Refrigerating machine jacket structure for superconduction magnet and installation and disassembly method of refrigerating machine jacket structure

A technology of superconducting magnets and refrigerators, which is applied in the directions of superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problem that the airtight performance of liquid helium-free magnets cannot be met, and the indium contact piece cannot be fully contacted by the cold head of the refrigerator. , The heat transfer efficiency cannot meet the problems of non-liquid helium magnets, etc., to prevent the magnet from quenching, ensure the installation accuracy, and ensure the vacuum sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

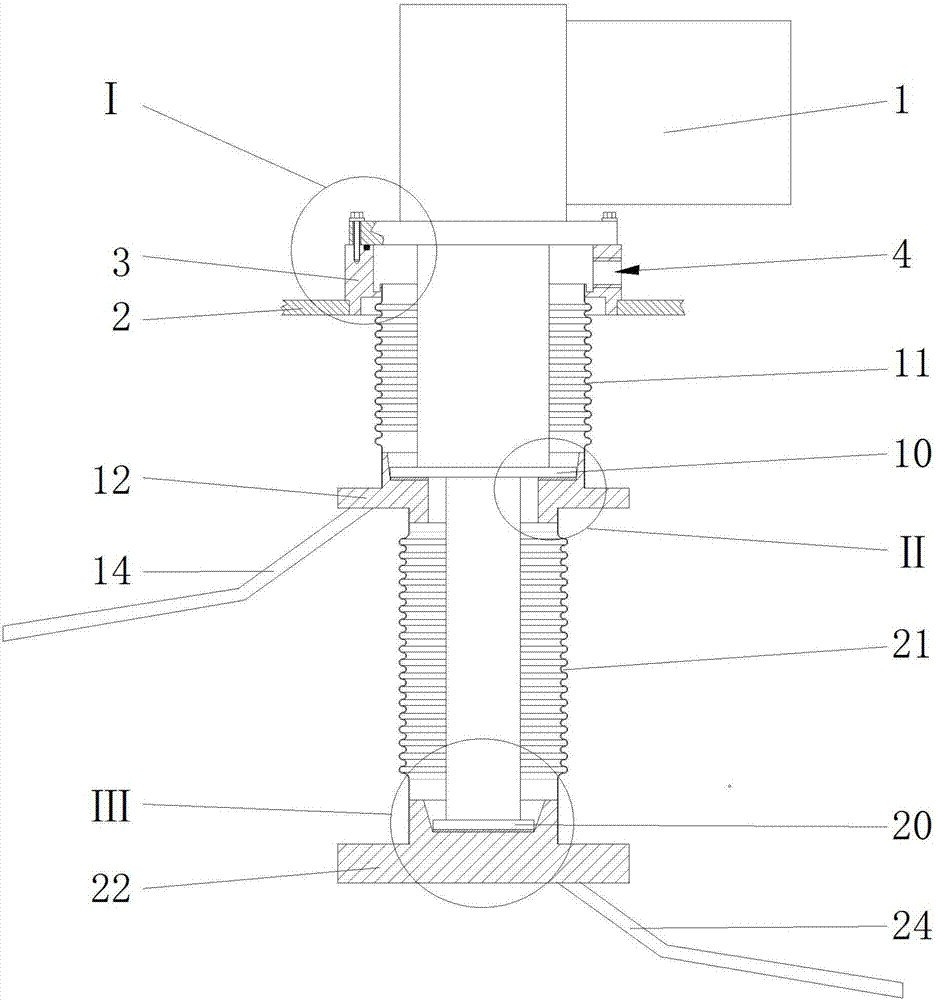

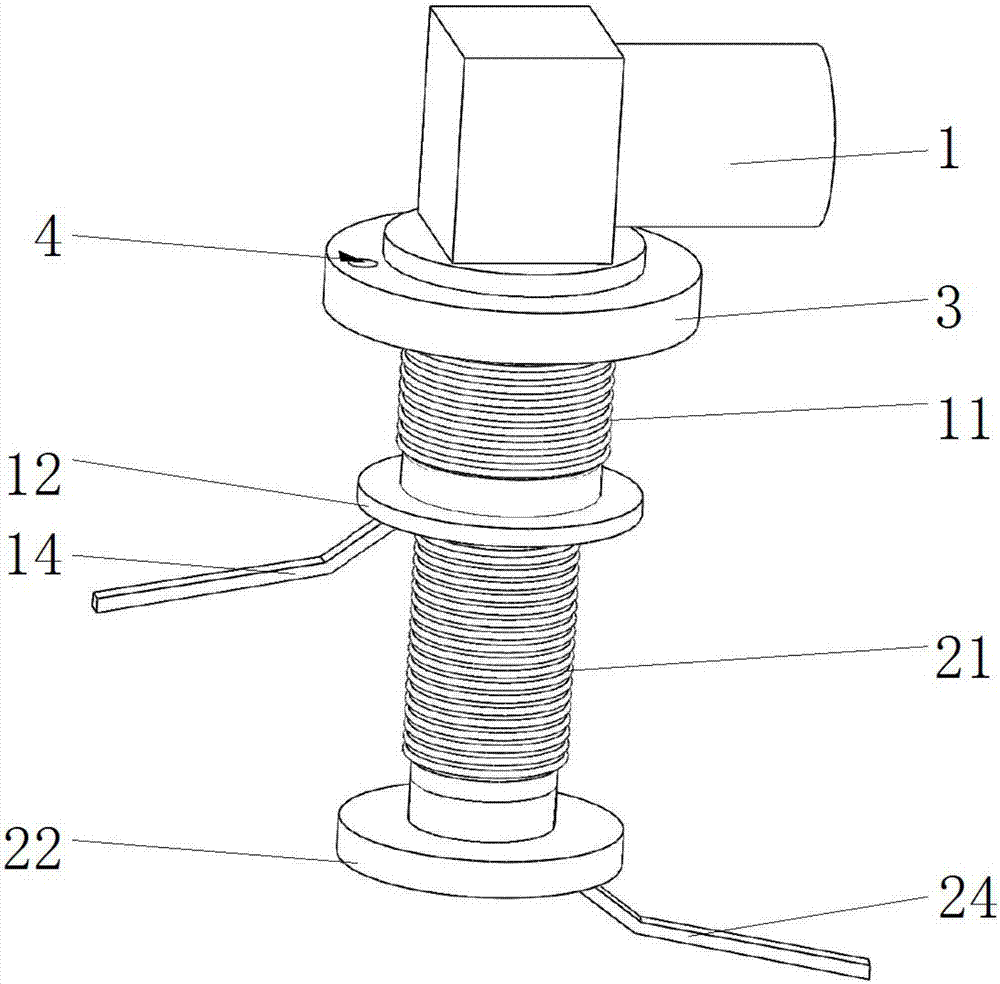

[0032] Figure 1 and figure 2 As shown, a refrigerator jacket structure for a superconducting magnet of the present invention is characterized in that, from top to bottom, it includes a refrigerator flange seat 3, a primary bellows 11, and a thermal connection with the cold shield. The first-stage flange seat 12, the second-stage bellows 21, and the second-stage flange seat 22 thermally connected to the superconducting coil; The pipe 11 is connected, and the first-stage flange seat 12 and the second-stage flange seat 22 are connected through a second-stage corrugated pipe 21 .

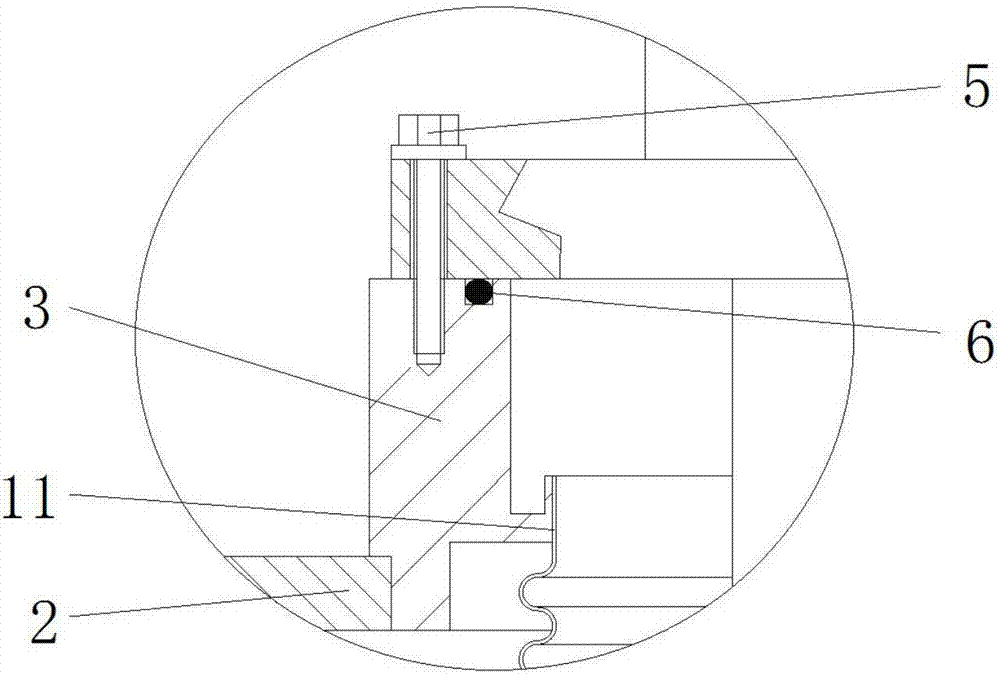

[0033] Figure 1 , figure 2 and image 3 As shown, a refrigerator jacket structure for a superconducting magnet in the present invention is characterized in that the upper end of the flange seat 3 of the refrigerator is provided with a sealing ring 6 that is sealed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com