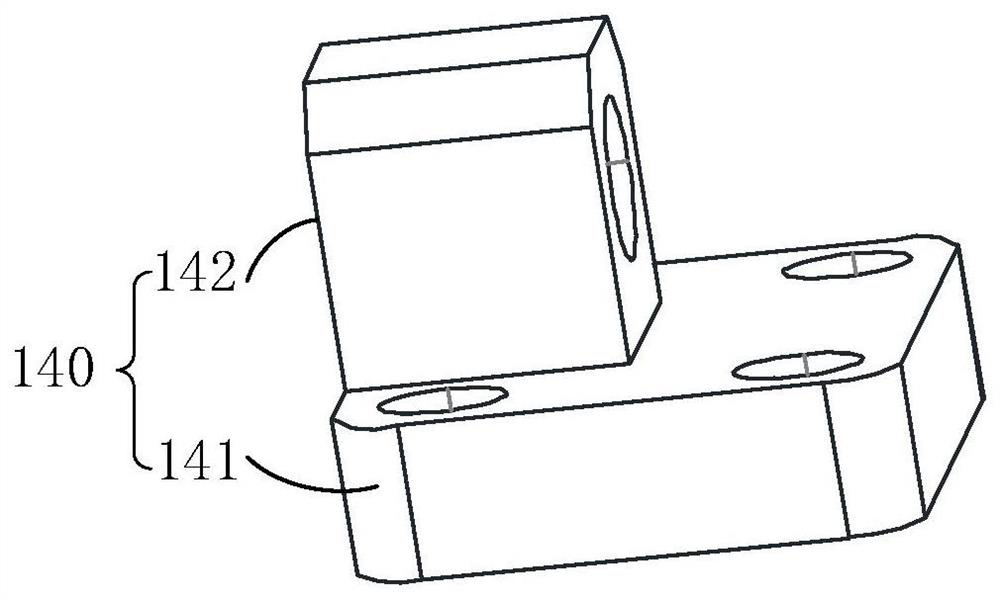

Hub and spoke connecting structure of drum-shaped filter screen and drum-shaped filter screen

ActiveCN113713477AMeet the precision requirementsReduce riskMoving filtering element filtersGear wheelIndustrial engineering

The invention relates to a hub and spoke connecting structure of a drum-shaped filter screen and the drum-shaped filter screen. The hub and spoke connecting structure of the drum-shaped filter screen comprises a hub, a plurality of spokes, a plurality of connecting bolts, a plurality of supporting blocks and a plurality of adjusting screw rods. According to the connecting structure of the hub and the spokes of the drum-shaped filter screen, the force (namely the shearing force borne by the connecting bolts) borne by the connecting bolts in the length direction X of the spokes is reduced, and the risk that the connecting bolts are sheared off and the potential safety hazard are reduced. Besides, when the spokes are installed on the hub, the installation gaps between the spokes and the hub can be adjusted through the adjusting screws, and the spokes and the hub are fixed through the connecting bolts after the installation gaps between the spokes and the hub are adjusted, so that the meshing precision of the gear ring of the drum-shaped filter screen and the gear of the driving device is guaranteed, and the precision requirement of the drum-shaped filter screen is met.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY +3

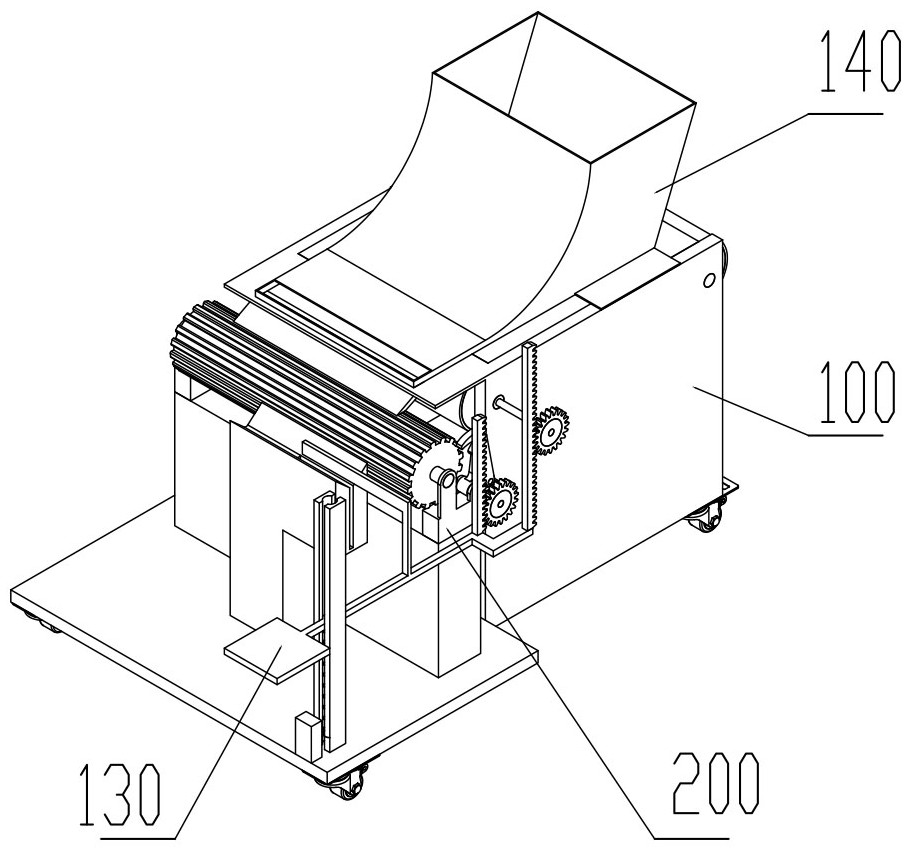

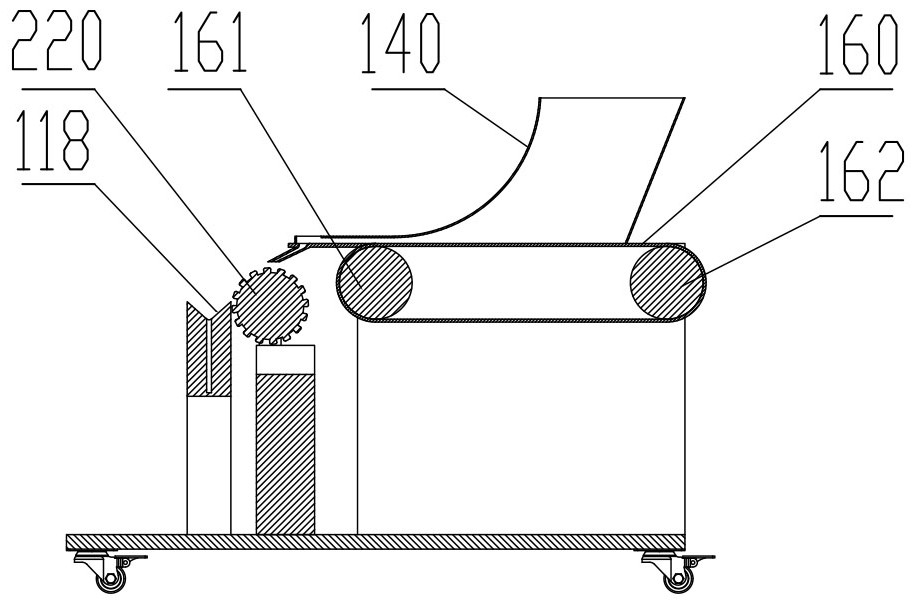

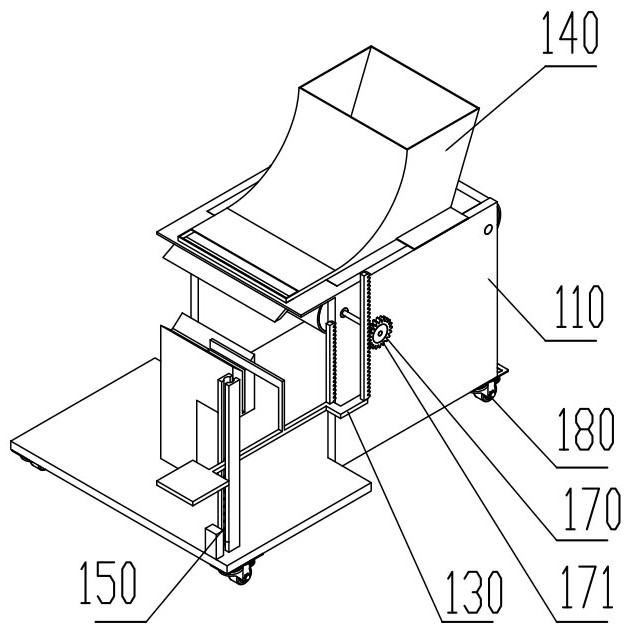

Welding device for engineering machine parts

InactiveCN113560773ASmooth slidingGuaranteed meshing accuracyWelding/cutting auxillary devicesAuxillary welding devicesMachine partsPilot hole

A welding device for engineering machine parts comprises a machine body device and a material stirring device. The machine body device comprises a rack, a pedal, a hopper, a spring, a belt, a front roller, a rear roller, a first gear and a first one-way bearing. The material stirring device comprises a material stirring frame, a material stirring roller, a cam, a rolling wheel, a pawl frame, a pawl, a second gear and a second one-way bearing, and the material shifting device is fixedly connected with the front portion of the rack. Vertical plates in bilateral symmetry are arranged on the rear side of the rack, rear roller holes are formed in the rear sides of the vertical plates and penetrate through the two vertical plates, front roller holes are formed in the front sides of the rear roller holes and penetrate through the two vertical plates, a front plate is arranged on the front sides of the vertical plates, a discharging groove is formed in the lower portion of the front plate, a receiving frame is arranged in the middle of the rack, a hopper opening is formed in the upper portion of the receiving frame, a clamping groove is formed in the right side of the hopper opening, a stand column is arranged on the front side of the rack, and a guide hole is formed in the middle of the stand column.

Owner:HARBIN VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com