Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Avoid scratching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

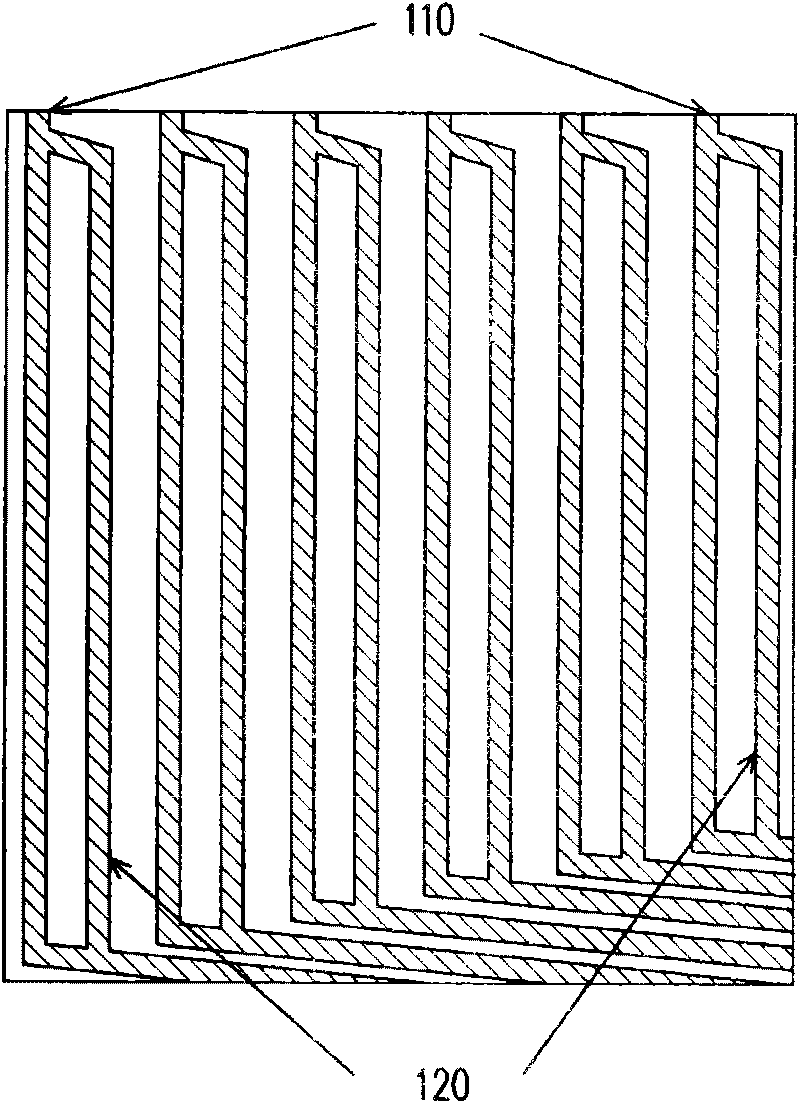

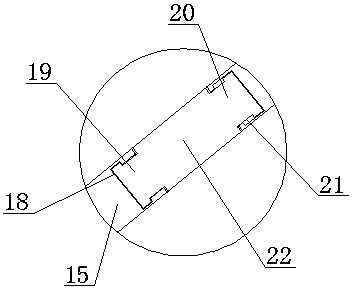

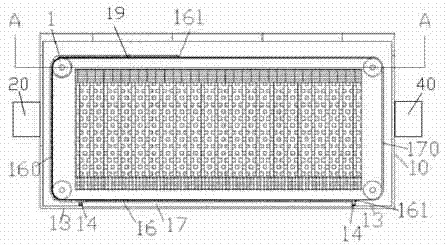

Fan-out circuit of array substrate

ActiveCN101718929AAvoid scratchingAvoid disconnectionSemiconductor/solid-state device detailsSolid-state devicesFistSemiconductor

The invention provides a fan-out circuit of an array substrate. The array substrate comprises a substrate and also comprises a first metal layer, a first insulating layer, a semiconductor layer, a second metal layer and a second insulating layer which are sequentially superposed on the substrate. The fan-out circuit comprises at least one fan-out lead and at least one block up layer, wherein the fan-out lead consists of at least one of the fist metal layer and the second metal layer; the block up layers are piled on the fan-out leads; the first insulating layer is arranged between the block up layers and the fan-out leads; and the second insulating layer is arranged on the block up layers.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

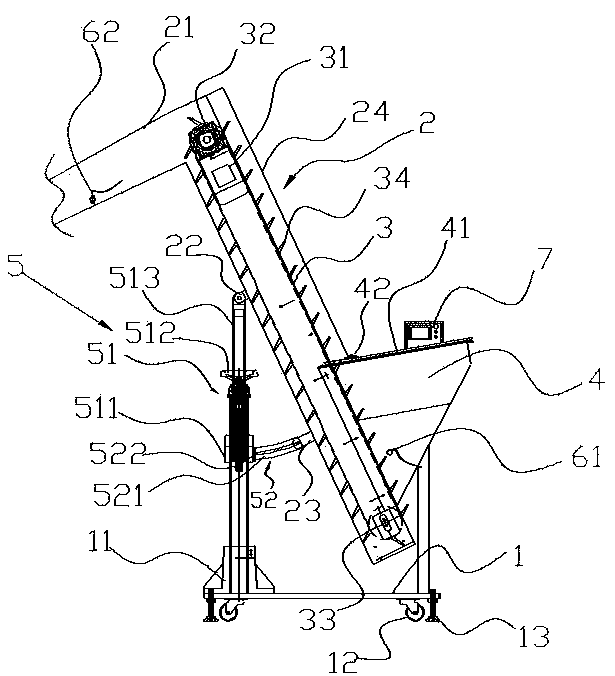

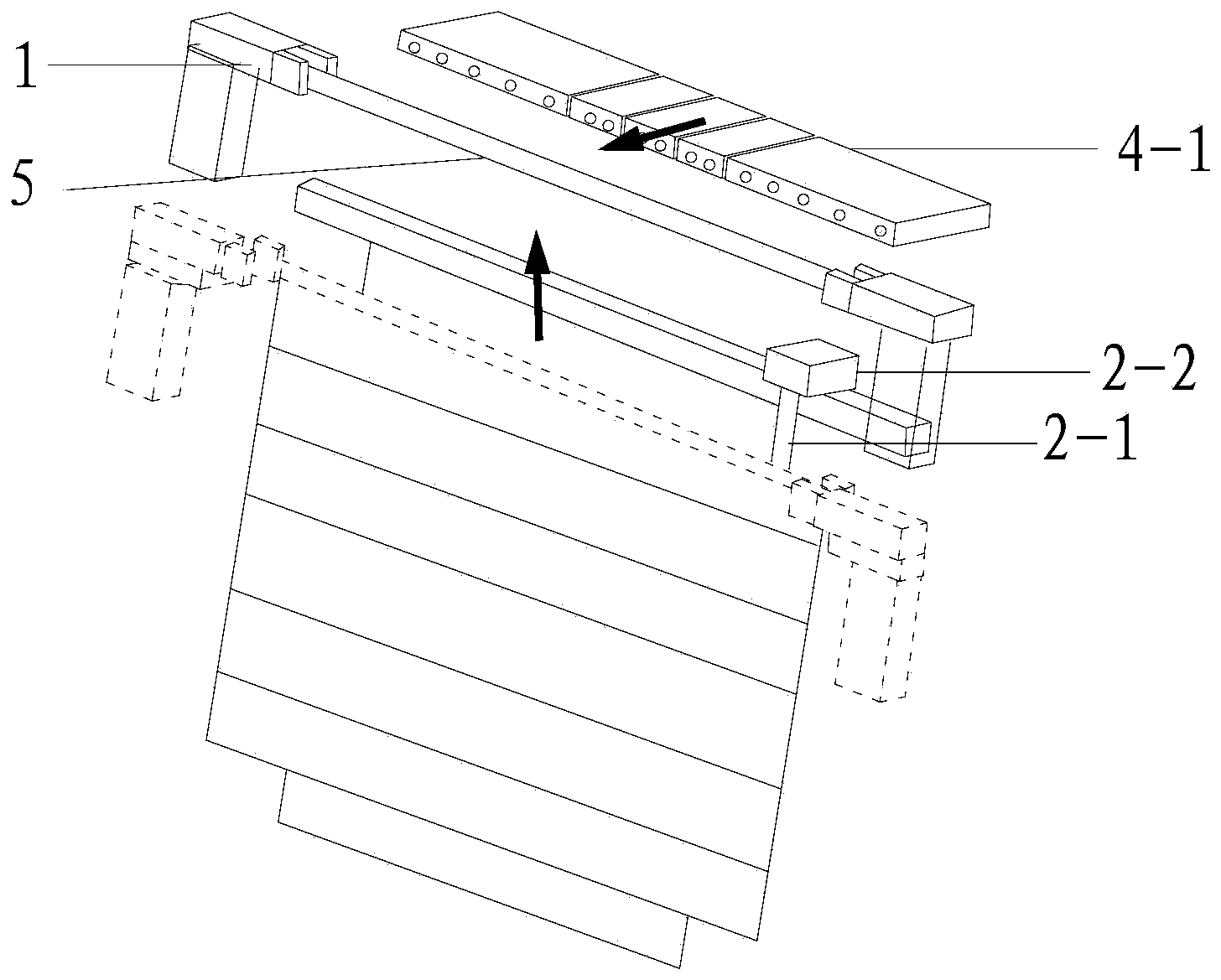

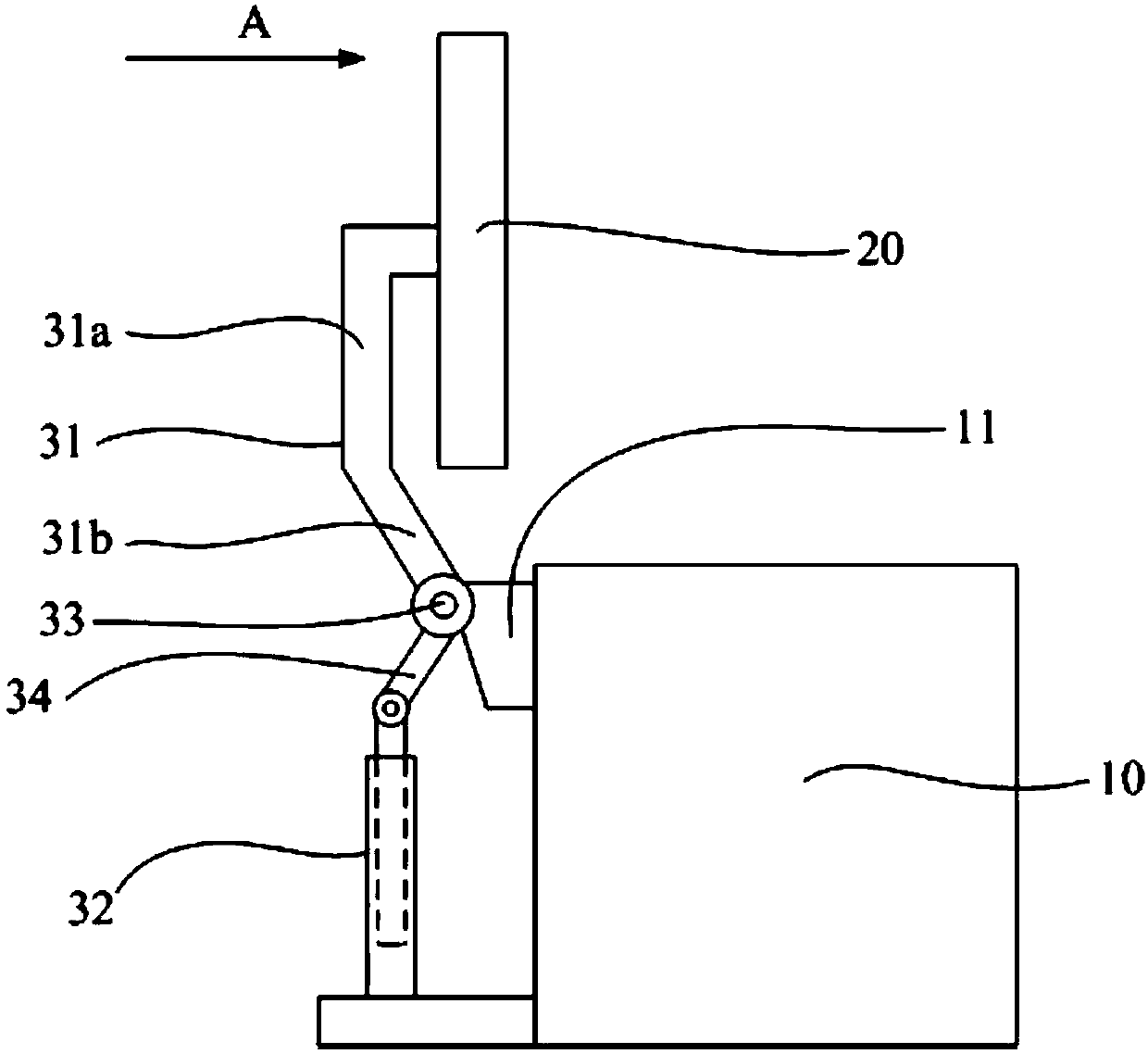

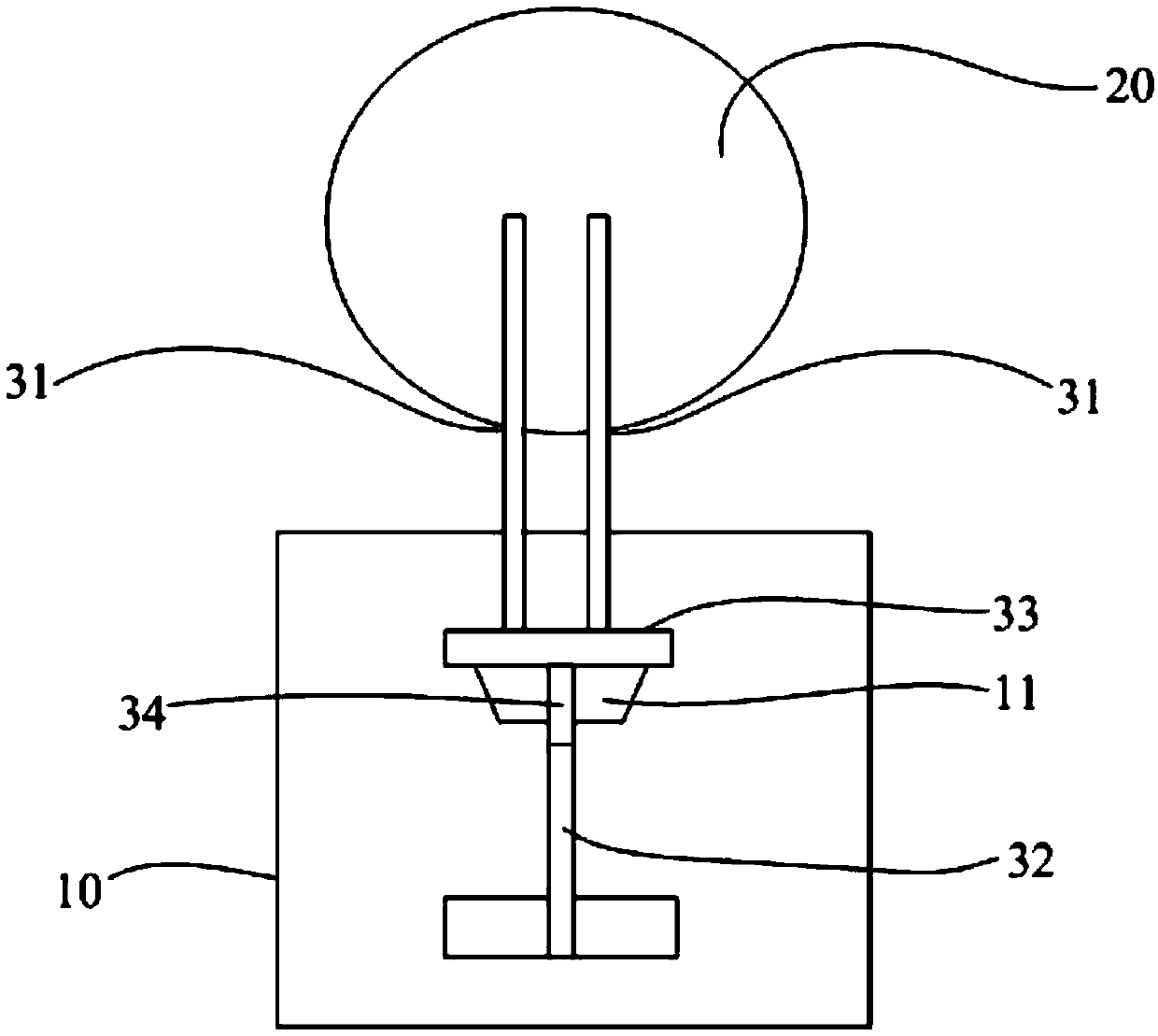

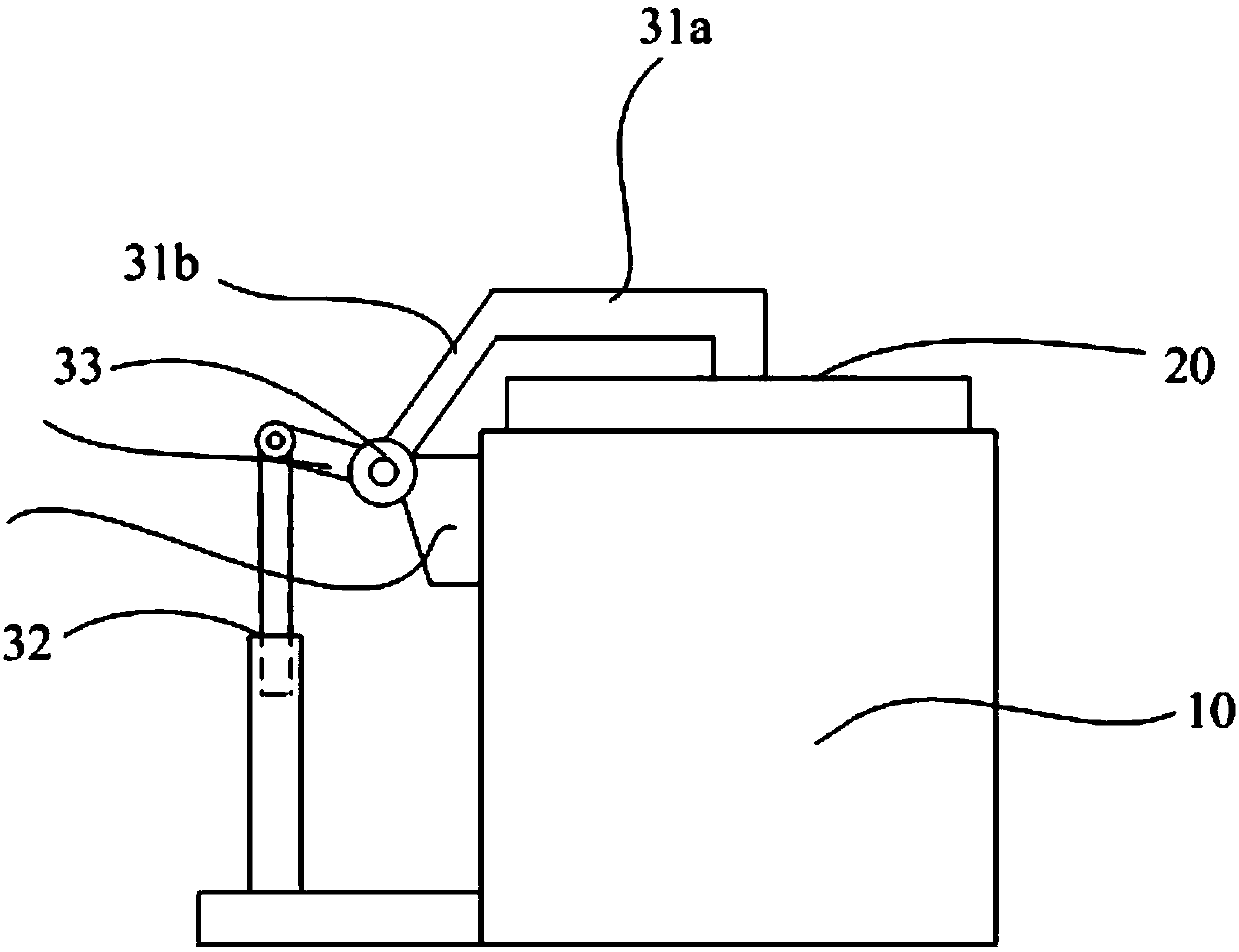

Auto-elevating conveying and feeding mechanism

ActiveCN104229391AHigh degree of automationAvoid scratchingConveyorsControl devices for conveyorsElectricityMaterial supply

The invention discloses an auto-elevating conveying and feeding mechanism comprising a base, a lifting conveyor belt arranged on the base, a conveying body, a material storage box and a conveyor motor. The auto-elevating conveying and feeding mechanism further comprises a regulating mechanism, a material detector used for detecting material and a control unit. Polyvinyl chloride retainers are evenly distributed on the lifting conveyor belt. The top of the conveying body is provided with a discharge outlet which is provided with a discharge detector. The material detector is arranged inside the material storage box. The regulating mechanism comprises a height regulating unit and an angle regulating unit both connected with the conveying body. The discharge detector, the material detector and the conveyor motor are electrically connected with the control unit. The auto-elevating conveying and feeding mechanism is high in automation level, allows full-automatic feeding control and needs no manual intervention for the whole process; materials can be reasonably fed according to idle materials; the material detector and the control unit allow excess or insufficient material supply to be detected, and a next procedure is guaranteed.

Owner:GUANGZHOU BEAUTY STAR CO LTD

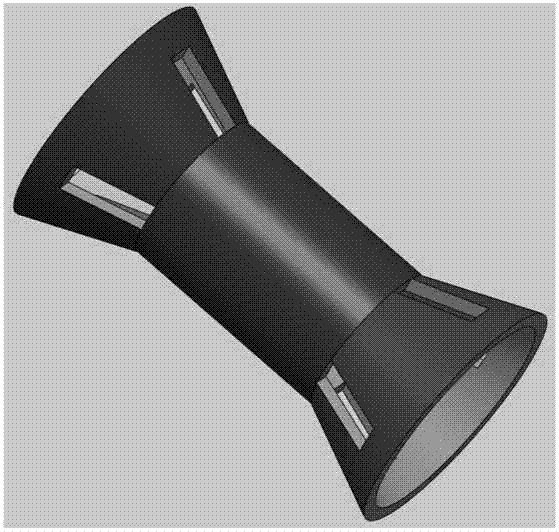

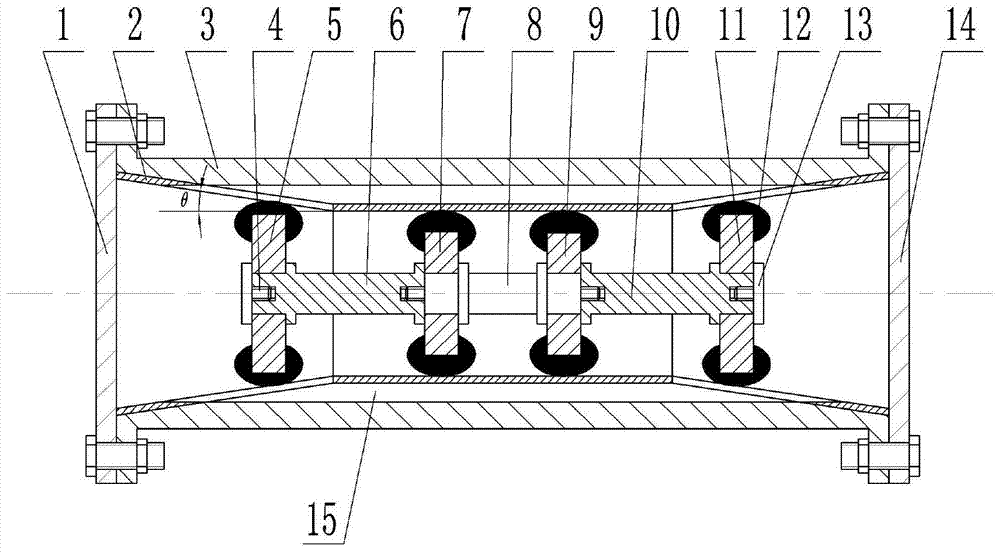

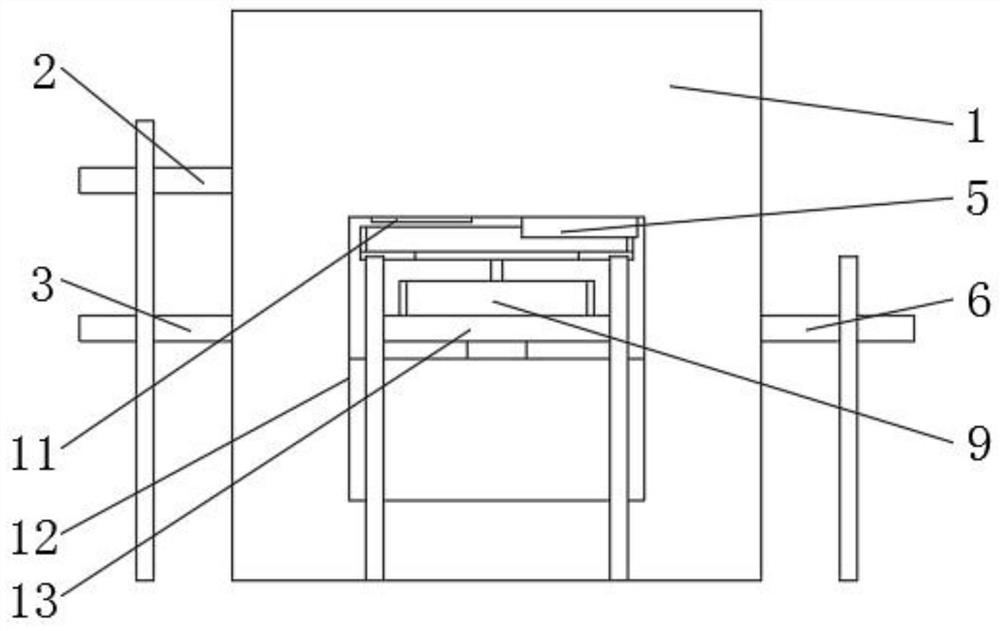

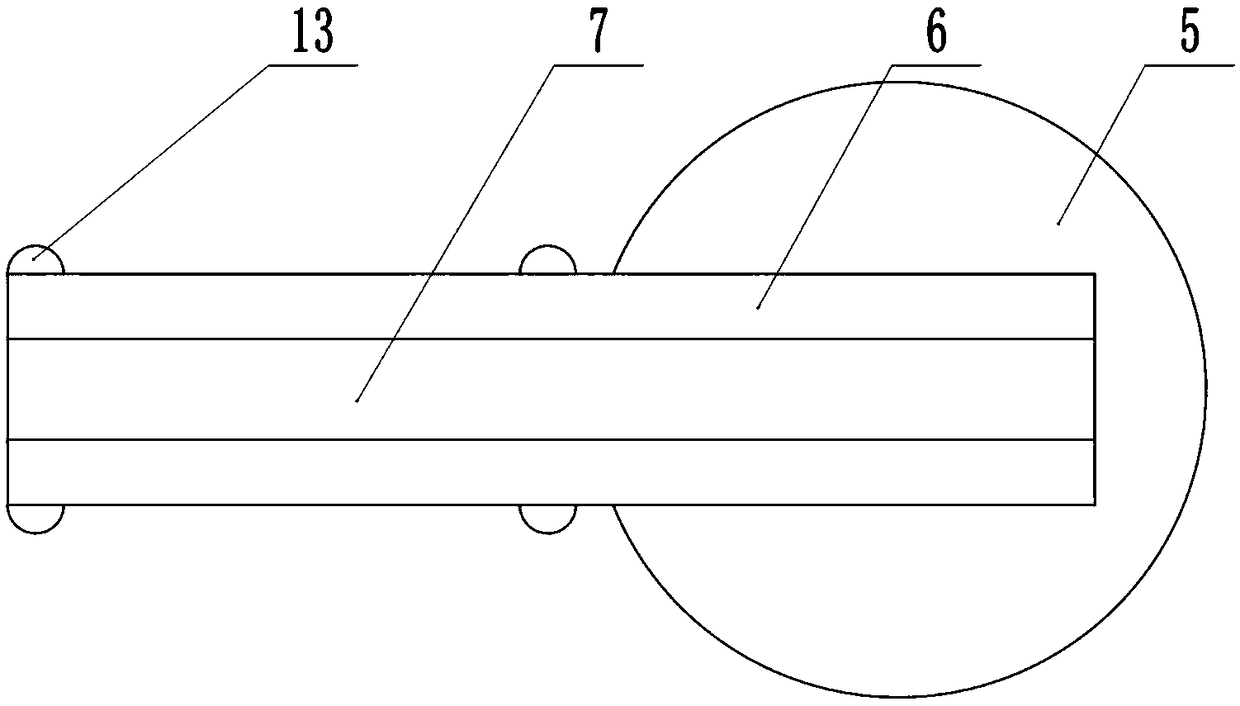

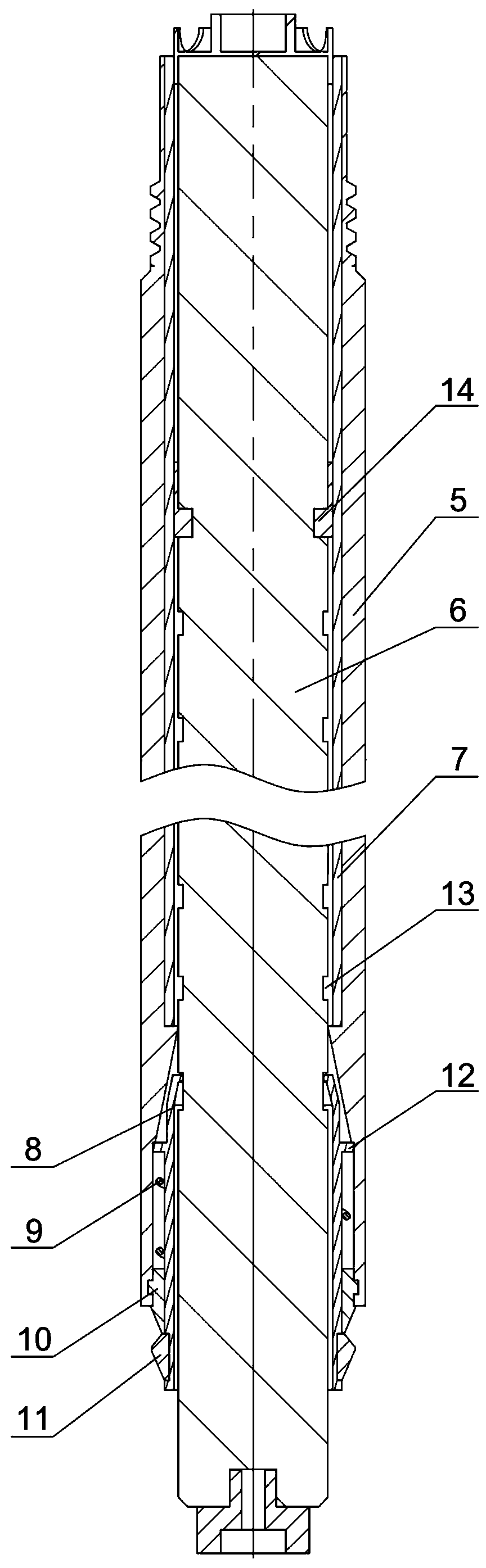

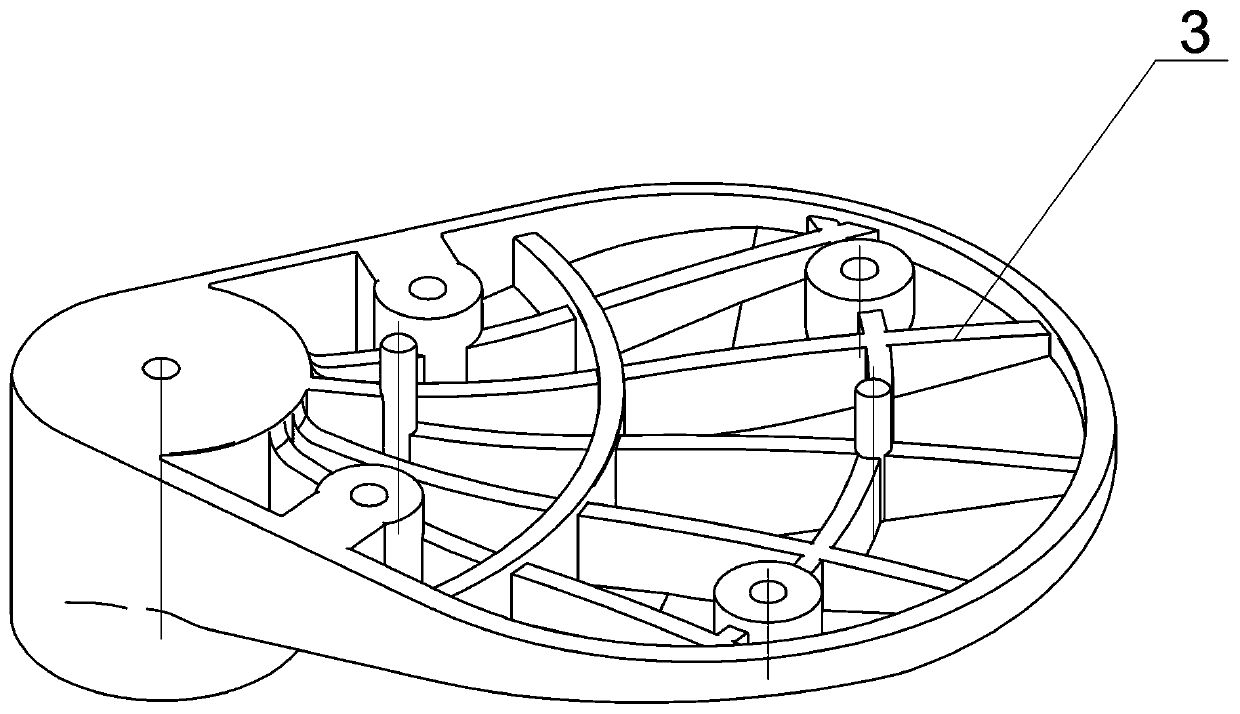

Inner taper angle magnetic liquid damping vibration absorber

InactiveCN104747647AAvoid scratchingAffect movement speedNon-rotating vibration suppressionMagnetic springsEnergy absorbingMagnetic liquids

The invention provides an inner taper angle magnetic liquid damping vibration absorber with an elastic cushion and belongs to the field of mechanical engineering vibration. The inner taper angle magnetic liquid damping vibration absorber successfully solves the problem that an existing magnetic liquid vibration absorber cannot be applied to engineering practice due to various structure problems. The inner taper angle magnetic liquid damping vibration absorber comprises a left end cover (1), the elastic cushion (2), a shell (3), a left thread check ring (4), a left positioning permanent magnet (5), a left positioning rod (6), a first energy dissipation permanent magnet (7), a connecting rod (8), a second energy dissipation permanent magnet (9), a right positioning rod (10), a right positioning permanent magnet (11), magnetic liquid (12), a right thread check ring (13), a right end cover (14) and a vent groove (15). When outside vibration occurs, the magnetic liquid moves together with the left positioning permanent magnet (5), the first energy dissipation permanent magnet (7), the second energy dissipation permanent magnet (9) and the right positioning permanent magnet (11), and therefore energy is absorbed; a frequency difference is formed between a mass block and the shell (3) under the taper angle action of the left positioning permanent magnet (5) and the right positioning permanent magnet (11), and vibration absorption efficiency reaches the maximum.

Owner:BEIJING JIAOTONG UNIV

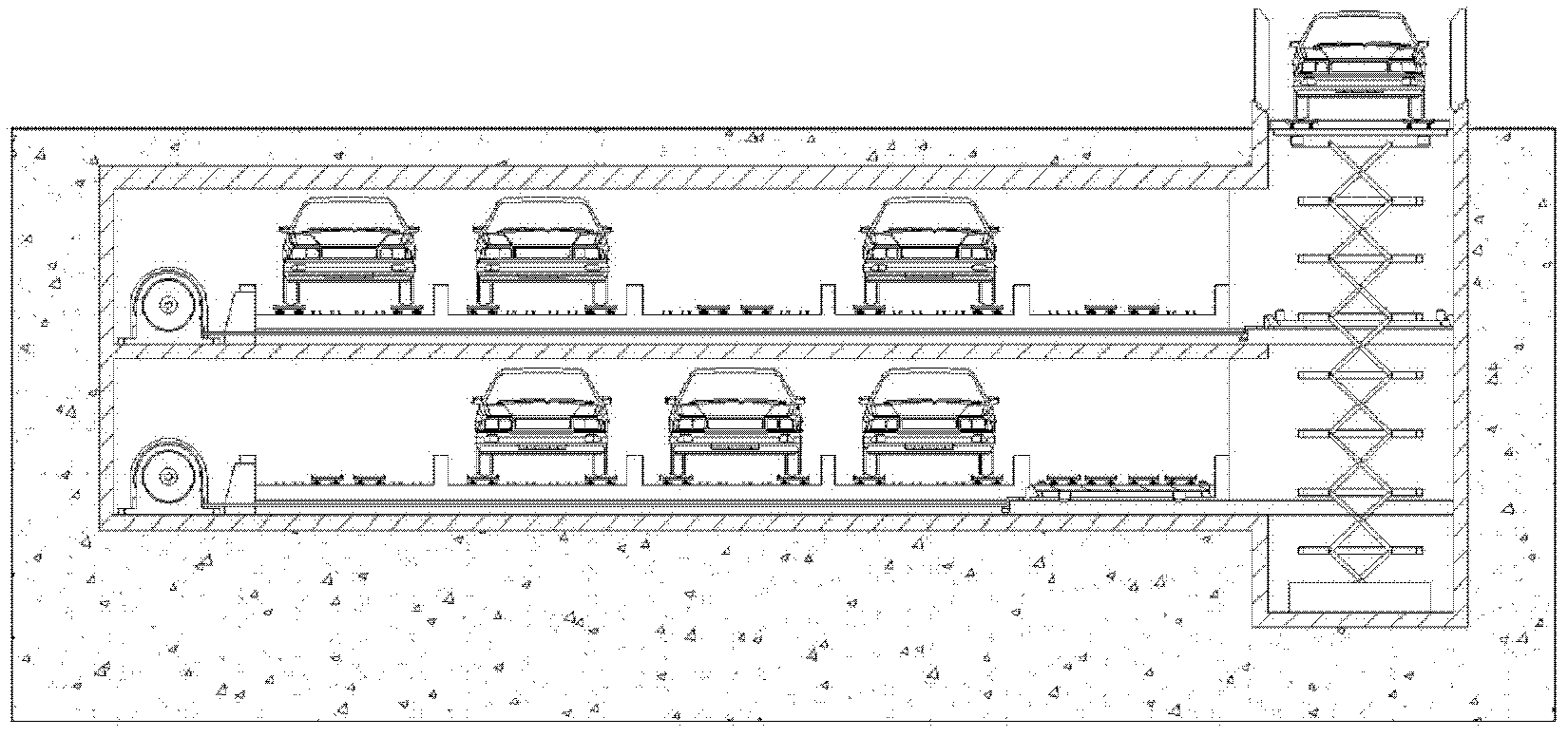

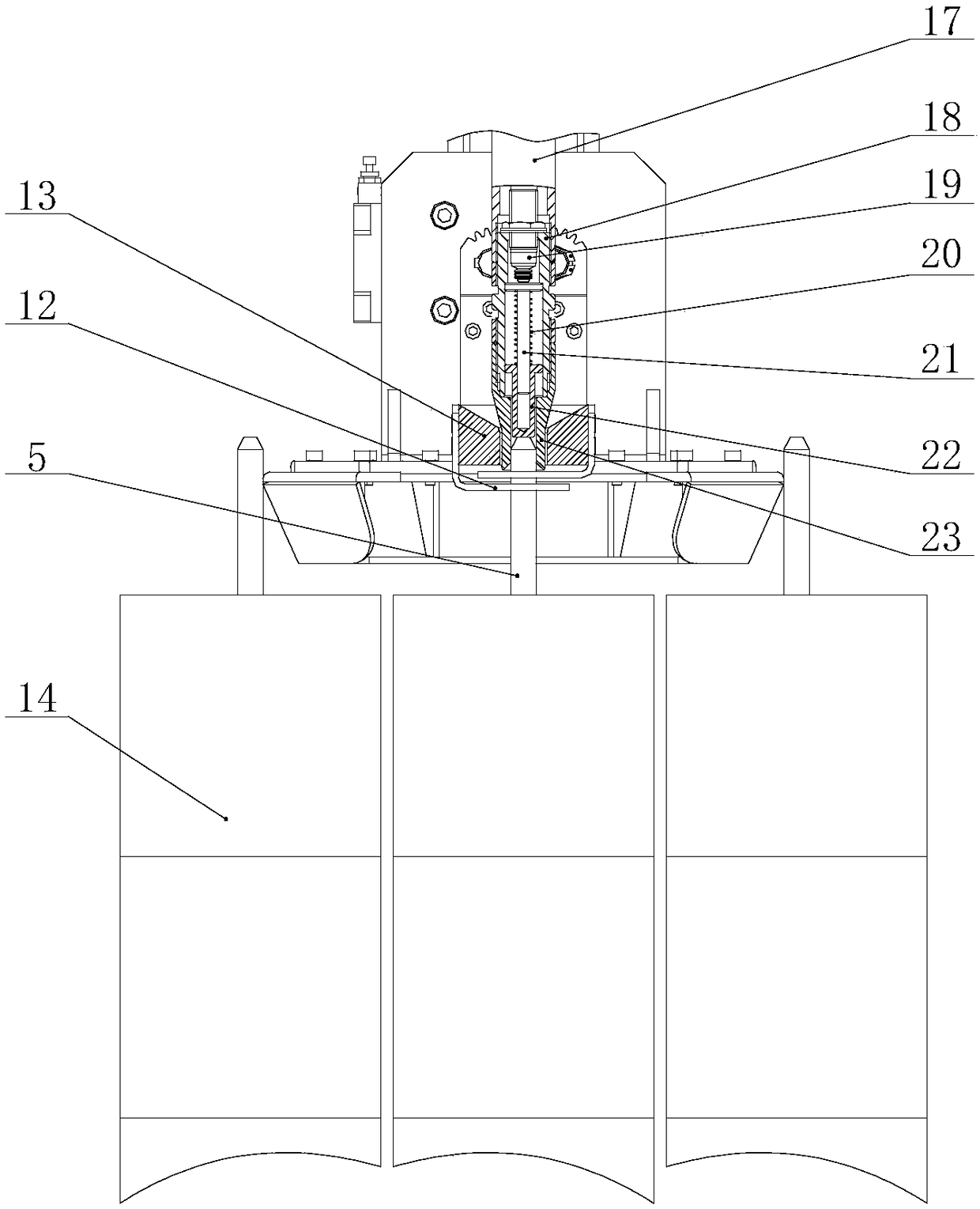

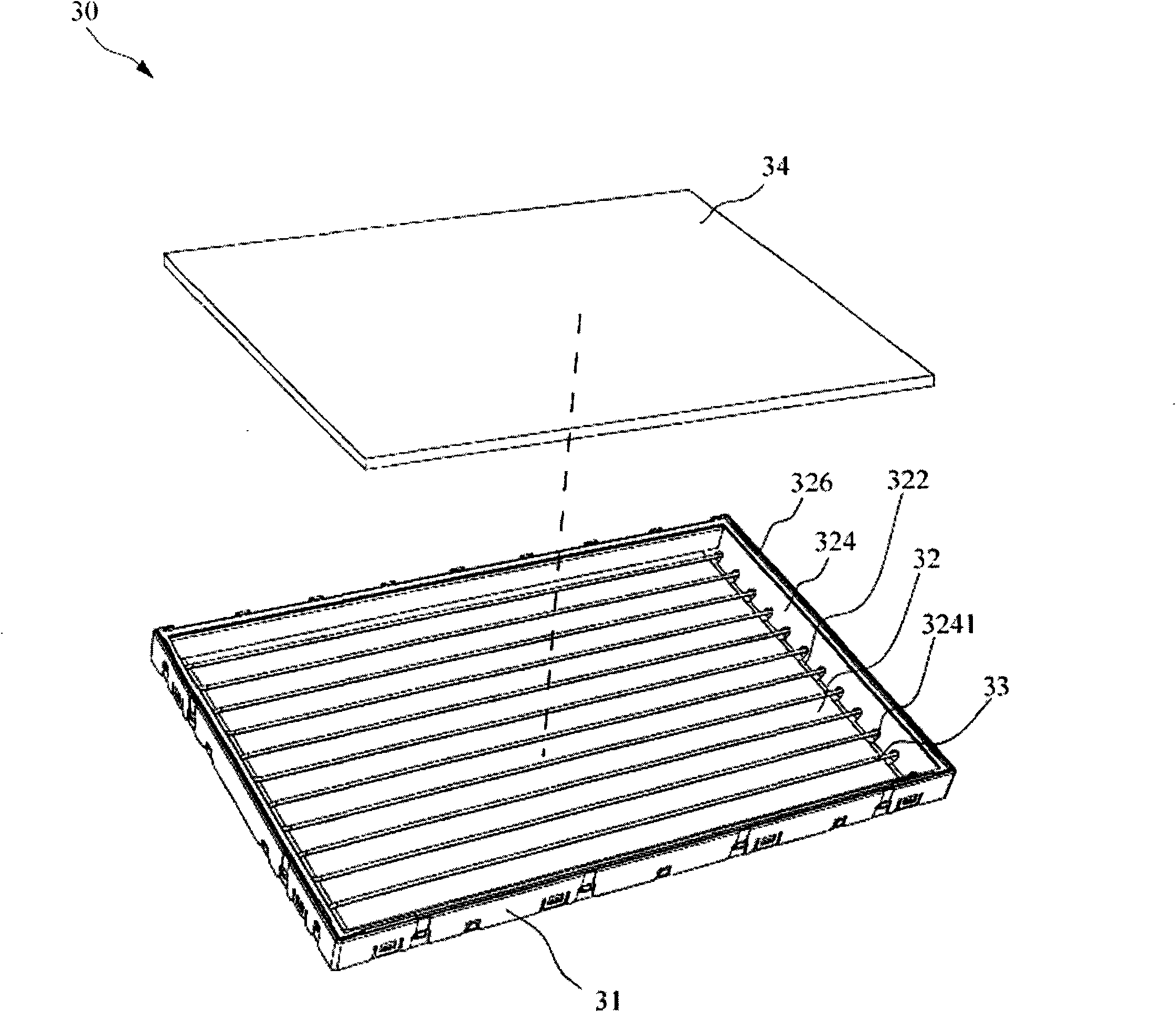

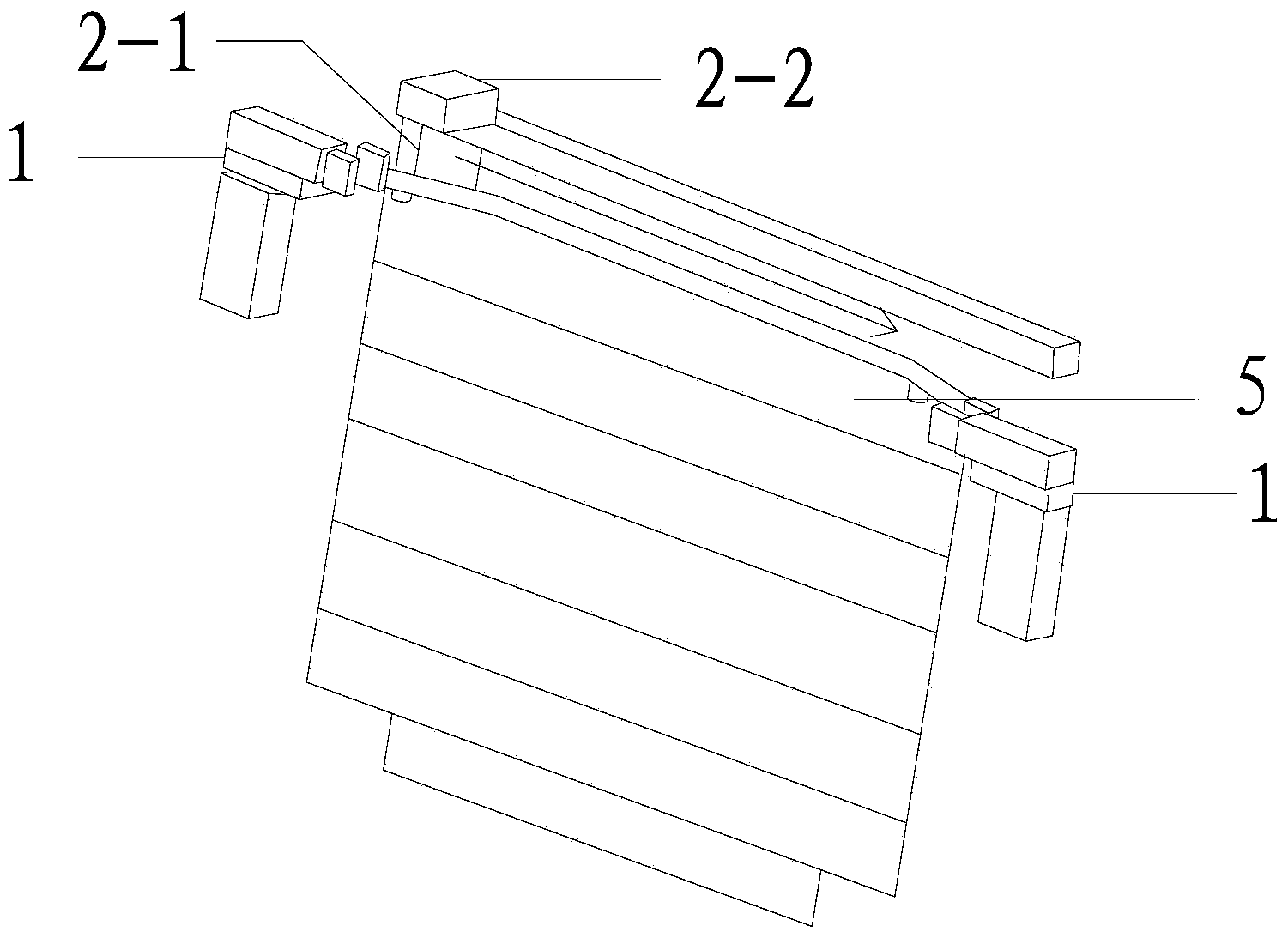

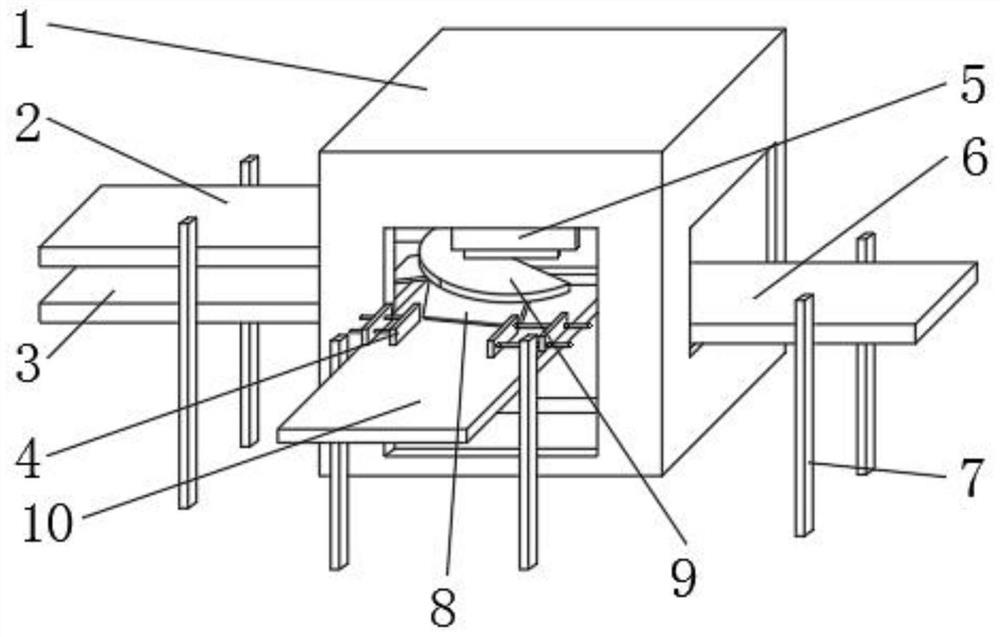

Underground double-row garage

The invention provides an underground double-row garage which has double-row parking platforms and a lift well; a track is arranged between the parking platforms; a trailer is stopped on the track; through holes are formed on the trailer; a car-loading bottom plate is covered on the through holes; the trailer is fixedly connected with two cable wires; another end of one cable wire is connected with a positive rotating winch; another end of another cable wire is connected with a negative rotating winch through a fixed pulley arranged at the edge of the lift well; the positive and negative rotating winches are connected with a reducing motor; a lifting device is arranged in the lift well; and each parking platform and vehicle-loading bottom plate are provided with a vehicle conveying mechanism. The garage provided by the invention has the advantages of small ground occupation area, automation of parking and pick-up process, damage resistance, burglary resistance, large quantity of parking, and can be built as a multi-story garage, and thus, the garage has great promotional value.

Owner:尹元利

Microwave curing moulding system of water-soluble moulding core

ActiveCN108339942AAvoid scratchingGuaranteed StrengthFoundry mouldsMoulding machinesWater solubleMicrowave curing

The invention discloses a microwave curing moulding system of a water-soluble moulding core and belongs to the technical field of casting. The microwave curing moulding system comprises a moulding sand spraying unit, a moulding core curing unit, a moulding core immersion unit and a moulding core sintering unit, wherein the moulding sand spraying unit comprises a liquid mixing bin, a liquid spraying device and a material spreading device. The liquid mixing bin is used for storing mixed spraying liquid. The material spreading device is used for spreading sand. The liquid spraying device sprays spraying liquid to spread moulding sand layer by layer in accordance with the layer thickness of 0.01-1mm. The spraying liquid enables the moulding sand to aggregate and to coagulate to a to-be-cured moulding core. The moulding core curing unit is used for conducting microwave heating for the to-be-cured moulding core to cure the to-be-cured moulding core to a cured moulding core. The moulding coreimmersing unit is used for immersing the cured moulding core. The moulding core sintering unit is used for sintering the to-be-sintered moulding core. The microwave curing moulding system realizes moulding core fast producing without moulds. The moulding core curing unit adapts microwave heating realizing synchronous heating both interiorly and exteriorly. The intermittent microwave heating method enables inner layer water to be evaporated completely. Thus, the strength of the moulding core is ensured.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

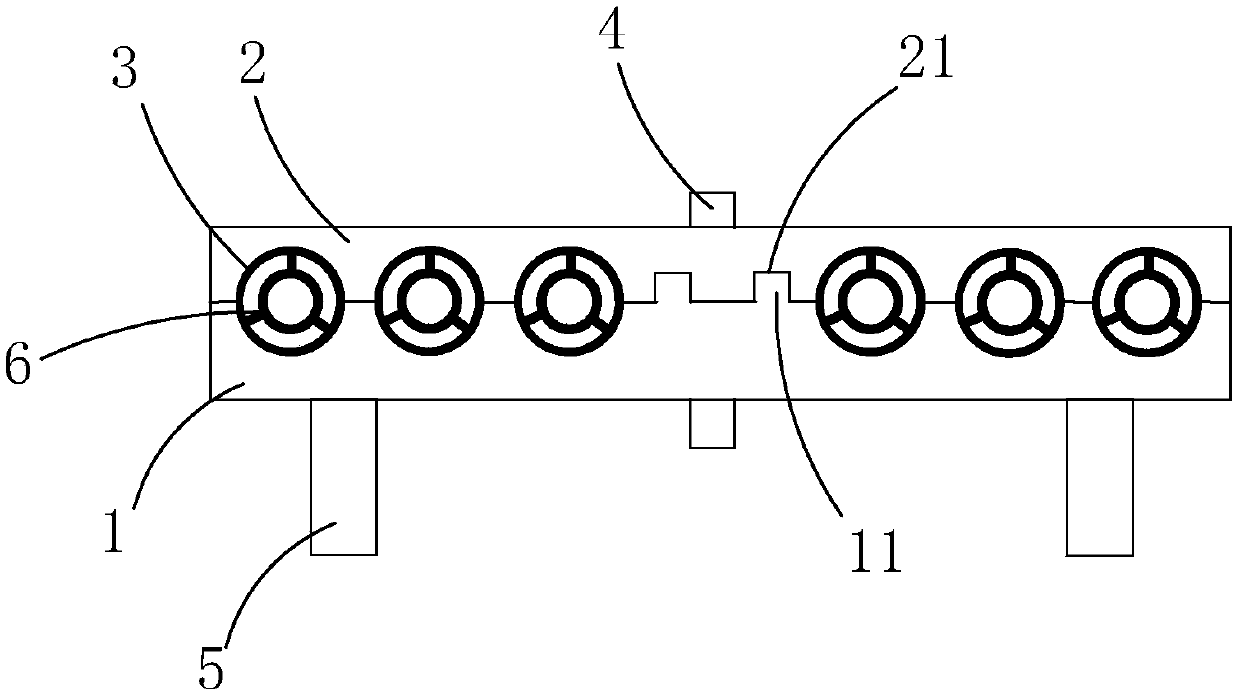

Yarn rod positioning device

The invention discloses a yarn rod positioning device for an automatic cheese loading and unloading robot. The yarn rod positioning device comprises a yarn rod strengthening assembly and a yarn rod positioning assembly which are both mounted on a Z-axis frame of the cheese loading and unloading robot; in the yarn rod strengthening assembly, a strengthening drive motor and a strengthening transmission device are used for driving an anti-interference mechanism and a strengthening mechanism to move, interference in yarn rods can be eliminated, and strengthening of the yarn rods required to be positioned can be achieved; and in the yarn rod positioning assembly, a positioning driving motor and a positioning transmission mechanism are utilized for driving a center positioning rod to move, and positioning and feedback of the yarn rods are achieved. The yarn rod positioning device has strong applicability, does not need to replace original yarn cages and yarn rods, can realize automatic positioning of the yarn rods, facilitates automation, is installed on the automatic cheese loading and unloading robot, and can ensure quick and inerrant loading and unloading of cheese by the robot.

Owner:TAIAN COMPANION MACHINERY

Decorative panel and method of manufacturing the same

InactiveCN101269607AAvoid scratchingIncrease stimulationSynthetic resin layered productsSpecial ornamental structuresFiber layerLiquid resin

The invention relates to a decoration panel and the manufacture method thereof, the decoration panel comprises an intertexture fiber layer, a pattern layer and a resin layer, wherein, the pattern layer is overlapped above the intertexture fiber layer, and the pattern layer comprises a reflection portion and a gridding portion; the resin layer is formed by hardening the resin positioned at the inside and the surface of the pattern layer, and the resin layer is used for fixing the pattern layer and the intertexture fiber layer. The invention also provides the manufacture method thereof, which comprises the steps as follows: providing the pattern layer including a reflection portion and a gridding portion in a mould and making the liquid resin soak into the inside and the surface of the pattern layer, then overlapping the intertexture fiber layer above the pattern layer, at last putting pressure on the intertexture fiber layer to harden the liquid resin into the resin layer and changing the gridding portion of the pattern layer into the light-transmission state; and thus the surface of the decoration panel has the metallic luster of the reflection portion and the fiber grain of the intertexture fiber layer, thus attracting the users and increasing the sale chances of the product.

Owner:HOCHENG CORPORATION

Backlight module

InactiveCN101871599ALow production costAvoid scratchingLighting support devicesNon-linear opticsBackplaneEngineering

The invention relates to a backlight module comprising a back plate, a reflection structure and a light source, wherein one side of the back plate is provided with a U-shaped accommodating part; the U-shaped accommodating part comprises a bottom, a side part which is connected with the bottom and forms an angle with the bottom and a top connected with the side part and opposite to the bottom. The reflection structure is configured on the bottom and the top and forms an accommodating space together with the side of the back plate. The light source is configured on the back light and extends into the accommodating space.

Owner:CORETRONIC (SUZHOU) CO LTD

Automatic tape attaching device and method

ActiveCN103879117AImprove work efficiencyAvoid scratchingLamination ancillary operationsLaminationLight guideElectrical and Electronics engineering

The invention discloses an automatic tape attaching device which comprises at least one group of subunits and at least one group of tape cutting mechanisms, wherein each group of subunits comprises a tape clamping air cylinder, a tape stripping mechanism and a tape adsorbing / attaching mechanism; each tape clamping air cylinder is used for fixing a tape; each tape stripping mechanism is arranged at any starting end of the tape; each tape adsorbing / attaching mechanism comprises a tape push rod opposite to the tape and a drive device of the tape push rod. According to the automatic tape attaching device, the tapes of regular / irregular light guide plates can be automatically cut and attached, so that the working efficiency is greatly improved; workers do not need to be in direct contact with the light guide plates, so that the scratch on the light guide plates is effectively avoided and the processing yield can be increased.

Owner:BOE TECH GRP CO LTD +1

Electric connector and manufacturing method thereof

ActiveCN101295828AAvoid scratchingSimple processingContact member manufacturingFixed connectionsSolder ballEngineering

The invention relates to an electric connector which comprises an insulation body provided with a plurality of holding holes, and a plurality of terminals and solder balls held in the holding holes; the terminals are provided with via holes; the solder balls are held in the via holes; the edge of the via hole is provided with a round corner at a side towards the core of the solder ball. A method for manufacturing the electric connector of the invention comprises the steps that: the insulation body provided with a plurality of holding holes is provided; a sheet-metal is provided and punched into a terminal rough casting provided with a contact part and a welding part; the welding part of the terminal rough casting is punched with a via hole, and the side of the edge of the via hole forms a round corner; a flat-shaped terminal is bent towards the side provided with the round corner to form a terminal needed; the terminal is arranged in the holding hole, and the side provided with the round corner faces the interior of the holding hole; the solder balls are arranged in the holding holes, one side of the solder ball is connected with the lower edge of the via hole. The electric connector of the invention is well welded with a circuit board; in addition, the electric connector is provided with the round corners, thus preventing the solder balls from being scratched; the round corners can be formed when the via holes are formed, thus being relatively simple.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

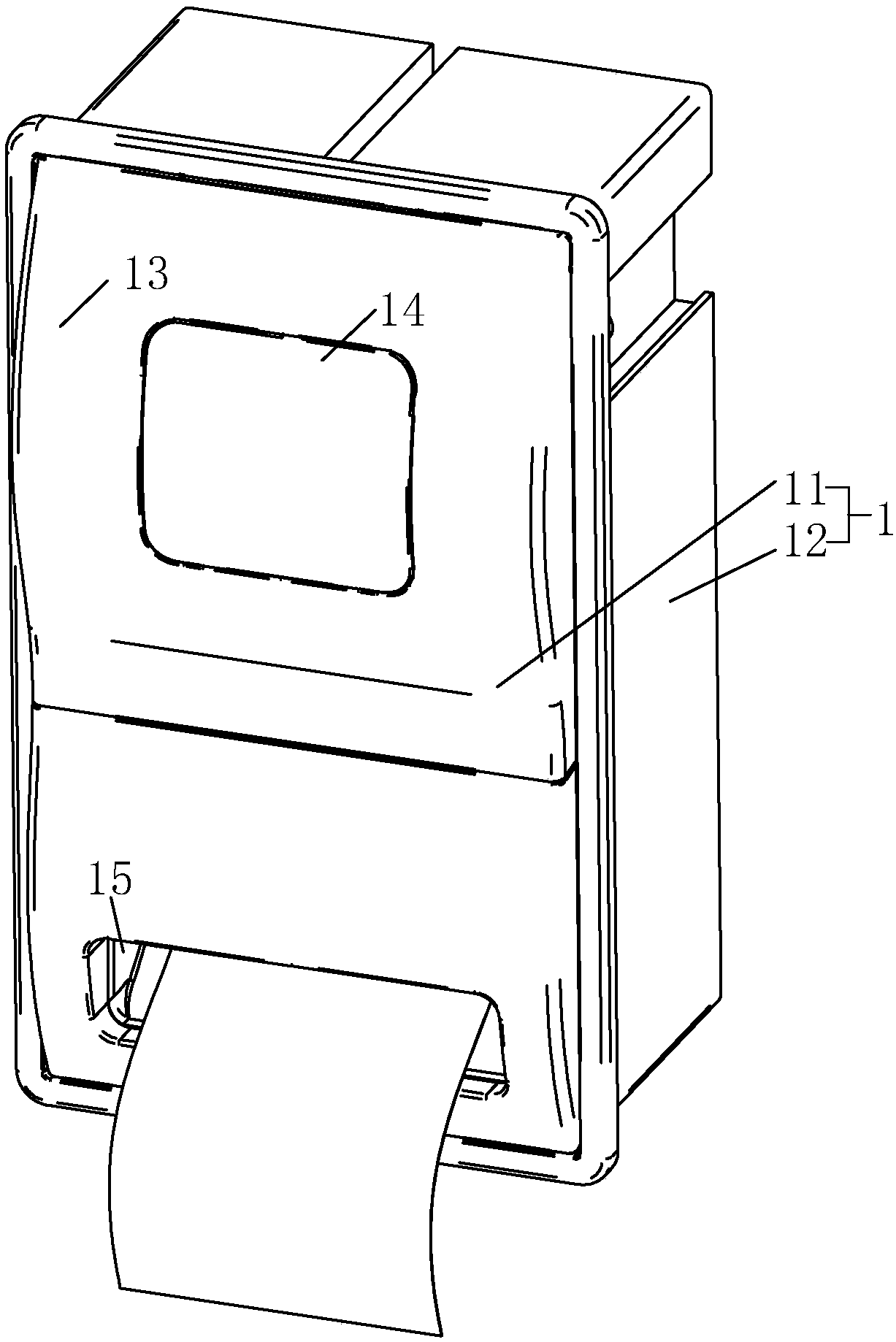

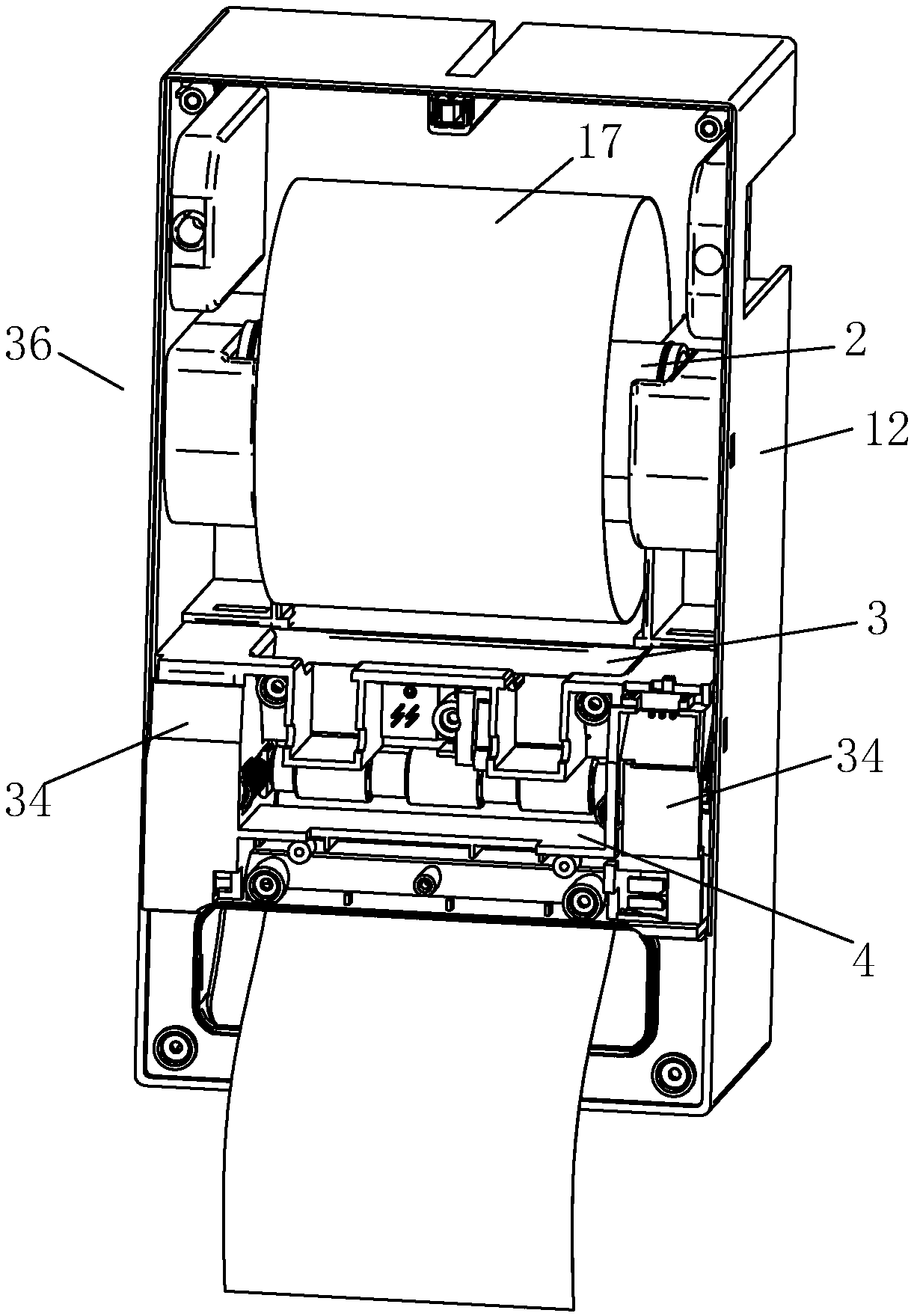

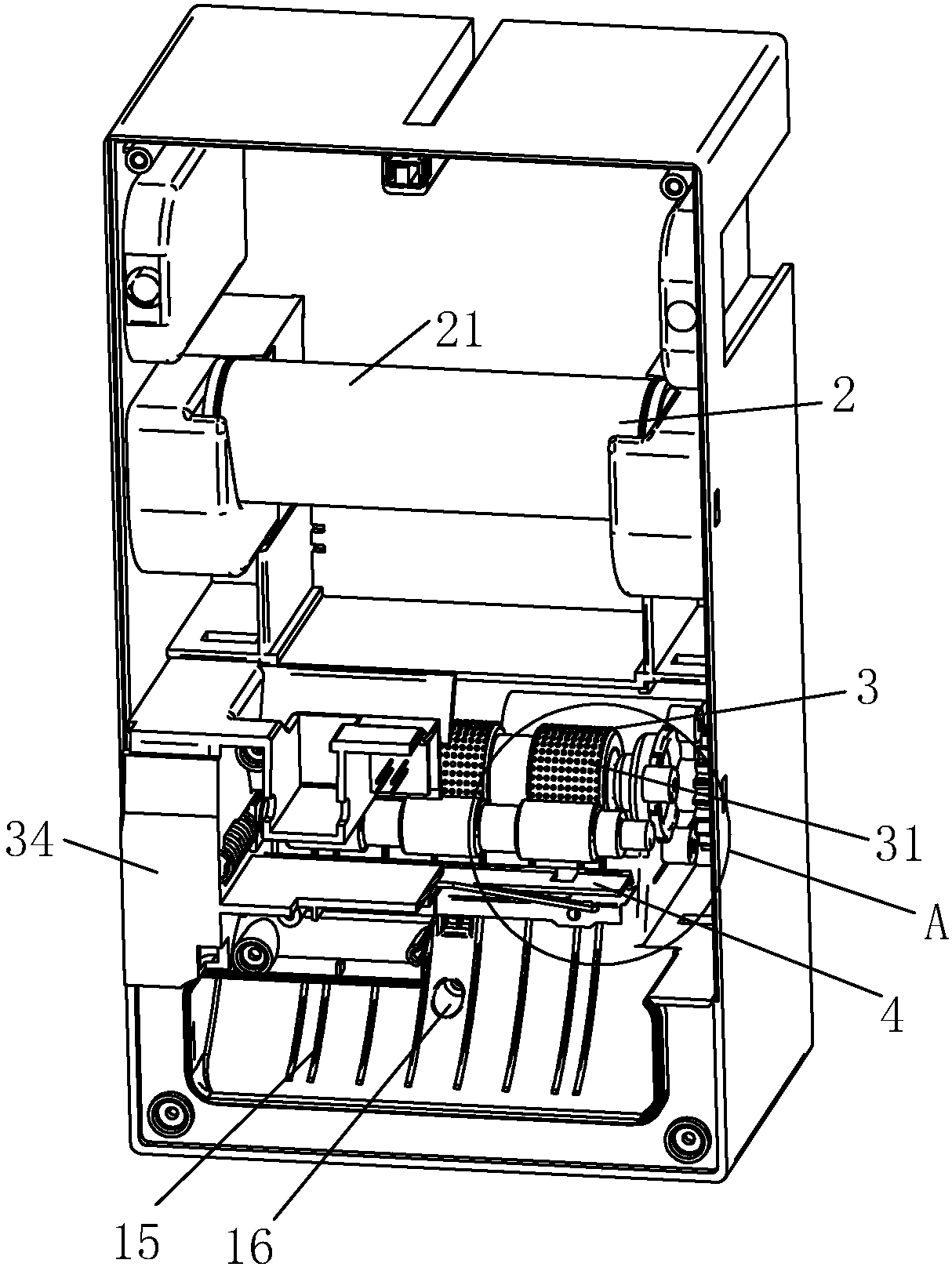

Paper extraction device

InactiveCN107773135AAvoid scratchingEasy to take outDomestic applicationsRolling paperPulp and paper industry

The invention discloses a paper extraction device. The paper extraction device comprises a casing, wherein a rotatable rolling shaft for loading roll paper is arranged in the upper part of the casing;a paper taking opening is formed in the lower part of the casing; a rotating roller and a pressing roller which allow the roll paper to pass and clamp the roll paper are arranged between the roll shaft and the paper taking opening; a driving mechanism which is connected with the rotating roller and the pressing roller and drives the rotating roller and the pressing roller to rotate is arranged inthe casing; an infrared detecting part for controlling the driving mechanism to work is outwards arranged in the paper taking opening. Automatic movement of the roll paper is realized under the action of pressing and rotating of the pressing roller and the rotating roller; meanwhile, starting and stopping of a motor are controlled by the infrared detecting part; by means of a protective plate, the roll paper is prevented from being scratched in the moving process, and cutoff of the roll paper can be guaranteed; with the adoption of storage grooves, the rotating shaft and the roll paper are convenient to take out.

Owner:SUZHOU YIFUER ELECTRONICS

Logistics good sorting device

PendingCN111715536AAvoid scratchingFast and efficient sortingSortingStructural engineeringMechanical engineering

The invention discloses a logistics good sorting device. The device includes a sorting tank body, a sorting chamber is arranged in the sorting tank body, a first conveyer belt, a second conveyer belt,a third conveyer belt, a fourth conveyer belt, and a fifth conveyer belt are arranged on four sides of the sorting tank body, an alignment device is arranged on the second conveyer belt, a handling structure is arranged above one end of the first conveyer belt at a top end of the sorting chamber, and a pushing structure is arranged on the middle of the top end of the sorting chamber. According tothe logistics good sorting device, a storage device is arranged, goods on conveyer belts are pushed through a fixing stop plate so that the goods are located on the middle of the conveyer belts, thestatement of occurrence of scratching between logistics and a conveyer belt fixing rack can be prevented, the device is comparative convenient, coordination between the pushing structure and a rotation device can make sorting more quick and efficient, the statements that the goods directly drop to the rotation device and are damaged are prevented, the conveyer efficiency is guaranteed, and the device is practical.

Owner:长兴正力物流设备有限公司

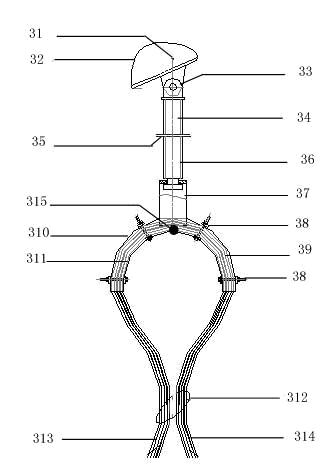

Communication cable positioning device

InactiveCN107769117AAvoid scratchingGood protection and guidanceElectrical apparatusEngineeringMechanical engineering

Owner:广东信通建设工程有限公司

Transparent conductive thin film and touch screen

PendingCN109545443AImprove adhesionAvoid scratchingConductive layers on insulating-supportsDiffusing elementsOptoelectronicsOxide

The invention relates to a transparent conductive thin film, which comprises a base material, a transparent conductive layer and a metal composite layer, wherein the metal composite layer comprises ametal conductive layer, and a first metallic oxide layer and a second metallic oxide layer attached to both sides of the metal conductive layer. When the transparent conductive thin film is applied toa touch screen, the metal conductive layer is a portion that forms a lead wire. Since the metallic oxide has higher roughness than that of the metal conductive layer, the second metallic oxide layercan have an effect of improving the adhesion of the metal composite layer. Further, the first metallic oxide layer and the second metallic oxide layer can protect the intermediate metal conductive layer. On the one hand, the water vapor of the inner and outer layers can be isolated to prevent the intermediate metal conductive layer from being oxidized; on the other hand, the metal conductive layercan be mechanically protected from scratches. Therefore, the transparent conductive thin film can effectively avoid the wear of the metal conductive layer, thereby facilitating the improvement of theyield of touch screen products. In addition, the invention further provides the touch screen.

Owner:江西新菲新材料有限公司

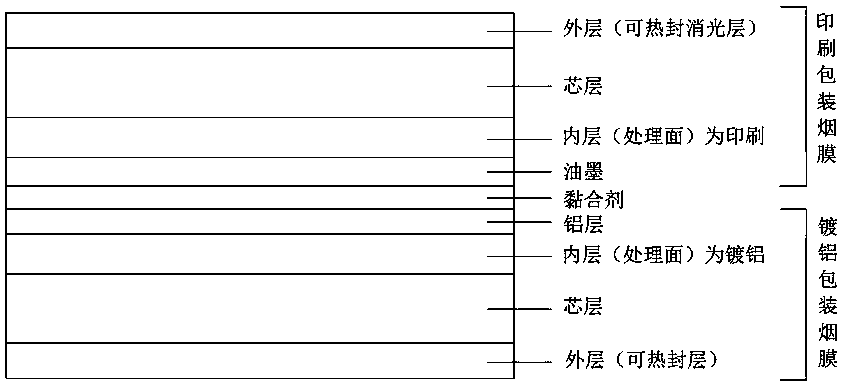

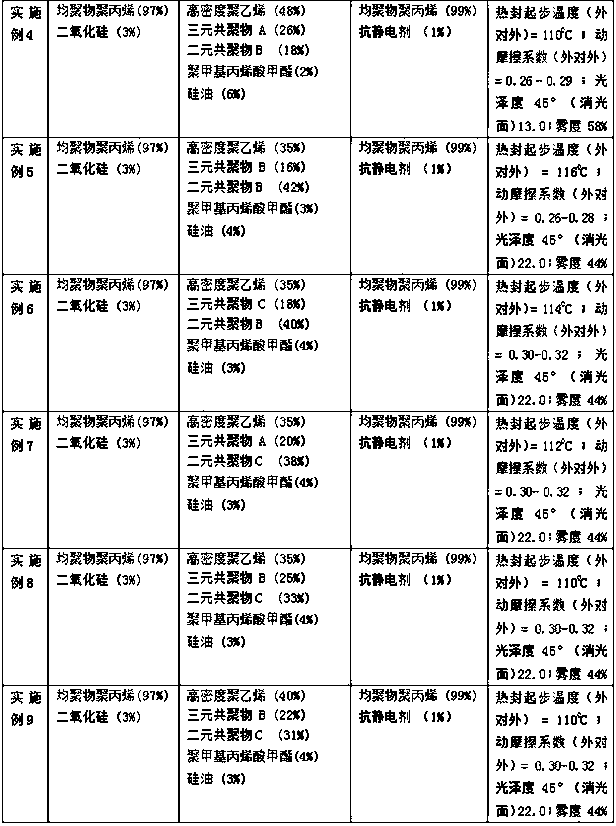

Heat-sealable matte aluminized printed composite packaging film for cigarettes and preparation method thereof

InactiveCN108656687ARealize the printing functionAvoid scratchingFlexible coversWrappersAluminiumHot-melt adhesive

The invention discloses a heat-sealable matte printed aluminized composite packaging film for cigarettes and a preparation method thereof. The composite packaging film comprises a printed matte film and an aluminized film which are laminated and processed by use of a binder or a hot melt adhesive, wherein the printed layer of the matte film can be laminated with the aluminized layer of the aluminized film to obtain the composite packaging film. The composite packaging film provided by the invention has the following advantages: a heat-sealable matte film is creatively proposed to be adopted asa printed packaging film; after inner printing of the inner surface of the matte film, the printed layer of the matte film is laminated with the surface of the aluminized layer of the aluminized film, so the problem of additional coating of a matting coating on the surface of a conventional cigarette packaging film is solved; meanwhile, the matted layer and the aluminized film have medium-and-low-temperature heat sealability, so a film can be packaged and bonded without the need of using a glue when a cigarette is subsequently packaged on a machine; and the composite packaging film provided by the invention realizes medium-and-low-temperature heat sealability and matte effects on the basis of guaranteeing conventional functions, effectively reduces energy consumption, is friendly to the environment, and has a matte metal texture.

Owner:SUZHOU KUNLENE FILM IND CO LTD +1

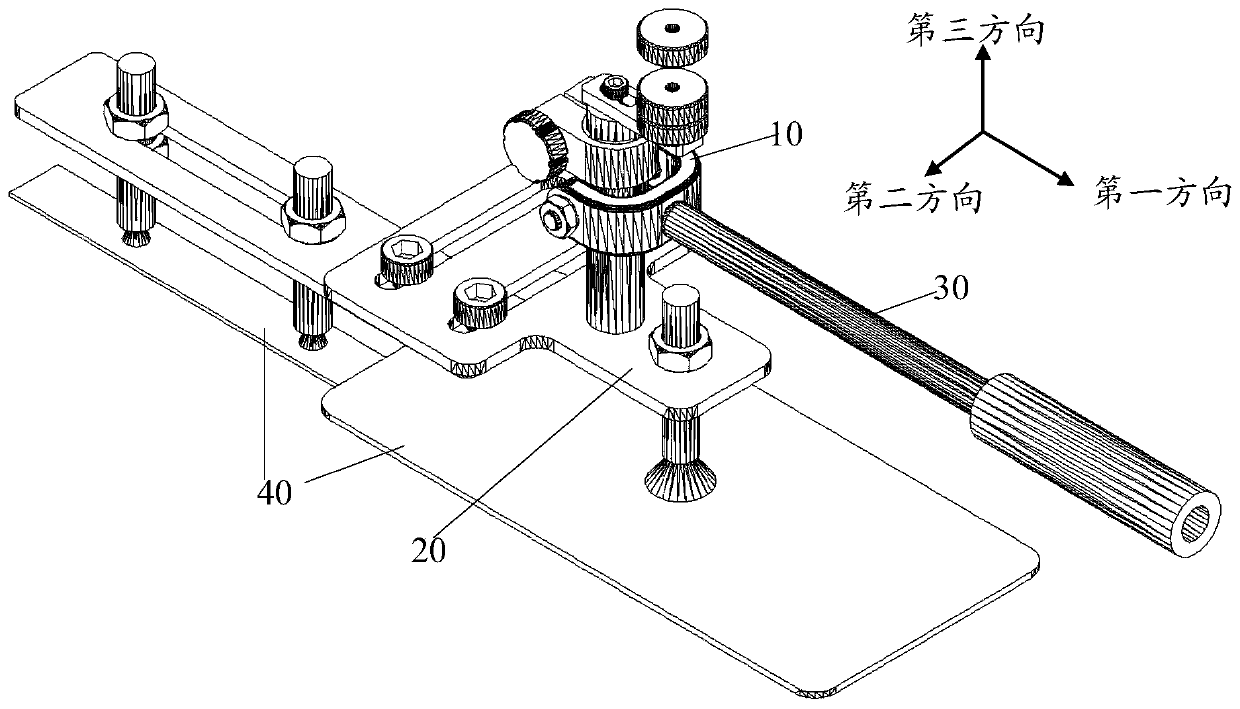

Taking and placing device and taking and placing method

InactiveCN109733876AAvoid collisionAvoid ScratchingConveyor partsEngineeringRotational degrees of freedom

The invention provides a taking and placing device and a taking and placing method. The device comprises a three-axis balance joint, an adsorption assembly and a control handle. The three-axis balancejoint has rotating freedom degrees in the three directions in a three-dimensional coordination system, the adsorption assembly and the control handle are fixedly connected with the three-axis balancejoint, and the adsorption assembly is used for adsorbing a target object under vacuum. The three-axis balance joint can enable the taking and placing device to keep balanced when taking and placing the target object, the target object is prevented from being collided and scratched in the taking and placing process, therefore, scrap is reduced, and the yield is improved.

Owner:BOE TECH GRP CO LTD +1

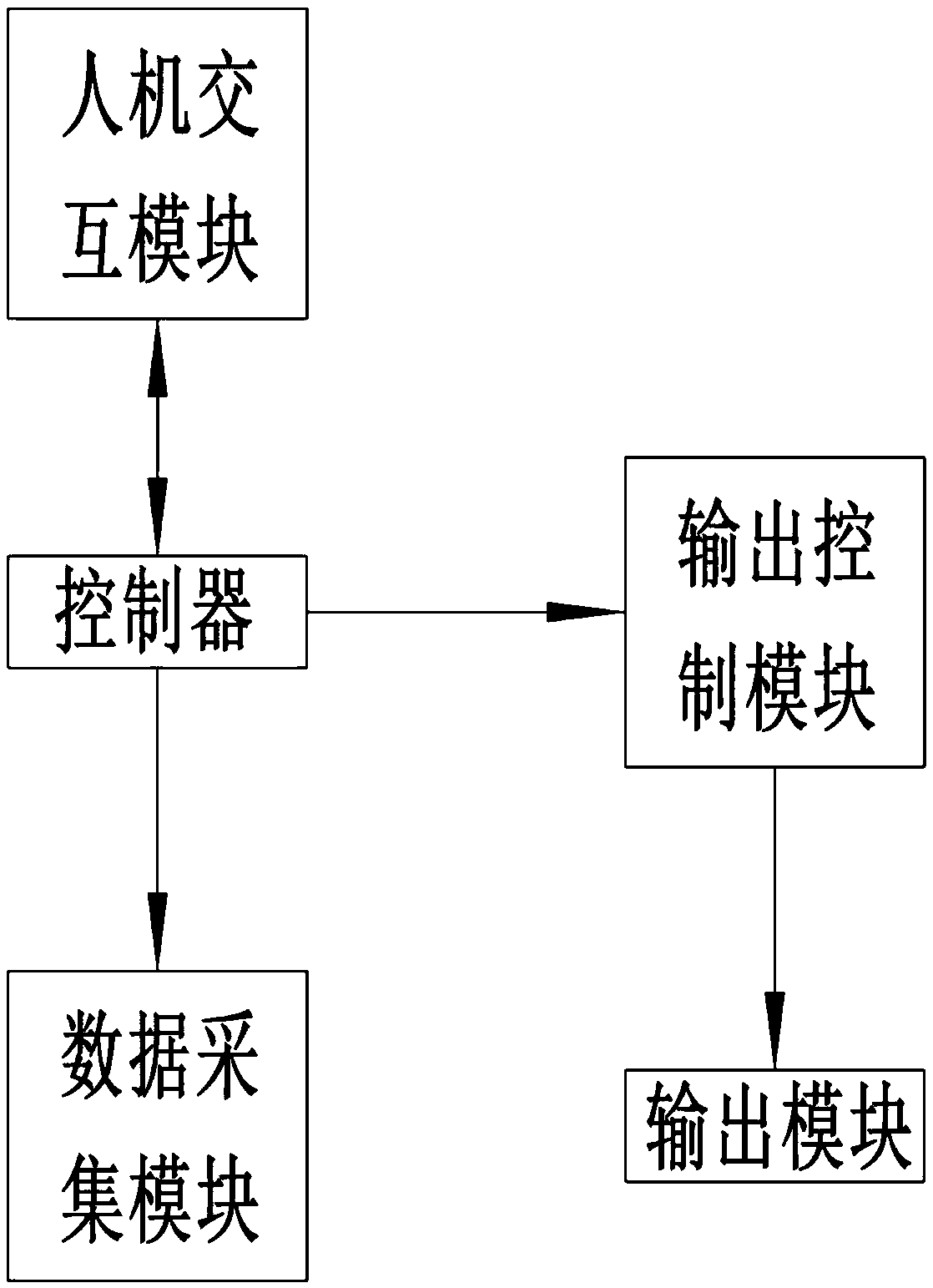

Underground parking system

The invention relates to an underground parking system. The underground parking system comprises an underground parking garage, multiple closed parking boxes and a controller used for completing vehicle parking / driving operation, wherein the underground parking garage is provided with multiple parking spaces, one or above parking-driving openings and rails connected with the parking spaces and theparking-driving openings; the controller is arranged at the parking-driving openings, the closed parking boxes are installed on the rails, and can move back and forth between the parking spaces and the parking-driving openings, and vehicle parking and driving are achieved. In this way, parking and driving of vehicles can be effectively and automatically completed, the vehicles are more breezily and conveniently parked and driven, and meanwhile the scraping and impact problem in the vehicle parking and driving processes is solved; the closed parking boxes have good antitheft protection effect,anti-water-logging protection effect and the like on the vehicles, persons are not required to enter the underground parking garage, and parking safety is extremely high.

Owner:ZHUHAI TIANREN TECH CO LTD

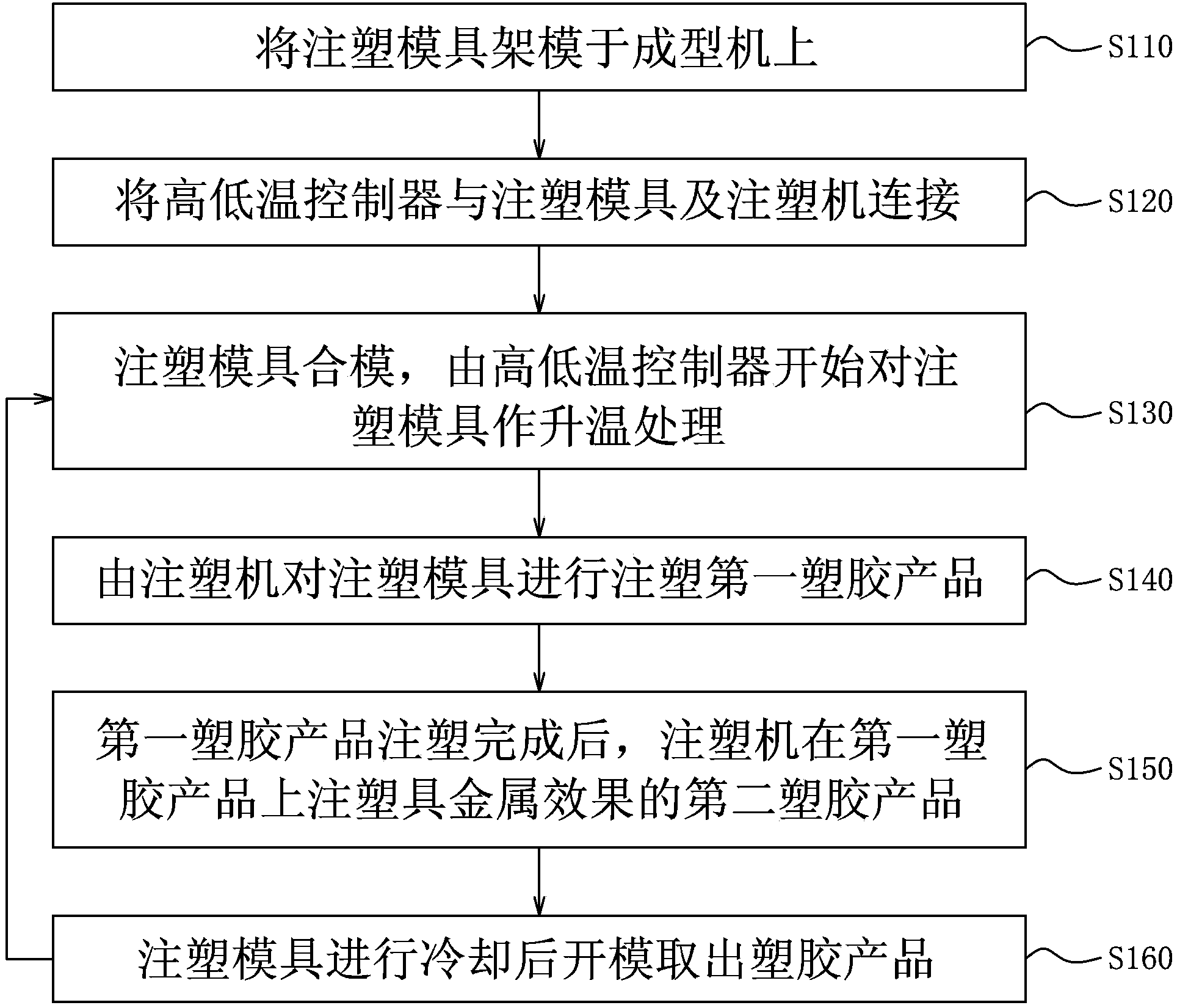

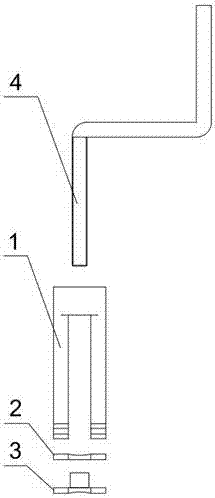

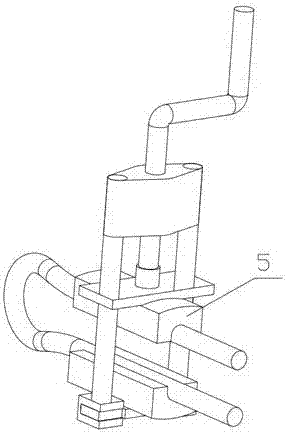

Plastic product and molding method thereof

The invention discloses a plastic product and a molding method thereof. The molding method comprises the following steps: (1) performing mold closing and heating on an injection mold controlled by a high / low-temperature controller; (2) obtaining a first plastic product through injection molding in the injection mold; (3) obtaining a second plastic product with metal effect on the first plastic product through injection molding in the injection mold; and (4) cooling the injection mold by using the high / low-temperature controller, opening the mold and getting a product consisting of the first plastic product and the second plastic product. The plastic product is the product generated through injection molding by using the above molding method.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

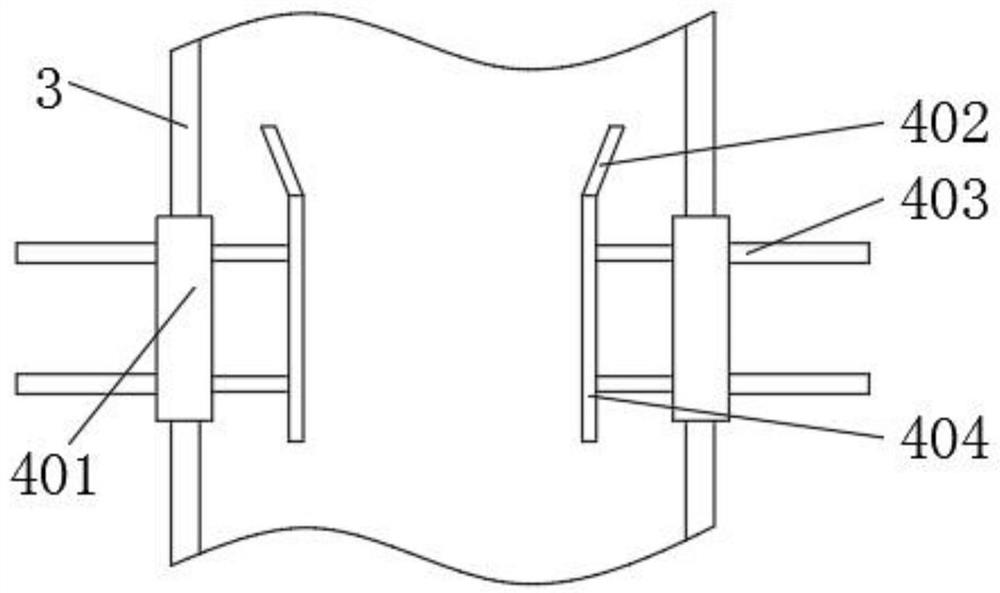

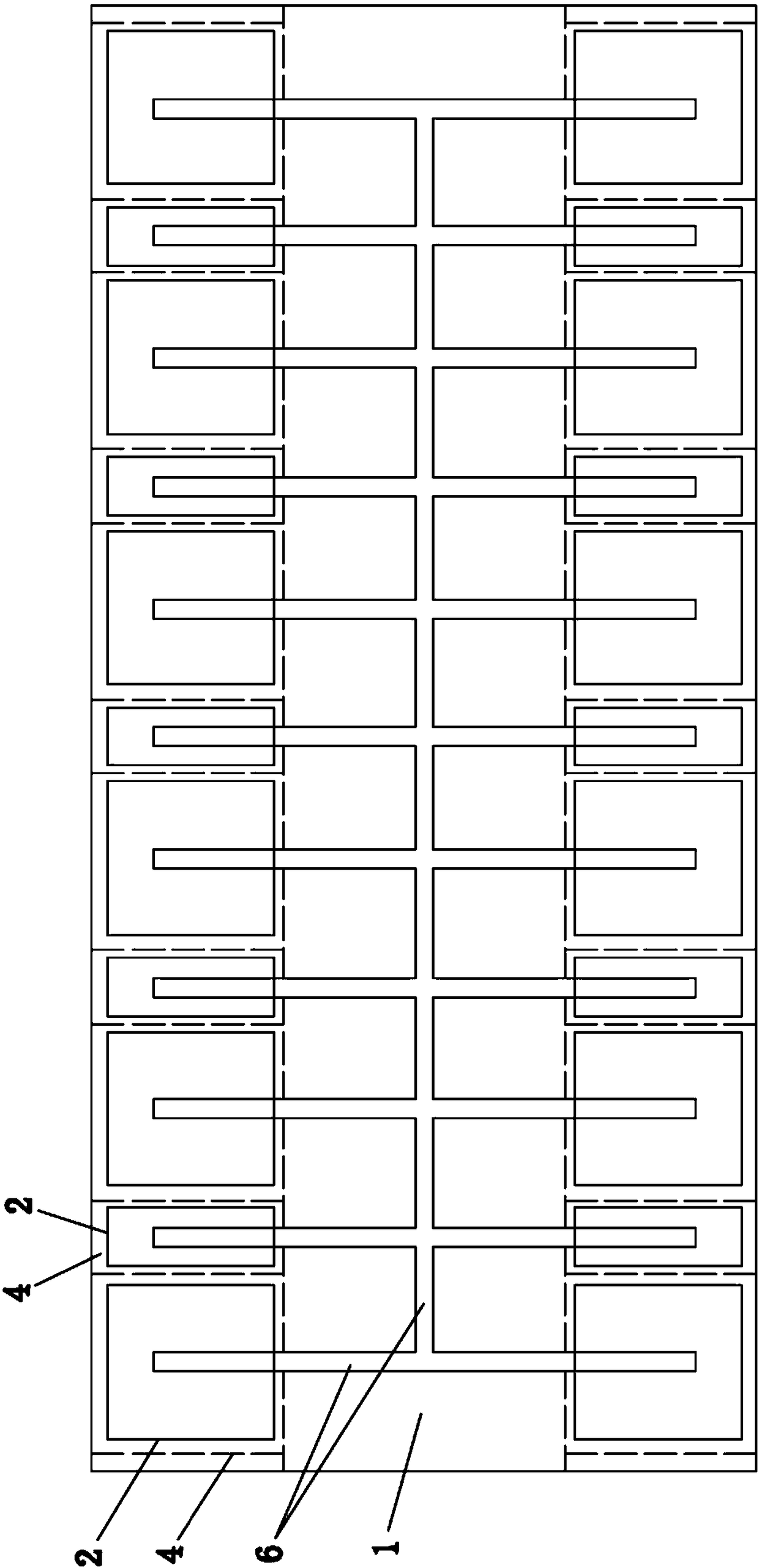

Wire clamp compressing device

InactiveCN107104386AAvoid scratchingSave strapping timeApparatus for joining/termination cablesApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention relates to the technical field of power line auxiliary devices, and in particular relates to a wire clamp compressing device comprising a guide rail, a fixed compressing plate, a movable compressing plate and a rocker, wherein the fixed compressing plate is fixed at the tail end of the guide rail, the movable compressing plate is fixed at the tail end of the rocker, and both the movable compressing plate and the rocker are movably connected with the guide rail. The wire clamp compressing device provided by the invention can compress and fix a wire clamp for fixing the return end of an insulated wire, facilitates connection of an upper wire clamp and a lower wire clamp, and is simple to operate, stable and firm, capable of preventing the insulation layer of the wire from being scraped, also capable of saving bundling time and improving work efficiency, and good in practicability and feasibility.

Owner:QINGYUAN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID CO LTD

Tufting processing treatment method for producing cotton textile yarns

InactiveCN111705389AEasy to change directionsAvoid scratchingTextile treatment machine partsLiquid/gas/vapor removalTextile yarnCotton thread

The invention relates to a tufting processing treatment method for producing cotton textile yarns. The tufting processing treatment method comprises a worktable, a tufting device, an immersion wettingdevice, a scraping and drying device and a winding device, wherein the tufting device is arranged on the right side of the upper end of the worktable; the immersion wetting device is arranged on theleft part of the tufting device; the scraping and drying device is arranged on the left part of the immersion wetting device; the winding device is arranged on the left part of the scraping and dryingdevice; and in addition, the immersion wetting device, the scraping and drying device and the winding device are all arranged at the upper end of the worktable. By use of the tufting processing treatment method for producing the cotton textile yarns, provided by the invention, the problems that the textile yarns are generally longer, and the scraping strength is difficultly grasped during artificial tufting, so that the textile yarns are easily broken, and exiting textile yarn producing equipment generally scrapes the textile yarns at a time only during tufting, and shorter yarns are left ontextile cotton threads after first-time scraping and are difficult to scrape, so that the surfaces of the textile yarns become rough and the like can be solved.

Owner:张浩

Cleaning and disinfecting device for obstetrical medical instruments

PendingCN112871857AAvoid scratchingGood drying effectDrying gas arrangementsCleaning using liquidsElectric machineryBiomedical engineering

The invention relates to the technical field of medical instrument cleaning and disinfecting devices, and particularly discloses a cleaning and disinfecting device for obstetrical medical instruments. The cleaning and disinfecting device comprises a fixed bottom plate, supporting legs are fixedly connected to four corners of the bottom of the fixed bottom plate, a cleaning and disinfecting cylinder is fixedly connected to the right side of the top of the fixed bottom plate, a drainage pipe fixedly communicates with the center of the bottom of the right side of the cleaning and disinfecting cylinder, a fixed frame is fixedly connected to the bottom of the fixed bottom plate at the position close to the center, and a driving motor is fixedly mounted in an inner cavity of the fixed frame. According to the cleaning and disinfecting device for the obstetrical medical instruments, a fixed rod is matched with a storage disc and a storage cylinder, so that when the medical instruments are placed, the medical instruments can be better placed in a layered and classified manner, and some sharp medical instruments are effectively prevented from scratching other medical instruments during cleaning.

Owner:曾红梅

Automobile cover cloth containing aluminum foil and oxford fabric (polyester taffeta)

InactiveCN102555350AStrong fastnessAvoid scratchingLaminationLamination apparatusPolyesterEngineering

The invention discloses an automobile cover cloth containing an aluminum foil and an oxford fabric (polyester taffeta). The upper layer of the automobile cover cloth is the aluminum foil; the oxford fabric or polyester taffeta is arranged on the lower layer of the aluminum foil; and the aluminum foil is adhered with the oxford fabric or polyester taffeta by glue. An automobile cover made by the cloth has a function of the common automobile cover, has high firmness, is difficult to tear away, and can preserve and insulate heat and prevent the paint on the surface of an automobile from being scratched.

Owner:杭州汇龙汽车用品有限公司

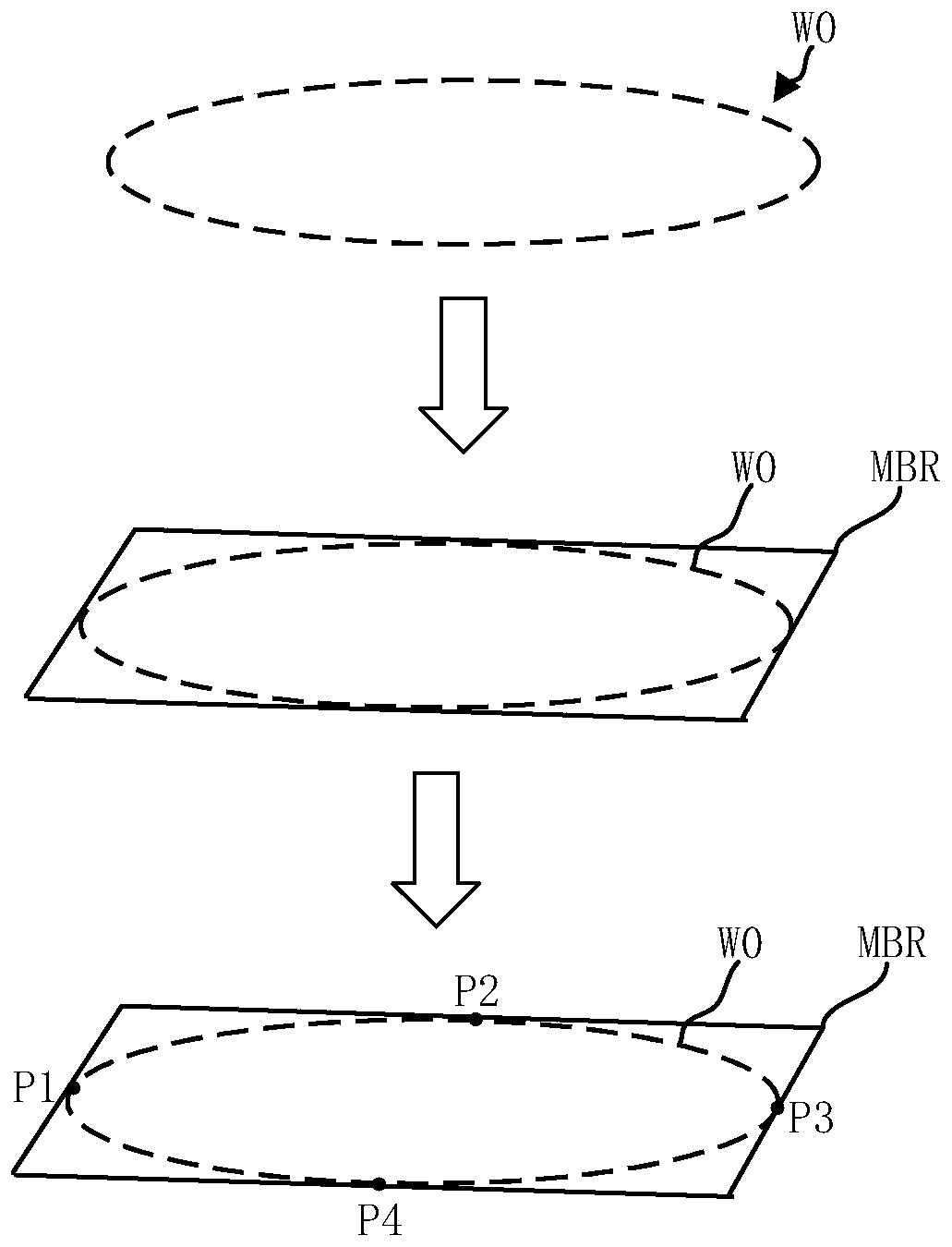

Wafer horizontal deviation detection method, detection device and furnace tube equipment

ActiveCN111063636AAvoid scratchingJudgment Offset VectorSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMechanical engineeringSemiconductor

The invention relates to the technical field of semiconductor manufacturing, and in particular relates to a wafer horizontal deviation detection method, a wafer horizontal deviation detection device and furnace tube equipment. The detection method comprises the steps of determining an excircle area of a reference wafer; calculating the minimum circumscribed rectangle of the excircle area of the reference wafer; determining a tangent point between the minimum circumscribed rectangle and the excircle area of the reference wafer; transferring the wafer to be measured to the outer circle area of the reference wafer; controlling a ray to enter from one side of the tangent point along the vertical direction; and judging whether the ray is received at the other side of the tangent point or not. The detection device comprises a CPU, a program storage part, a memory and a data bus, wherein the CPU, the program storage part and the memory are respectively connected with the data bus. A program is stored in the program storage part and is used for executing the detection method. The furnace tube equipment comprises a ray receiving and transmitting system, a wafer boat, a moving device, a moving driving system and a detection device. According to the invention, the offset vector of the wafer to be detected in the horizontal direction is detected through the ray, and the horizontal offset vector can be corrected in time according to the offset vector.

Owner:HUA HONG SEMICON WUXI LTD

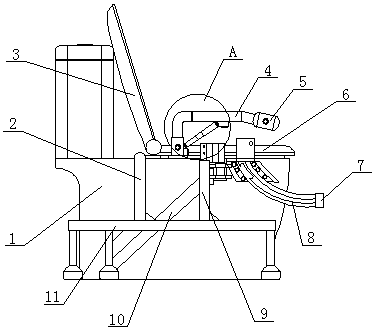

Multifunctional closestool supporting seat

PendingCN111202374AReduce gapAvoid the phenomenon of low stabilityBathroom coversLavatory sanitoryFoot cushionEngineering

The invention discloses a multifunctional closestool supporting seat comprising a closestool. Fixing frames are symmetrically arranged on the two sides of the closestool; a plurality of rubber foot pads are fixed to the bottoms of the fixing frames; a connecting rod is arranged on the portion, corresponding to the rear side of the seat, of the surface of the closestool; the two ends of the connecting rod and the fixing frames are in a fixed state; and first telescopic rods are symmetrically arranged on the portions, corresponding to the two sides of the closestool, of the front side of the connecting rod. With a movable column, a movable groove, a movable block, a rotary block and a rotary groove, tolerances during production can be avoided and thus a certain gap is formed between every two parts, so thata phenomenon of low stability of the supporting rod is avoided; with a supporting rod, a situation that because the gravity center of force exerted by a user is located at the top endof the handrail, the pressure is generated at the included angle of the handrail for a long time, and consequently a certain breaking risk exists is avoided; the included angle of the handrail is supported through the supporting rod, so that the gravity bearing capacity and use safety of the handrail are improved.

Owner:GUANGDONG YIMING INTELLIGENT MEDICAL TECH CO LTD

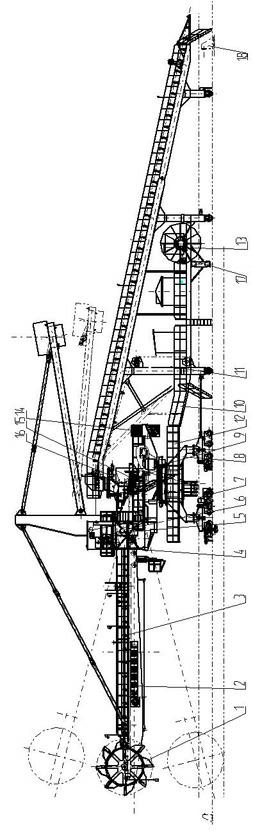

Novel electrifying way and device for bucket wheel machine

ActiveCN102431810AImprove anti-interference abilitySave control cablesLoading/unloadingElectricityControl room

The invention relates to a novel electrifying way and device for a bucket wheel machine. A conductor line is selected preferably for supplying power to the bucket wheel machine; a collector brush on a current collector at the bottom end of a machine body is in sliding contact with a guide rail; electric energy is directly conducted to a walking system; the current collector of a conductor line system is electrically connected with the walking system through a cable; the walking system is used for controlling a part of lines to enter an auxiliary control room on a trailer; a communication linegetting out of the auxiliary control room reaches upwards to an electrifying device on the revolving central line of an upright post through a trailer main beam together with power lines of a bucket wheel, a belt feeder, a revolving mechanism and a pitching system; the power lines of the bucket wheel, the belt feeder, a revolving mechanism and the pitching system and a communication line between the auxiliary control room and a driving cab pass through the electrifying device; a communication line which gets out of the electrifying device and is used for connected the auxiliary control room with the driving cab directly enters the driving cab; a power wire getting out of the electrifying device is introduced into the bucket wheel, the belt feeder, the revolving mechanism and the pitching system for supplying power respectively; and communication lines of these parts get back to the driving cab.

Owner:HUNAN CHANGZHONG MACHINERY

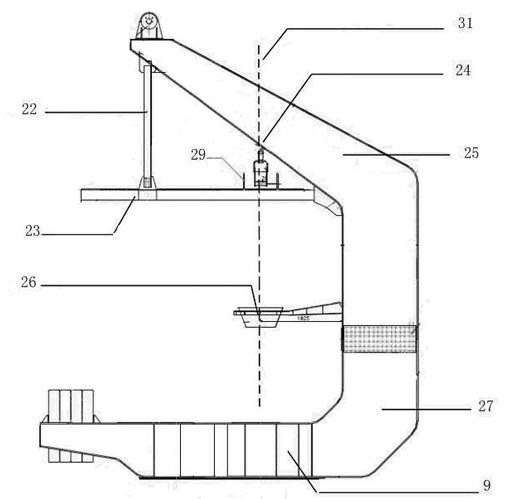

Anti-collision reclaimer and anti-collision system thereof

InactiveCN109335714AAvoid scratchingReduce security risksConveyorsControl devices for conveyorsCollision systemLaser scanning

The invention provides an anti-collision reclaimer and an anti-collision system thereof. The anti-collision reclaimer comprises a walking module; the top part of the walking module is rotatably connected with a bearing platform; the bearing platform is provided with a driving device I; the top part of the bearing platform is rotatably connected with a cantilever supporting plate; the cantilever supporting plate is provided with a driving device II; the top part of the cantilever supporting plate is fixedly provided with a discharge cantilever; the discharge cantilever is provided with a discharge belt conveyor; the side wall of the discharge cantilever is provided with a plurality of laser scanners; the bearing platform is fixedly provided with a supporting arm; the top part of the supporting arm is hinged with a reclaiming arm; the bottom part of the reclaiming arm is provided with a hydraulic cylinder; the reclaiming end of the reclaiming arm is provided with a bucket wheel; and a driving device, the driving device I and the driving device II of the walking module are all electrically connected with a controller. According to the anti-collision reclaimer and the anti-collision system thereof provided by the invention, a distance between a barrier and a facility is measured by employing the laser scanners, and under cooperation of normal operation, deceleration and shut down actions and an alarm device, a technician is hinted about a fault location in time, so that scratch and collision accidents between facilities are avoided, and the potential safety hazard is reduced.

Owner:INSTALLATION ENG CO LTD OF CCCC FIRST HARBOR ENG +1

Conveniently mounted power and electric cabinet device with radiating function

ActiveCN104505731AGood sealing effectAvoid scratchingSubstation/switching arrangement casingsEngineeringWheel and axle

Owner:广州龙越自动化设备有限公司

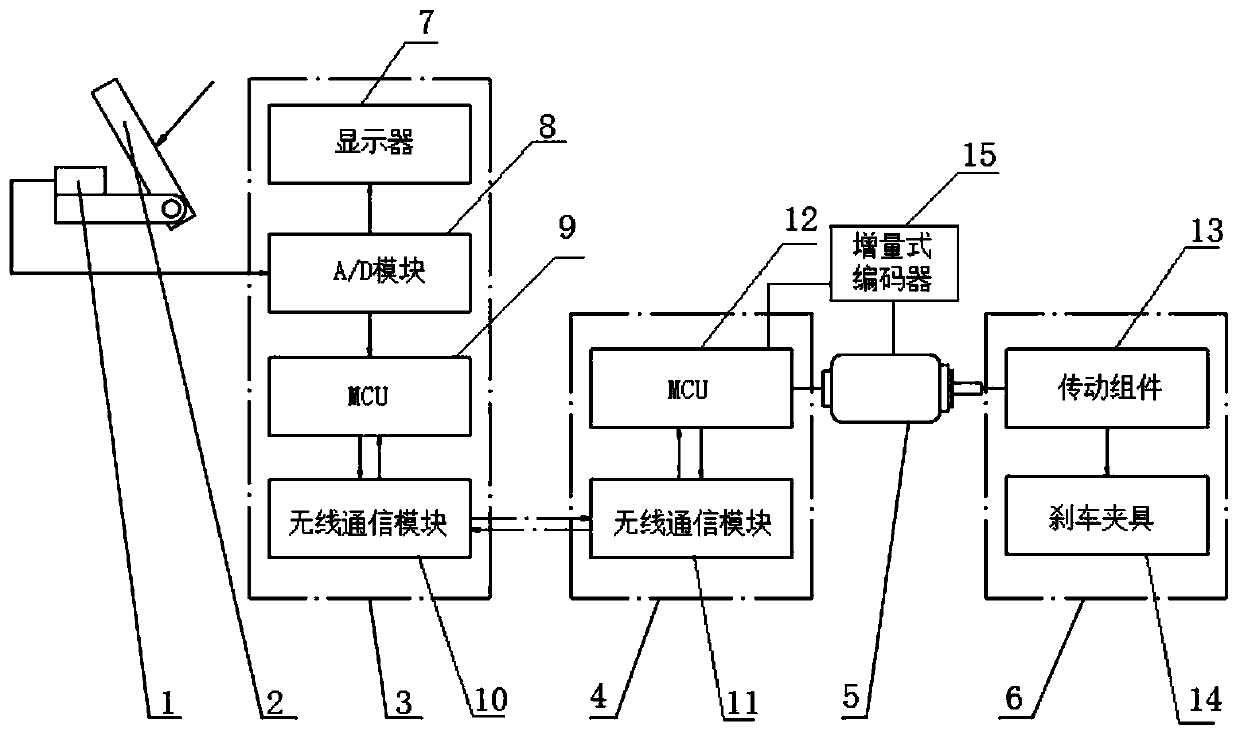

Wireless braking system

The invention relates to a wireless braking system. The wireless braking system comprises a braking control module and a braking realizing module which are connected with each other through a wirelessmode; the braking control module comprises a pedal plate and a first control module; an angle sensor used for detecting a steering angle and an angular acceleration of the pedal plate is arranged onthe pedal plate; the angle sensor is connected with the first control module; the first control module comprises a first micro-control unit and a first wireless communication module connected with thefirst micro-control unit; the braking realizing module comprises a second control module, a motor and a mechanical brake unit which are connected with each other in sequence; the second control module comprises a second micro-control unit and a second wireless communication module connected with the second micro-control unit; and the first wireless communication module is connected with the second wireless communication module. Compared with the prior art, the wireless braking system has the advantages that the oil leaking phenomenon of an oil braking system is avoided and the wiring harnessarranging space of a vehicle compartment is also saved by using an electronic control and mechanical structure combined method.

Owner:TONGJI UNIV

Smelting furnace

InactiveCN110857839AAvoid scratchingPrevent slidingCrucible furnacesEnvironmental geologyHydraulic drive system

The invention discloses a smelting furnace. The smelting furnace comprises a smelting furnace body provided with an opening, a furnace cover used for closing the opening and a hydraulic driving mechanism. The hydraulic driving mechanism is connected with the furnace cover to control opening and closing of the furnace cover by converting hydraulic energy of the hydraulic driving mechanism to mechanical energy. In the process that the hydraulic driving mechanism controls the furnace cover to be opened or closed, the furnace cover is made to directly get away from the smelting furnace body and cannot make contact with or scratch the smelting furnace body. The possibility that impurities on the smelting furnace body are taken into the smelting furnace when the furnace cover is opened or closedis reduced. Moreover, the furnace cover can be opened more conveniently and quickly through control of the hydraulic driving mechanism.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

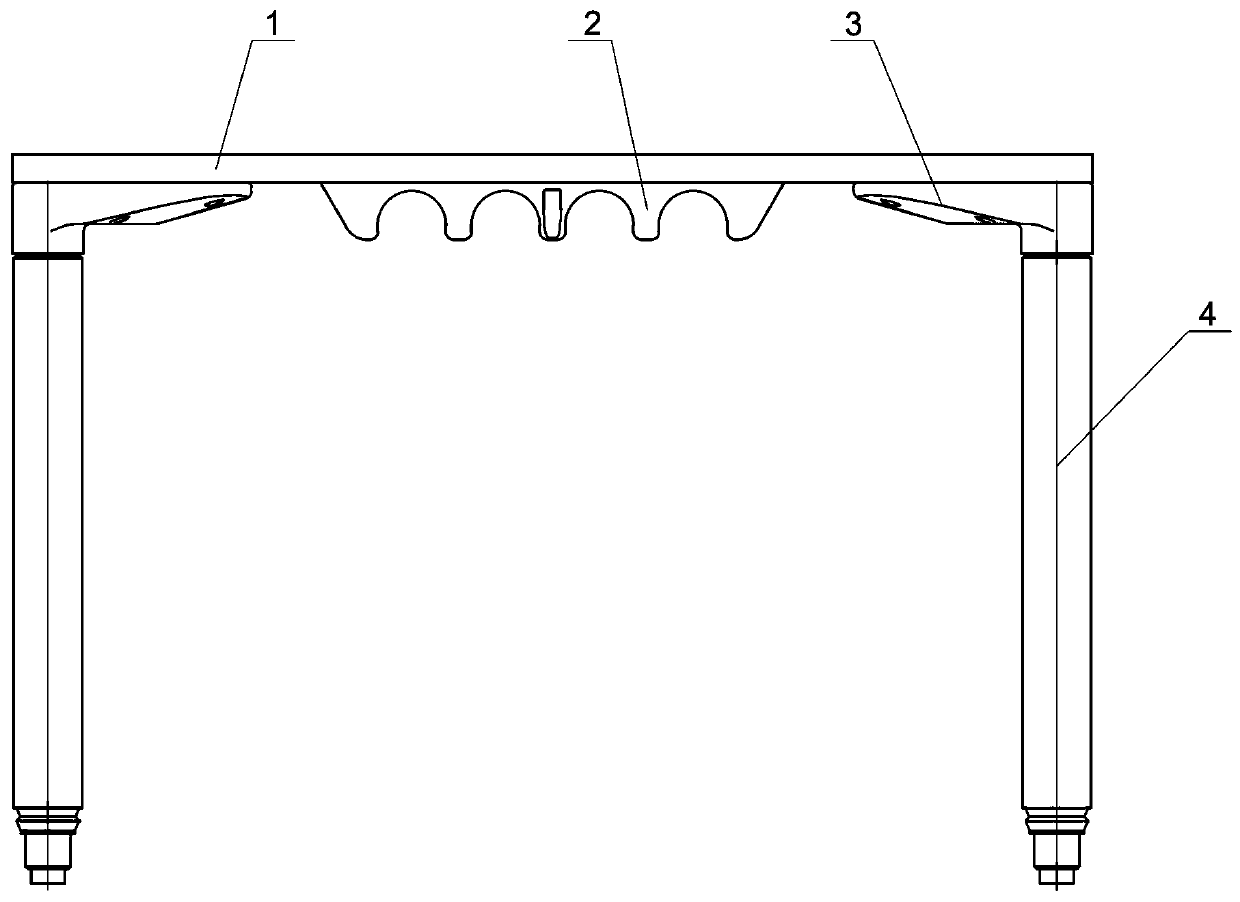

Desk with adjustable height

PendingCN110236296ASmooth outer surfaceAvoid scratchingFoldable tablesStowable tablesBruiseCircular surface

The invention relates to a desk with the adjustable height, which includes a desktop and desk legs. The four desk legs are mounted on the lower plane of the desk; the desk legs are mainly composed of outer cylinders and inside circular columns, inner holes of the outer cylinders sleeve the inside circular columns in a clearance fit mode, the outer circular surfaces of the upper ends of the outer cylinders are fixedly installed on the lower plane of the desktop through a connecting seat, and height adjusting devices are arranged between the inner holes in the lower ends of the outer cylinders and the outer circular surfaces of the inner circular columns; and the outer circular surfaces of desk legs are level and smooth, scrapes and bruises on skin of infants by projections are avoided, and using safety performance is good. The small desk is suitable for children writing and drawing.

Owner:LIBEN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com