Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Good polishing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

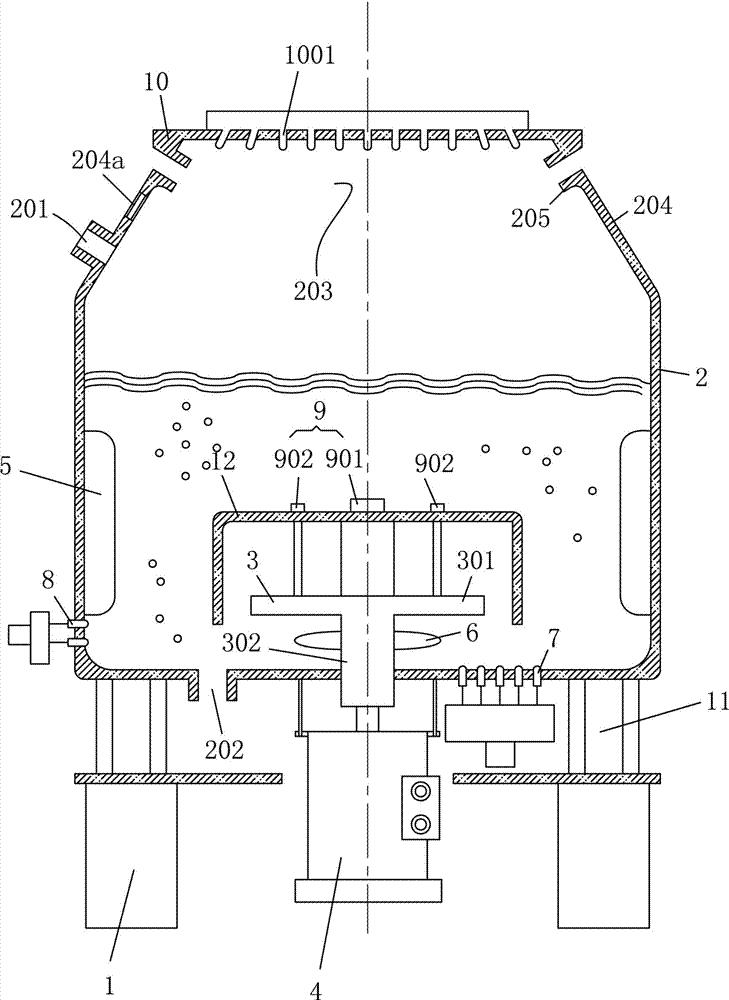

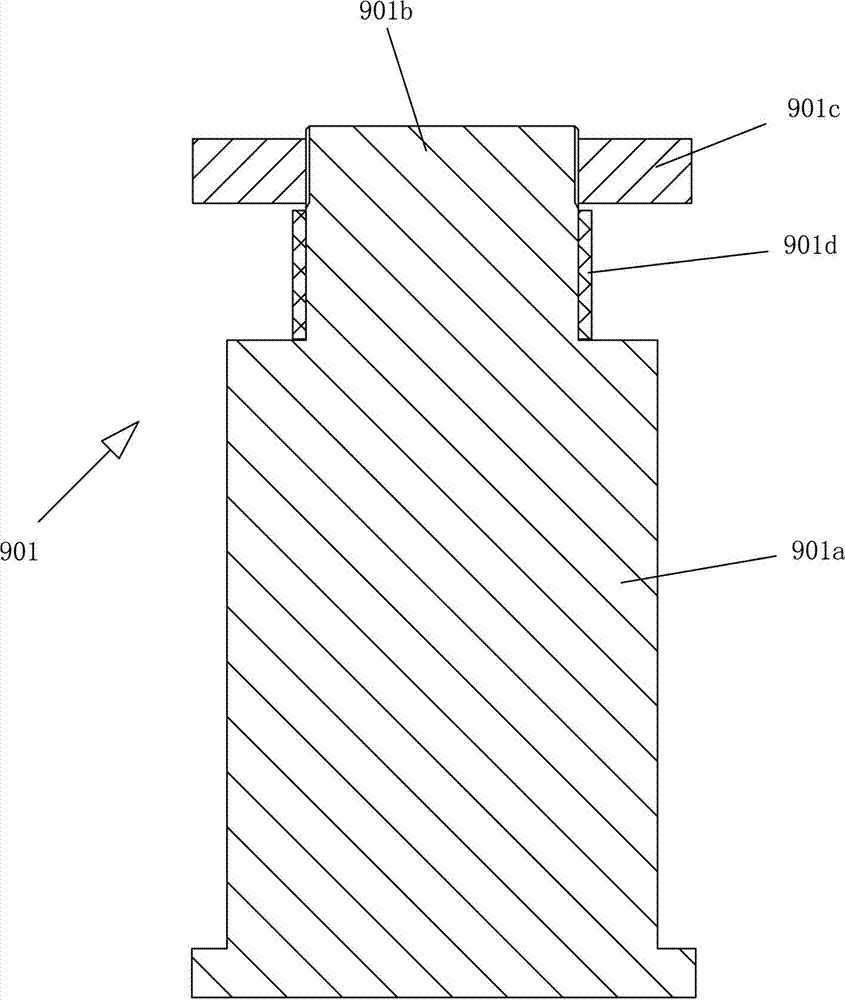

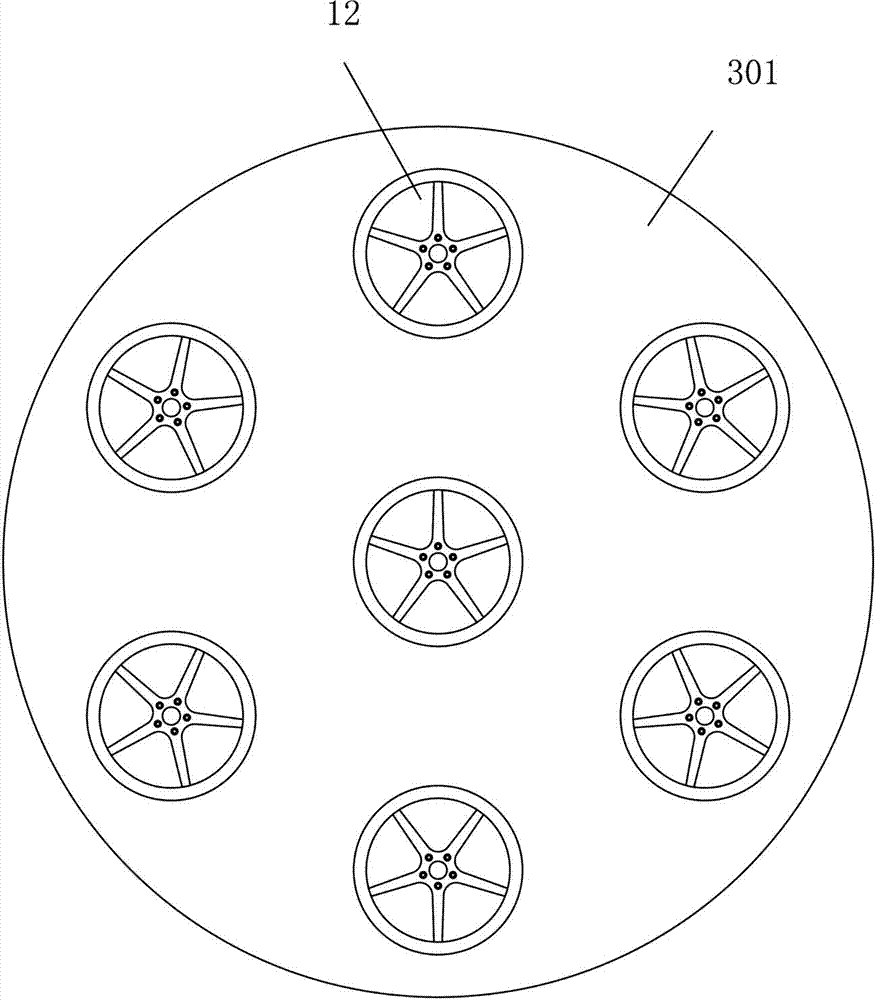

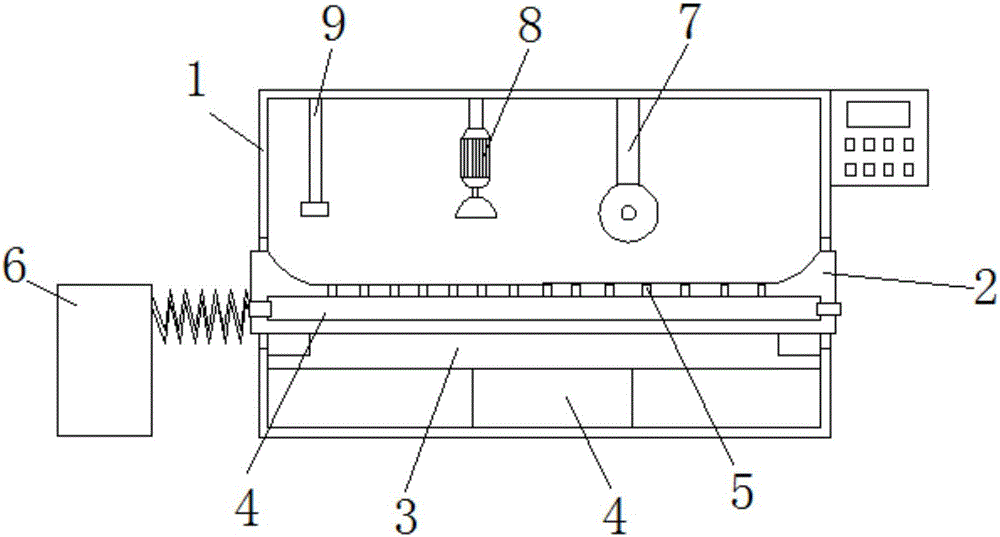

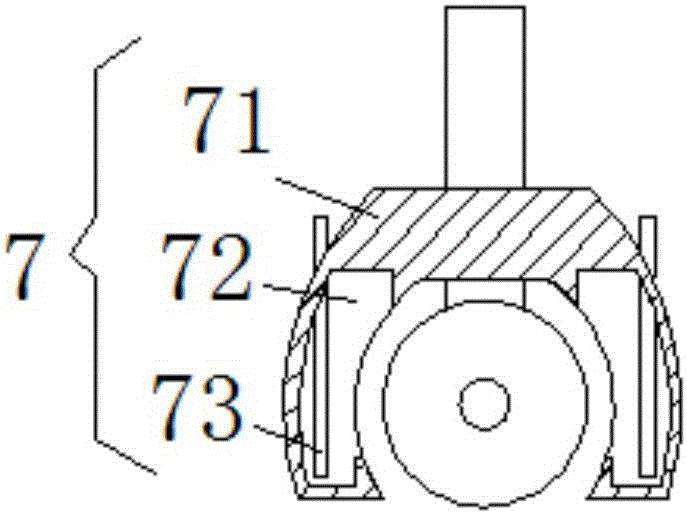

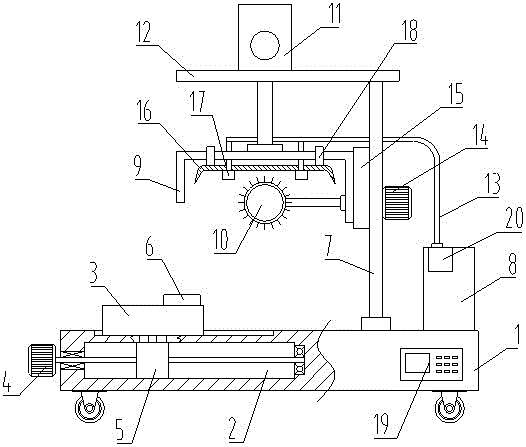

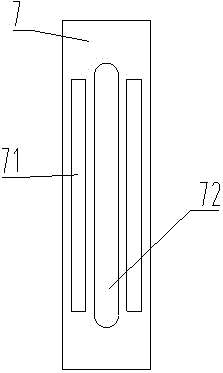

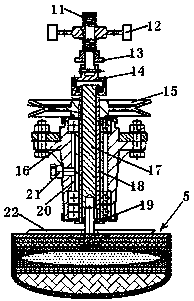

Hub polishing and lapping machine

The invention discloses a hub polishing and lapping machine which comprises a base, a material lapping barrel installed on the base, a fixing device and a rotating motor. The material lapping barrel is provided with a loading port, an unloading port and an opening, a flying wheel disc is installed at the bottom of the material lapping barrel, the fixing device is arranged on an upper surface of the flying wheel disc and used for fixing hubs on the flying wheel disc, and the rotating motor drives the flying wheel disc to rotate. The hub polishing and lapping machine is rapid in polishing speed and good in polishing effects.

Owner:ZHEJIANG GINHENRY NEW TECH DEV

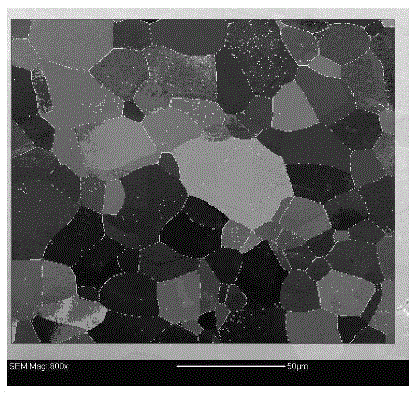

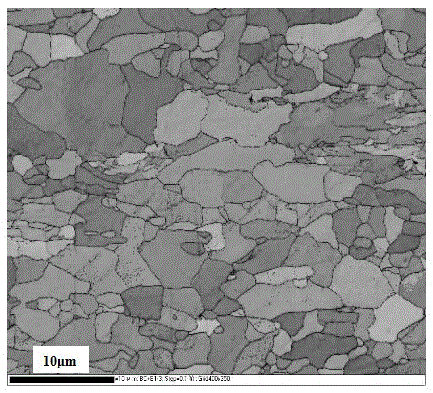

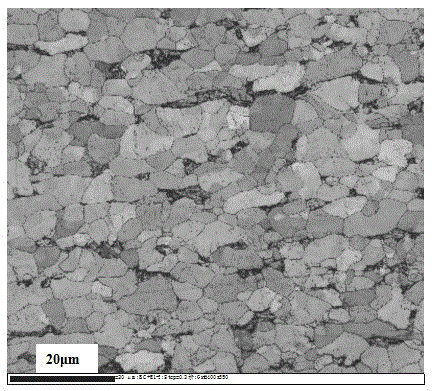

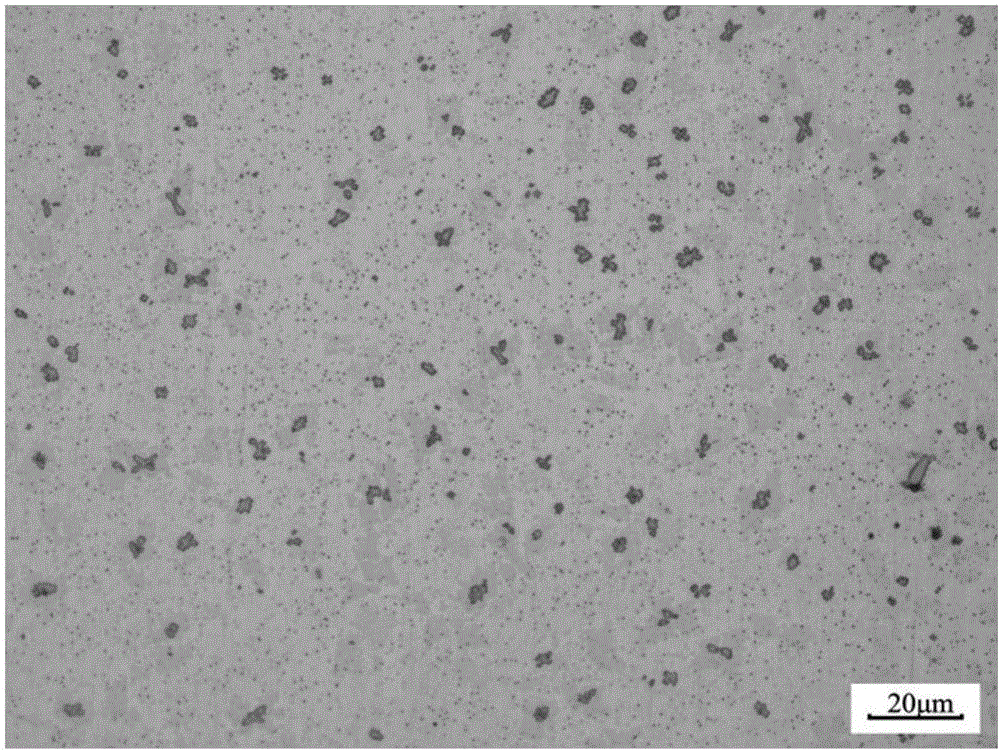

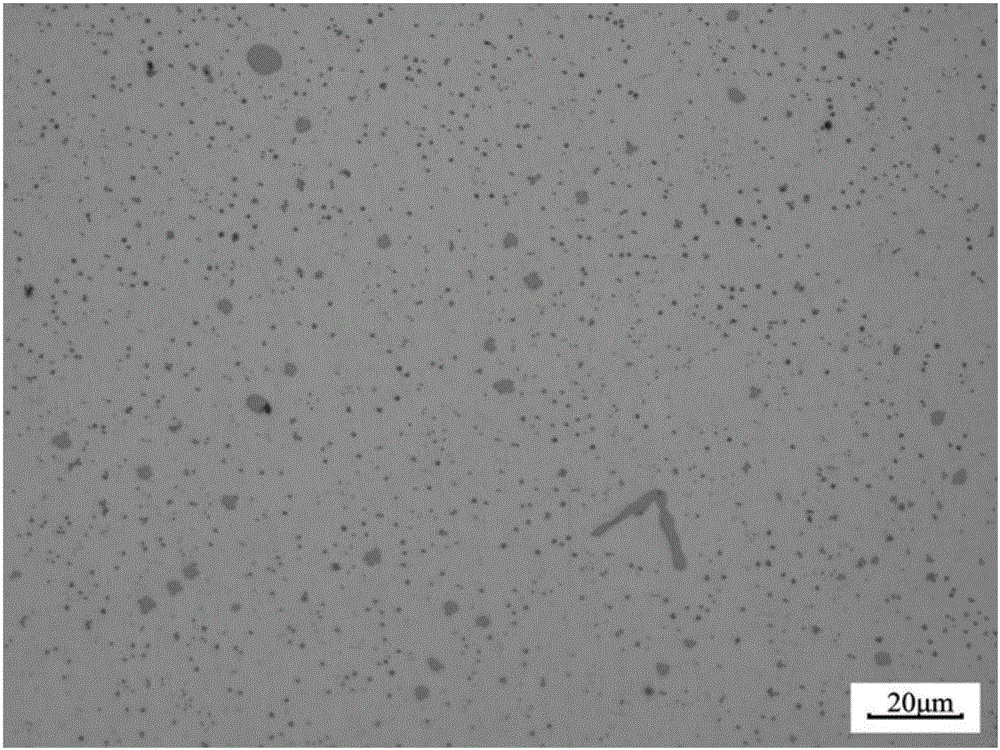

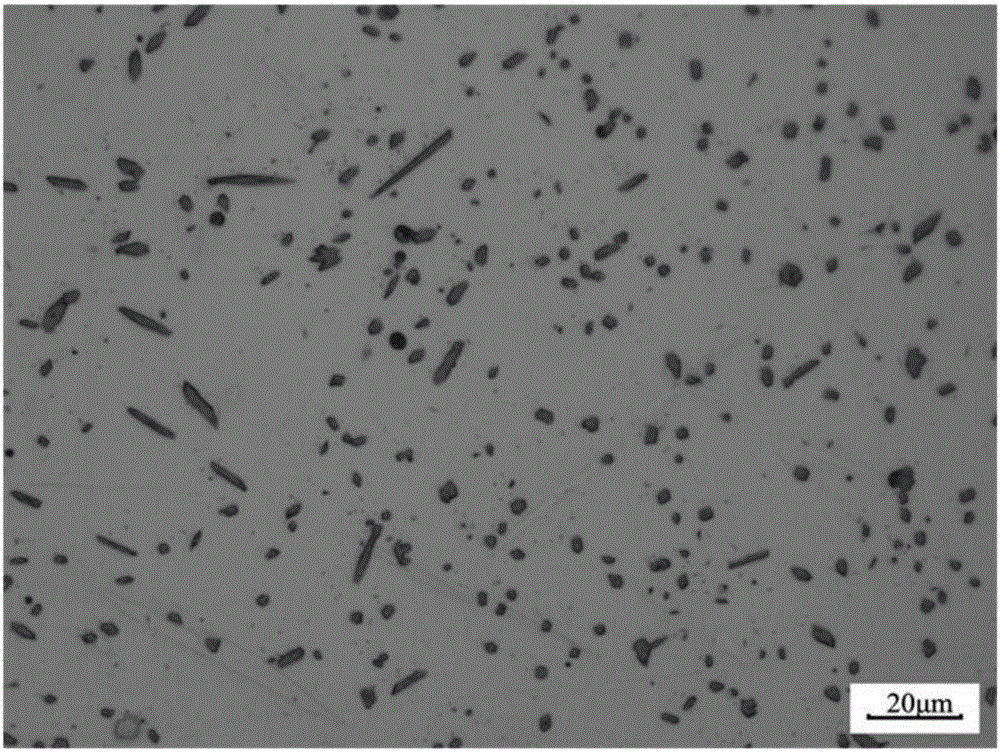

Preparation method of low-carbon steel sample for electron back scattering diffraction analysis

InactiveCN106813966AGood polishing effectStress relief layerPreparing sample for investigationCarbon steelMaterials science

The invention relates to a preparation method of a low-carbon steel sample for electron back scattering diffraction analysis and mainly solves the technical problem that an existing low-carbon steel sample for electron back scattering diffraction analysis has low indexing rate and poor sample repeatability. The preparation of the low-carbon steel sample for the electron back scattering diffraction analysis comprises the following steps: 1) cutting a low-carbon steel plate to manufacture into an embedded sample; 2) mechanically grinding the embedded sample; 3) mechanically polishing the embedded sample; 4) polishing the embedded sample in a vibrating mode; 5) cutting a piece of slice with the thickness of 1 to 3mm from the embedded sample which is polished in the vibrating mode with a side to be observed as standard, taking a sample from the slice, sequentially washing through deionized water and alcohol and blowing dry. The electron back scattering diffraction analysis sample obtained according to the method is put into electron back scattering diffraction equipment to be observed and analyzed. The preparation method disclosed by the invention is simple to operate and wide in adaptability, and the sample has good repeatability.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Sapphire grinding and polishing integrated device

InactiveCN106425787AAvoid contactGood polishing effectPolishing machinesGrinding drivesSapphireEngineering

The invention relates to the technical field of crystal machining, in particular to a sapphire grinding and polishing integrated device. The sapphire grinding and polishing integrated device comprises a box body and a tray penetrating through the two sides of the box body, a slide track used for moving the tray and a driving device used for driving the tray are arranged on the box body correspondingly, and negative pressure is formed in cavities through a high-pressure air pump, so that a sapphire crystal chip is sucked on the tray through through holes. Fine powder generated when the grinding work between a grinding wheel and the sapphire crystal chip is conducted and enters dirt-collecting grooves through high-speed rotation of the grinding wheel, the phenomenon that the powder is scattered on the sapphire crystal chip and then affects the grinding work is prevented, the powder particles collected in the dirt-collecting grooves are discharged through dust-absorbing pipes and dust-absorbing devices. The powder particles are removed again through a rotary hairbrush, and the contact of a polishing wheel and the powder particles is avoided. The sapphire crystal chip and the tray are cleaned by a spraying pipe and the hairbrush, and a dust absorbing head is used for absorbing water and dirt on the sapphire crystal chip and the tray.

Owner:TDG YINXIA NEW MATERIAL CO LTD

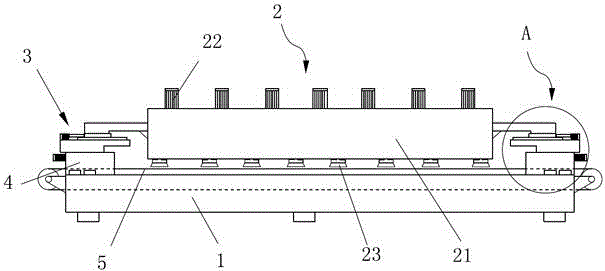

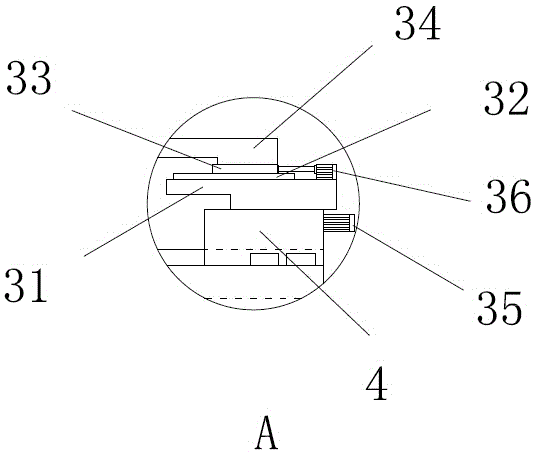

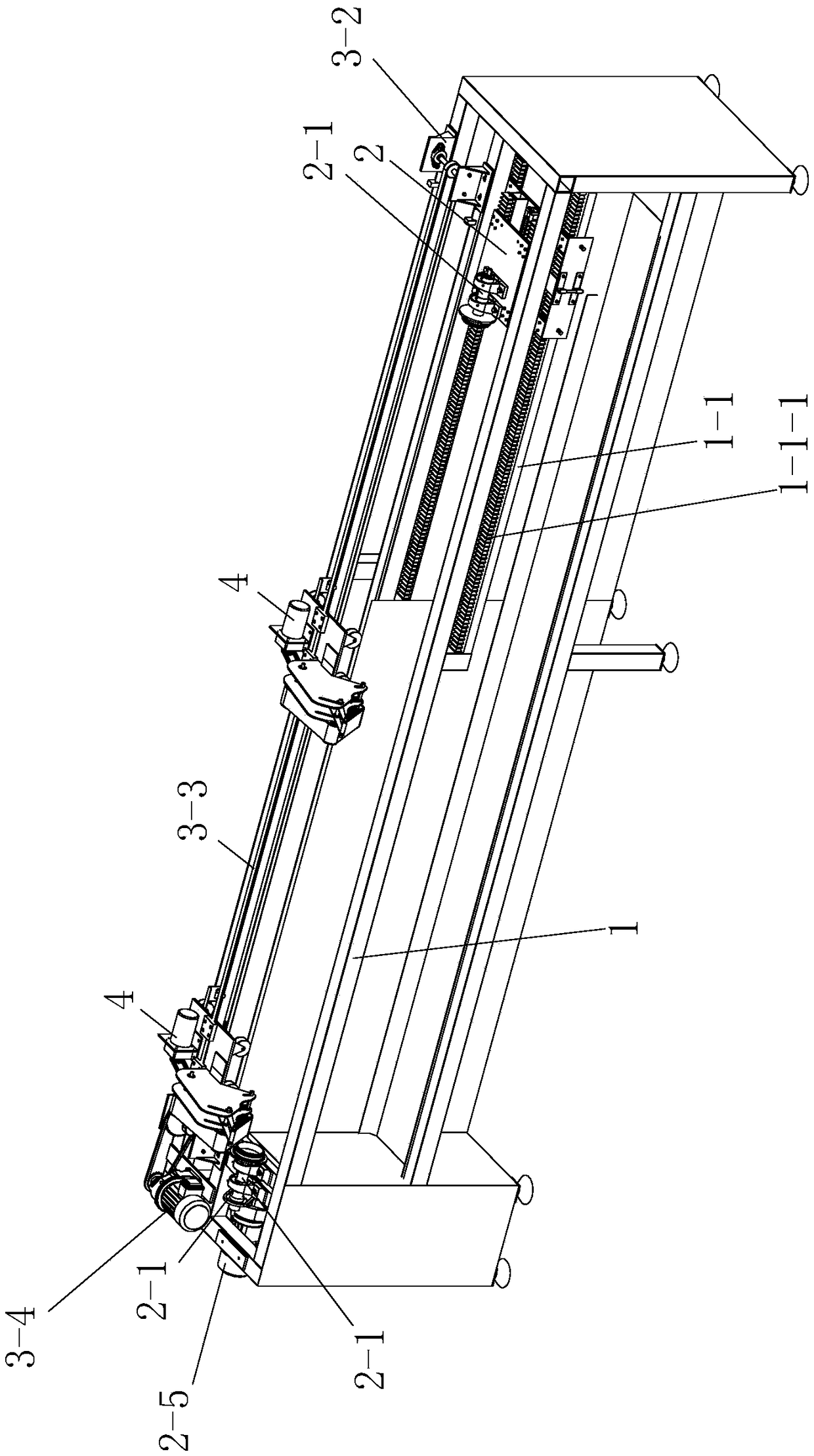

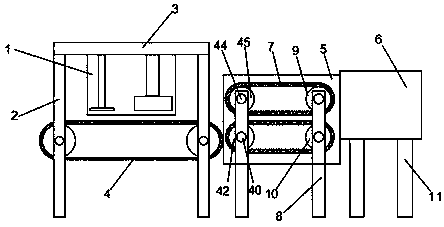

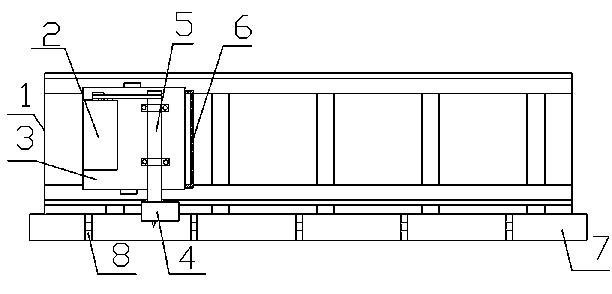

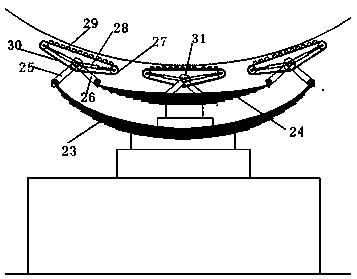

Quartz stone plate polisher

ActiveCN104625909AIncrease productivityGood polishing effectGrinding drivesPlane surface grinding machinesEngineeringMechanical engineering

The invention discloses a quartz stone plate polisher which comprises a base and a conveying belt used for conveying quartz stone plates and arranged on the base, and a polishing assembly is arranged above the conveying belt. The quartz stone plate polisher is characterized in that beams stretching across the base in the width direction are arranged at the two ends of the base, the two beams are provided with rotating mechanisms, each rotating mechanism comprises a driving rotating arm rotating on the beam and a driven rotating arm with one end connected with the driving rotating arm, the two ends of a rack of the polishing assembly are connected with the other ends of the driven rotating arms respectively, the beams are provided with rotation driving motors, and the polishing assembly can conduct curve swinging on the upper surface of the base under the drive of the rotating mechanisms. The quartz stone plate polisher has the advantages that the production efficiency is high and the polishing effect is good in the polishing process of quartz stone plates.

Owner:肇庆泰尔图斯石英石有限公司

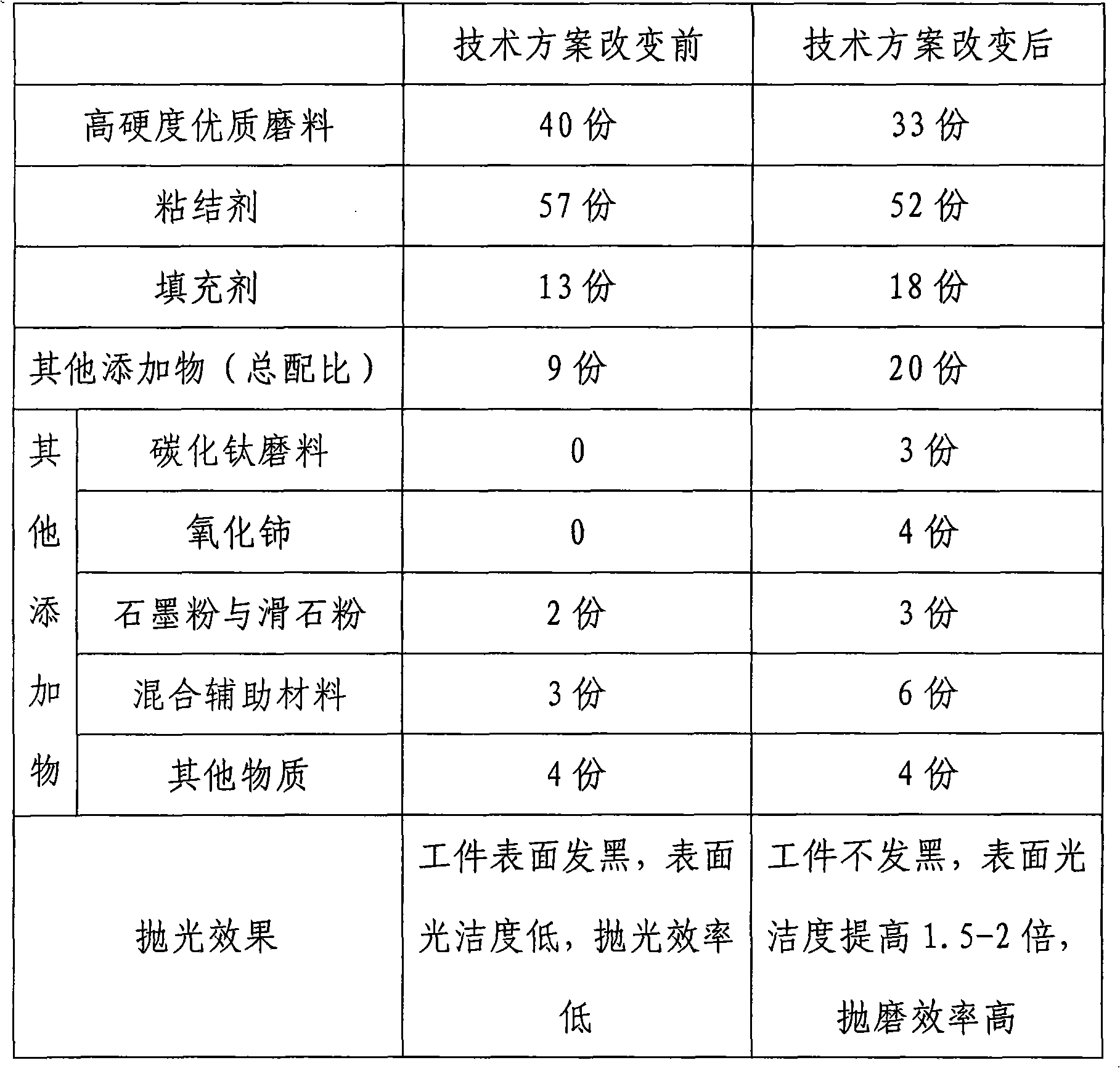

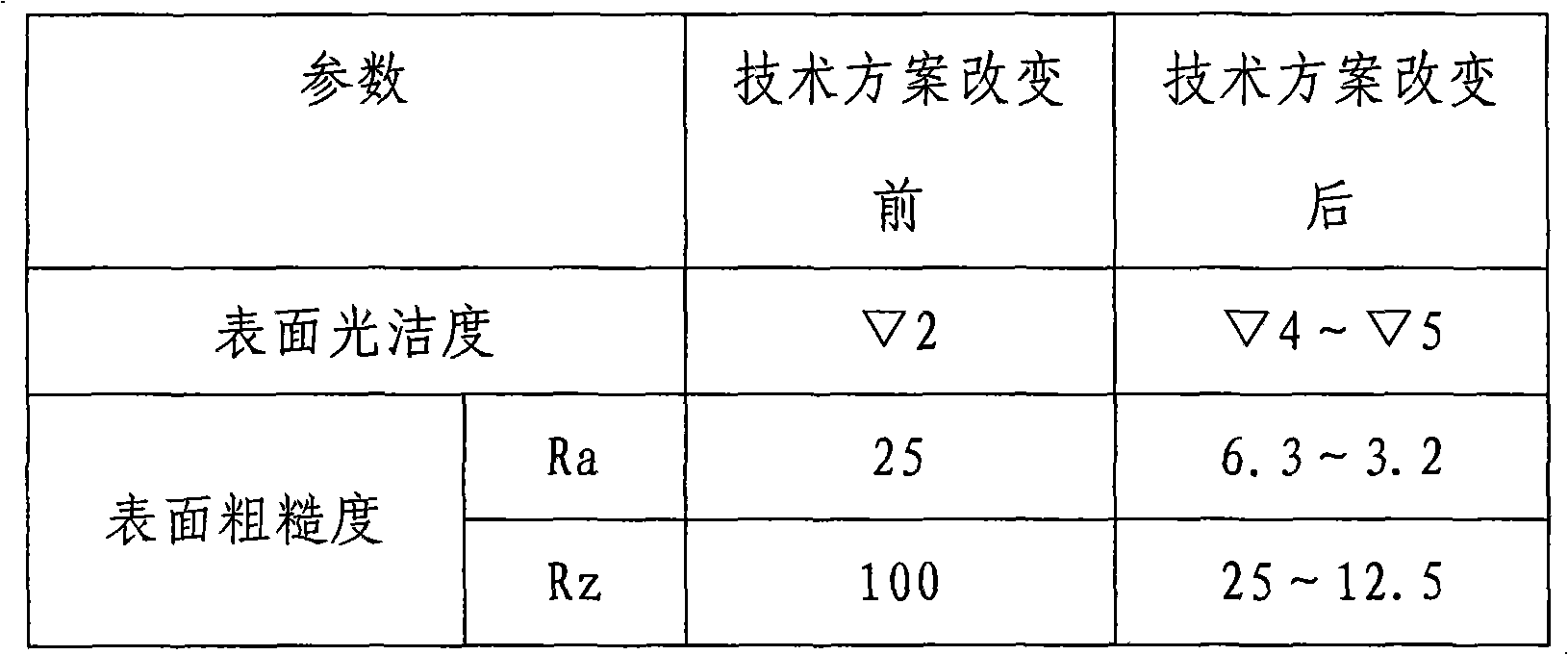

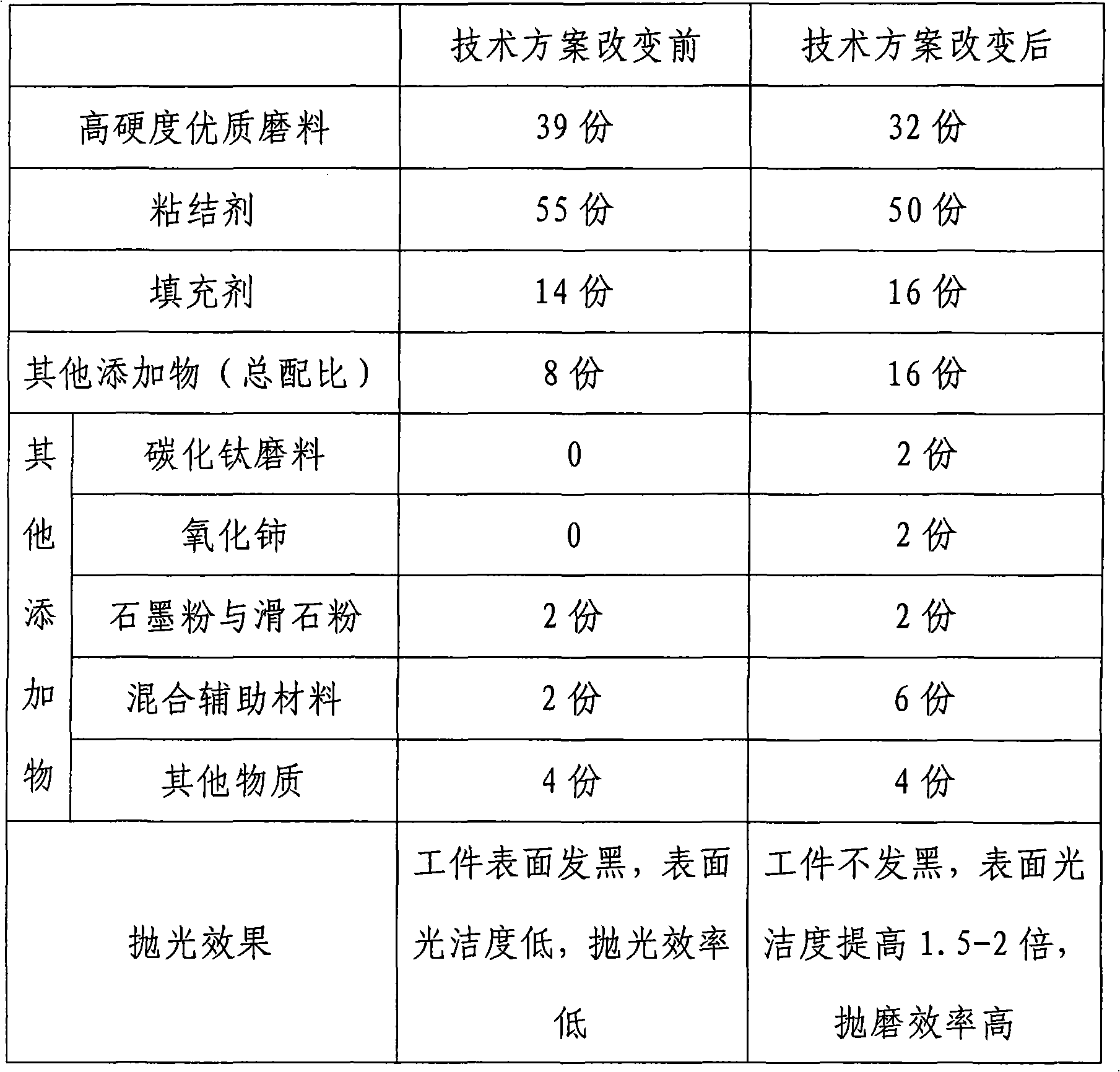

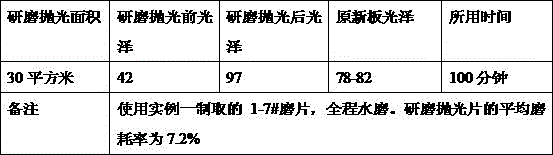

Nylon wheel and preparation method thereof

InactiveCN101570005AGood self-sharpeningGood polishing effectOther chemical processesFlexible-parts wheelsSurface finishPolymer science

The invention relates to a nylon wheel and a preparation method thereof. The nylon wheel comprises a nylon fiber silk screen (1) with a reticular fiber structure and a working layer (2) poured in the nylon fiber silk screen (1), wherein the working layer (2) is a mixture prepared from a high-hardness high-quality grinding material, a binding agent and a filling agent, and the weight proportion of the nylon fiber silk screen (1) to the mixture is 1:5-7. The method for preparing the nylon wheel comprises the following steps: 1) adding the high-hardness high-quality grinding material and the filling agent into the binding agent in an agitator tank in turn according to the sequence, stirring the mixture evenly under a condition of heating; 2) pouring the liquid mixture obtained in the step 1) into the nylon fiber silk screen, and performing an extrusion process so that the material is evenly distributed in the nylon fiber silk screen; and 3) according to the diameter and the thickness of the nylon wheel to be produced, performing laminating processing on the nylon fiber silk screen, cutting off and processing the nylon fiber silk screen into required shapes after standing, and performing hot working under a condition of heating to obtain the finished product. The nylon wheel has the advantages of low cost, long service life, capability of improving the surface finish quality of a workpiece, and high polishing efficiency. The method for preparing the nylon wheel has convenient manufacture and high production efficiency.

Owner:YANGJIANG WEIYI POLISHING MATERIAL

Machining polishing device

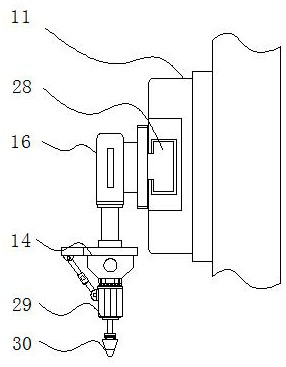

ActiveCN106737104AGood polishing effectImprove work efficiencyGrinding carriagesPolishing machinesTelescopic cylinderEngineering

The invention discloses a machining polishing device. The machining polishing device includes a base, a machining platform, a support vertical plate, a dust suction box, a polishing rack, a polishing abrasion ball and a top plate; a cavity is formed in a left internal chamber of the base; a guide rail is arranged on an inner wall of the cavity; a feeding slide block is slidingly arranged on the guide rail; the machining platform and the feeding slide block are fixedly connected through a connection block; the support vertical plate is fixedly arranged on an upper surface of the base in the vertical direction; the top plate is fixedly arranged on the top end of the support vertical plate in the horizontal direction; an electrical telescopic cylinder is arranged on the top plate; a slide plate is slidingly arranged on an inner side wall of the support vertical plate; a surface of the slide plate is fixedly connected to a right side plate of the polishing rack through bolts; and a top plate of the polishing rack is connected to a piston rod of the electrical telescopic cylinder. The machining polishing device is simple in structure, is reasonable in design, is excellent in polishing effect, is flexible to use, is high in working efficiency, and can effectively reduce influence of dust generated in the polishing process on a machining environment.

Owner:东莞市域标五金制品有限公司

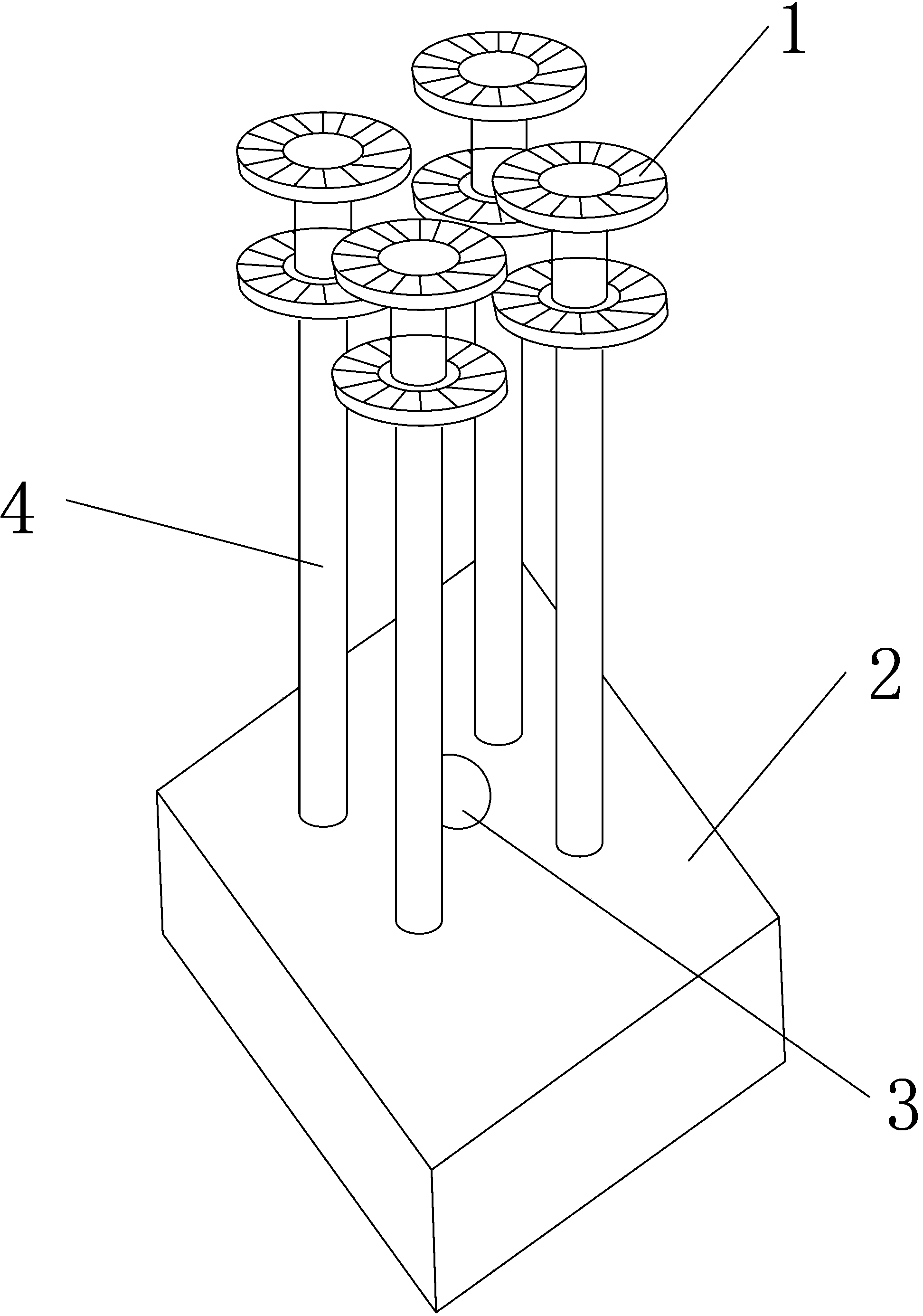

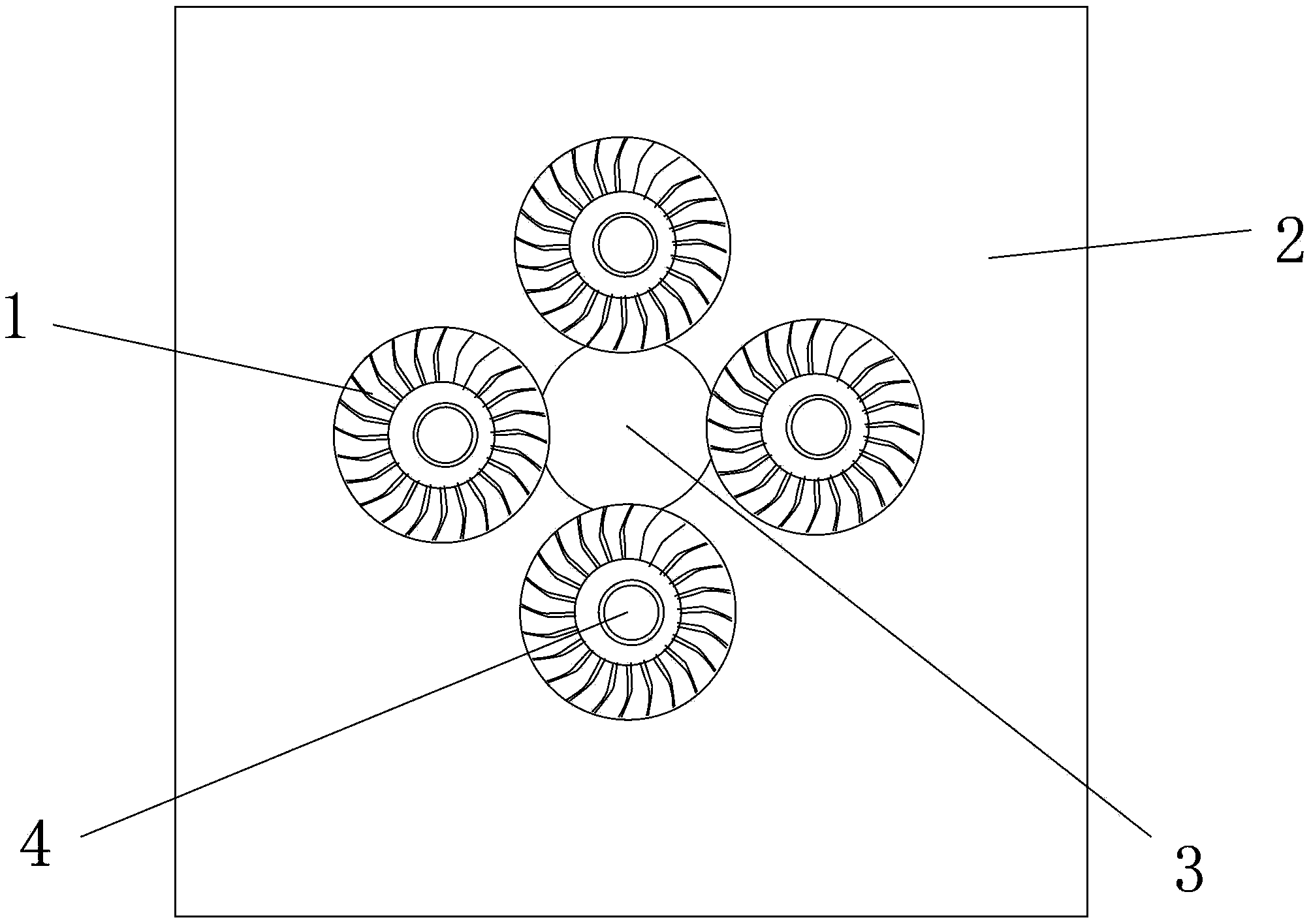

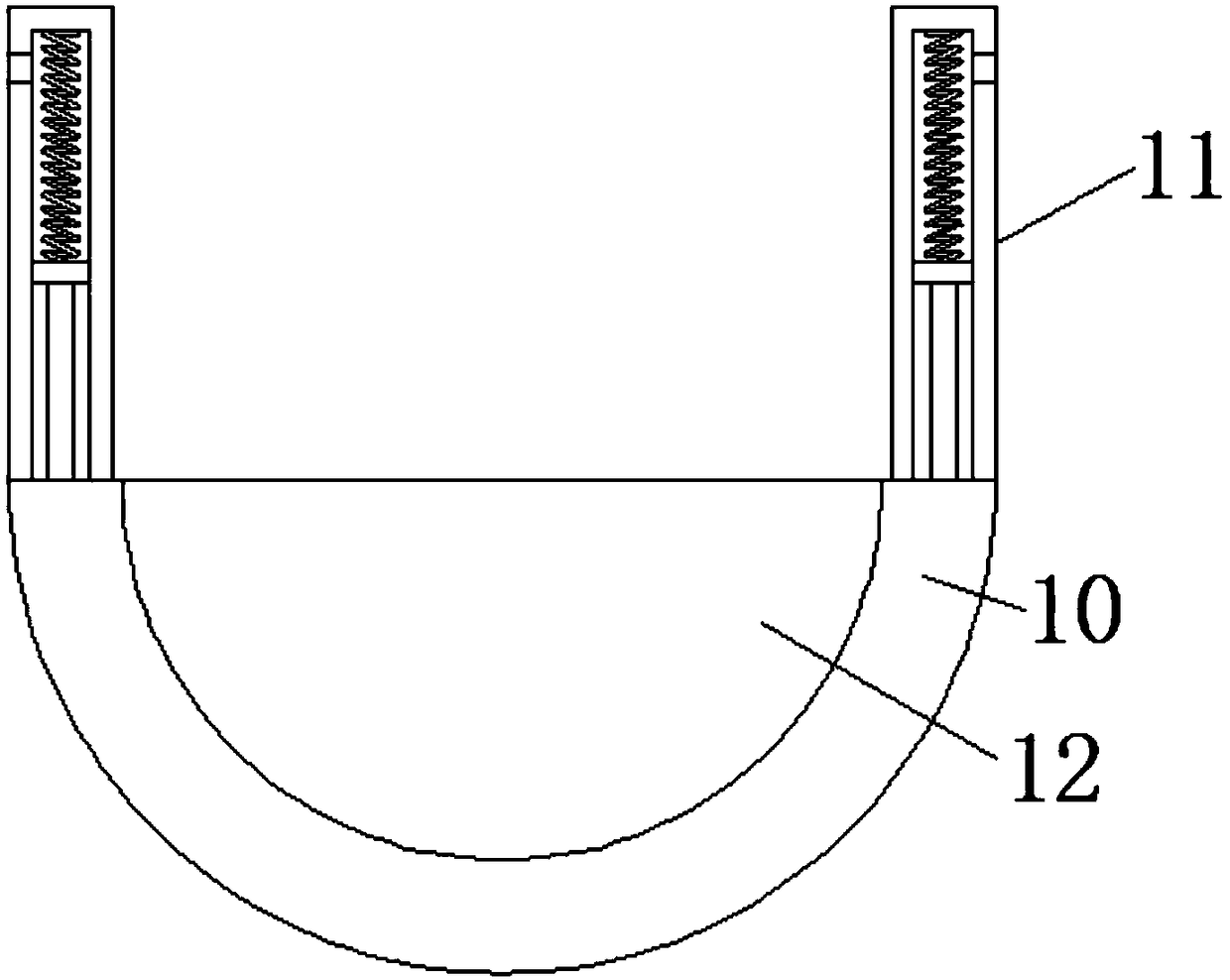

Stainless steel pipe polishing device

InactiveCN104044051ASimple structureGood polishing effectPolishing machinesElectric energyMaterials science

The invention relates to the technical field of the production of a stainless steel material, in particular to a stainless steel pipe polishing device. The stainless steel pipe polishing device comprises polishing wheels, a motor, a through hole and rotating shafts; the motor is provided with the rotating shafts, and the through hole which is used for a stainless steel pipe to pass through is arranged in the central point of the junction of a plurality of rotating shafts on the motor; each rotating shaft is provided with at least one polishing wheel, and the polishing wheels are encircled to form a square and are separated from one another. The polishing device is suitable for polishing the stainless steel pipe, simple in structure, good in polishing effect and high in working efficiency; less electric energy is needed for the polishing, and the polishing device can work only through one motor.

Owner:天津畅兴建筑装饰工程有限公司

Preparation method of polyurethane matrix stone grinding and polishing disc

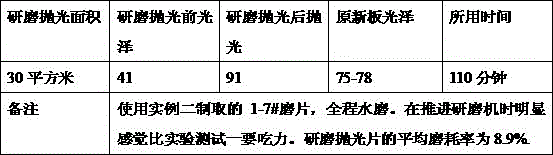

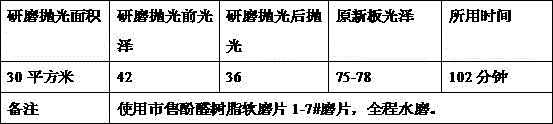

ActiveCN106272125AGood self-sharpeningImprove grinding effectAbrasion apparatusGrinding devicesSilicon oxideZinc

The invention discloses a preparation method of a polyurethane matrix stone grinding and polishing disc, and relates to a synthesis technology adopting a prepared polyurethane matrix and mixed artificial diamond micro powder, silicon carbide, silicon oxide, aluminium oxide and zinc oxide super fine powder as abrasive components. The novel stone grinding and polishing material can better meet the requirement on high luster during the decorative stone processing process or the later renovation process, the efficiency is higher, and the material has better environmental protection property.

Owner:王建秋

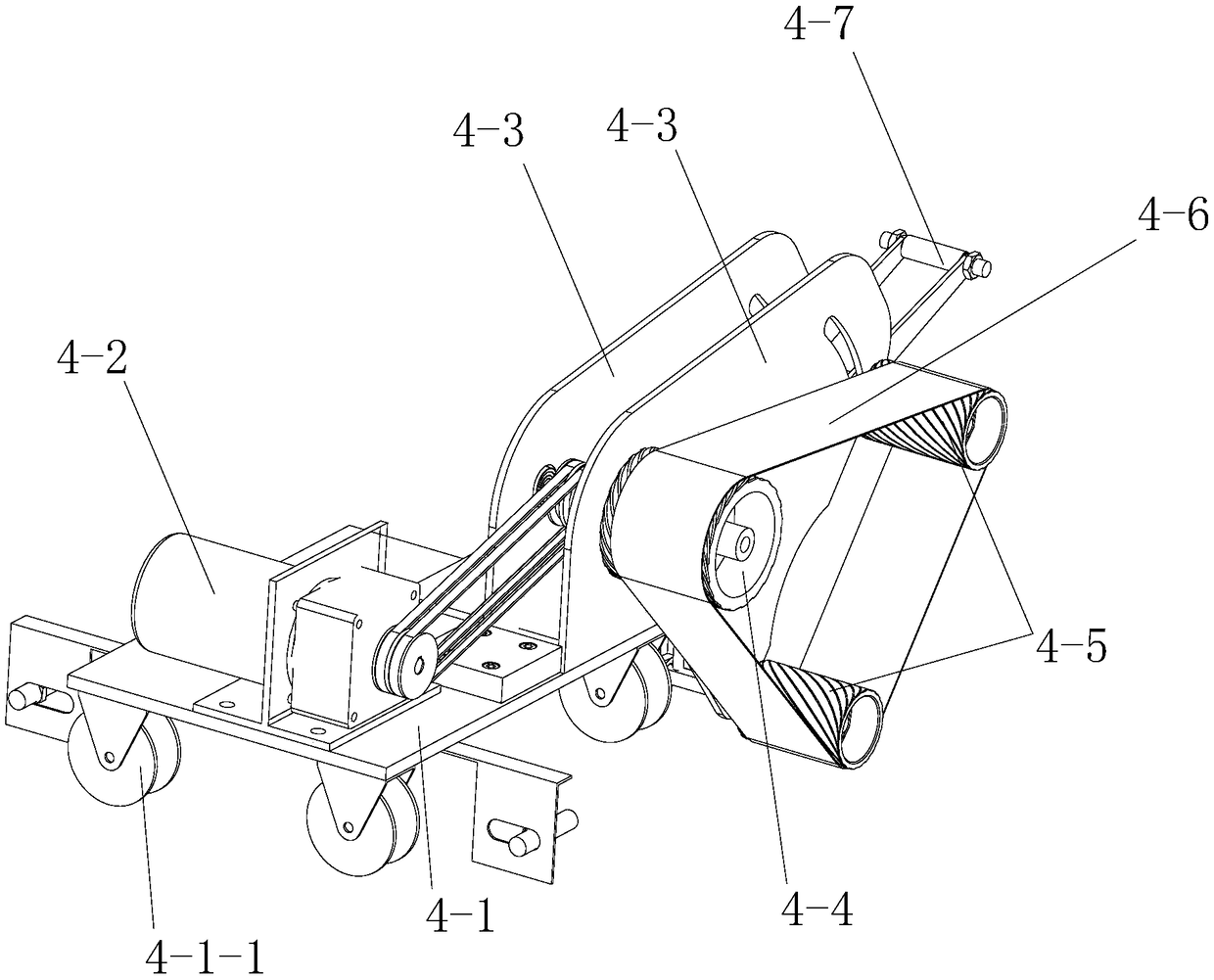

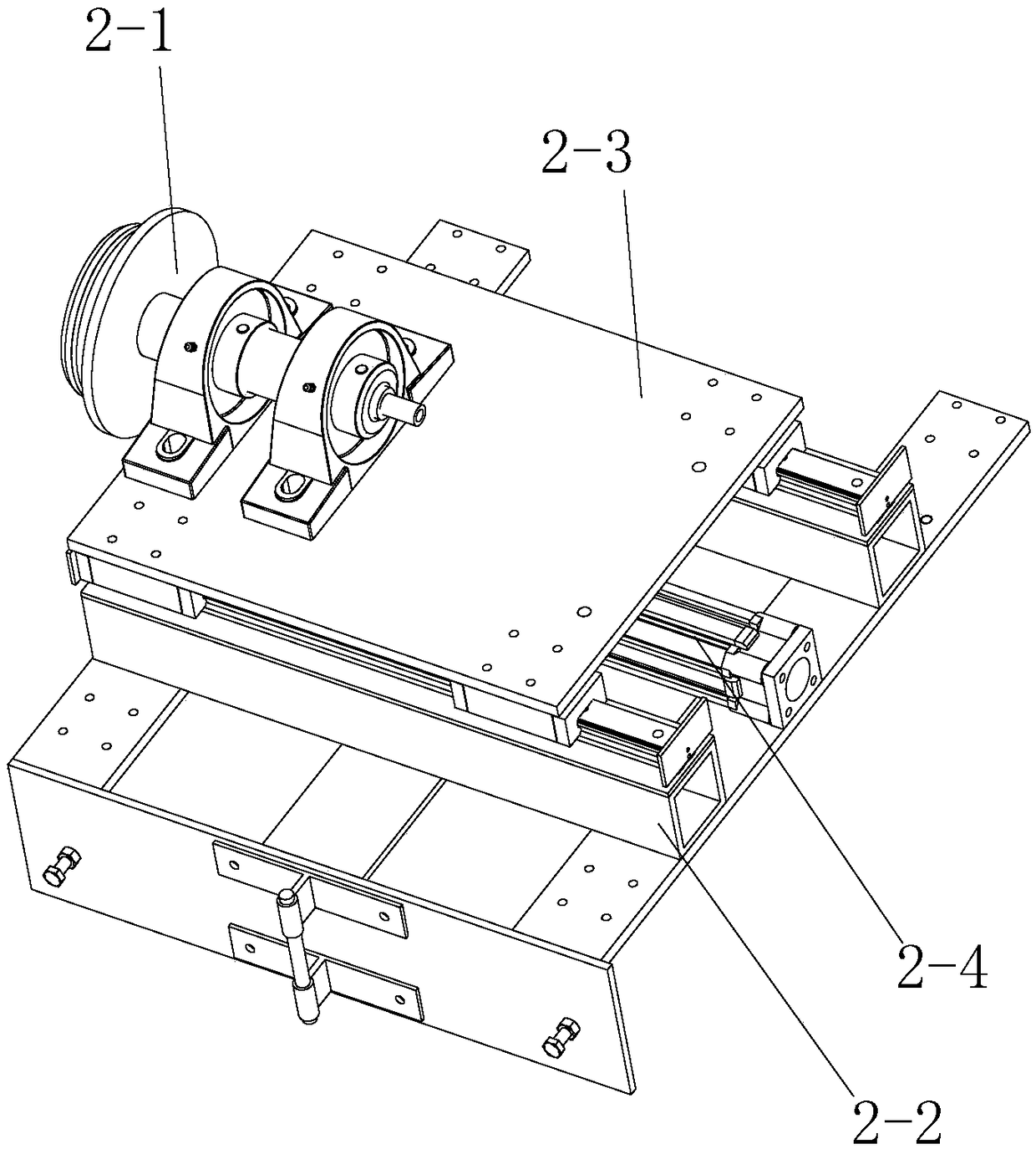

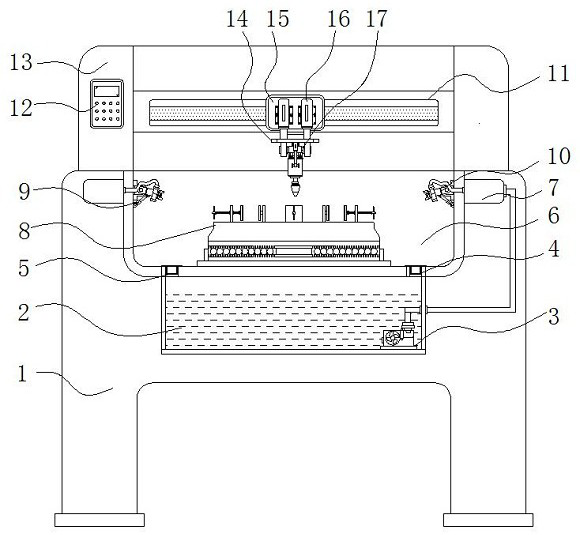

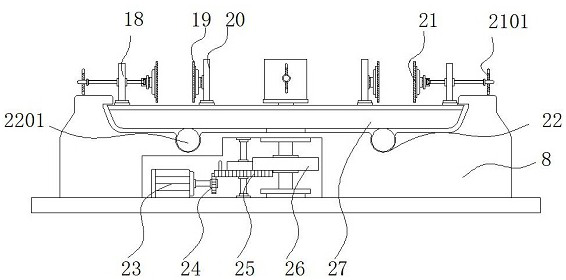

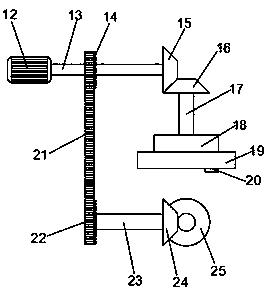

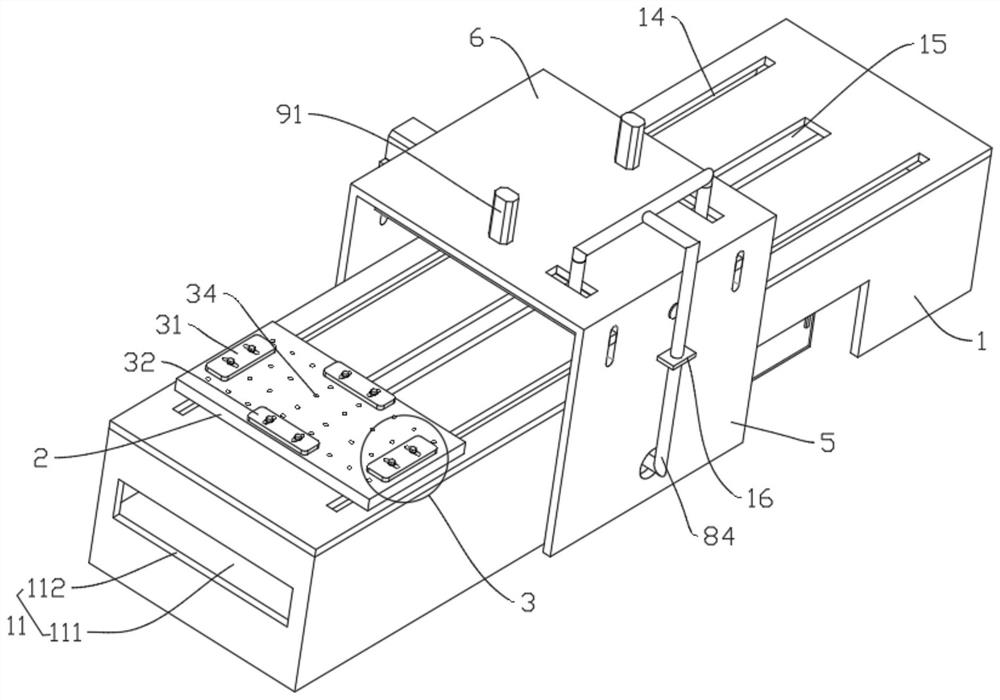

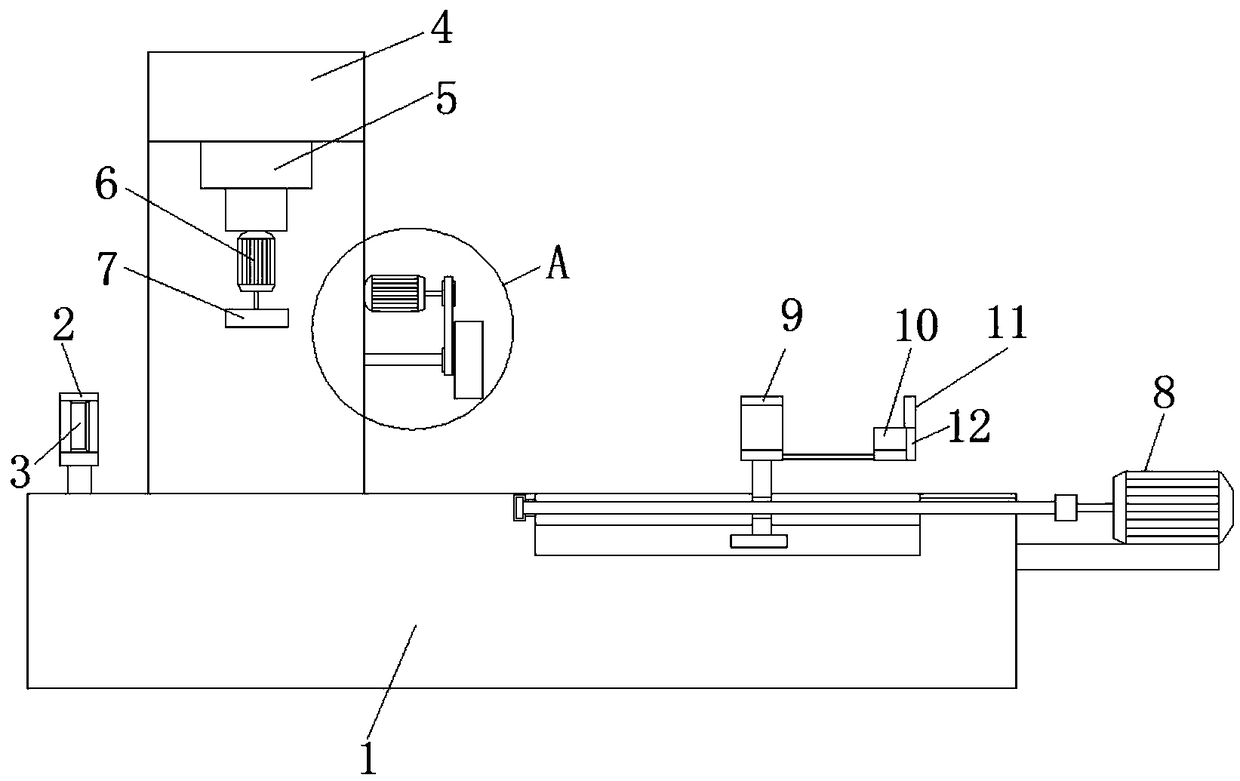

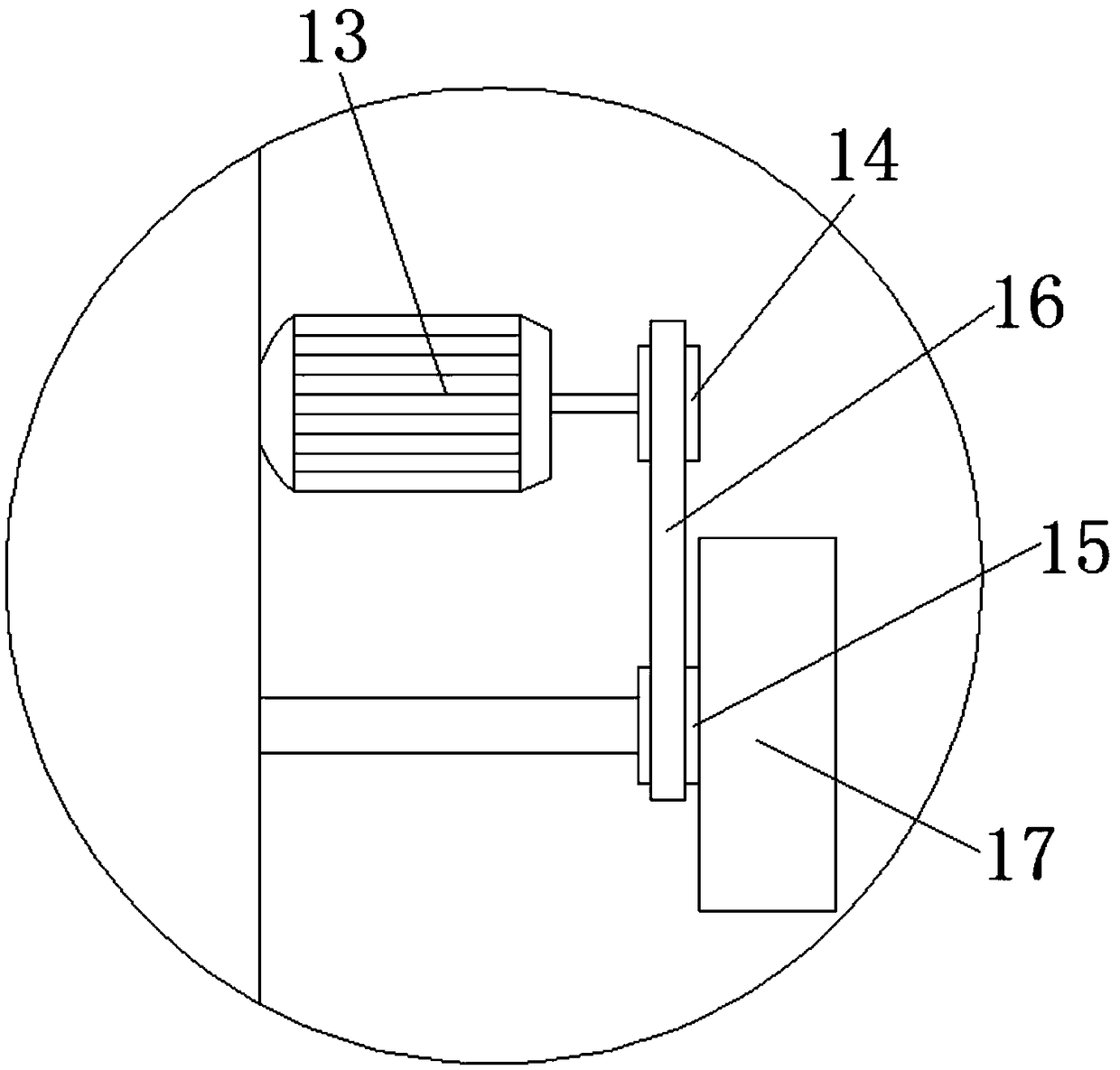

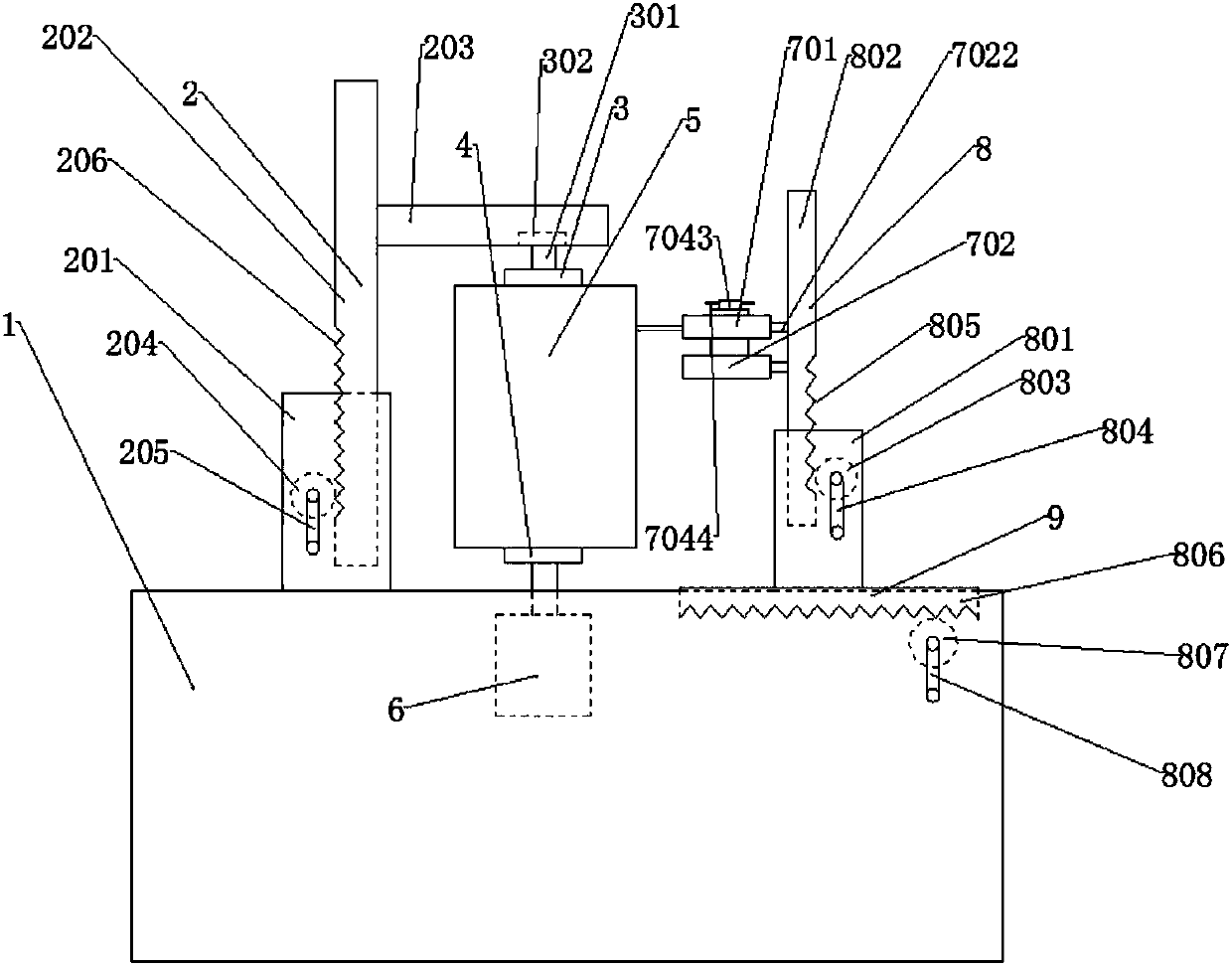

Equipment for polishing surface of steel tube

InactiveCN108857770AGrinding and polishing evenlyGood polishing effectGrinding drivesBelt grinding machinesSteel tubeEngineering

The invention discloses equipment for polishing the surface of a steel tube. The equipment comprises a rack, and a steel tube tightening rotating device, a transverse moving device and a belt sandingdevice mounted on the rack. The steel tube tightening rotating device comprises a moving platform, a driving mechanism and two tightening heads; the moving platform is arranged on the rack; the two tightening heads are symmetrically arranged and are located on a same horizontal plane, one of the tightening heads is mounted on the top of the rack through a bearing pedestal while the other tightening head is mounted on the top of the moving platform through a bearing pedestal; the driving mechanism drives one tightening head to rotate; and the belt sanding device comprises a grinding assembly, amoving trolley and a grinding driving motor. The equipment disclosed by the invention is skillful in structure, suitable for steel tubes of various length specifications, wider in applicability and more convenient in fixing mode, and achieves automatic grinding and polishing, so that all parts of the steel tube are uniformly ground and polished, and the equipment is excellent in grinding and polishing effect and high in work efficiency.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

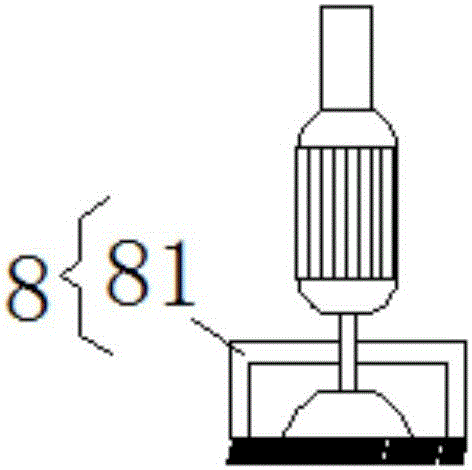

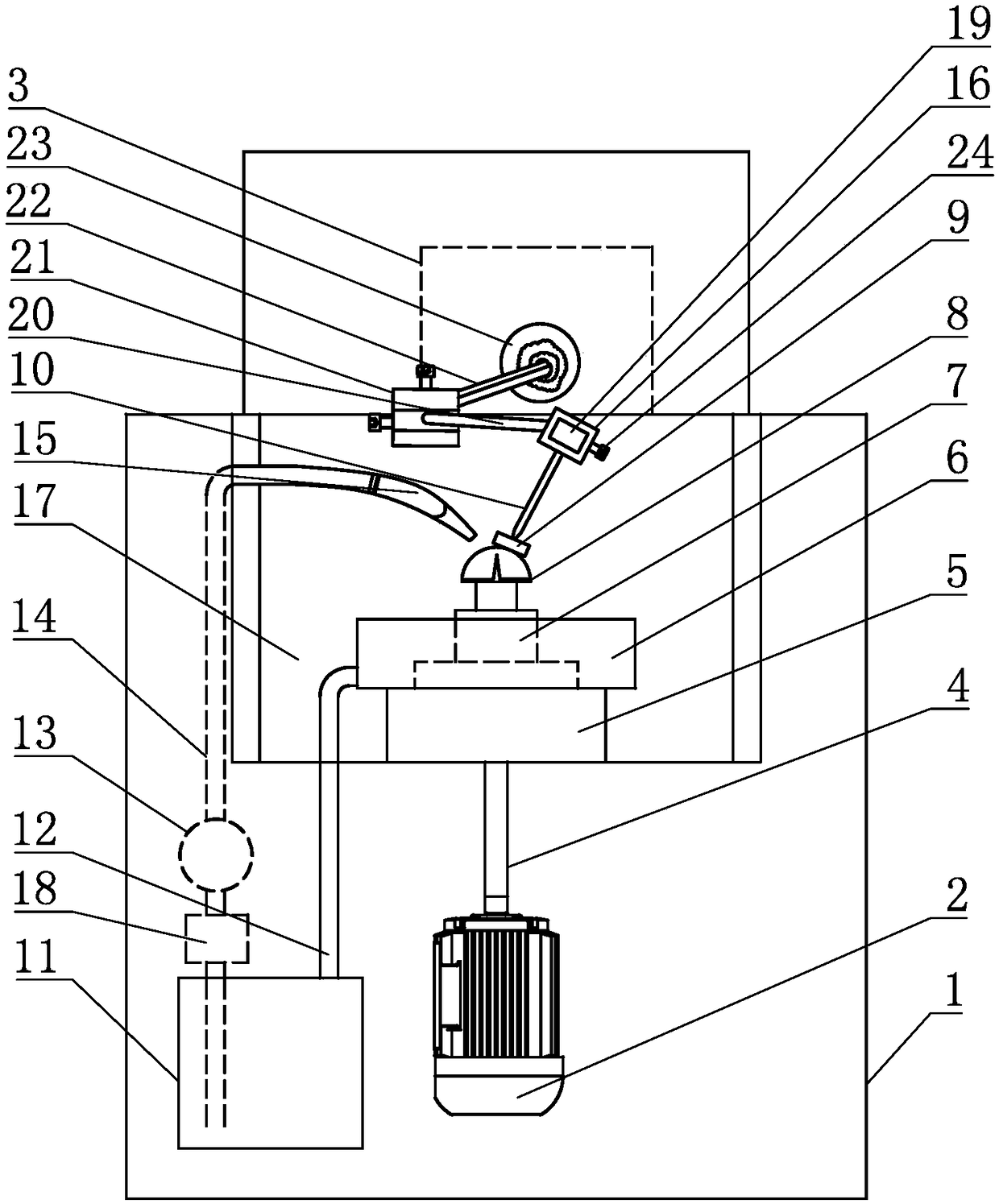

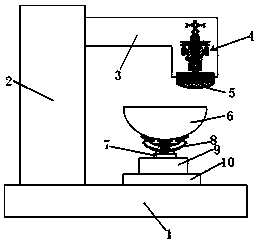

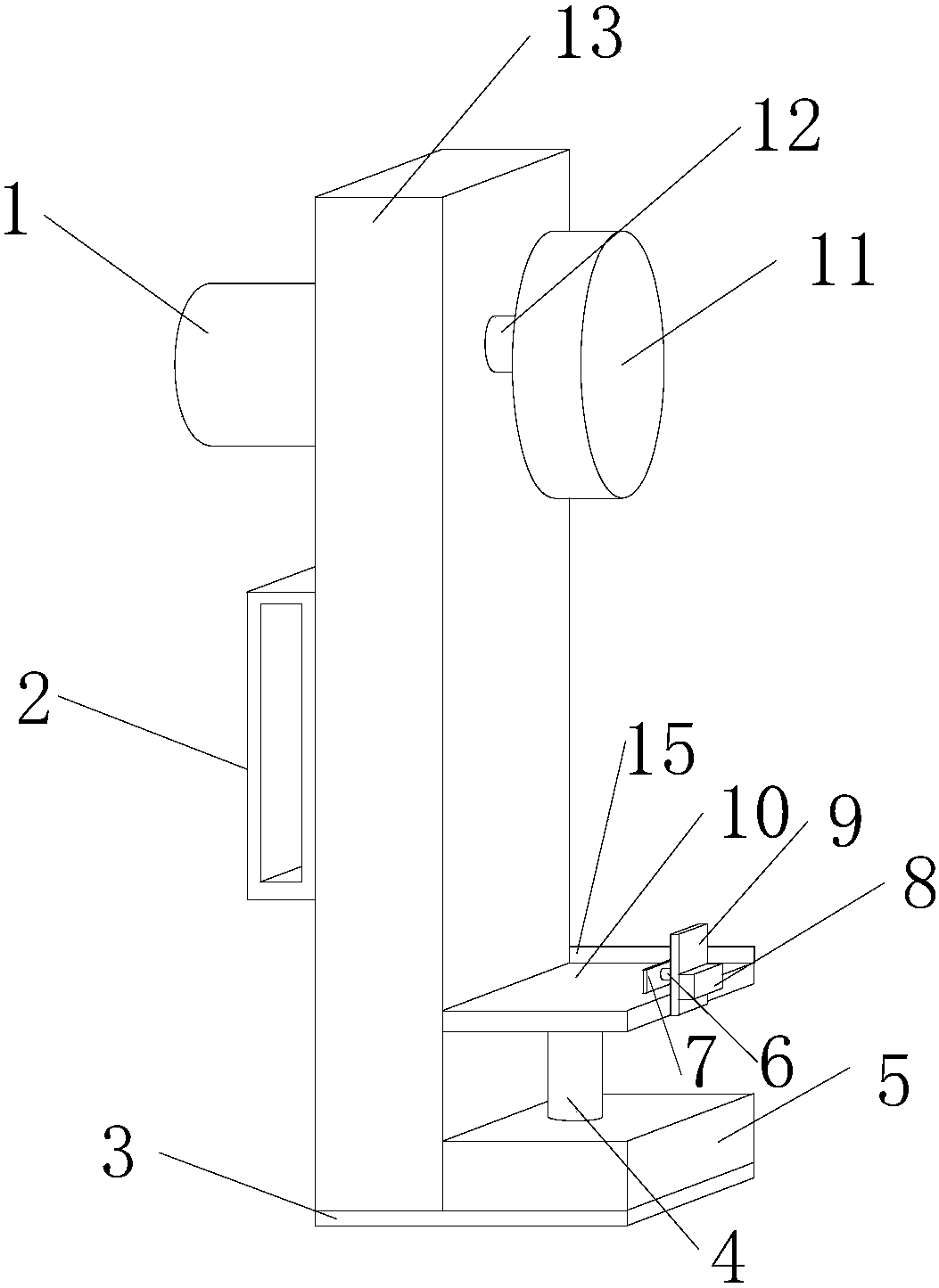

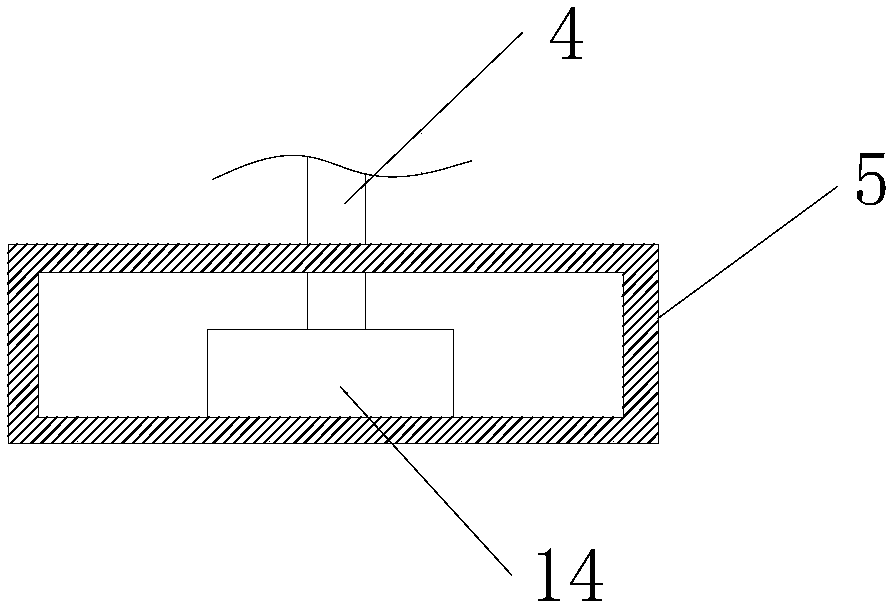

Lens polishing machine

InactiveCN108188866AGood polishing effectReduce use costOptical surface grinding machinesGrinding/polishing safety devicesSpray nozzlePressure sensor

The invention provides a lens polishing machine which comprises a machine tool. A working bin with an opening in the upper portion is formed in the machine tool, a fixing base is fixed to the bottom of the working bin, a shaft base is fixed to the fixing base, the upper end of a motor shaft of a rotating motor is provided with the fixing base in a penetrating manner to be then rotationally installed on the shaft base, a hemispheric grinding head is detachably installed at the upper end of the motor shaft, a centre arranged in an inclined manner is provided with an installing base in a penetrating manner to vertically abut against the surface of the right side of the hemispheric grinding head, the upper end of the centre is connected to the installing base in a sliding manner in the lengthdirection of the centre, the centre is in transmission connection with a rotary knob installed on the installing base, a pressure sensor is arranged at the tip of the centre, and the installing base is fixedly connected with a swing rod of a swing motor; and one end of a spraying nozzle faces the left side of the hemispheric grinding head, the other end of the spraying nozzle communicates to the bottom of a water storing box through a water outlet pipe after passing through a water pump, a water gathering groove is fixed to the fixing base, and the bottom of the water gathering groove communicates to the water storing box through a water inlet pipe.

Owner:望江县天长光学仪器有限公司

Waxing machine with automatic wax-spraying function

ActiveCN102334958AGood polishing effectShorten polishing timeFloor surfacing/polishing machinesWaxEngineering

The invention discloses a waxing machine with an automatic wax-spraying function, which at least comprises a wax box, a pump, a nozzle, a circuit board, a waxing motor and a brushing disk, one end of the pump is connected with the wax box, the nozzle is connected with the other end of the pump, the operation of the pump is controlled by the circuit board, power is supplied by the waxing motor, and the brushing disk is driven by the waxing motor. When the waxing machine is adopted, melted wax can be atomized and can be uniformly covered on a floor, and thereby the polishing effect is better.

Owner:KINGCLEAN ELECTRIC

Method for machining concave spherical crowns or concave ball ring surfaces through multi-magnet distributed annular magneto-theological polishing tool

ActiveCN109396966AGood polishing effectGood processing stabilityGrinding/polishing apparatusSmooth surfaceMagneto

A method for machining small-bore concave spherical crown or concave ball ring surface parts through a multi-magnet distributed annular magneto-theological polishing tool is characterized in that according to the size of the parts, a plane equivalent polishing tool and a test are prefabricated to determine the main process parameters, and permanent magnets are designed according to the process parameters and the structural shape of the parts and assembled into the annular magneto-theological polishing tool. Track simulation is conducted through the Matlab software to determine the rotation speed series capable of achieving axial and circumferential even removal. The parts and the annular polishing tool are subjected to sphere center positioning mounting, and the inclination angle alpha ofthe part axis and the tool axis is adjusted. According to the main process parameter values, a machine tool workpiece shaft and a tool shaft are started, and magneto-theological polishing liquid is continuously supplied to the machining area to conduct polishing machining on the concave spherical crown (concave ball ring surface) parts. The method can make the surface roughness achieve the nanoscale super-smooth surface, and achieves a better correction function for the surface figure accuracy (sphericity) of the parts.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

An electrolytic polishing method for complex brass

An electrolytic polishing method for complex brass is disclosed. The method includes (1) grinding complex brass and then preforming mechanical polishing, (2) performing electrolytic polishing, with the complex brass after mechanical polishing being adopted as an anode, a lead block being adopted as a cathode, an electrolytic polishing direct voltage being 1-4 V, a current being 0.1-4 A, an electrolytic polishing temperature being room temperature, and electrolytic polishing time being 5-30 s, and (3) taking the complex brass out after electrolytic polishing, washing with absolute ethanol and then drying the complex brass to obtain a product, wherein an electrolytic polishing liquid comprises H3PO4, gelatin and oxalic acid, 2-4 g of the gelatin and 2-4 g of the oxalic acid are added for each 30-70 mL of the H3PO4 and the H3PO4 concentration is not less than 85%. According to the method, requirements on previous mechanical polishing quality before the electrolytic polishing are low, the electrolytic polishing can be operated at room temperature, and the electrolytic polishing liquid is simple in formula, nontoxic, nonirritant and nonvolatile, and can be stored for a long term and repeatedly used.

Owner:HEBEI UNIV OF TECH

Electrolytic polishing liquid, polishing device and polishing method

PendingCN109778298AGood polishing effectIncreased electrolytic reaction speedElectrolysis componentsMartensitic stainless steelSurface-active agents

The invention discloses an electrolytic polishing liquid, a polishing device and a polishing method. The electrolytic polishing liquid comprises, by weight, 18%-28% of sulfuric acid, 20%-32% of citricacid, 5%-15% of tartaric acid, 1%-5% of a surface active agent and the balance deionized water; the concentration of the sulfuric acid is 98%; and the surface active agent is an anionic surfactant. The method for adopting electrolytic polishing to remove oxide skin inside a heat treatment part small hole and burrs in a threaded hole is adopted, and the technical problem that the inner surface ofthe martensitic stainless steel small hole is difficult to polish is solved.

Owner:CHANGZHOU WASTON MEDICAL APPLIANCE CO LTD

Polishing machine with cooling function for bearing machining

InactiveCN111687740AImprove work efficiencyGood polishing effectGrinding carriagesPolishing machinesWater pipePolishing

The invention discloses a polishing machine with a cooling function for bearing machining. The polishing machine specifically comprises a workbench, a water tank, an operation table, a fluted disc anda transmission disc, wherein a working bin is formed in the middle position of the top end of the workbench, a water cavity is formed in the edge position of the working bin, the water tank is fixedinto a position, below the working bin, of the workbench, a water pump is mounted at the bottom end in the water tank, the output end of the water pump communicates with the water cavity through a water pipe, water inlets are formed in two sides of the top of the water tank respectively, a filter hopper is mounted in each water inlet, spray guns are uniformly arranged at each of two sides in the working bin, and the input end of each spray gun is connected with the water cavity through a hose. According to the polishing machine with the cooling function for bearing machining, through the arrangement of the water pump and the spray guns, a bearing can be water-cooled in the polishing process, and the situation that polishing precision is influenced by excessive temperature in the polishingprocess is avoided; and cooling water can flow back into the water tank through the water inlets, so that water-cooling circulation is realized.

Owner:东莞市固德智能科技有限公司

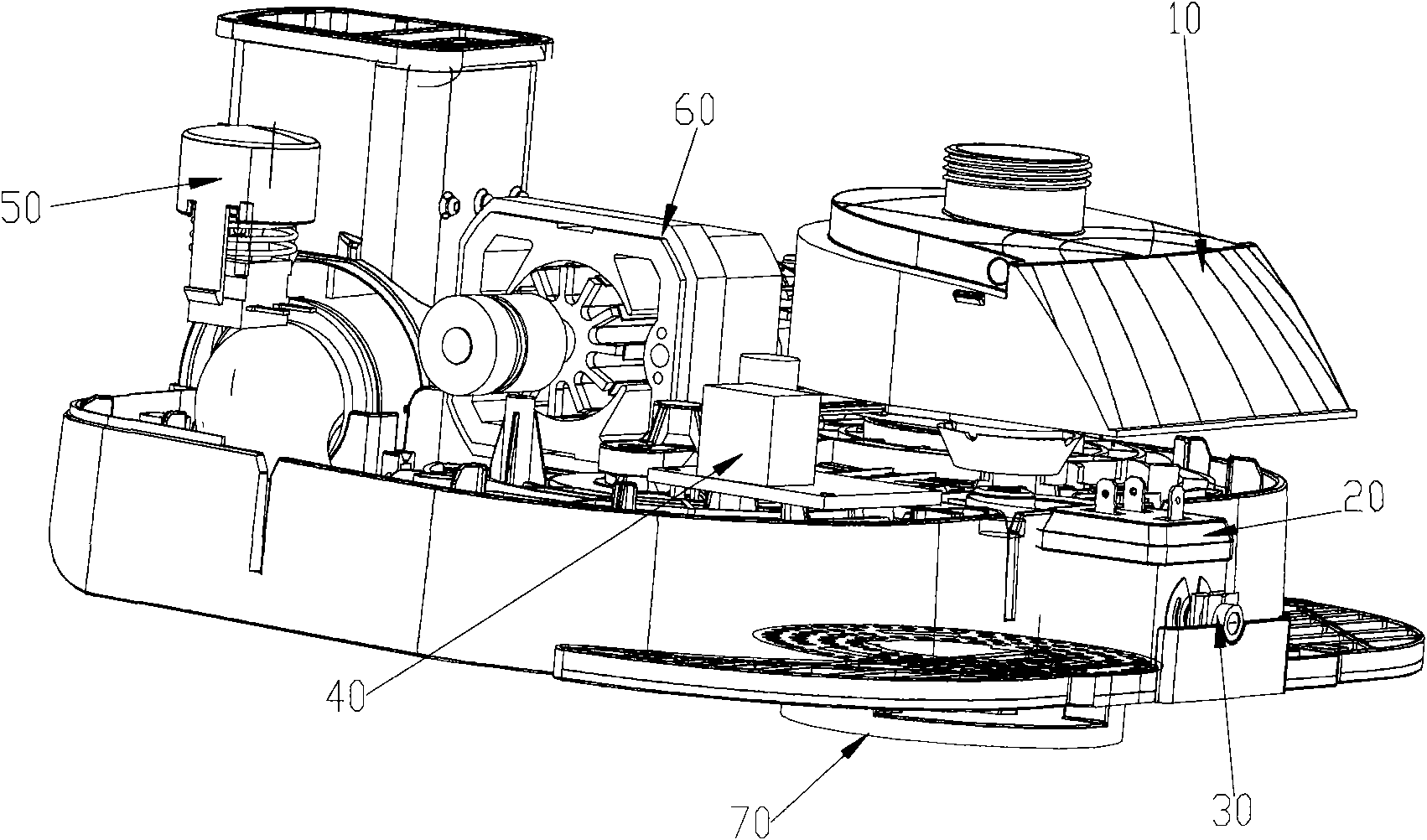

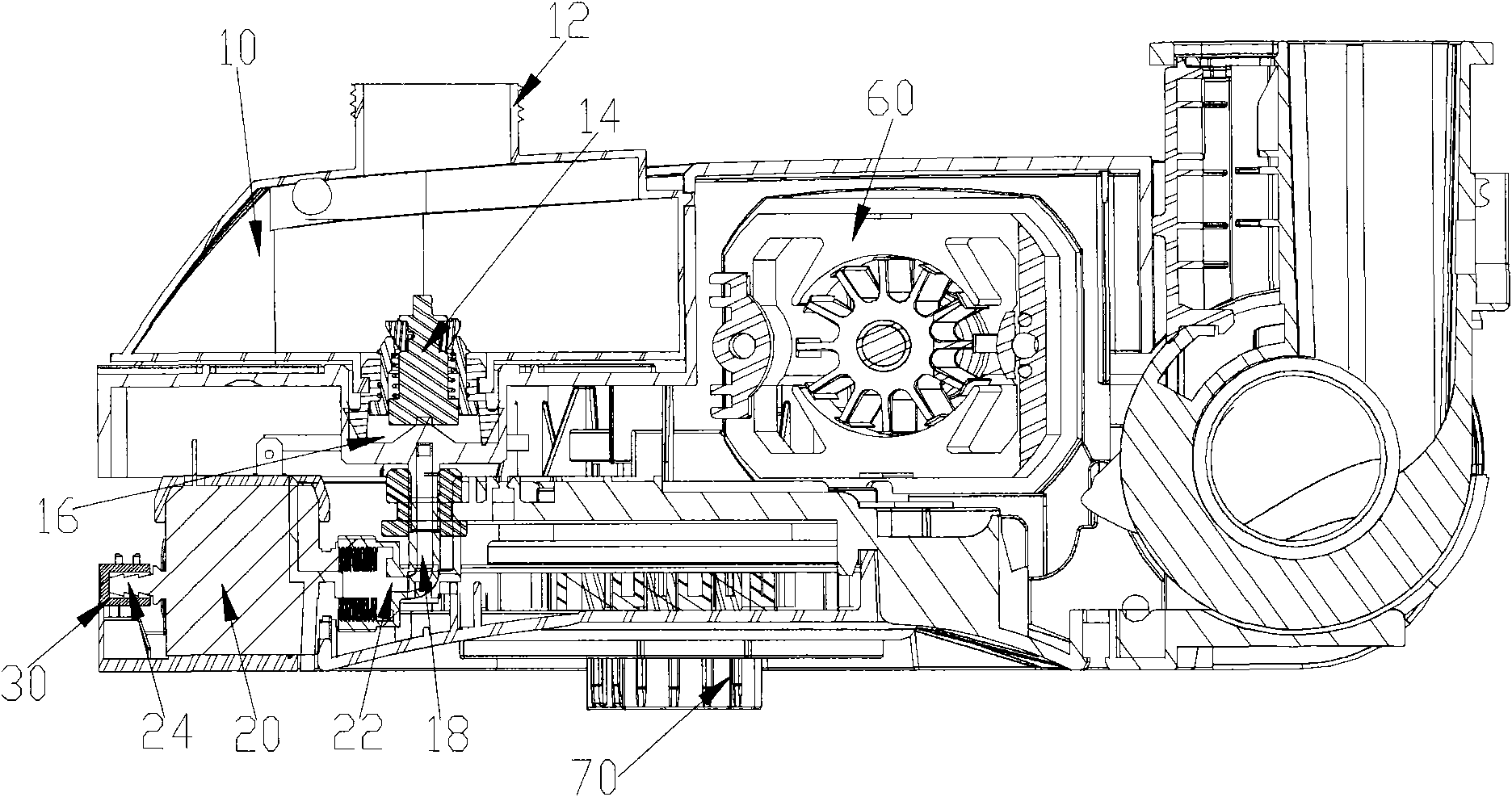

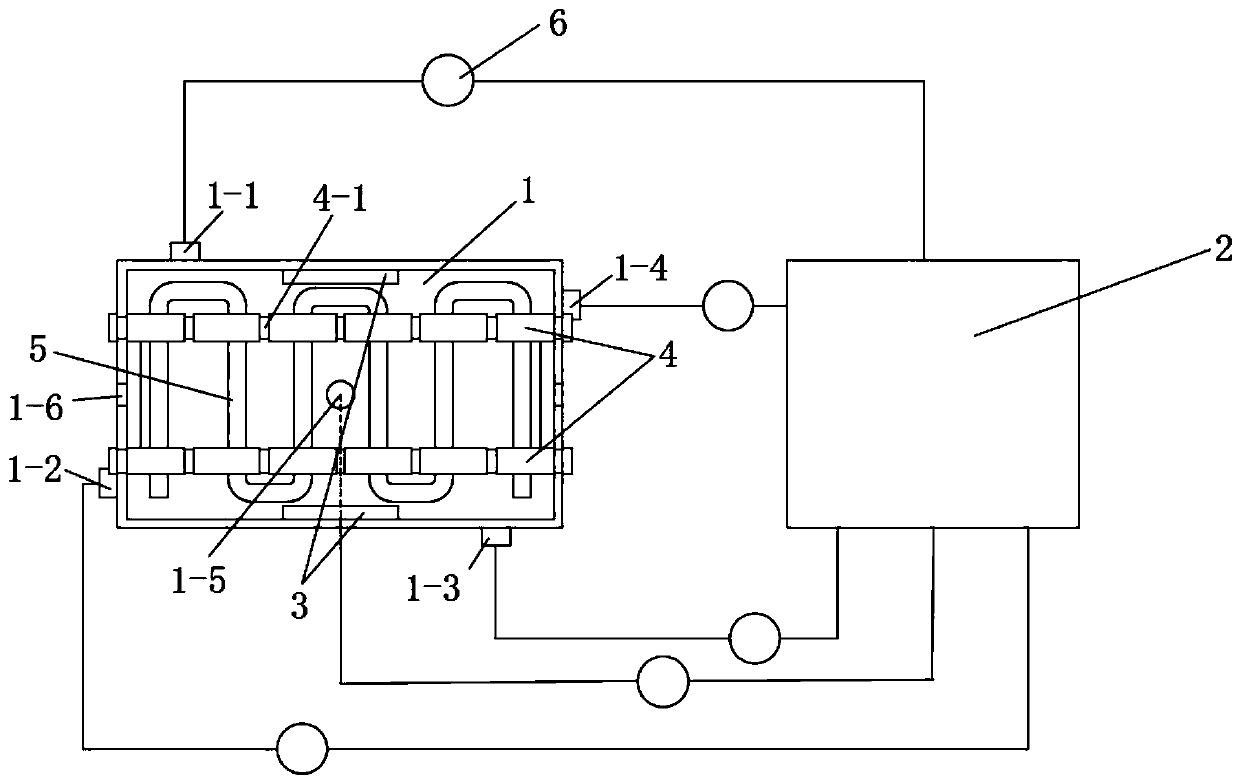

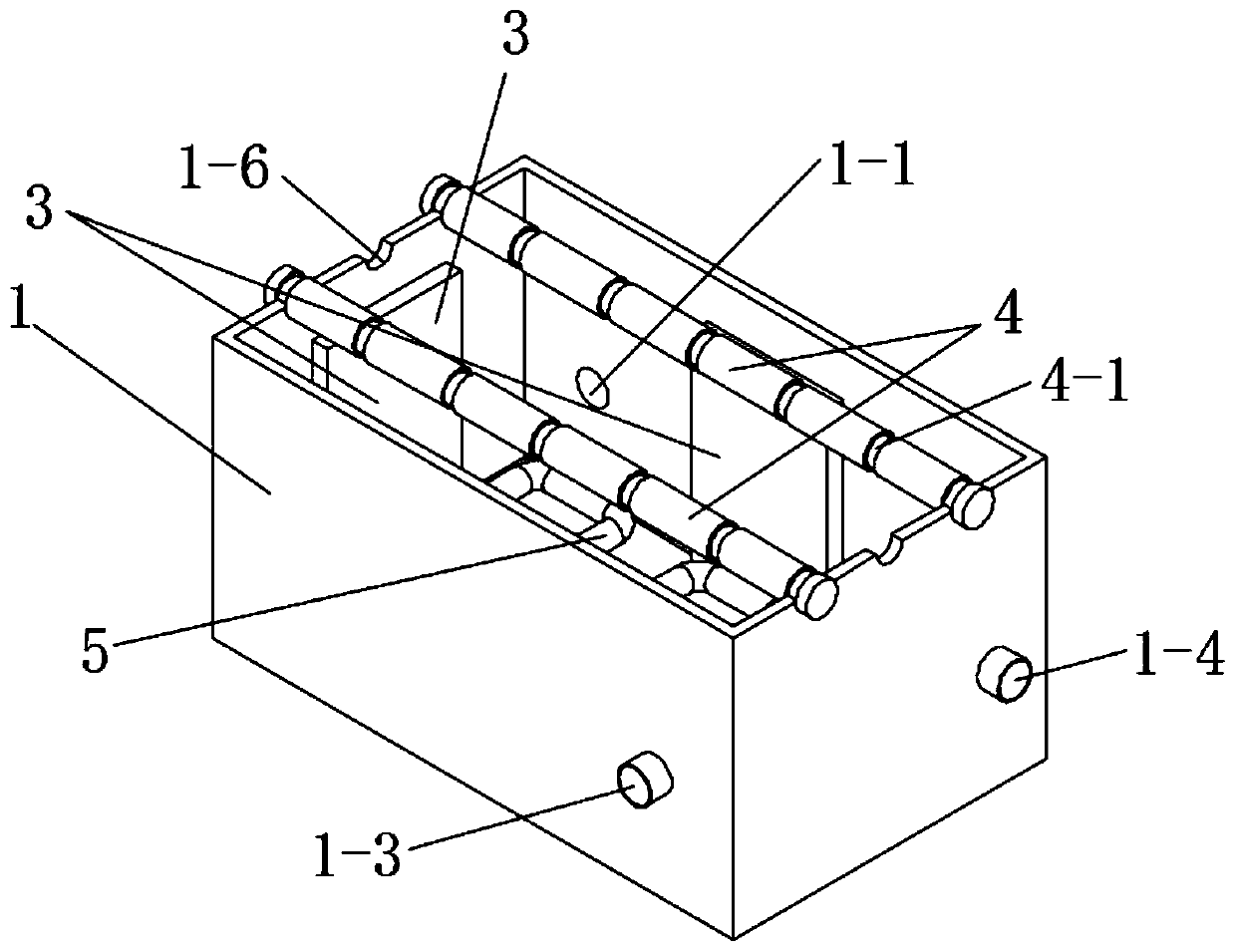

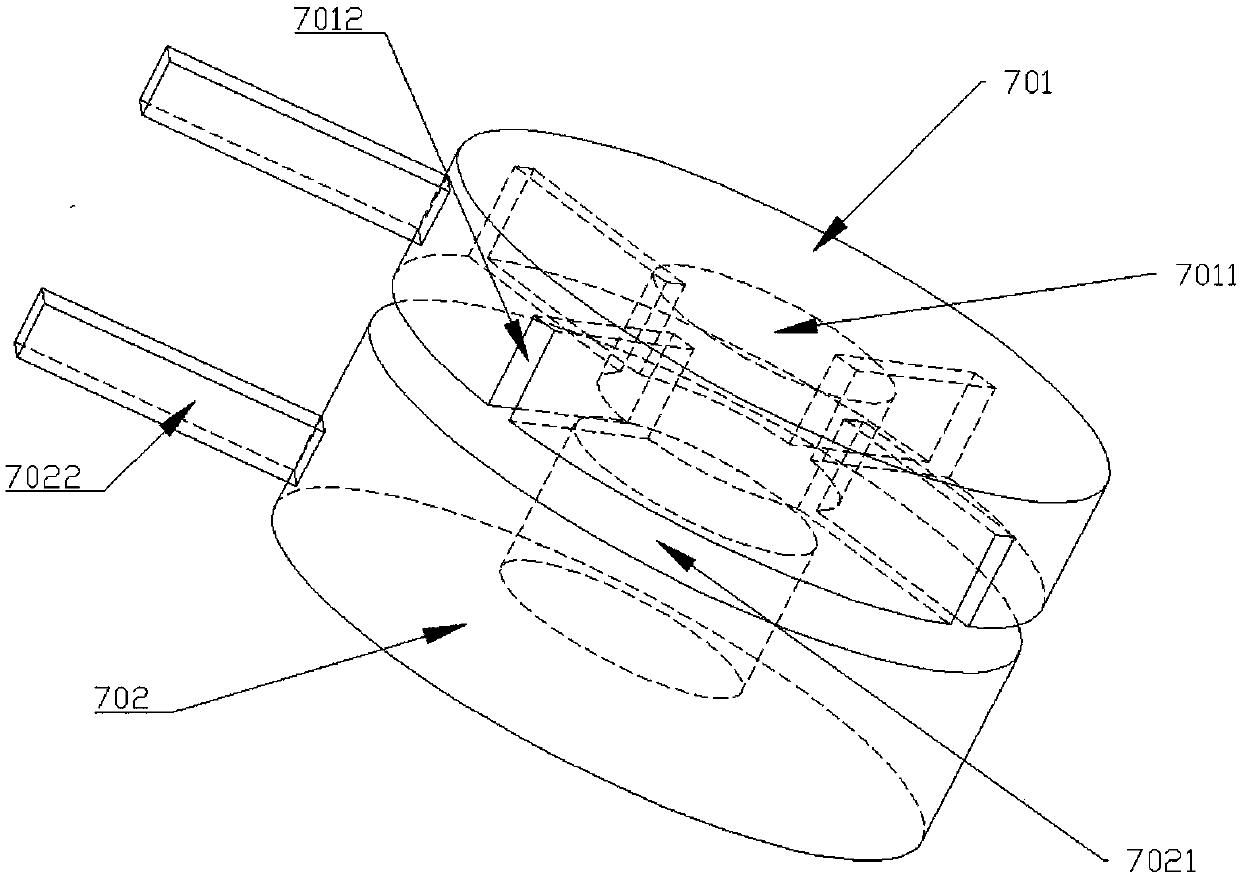

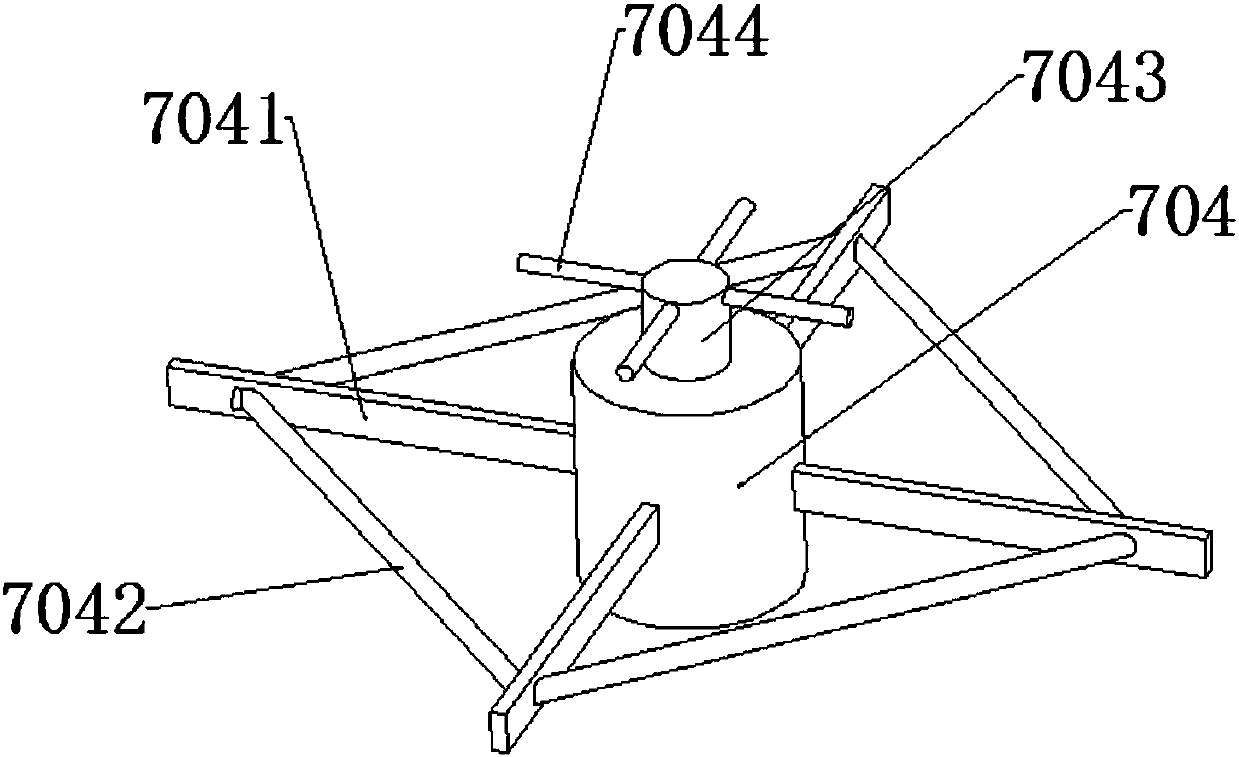

Centrifugal stirring optical lens polishing equipment

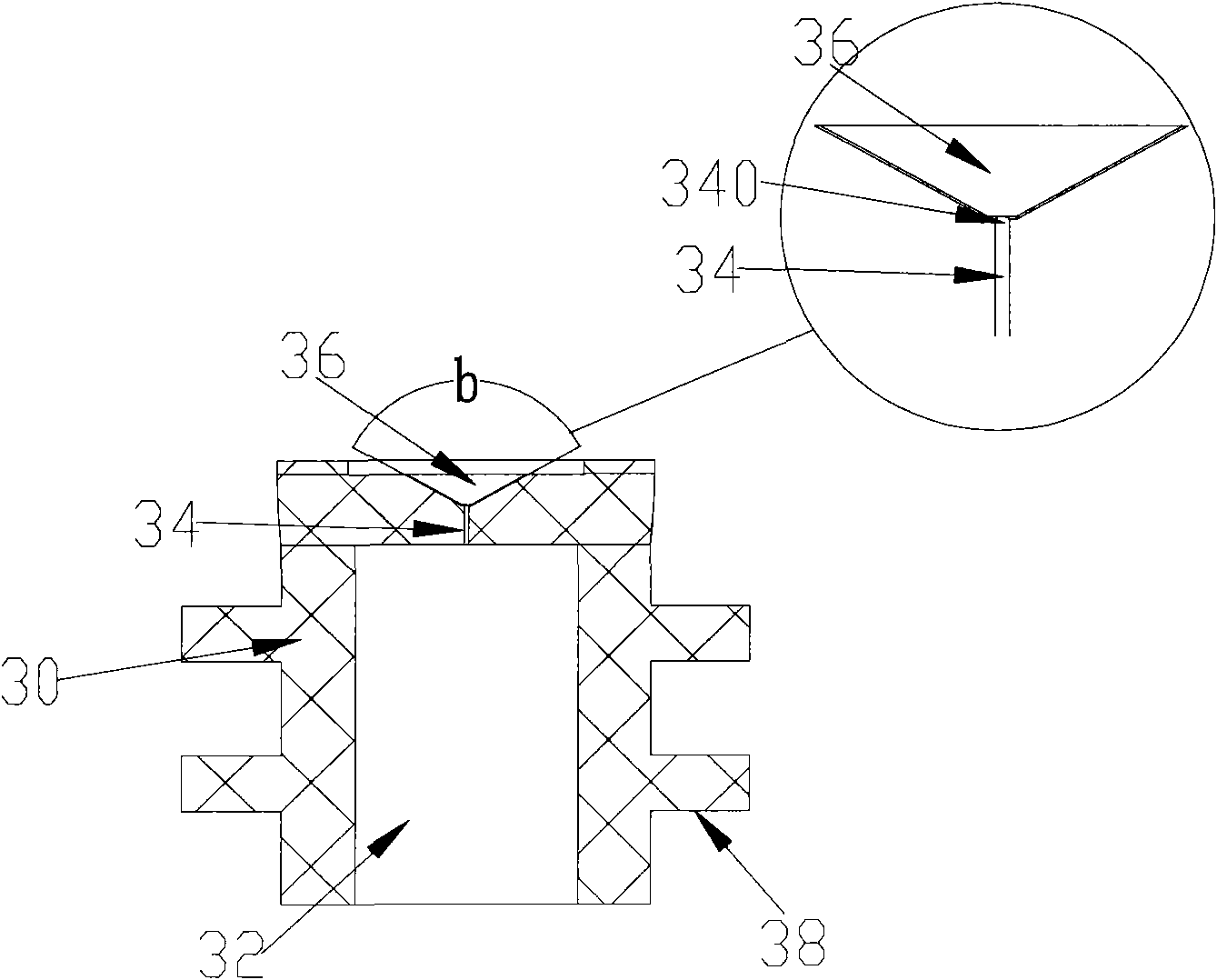

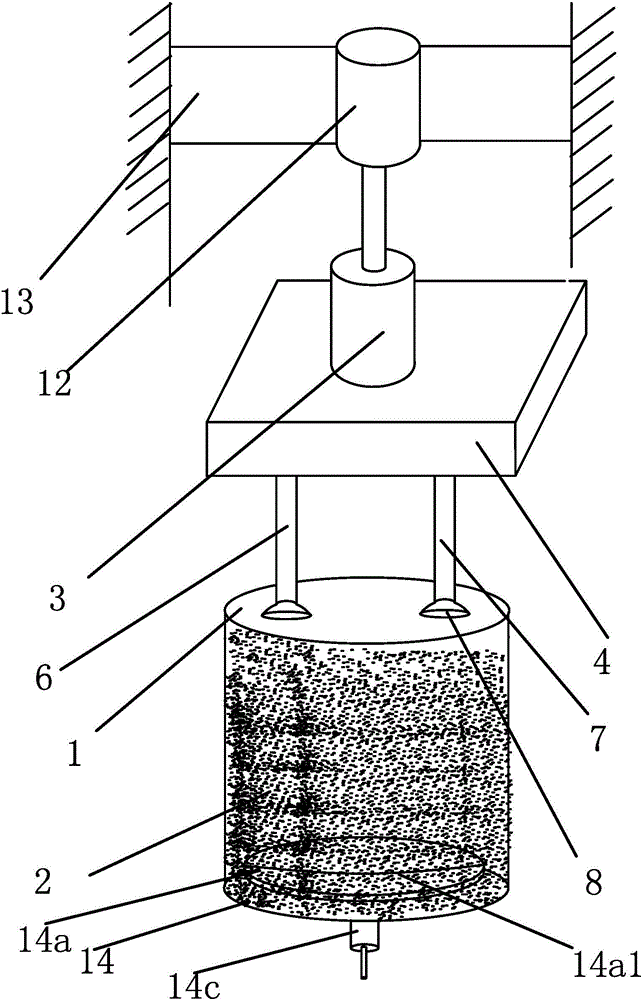

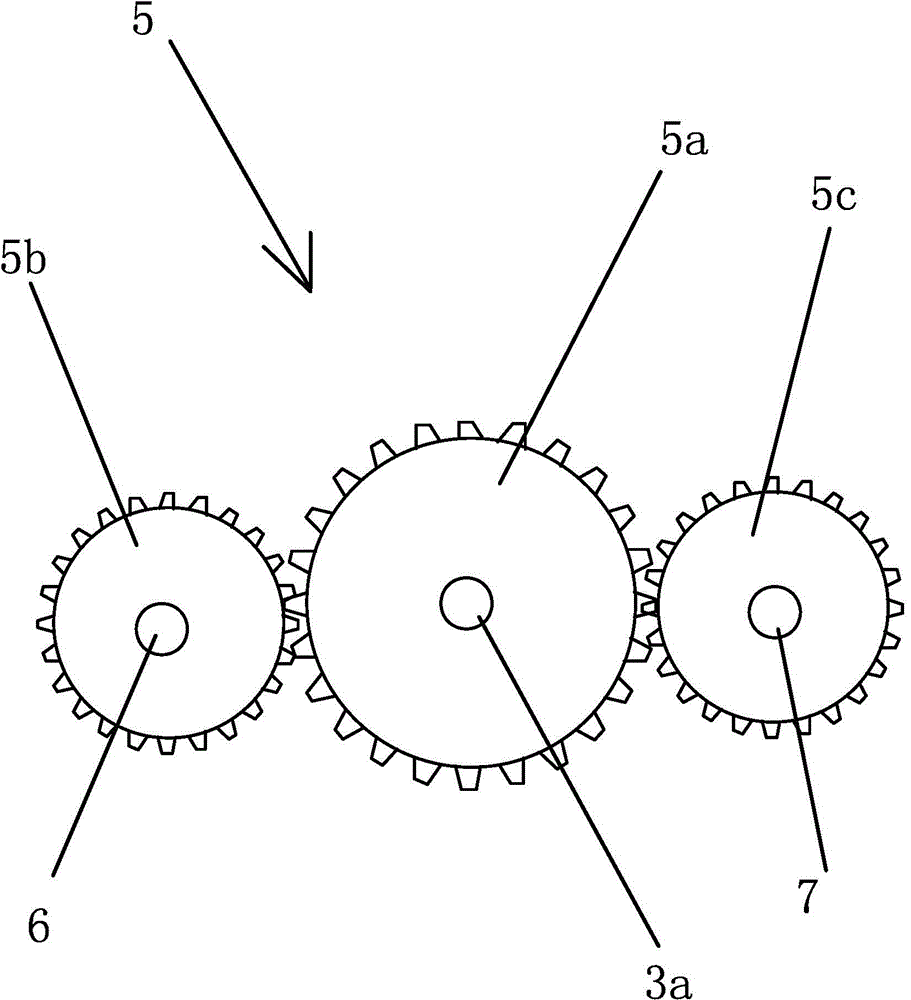

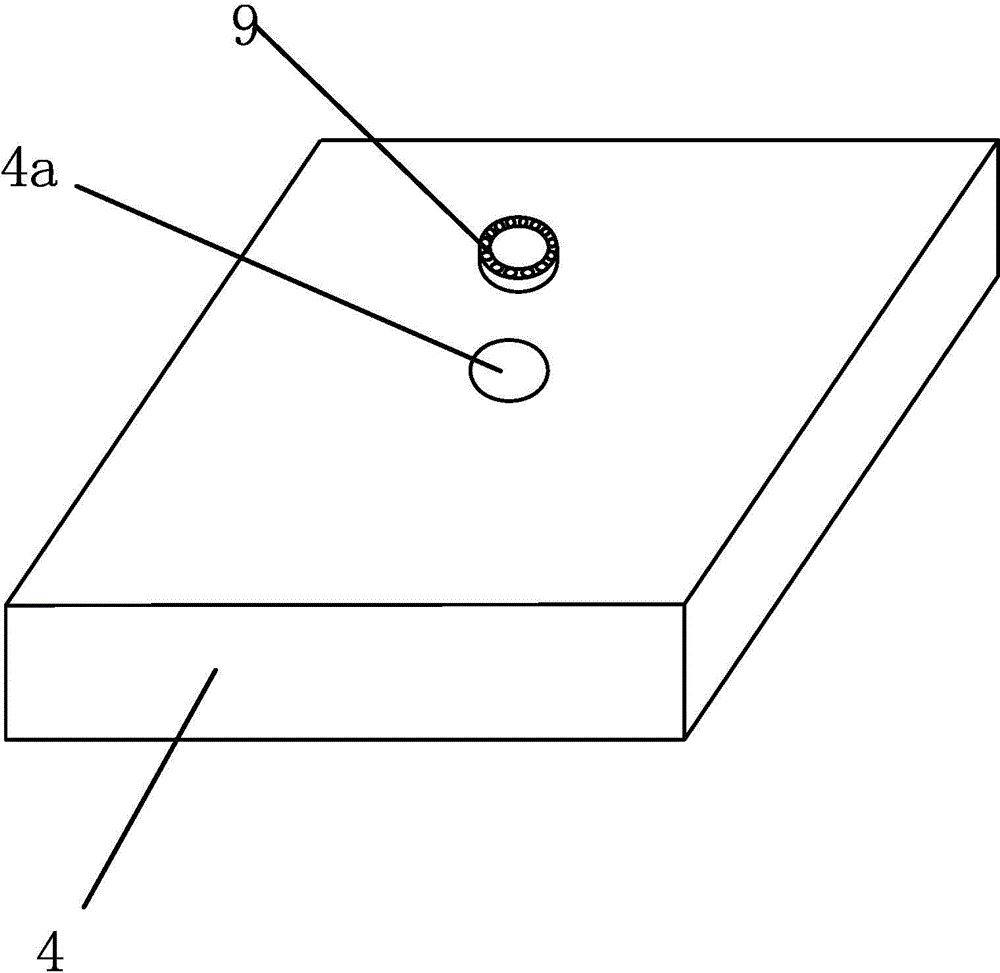

ActiveCN104308693AGood polishing effectImprove efficiencyOptical surface grinding machinesElectric machineryLinear motor

The invention provides centrifugal stirring optical lens polishing equipment and belongs to the field of machining of an optical lens. The polishing equipment comprises a machining barrel with polishing liquid and a rotary motor I; a rotary shaft of the motor extends into a bidirectional box; the end part of the rotary shaft of the motor is connected with a steering mechanism; the steering mechanism drives a straight rod I and a straight rod II to rotate in opposite clock directions; suckers are connected to the outer ends of the two straight rods; the steering mechanism comprises a gear I, a gear II and a gear III; the gear II and the gear III are meshed with the gear I respectively; the rotary shaft of the motor is tightly matched in a bearing I and the gear I; the inner ends of the straight rod I and the straight rod II are respectively tightly matched with the gear II and the gear III; a linear motor connected with the rotary motor I is arranged above the rotary motor I; a carrier plate is arranged at the bottom of the machining barrel; a rotary motor II is connected to one side of the carrier plate and is connected with a linear motor II; a straight line shaft of the linear motor II is fixedly connected with a shell of the rotary motor II. The polishing equipment is good in polishing effect and efficient and has a stirring function.

Owner:南京蔚蓝新材料科技有限公司

Method for preparing metal polishing agent

The invention discloses a method for preparing a metal polishing agent and belongs to the technical field of preparation of polishing agents. The method comprises the following steps: first, wool-washing wastewater sludge is treated by using an acid and an alkali, thereby extracting lanolin in the wool-washing wastewater sludge; then, diatomite, diamond micro-powder and the like are subjected to ball milling, thereby obtaining an abrasive material; and finally, the obtained lanolin and abrasive material are blended with surfactants and organic acids, thereby obtaining the metal polishing agent. In the method, citric acid is blended with the surfactants as a chelating agent, and can be used for quickly removing rust and oil dirt on a metal surface. The metal polishing agent prepared according to the method disclosed by the invention is stable in performance and has the advantages that oil dirt and rust spots on the metal surface can be effectively removed, and then the metal surface can be kept shiny and bright; meanwhile, a protective film layer is formed on the metal surface, so as to preventing the air from corroding metal; in addition, no fluorine-containing compound or phosphorous compound is contained in the metal polishing agent, so that the metal polishing agent is safe and environmentally friendly; and the metal polishing agent has the characteristics of being wide in application scope, stable in polishing effect, convenient to use, and efficient.

Owner:仇颖莹

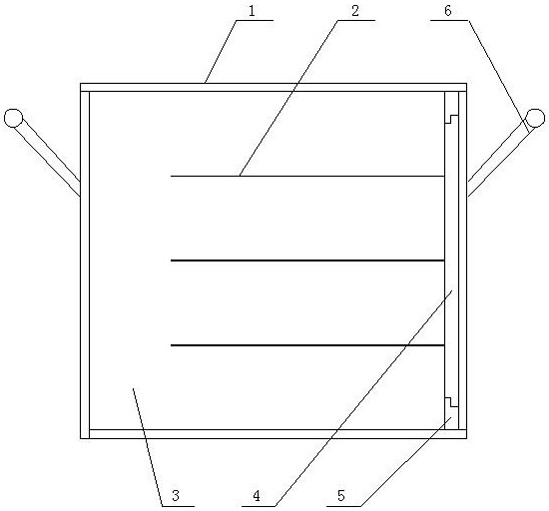

Board polishing device for processing of solid wood furniture

ActiveCN109048628AGood polishing effectDoes not affect polishing effectGrinding carriagesPolishing machinesSolid woodEngineering

The invention discloses a board polishing device for the processing of solid wood furniture, and belongs to the technical field of the polishing equipment of wood board. The Board polishing device forprocessing of solid wood furniture comprises a coarse polishing device, a first supporting frame, a fine polishing feeding device and a fine polishing device, and is characterized in that: a fixing plate is fixedly arranged at the top end of the first supporting frame, a conveyor belt is fixedly arranged in the middle of the first supporting frame, a coarse polishing device is fixedly arranged below the fixing plate, the coarse polishing device is positioned above the conveyor belt, a second supporting frame is arranged on the right side of the conveying belt, the fine polishing feeding device is fixedly connected with the second supporting frame, the fine polishing device is fixedly connected to the right side of the fine polishing feeding device, and a third supporting frame is fixedlyarranged at the lower end of the fine polishing device. According to the board polishing device for processing of solid wood furniture, wood chips can be cleaned after rough polishing, feeding is stabilize in fine polishing, and polishing quality is good.

Owner:六安同辉智能科技有限公司

Sapphire polishing agent and preparation method thereof

InactiveCN110577800AGood polishing effectEasy to preparePolishing compositions with abrasivesIonCarbon black

The invention belongs to the technical field of gem processing, and particularly relates to a sapphire polishing agent and a preparation method thereof. The sapphire polishing agent comprises the following components in parts by mass: 80-120 parts of silicon, 34-44 parts of alpha-aluminum oxide, 22-35 parts of aluminum oxide, 22-34 parts of titanium dioxide, 16-21 parts of zirconium oxide, 14-18 parts of disodium hydrogen phosphate, 14-19 parts of chitosan, 12-16 parts of ferric trichloride, 8-14 parts of titanium diboride, 5-9 parts of carbon black, 3-5 parts of a dispersing agent and 120-150parts of deionized water. The sapphire polishing agent prepared by the invention has better polishing effect and higher polishing efficiency; and the preparation method is simple in process and suitable for industrial production.

Owner:江苏吉星新材料有限公司

High-precision bearing steel ball polishing production process for field of 5G or 6G communication

PendingCN112643526AGood polishing effectImprove polishing effectEdge grinding machinesPolishing machinesSodium carbonatePolishing

The invention relates to a high-precision bearing steel ball polishing production process for the field of 5G or 6G communication. The process comprises the following steps that firstly, a steel ball is put into special cleaning equipment in a shutdown state, and the steel ball is cleaned by using water, magnesium oxide and sodium carbonate; a sodium oleate soap water solution is selected to conduct boiling treatment on the cleaned steel ball; special polishing equipment is cleaned and detected, cloth strips are put into an iron polishing barrel and properly scattered, and then the steel ball boiled by the sodium oleate soap water solution is put into the iron polishing barrel to be polished and blow-dried; and it is ensured that no dead angle ball exists in the iron polishing barrel and a screening table through inspection, and the polished steel ball must ensure that the surface is bright, clean, free of mist and free of dirt attachment. The process has the advantages that through cooperation of the special cleaning equipment and the special polishing equipment and design of parameters such as the cleaning time, the boiling temperature and the polishing time, the surface of the steel ball can be cleaned more sufficiently before polishing, and the polishing effect is better during polishing.

Owner:JIANGSU LIXING GENERAL STEEL BALL

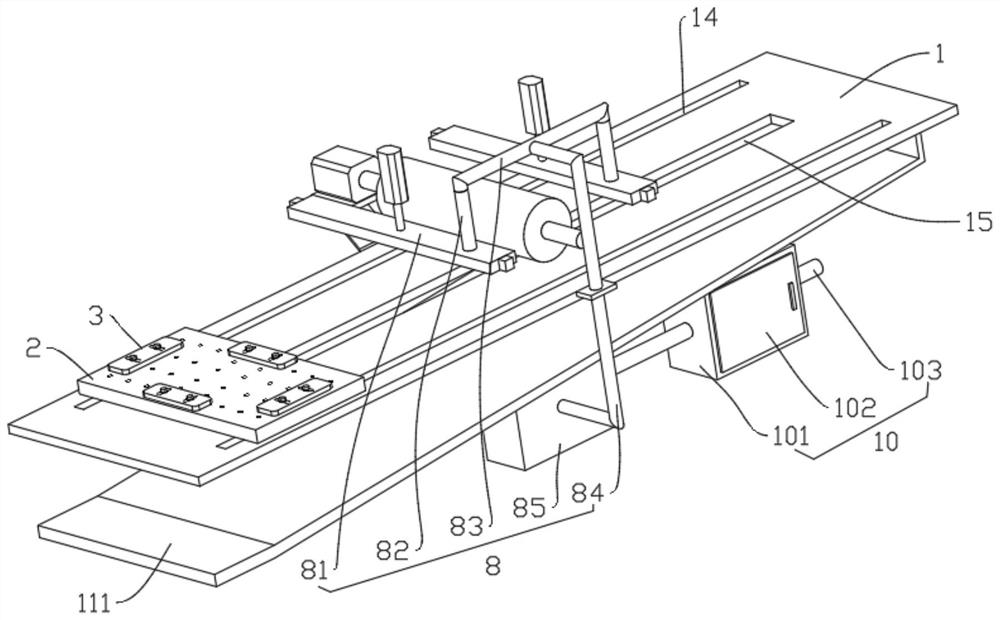

Aluminum plate production surface treatment device with adjustable structure

PendingCN113997140APrecise positioningImprove processing qualityEdge grinding machinesGrinding work supportsEngineeringWaste material

The invention discloses an aluminum plate production surface treatment device with an adjustable structure. According to the key points of the technical scheme, the device comprises an operation table, the top of the operation table is slidably connected with a containing plate used for containing an aluminum plate, and the containing plate is provided with a positioning assembly used for positioning the aluminum plate; a driving assembly used for driving the placing plate to move is arranged in an inner cavity of the operation table, vertical plates are fixedly connected to the two sides of the operation table correspondingly, a mounting plate is fixedly connected to the tops of the two vertical plates jointly, and a grinding assembly used for grinding and cleaning the aluminum plate is arranged between the two vertical plates; an adsorption assembly used for absorbing polishing scraps is arranged in an inner cavity of the operation table, and an adjusting assembly used for adjusting the height of the adsorption assembly is arranged on the mounting plate. The problems that in the prior art, an aluminum plate surface treatment device is low in applicability, large in labor intensity and inconvenient to collect waste are solved.

Owner:昆山慧东铝业有限公司

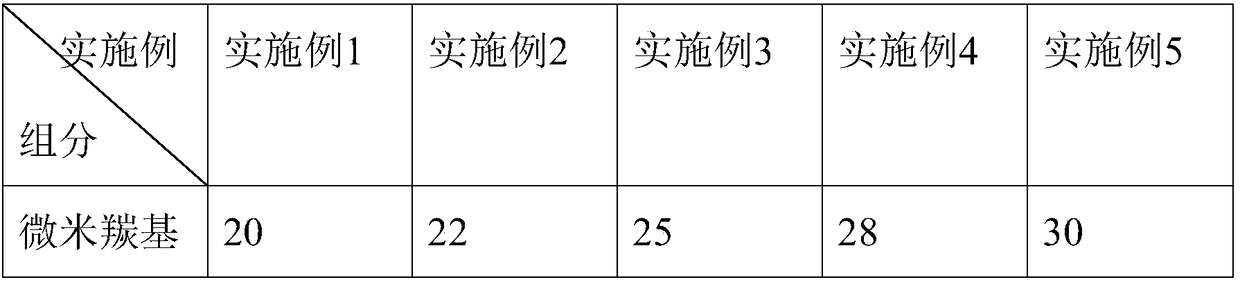

Glaze chemical polishing fluid

ActiveCN108822738AStrong physical stabilityGood polishing effectPolishing compositions with abrasivesPhysical stabilityCompound (substance)

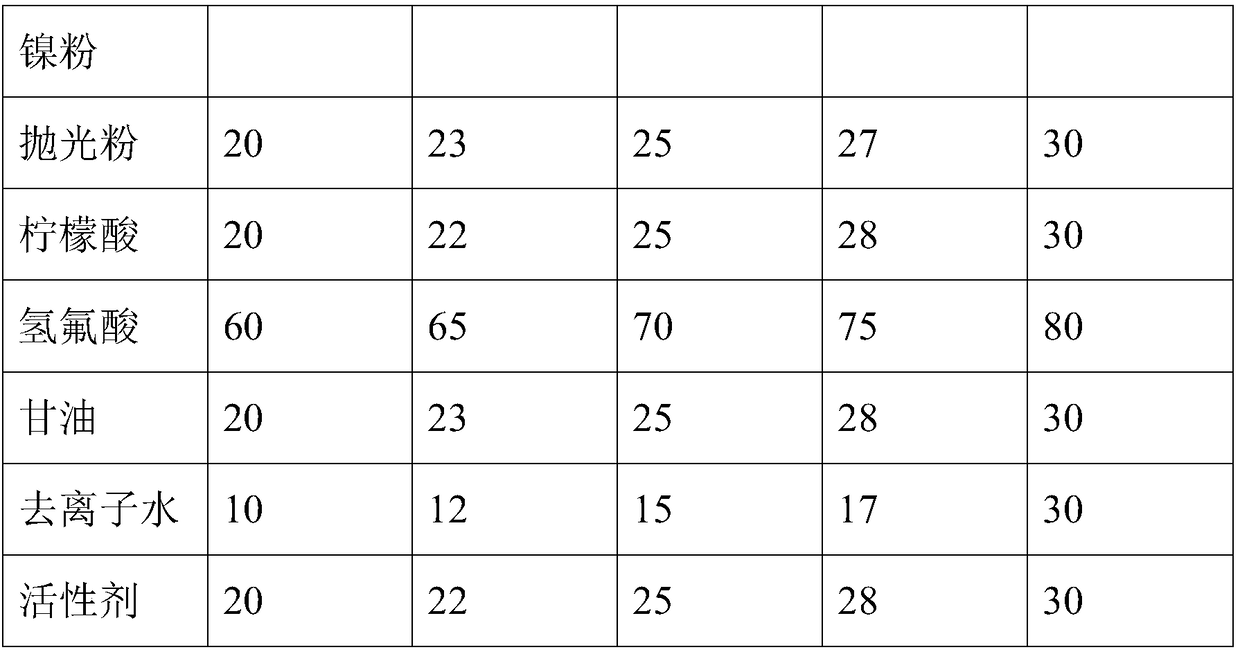

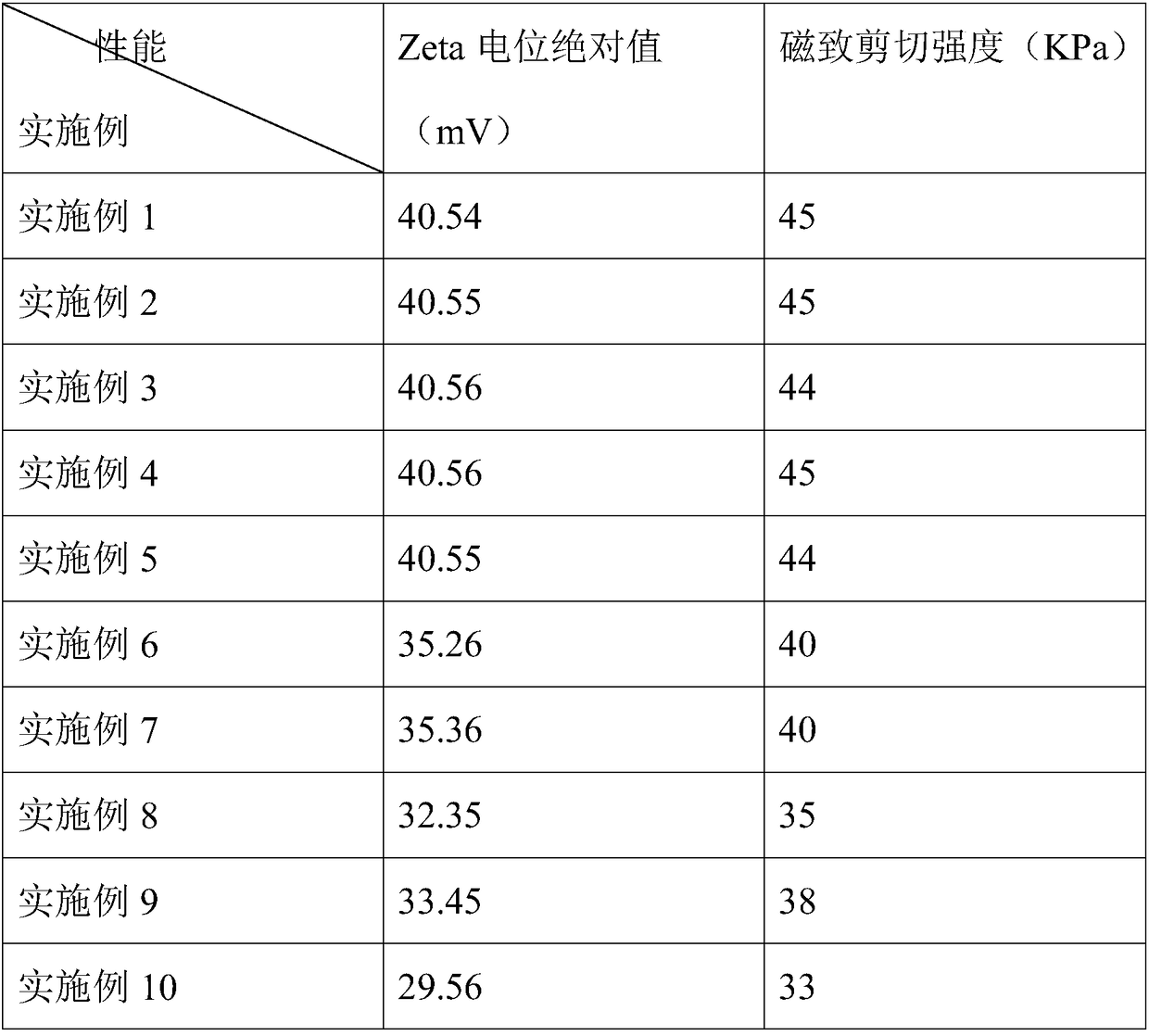

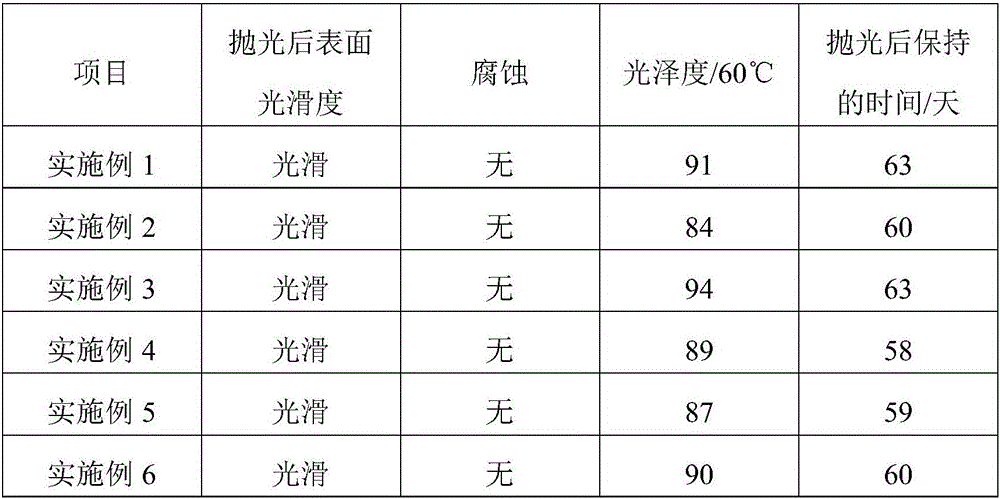

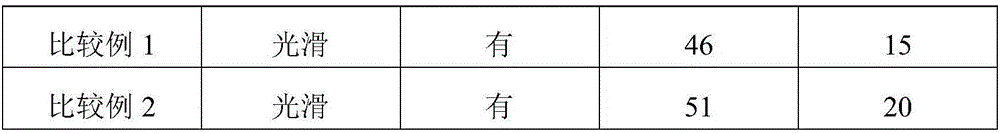

The invention relates to a polishing fluid, in particular, relates to a chemical polishing fluid applied to the field of glaze, and belongs to the field of glaze polishing. The glaze chemical polishing fluid comprises the following components in parts by weight: 20-30 parts by weight of micron carbonyl nickel powder, 20-30 parts by weight of polishing powder, 20-30 parts by weight of citric acid,60-80 parts by weight of hydrofluoric acid, 20-30 parts by weight of glycerin, 10-20 parts by weight of deionized water, and 20-30 parts by weight of an activating agent. By using the micron carbonylnickel powder as magnetic particles and addition of the polishing powder, citric acid and hydrofluoric acid, the obtained glaze chemical polishing fluid has strong physical stability and good polishing effect.

Owner:NINGBO TSIANYU COLORED GLAZE PROD CO LTD

Environment-friendly rust-proof polishing solution for mechanical equipment

InactiveCN106519988AMaintain glossGood polishing effectPolishing compositions with abrasivesParaffin waxCellulose acetate

The invention discloses an environment-friendly rust-proof polishing solution for mechanical equipment. The raw material of the environment-friendly rust-proof polishing solution comprises the following components in parts by weight: 25-60 parts of silica powder, 1-20 parts of antirust agents, 10-30 parts of salicylic acids, 1-20 parts of cellulose acetates, 10-60 parts of paraffin, 3-15 parts of methyl alcohol, 1-10 parts of organic solvents, 1-10 parts of surface active agents, 1-10 parts of stabilizers and 30-60 parts of water, wherein the weight ratio of cellulose acetates to paraffin is (1:9)-(1:1), and the sum of the adding proportions of the surface active agents and stabilizers is 3-6% of the total weight of the raw materials of the environment-friendly rust-proof polishing solution. The environment-friendly rust-proof polishing solution for mechanical equipment has higher stability and polishing rate, can keep the surface glossiness of the mechanical equipment for a long time, and has no pollution to the environment; and the production cost is low, and the preparation method is simple.

Owner:苏州聚贝机械设计有限公司

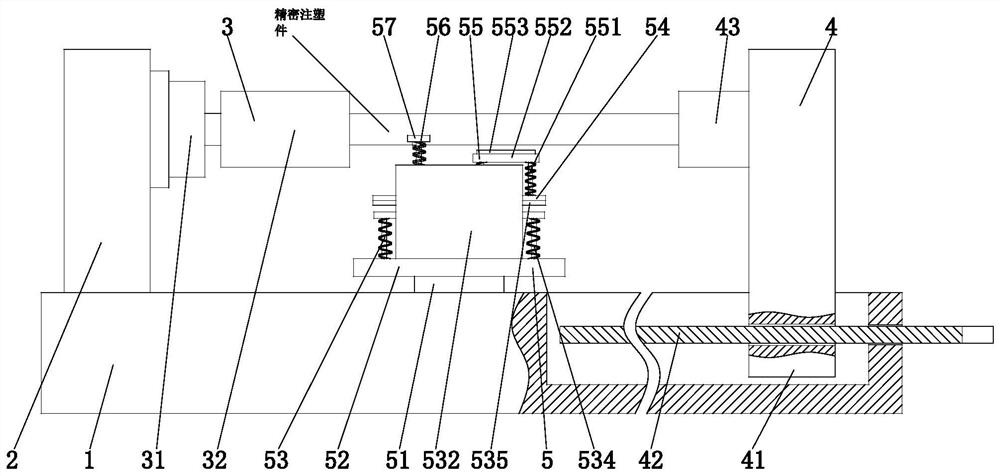

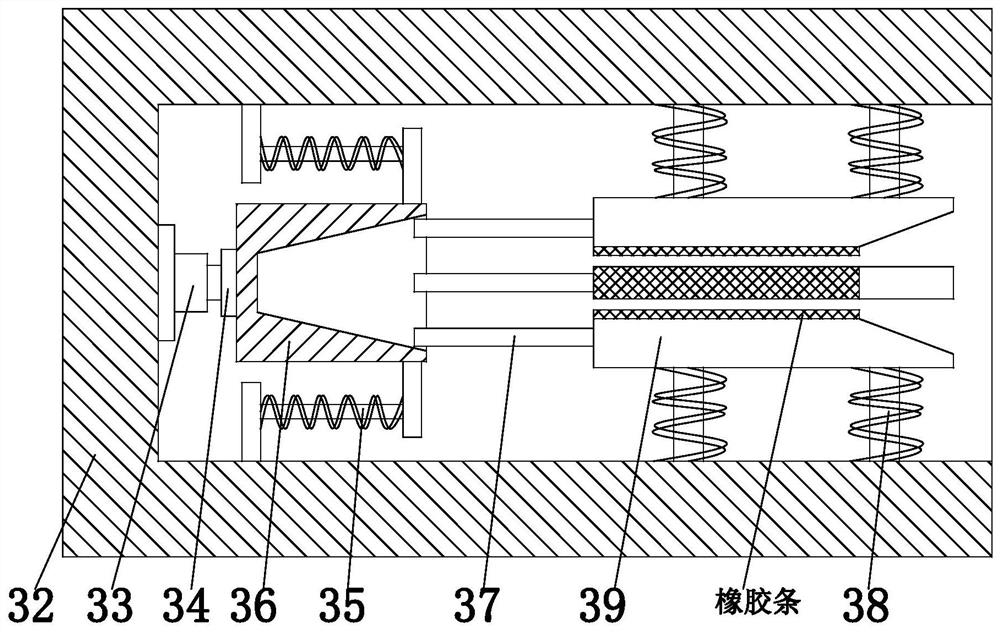

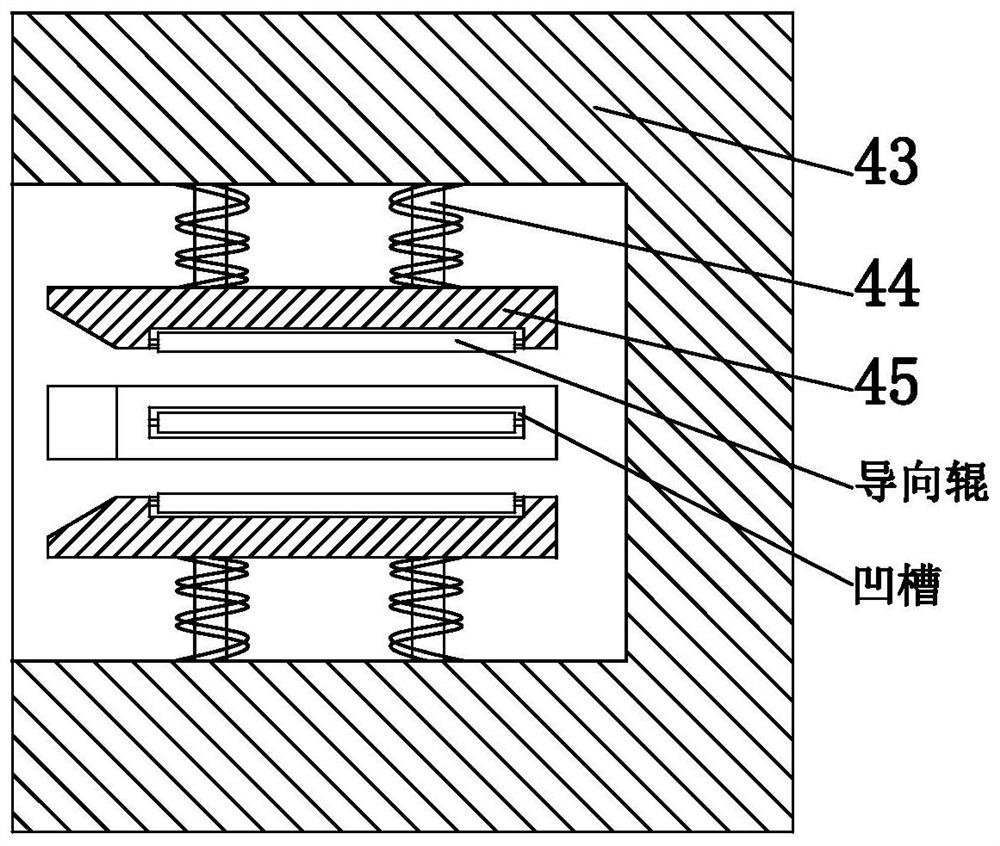

Manufacturing and processing system of precise injection molding part

ActiveCN112917820AIncrease frictionAvoid damageGrinding work supportsMachining systemMachining process

The invention relates to a manufacturing and processing system of a precise injection molding part. The system comprises a bottom rack, a fixed rack, a rotating mechanism, a clamping adjusting mechanism and a movable grinding mechanism. According to the system, the following problems that in the manufacturing and forming process of the precise injection molding part, a burr structure exists on the surface of the precise injection molding part in the manufacturing and forming process, if burrs are not subjected to deburring treatment, the existing burr structure can affect subsequent usage of the precision injection molding part, and the usage effect of the precision injection molding part is influenced are solved, and the problems that clamping and fixing treatment generally needs to be carried out on the precise injection molding part in the forming and machining process, only the precise injection molding parts with the same diameter and length can be fixed and clamped in the traditional clamping and fixing process, different clamps need to be replaced if the models and sizes of the precise injection molding parts are different, the cost is high, the process is complex, and the forming efficiency of the precision injection molding part is influenced can be solved.

Owner:台山龙泰塑料制品有限公司

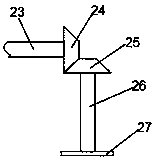

Pipe polishing device for manufacturing office chair

InactiveCN108637870AImprove polishing efficiencyGood polishing effectPolishing machinesGrinding drivesEngineeringOffice chair

The invention discloses a pipe polishing device for manufacturing an office chair. The pipe polishing device comprises a workbench, a limiting pipe is welded to the left side of the top of the workbench, and annular abrasive paper is adhered to the inner portion of the limiting pipe; a supporting plate is welded to the top of the workbench and located on the right side of the limiting pipe, and alifting structure which is located right over the workbench is welded at the bottom of the supporting plate; a polishing motor is welded at the bottom of the lifting structure, and a polishing plate is welded to an output shaft of the polishing motor; and a driving structure is welded to the top of the workbench, a positioning pipe is welded to the top of the driving structure, and a bearing plateis welded to the right side face of the positioning pipe. According to the pipe polishing device for manufacturing the office chair, a rotary pipe is subjected to secondary polishing of the annular abrasive paper, and therefore, the polishing effect is better, the polishing efficiency of the pipe can be improved, furthermore, the trace of polishing is smaller, and the appearance of the polished pipe is better.

Owner:河南麦锐克电子商务有限公司

Track polishing device for polishing stainless steel rod

The invention discloses a track polishing device for polishing a stainless steel rod. The track polishing device comprises a support, a motor, a trolley and a polishing cloth wheel. A sliding way is arranged on one side of the support. Sliding wheels on the bottom of the trolley are placed on the sliding way for sliding. A rotating shaft and the motor are fixed on the trolley respectively, one end of the rotating shaft is connected with the motor through a belt, and the other end of the rotating shaft fixes the polishing cloth wheel. A handle is arranged at one end of the trolley. The track polishing device has the advantages that polishing effect is good, stability is high, meanwhile, the labor intensity of working personnel is lowered, and working efficiency is improved.

Owner:XINGHUA CITY XINTIANDI STAINLESS STEEL PROD

Tableware polishing and machining device

InactiveCN108581792AGood polishing effectAvoid scratchingPolishing machinesGrinding machinesEngineeringMechanical engineering

The invention discloses a tableware polishing and machining device which comprises a base, a stand column, a cross beam, a polishing head assembly, a polishing head, tableware, a clamping fixing base,a tableware fixing assembly, a rotary workbench and a workbench base. When the polishing head polishes the tableware at a high sped, the polishing head assembly is provided with an abutting keeping assembly for keeping the polishing head abut against the tableware all the time, and the polishing head is of a high-elasticity structure. During polishing, the tableware fixing assembly can well flexibly position the tableware, the surface of the tableware is prevented from being scraped, and the polishing stability of the tableware is ensured at the same time. The polishing head assembly can abutagainst the tableware all the time and is matched with a spindle for feeding, polishing of various arc faces of the tableware can be achieved accurately, no dead corner exists during polishing, uniformity is good, the good polishing effect is achieved, the polishing head has the proper elasticity, and brightness and attractiveness of the tableware after polishing are facilitated.

Owner:郇梓堉

Polishing device for cylindrical metal products

InactiveCN109909858AGood polishing effectNovel structurePolishing machinesGrinding drivesEngineeringMetal

A polishing device for cylindrical metal products comprises a machine table, a first lifting mechanism, an upper chuck, a lower chuck, the cylindrical metal products, a motor, a polishing mechanism, asecond lifting mechanism and a feeding mechanism, wherein the polishing mechanism comprises an upper support, a lower support, a connecting column and a steering cylinder, polishing stones with different degrees of roughness can be switched by rotating the steering cylinder, the polishing stones can have a good polishing effect on the cylindrical metal products, and in a polishing process, the polishing stones with different degrees of roughness can be quite conveniently switched according to different to-be-polished materials and different polishing stages of the same material. The polishingdevice is novel in structure, simple in operation and great in practicability.

Owner:NINGBO RENHONG ELECTRIC APPLIANCE CO LTD

Topaz polishing solution

InactiveCN106566418AGood polishing effectHigh glossPolishing compositions with abrasivesComposite oxideChemistry

The invention discloses a topaz polishing solution. The polishing solution is prepared from following components including, by weight, 35-55 parts of nanometer phosphate neodymium glass particles, 18-30 parts of cerous nitrate, 20-32 parts of cerium-zirconium composite oxide, 4-14 parts of 1,2,4-triazole and 21-39 parts of nonyl phenol polyoxyethylene ether. By means of the manner mentioned above, the topaz polishing solution has the beneficial effects of being good in polishing effect, bright, uniform, high in gloss and high in flatness, and the requirement for modern jade processing can be met.

Owner:扬州翠佛堂珠宝有限公司

Grinding tool for surface polishing of diamond fiber quartz stone

InactiveCN107838795AGood polishing effectWide range of applicationsPolishing machinesGrinding drivesMotor shaftFiber

The invention relates to an abrasive tool for polishing the surface of diamond fiber quartz stone, comprising a motor, a handle, a suction cup, a lifting rod, a cylinder one, a plate, a lifting plate, a polishing wheel, a connecting shaft, a fixed plate, a cylinder two and a baffle plate, The left end of the fixed plate is fixed with a motor, the right end of the main shaft of the motor is fixed with a connecting shaft, the right end of the connecting shaft passes through the fixed plate, and extends to the right side of the fixed plate, and the right end of the connecting shaft is fixedly connected with the polishing wheel. The right end of the fixing plate is fixed with a base, the inner bottom of the base is fixed with a cylinder two, the upper end of the cylinder two is fixed with a lifting rod, the upper end of the lifting rod passes through the base, and extends to the top of the base, and the upper end of the lifting rod is connected to the base. The lifting plate is fixedly connected, the right end of the lifting plate is fixed with a plate, the right end of the plate is fixed with a cylinder one, and the left end of the cylinder one is fixed with a pressure rod. The present invention has good polishing effect, wide application range, small size and convenient portability.

Owner:李笑美

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com