Linear actuator

A technology of linear actuators and drive motors, which is applied to electric components, transmission devices, and mechanical energy control, etc., can solve the problems of poor actuator transmission efficiency, increased joint cost, and high noise, and achieves simple and convenient changes in stroke and connection methods. Ease of use and the effect of prolonging the life of the lead screw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

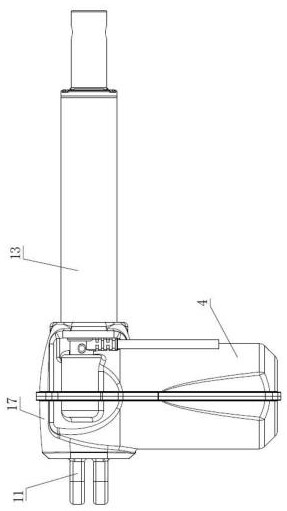

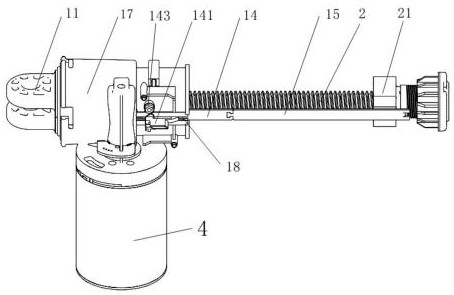

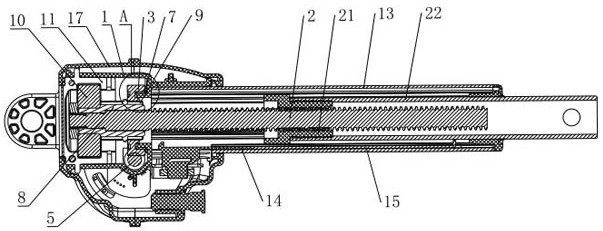

[0049] See Figure 1 to Figure 7, the present invention provides a linear actuator, including a main housing 1, a screw 2, a worm wheel 3, a drive motor 4 and a worm 5, the power output of the drive motor 4 is a worm 5, the worm 5 meshes with the worm wheel 3, and the worm wheel 3. There is a hole in the core part of the threaded mandrel 2 and the gear teeth of the outer ring meshing with the worm 5. A mounting circumferential surface 301 is provided on the contour surface of the worm gear between the hole and the gear teeth. The main housing 1 is provided with There is a centering circumferential surface 101 adapted to the installation circumferential surface 301, and the installation circumferential surface 301 and the centering circumferential surface 101 only need to be adapted, and only one is an inner cylindrical surface and the other is an outer cylindrical surface, and the worm gear 3 is installed by The circumferential surface 301 and the centering circumferential sur...

Embodiment 2)

[0063] Compared with Embodiment 1, this embodiment is equipped with a screw shaft sleeve 8 through a spline 16 at the rear of the screw shaft 2, and the inner ring of the worm wheel 3 is sleeved on the front portion of the screw shaft sleeve 8 through a key 9. 3 is in clearance fit with the screw shaft sleeve 8, and the screw shaft 2 and the worm gear 3 are fixed through the screw shaft sleeve 8, so as to avoid the tight fit between the worm gear 3 and the screw shaft 2, and prevent the worm gear 3 from directly pressing on the screw shaft 2 to cause the screw The rod 2 is bent to ensure the linearity of the screw rod 2 .

[0064] A bearing 10 is installed at the rear of the screw shaft sleeve 8, the rear end of the screw mandrel 2 is provided with an external thread, and the fastening nut 6 with internal thread is engaged with the external thread of the screw mandrel 2, and the front end surface of the fastening nut 6 is in contact with the external thread of the screw mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com