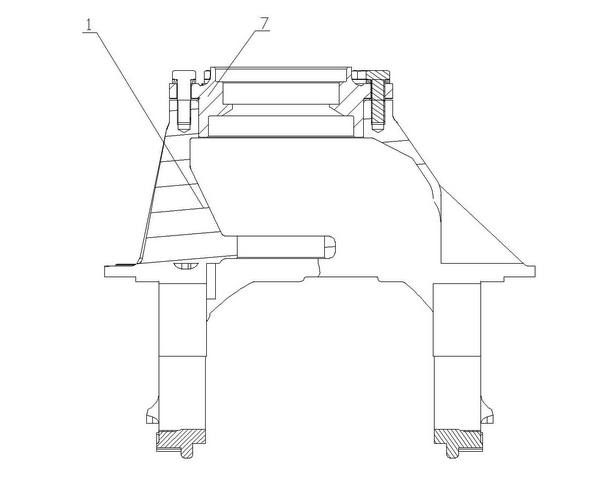

Main speed reducer housing for light car axle

A technology of main reducer and reducer, applied in the direction of transmission parts, components with teeth, belts/chains/gears, etc., can solve problems such as limited space, save space, reduce vehicle mass, and achieve lightweight design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Such as Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the present invention directly casts the front step 11 and the rear step 10 for respectively installing the front bearing 4 and the rear bearing 5 on the reducer housing 1 according to the requirements of gear meshing and bearing installation accuracy, and directly casts the The front bearing hole 12 and the rear bearing hole 9 are used to assemble the front bearing 4 and the rear bearing 5. The front bearing 4 and the rear bearing 5 are directly assembled on the reducer housing 1, and the driving bevel gear 2 is directly assembled on the front bearing 4 and the rear bearing. In the hole of the bearing 5; the installation surface of the reducer housing 1 is a plane 16 that does not need to install the through hole of the guide bearing, through which the surface is fixed with the thread on the axle housing; the front bearing 4 and the rear of the driving bevel gear 2 are assembled The correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com