Face tooth grinding fixture

A face gear and grinding technology, which is applied in the field of auxiliary face gear grinding and end face gear grinding fixtures, can solve the problem that the roughness of the tooth surface and the shape of the tooth cannot be ground or trimmed, and the meshing accuracy of the face gear is difficult to be guaranteed. It is difficult to ensure the roughness of the end face teeth, etc., to achieve the effect of compact structure, low manufacturing cost and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

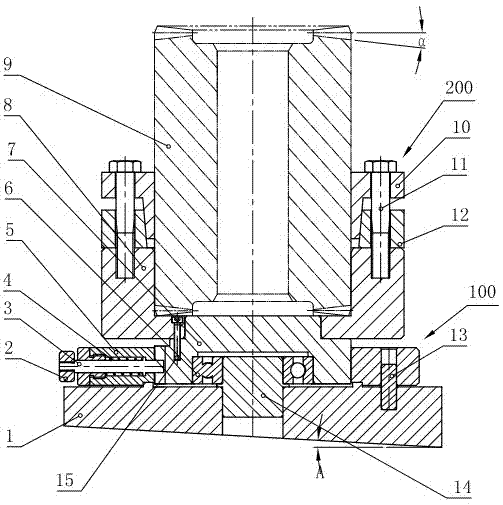

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

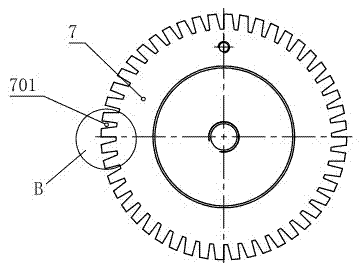

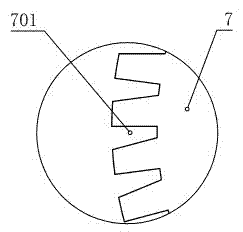

[0020] Such as figure 1 As shown, the present invention comprises a lower pallet 1, an indexing device 100 is installed on the lower pallet 1, a positioning sleeve 8 is fixedly installed on the indexing device 100, and the positioning sleeve 8 is coaxially installed with the indexing device 100 and is installed with the indexing device 100. synchronous rotation. The indexing device 100 includes a mandrel 14 fixedly installed and a fixed sleeve 5. The fixed sleeve 5 is fixedly installed on the lower supporting plate 1 through screws and cylindrical pins 13. The indexing plate 7 is rotatably set in the fixed sleeve 5. Rotatably installed on the mandrel 14 through the bearing 6, the outer circumference of the index plate 7 is provided with an index groove 701 ( figure 2 , image 3 ), the number of indexing grooves 701 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com