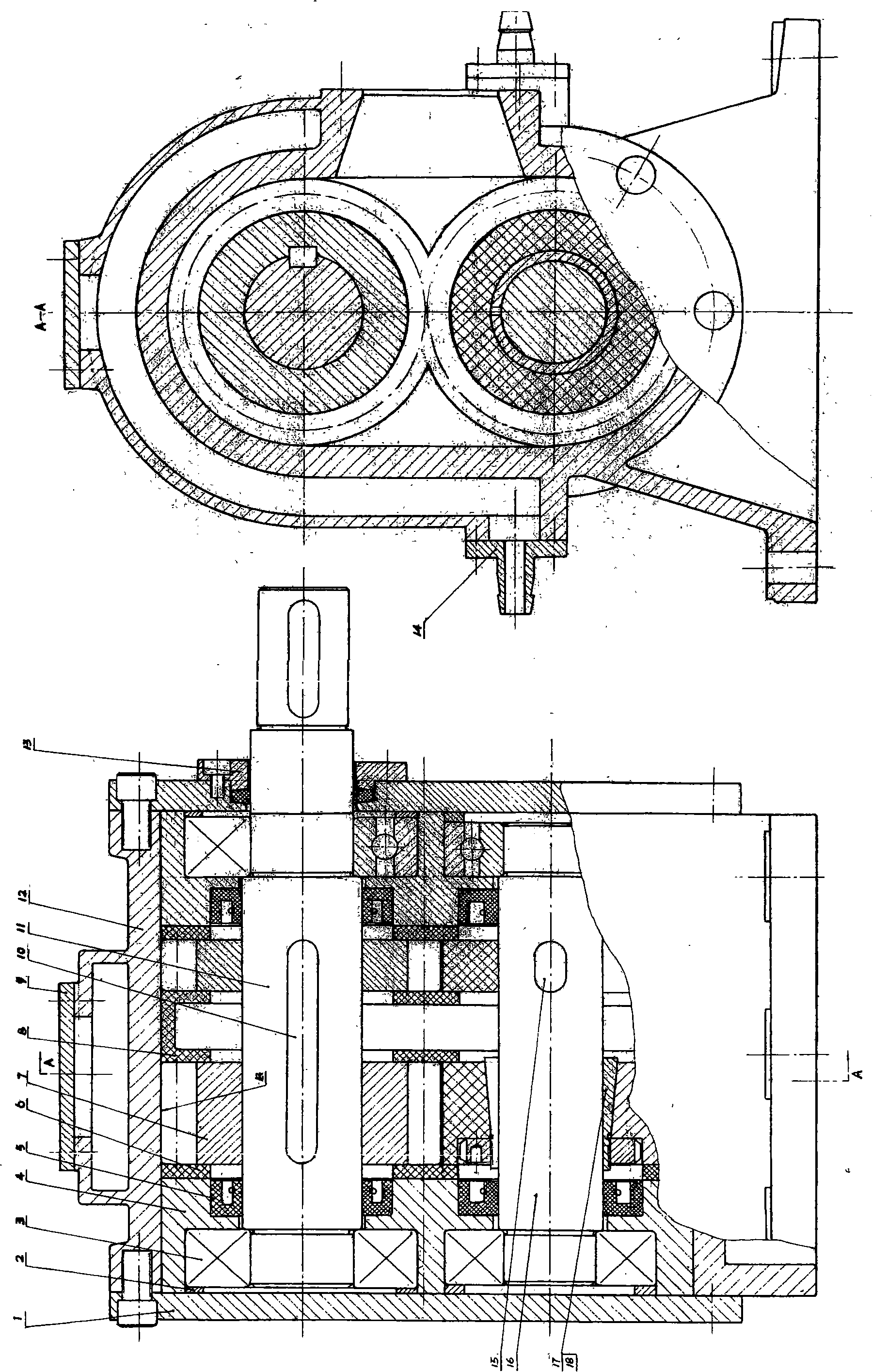

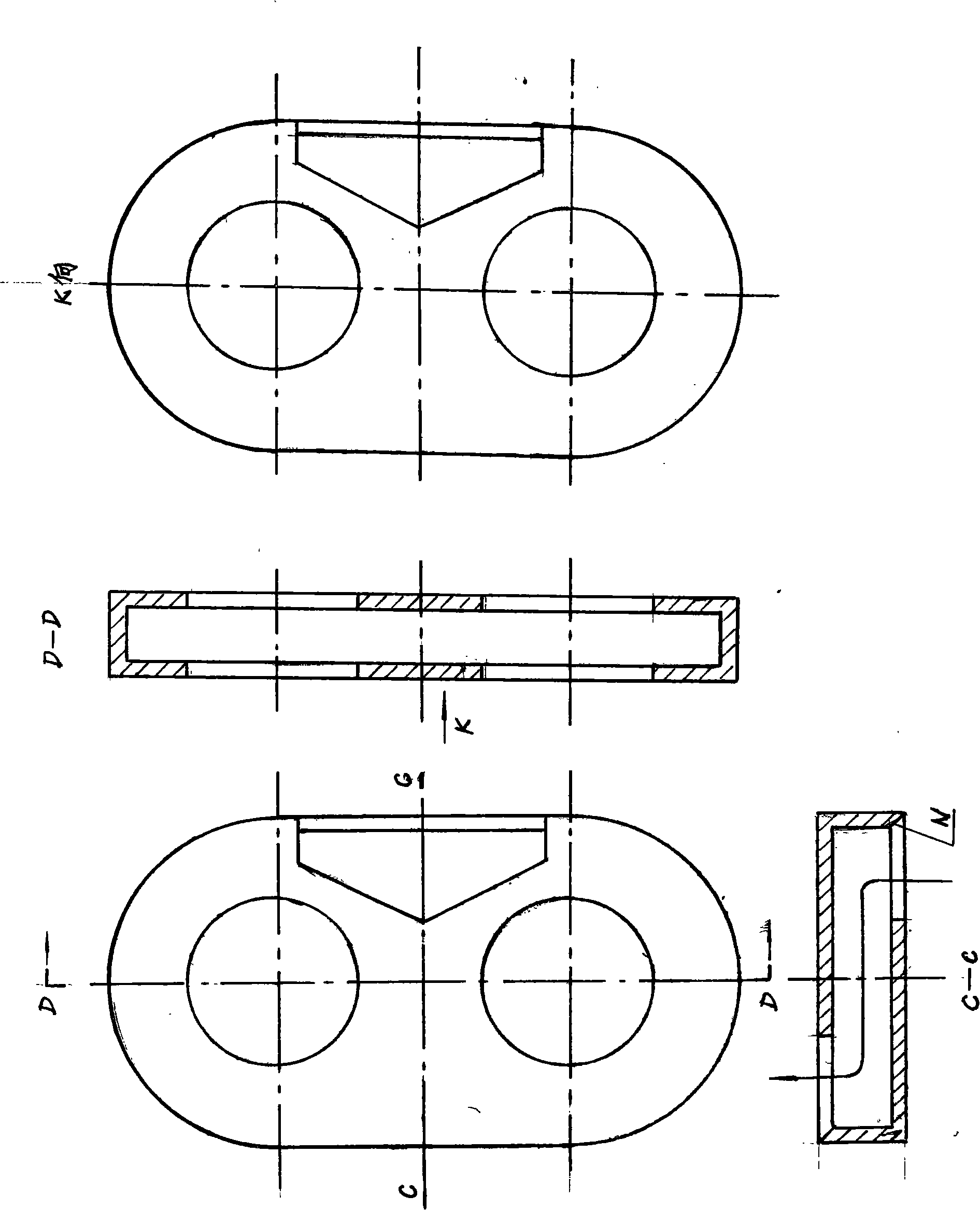

Multilevel inner series dual supercharging double-circular-arc gear pump

A double-arc, gear pump technology, used in pumps, pump components, rotary piston pumps, etc., can solve the problems of sharp increase in cubic function and large consumption, achieve simple structure, improve stability, output pressure pulsation and The effect of flow pulsation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

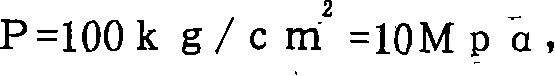

[0021] 5.1 Structural data: The modulus m of the multi-stage double-arc gear pump is selected to be 52 mm (the largest modulus of the known gear hob), and the number of teeth Z is 12. The tooth width of the final sub-pump is B=200mm, which is composed of two thin teeth with a width of 100mm each, staggered tooth tops and superimposed tooth gaps. When transporting liquid, the tooth thickness of the previous stage is increased by 0.5%, which is 201mm, and the tooth thickness can be calculated step by step according to this ratio. For safety, an interstage safety valve is added to return the flow to the inlet, and an interstage pressure gauge can also be installed. When used for gas compressors, the tooth thickness of the previous stage is taken as B=400mm. Also set safety valve and pressure gauge.

[0022] 5.2 Flow calculation: gears are manufactured according to GB12759-91, full tooth height h=2m=104mm (high tooth type h=2.25m), pitch circle d=624, addendum circle D=717.6, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com