Polishing wheel device

A technique for polishing wheels and driven gears, which is applied in the direction of grinding drive devices, machine tools for surface polishing, grinding/polishing equipment, etc. It can solve the problems of high disc bounce, easy falling off, and pollution of polishing fluid, etc., and achieve rigidity Good beating performance, guaranteed polishing effect, and reduced beating degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

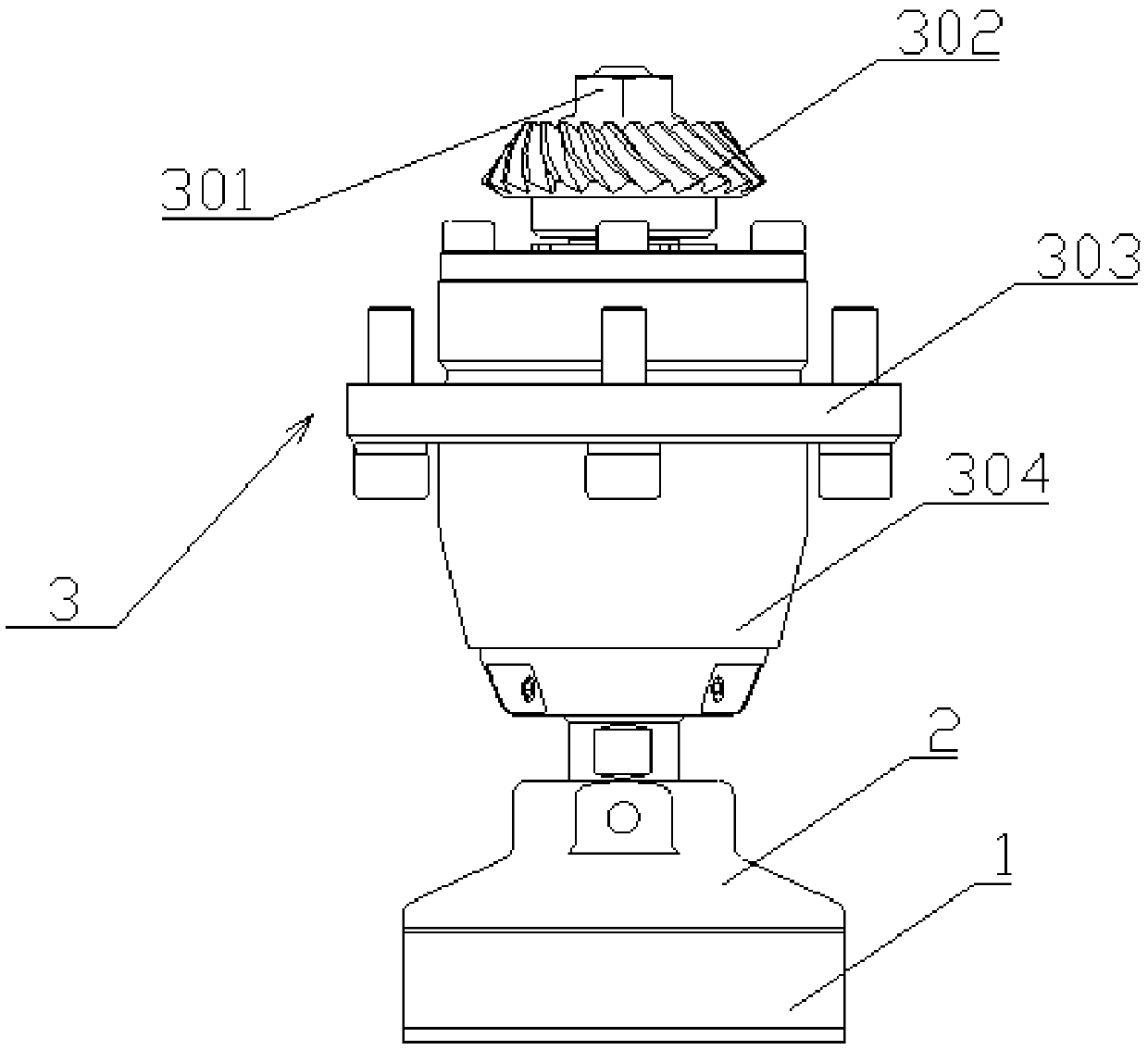

[0027] This embodiment provides a kind of polishing wheel device, and it is used for polishing glass, improves the smoothness of glass surface, and described polishing wheel device is as figure 1 As shown, it includes a polishing wheel 1, a rotating base 2 and a transmission assembly 3 connected in sequence, wherein the transmission assembly is connected with a driving mechanism, and the driving mechanism is a driving motor.

[0028] Specifically, such as figure 1 As shown, the transmission assembly includes a rotating shaft 301. One end of the rotating shaft 301 is connected to the rotating base 2, and the other end is connected to a driven gear 302. The driven gear 302 is adapted to be connected with a driving gear. The driving gear is connected to the driving motor, the driving motor drives the driving gear to rotate, and then drives the driven gear 302 to rotate, and the rotation of the driven gear 302 drives the rotating shaft 301 adapted to it to rotate, thereby driving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com