Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Meet roughness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

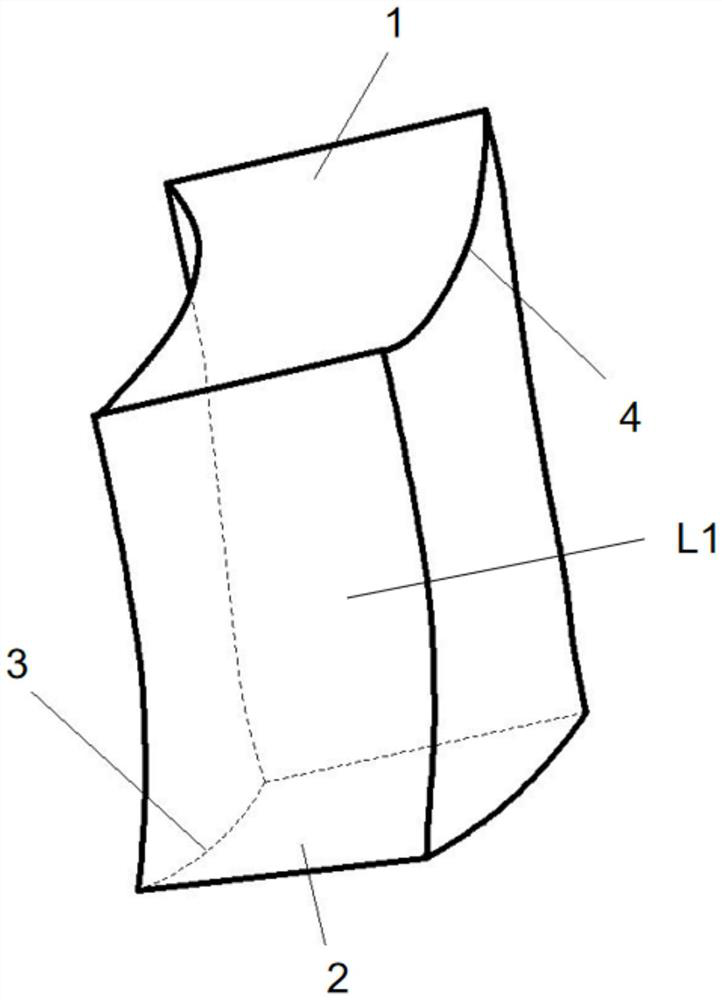

Milling method of curved surface of titanium alloy parts

The invention relates to a milling method for curved surfaces of titanium alloy parts, comprising the following steps: 1) inserting the drilled and reamed holes of the parts into the positioning pins of the auxiliary positioning fixture, and fixing them with the auxiliary positioning fixture; Install the rotary table on top; 3) Install the auxiliary positioning fixture embedded on the rotary table so that the curved surface of the part is vertical and tangent to the vertical milling cutter; 4) Rotate the rotary table to control the rotary table The rotation angle of the milling cutter can be used to mill the curved surface with the side edge of the milling cutter. The method can not only improve the machining efficiency of the curved surface of the titanium alloy part, but also greatly improve the smoothness of the curved surface of the titanium alloy part.

Owner:SHENYANG AIRCRAFT CORP

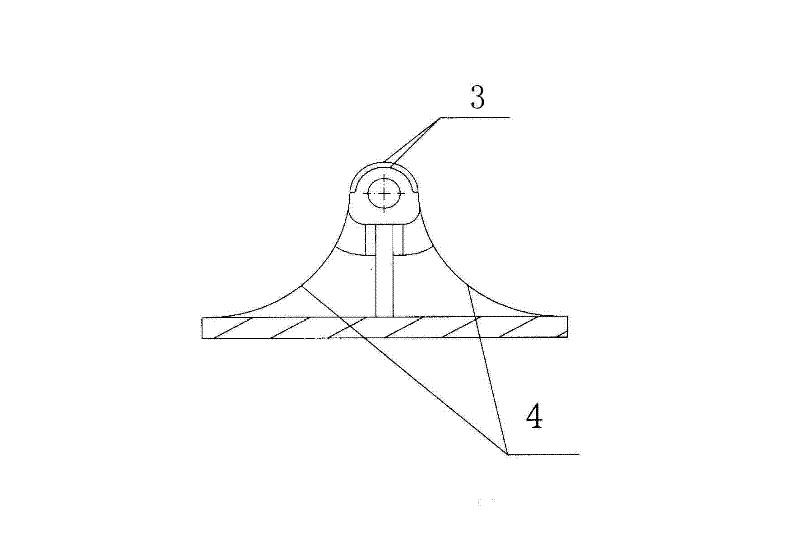

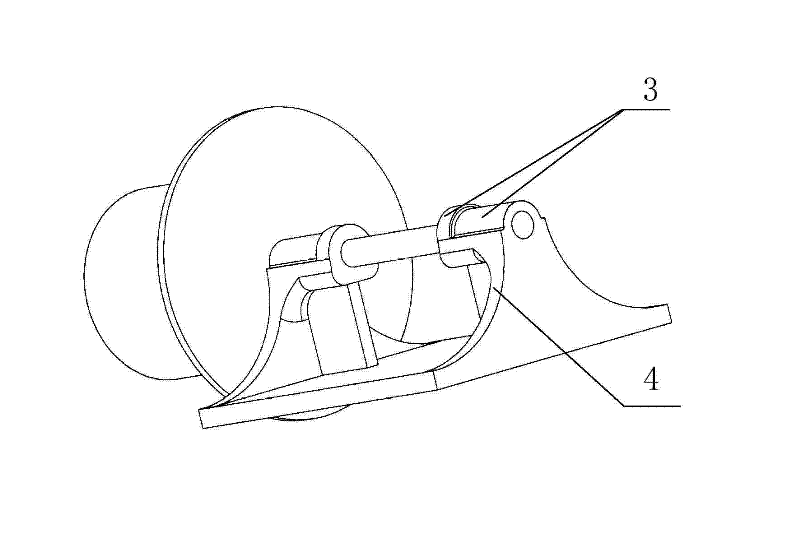

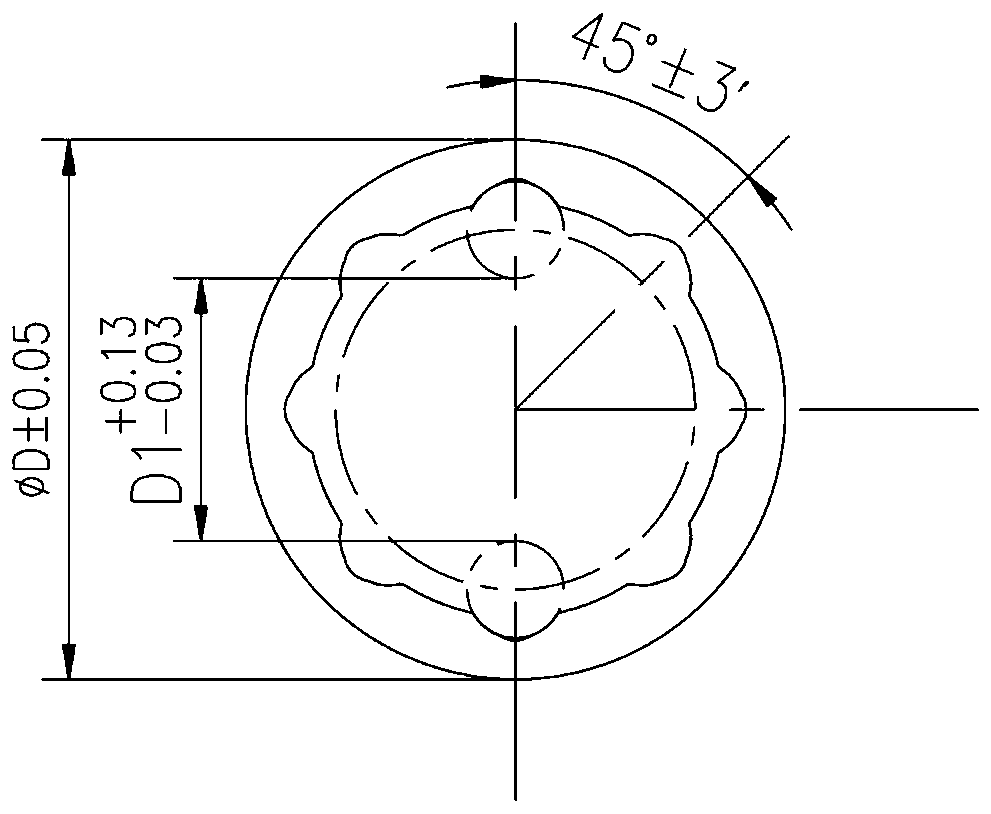

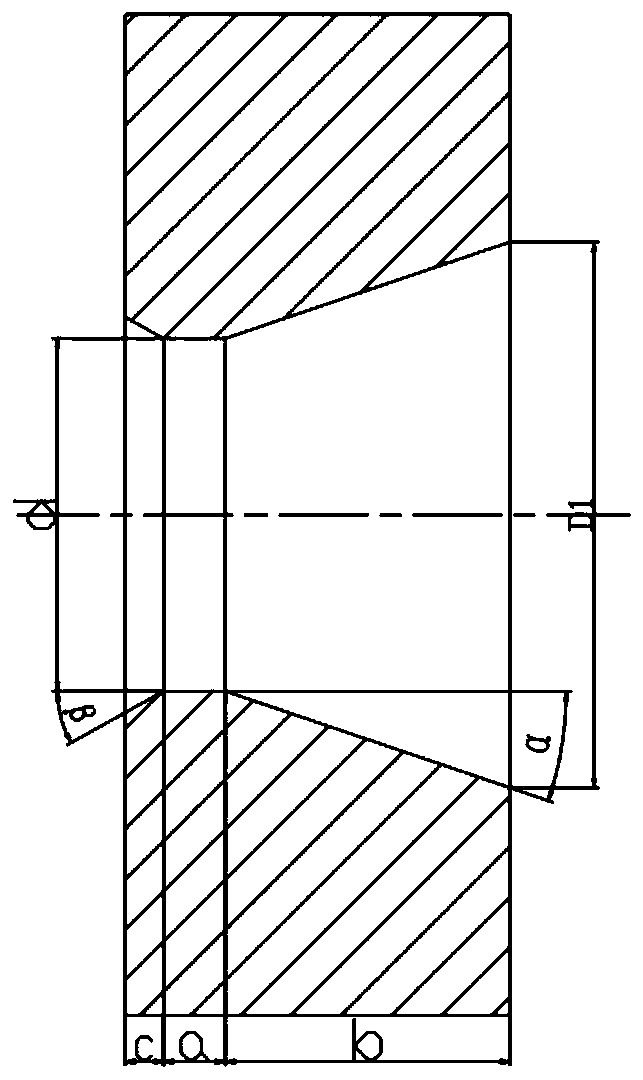

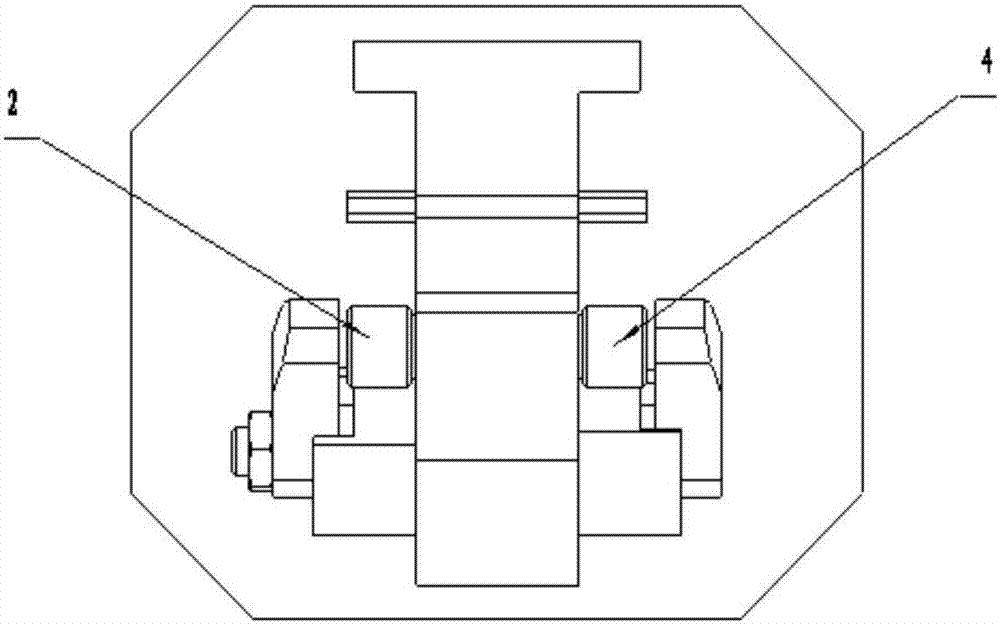

Face tooth grinding fixture

InactiveCN102248229AGuaranteed meshing accuracyExtended service lifeGear-cutting machinesGear teethLine of actionEngineering

The invention relates to a face tooth grinding fixture characterized by comprising a bottom support plate, wherein a dividing device is installed on the bottom support plate, a positioning sleeve is fixedly installed on the dividing device, the positioning sleeve and the dividing device are coaxially installed, a clamping device is arranged at the upper end of the positioning sleeve, an inclined surface is formed on the bottom surface of the bottom support plate, and the angle of the inclined surface is equal to the included angle between the root of the processed face tooth and the theoretical line of action. The face tooth grinding fixture has a simple and compact structure, low manufacturing cost and convenience in operation, can realize grinding of the face tooth only by a common tool grinder without needing extra special equipment, provides a means for grinding the face tooth, meets the requirement on the roughness of the face tooth surface, improves the tooth form accuracy, ensures the accuracy of mesh of the face tooth, prolongs the service life of the face tooth and reduces waste.

Owner:WUXI RL PRECISION MACHINERY

Coping process of coating roller

InactiveCN103551938AMeet the roughnessMeet roughness requirementsRevolution surface grinding machinesBelt grinding machinesSurface roughnessMaterials science

The invention discloses a coping process of a coating roller, and belongs to the technical field of rubber processing. The coping process comprises the process steps of rough grinding, medium grinding and fine grinding, wherein a wheel grinding machine is adopted to roughly grind to remove defects of scratches and indentations on the surface of the coating roller and eliminate delamination of the surface of the coating roller; a lathe and an abrasive belt are combined to perform the medium grinding and fine grinding; after the roughness of the surface of the coating roller reaches the range required in use, the coating roller is hermetically packed and warehoused. On the basis of the original process, the step of turning the defect layer by the lathe is removed, the process is simplified, the same technical effect can be realized, the requirement on the roughness of the surface of the coating roller is met, the waste of an adhesive layer is reduced, the use times of the roller body is prolonged, the maintenance cost is lowered, and the production efficiency is improved.

Owner:SICHUAN GUOXIN MACHINERY MFG CO LTD

Technological method for processing vehicle timber support

ActiveCN101274318AEfficient removalMeet roughness requirementsLiquid surface applicatorsCoatingsAdhesiveMetal framework

The invention relates to a vehicle framework processing technique and method, which implements the tuning, fixing, assembling and welding of a metal roughcast of a vehicle framework, the first ball blast processing, the fault detection of welded parts and the finish machining of the framework, and implements the secondary assembling and welding according to design requirements, assembles and welds the parts on each base of the framework, implements the secondary ball blast processing, removes the oil stain, roll scale and dirt on the surface of each framework, sprays undercoat and finish coat on the surface of each framework after dust removing processing, and finally assembles each framework after spraying treatment. The invention adopts the processing technique and method that implements the processing previously and then the ball blast, and finally the integral spraying and assembling, thus leading the metal framework surface to be even and smooth, reaching the requirements of surface roughness, simultaneously leading the metal surface to have certain roughness, improving paint adhesive attraction, leading the paint surface to be even and smooth, ensuring product appearance quality, lowering the laboring intensity of workers and production cost, having reasonable and reliable process flow, and improving production efficiency.

Owner:CRRC QINGDAO SIFANG CO LTD

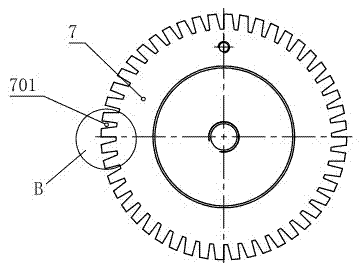

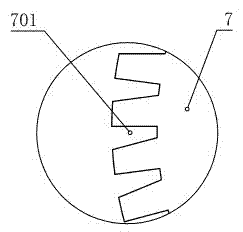

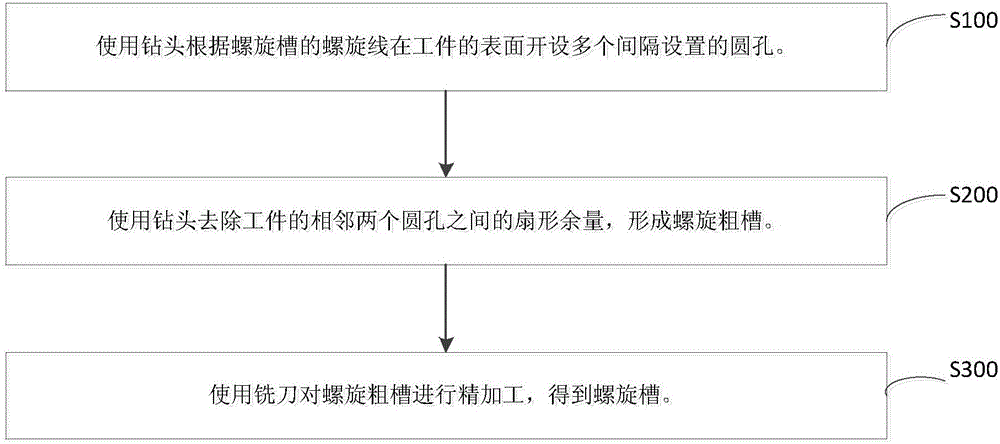

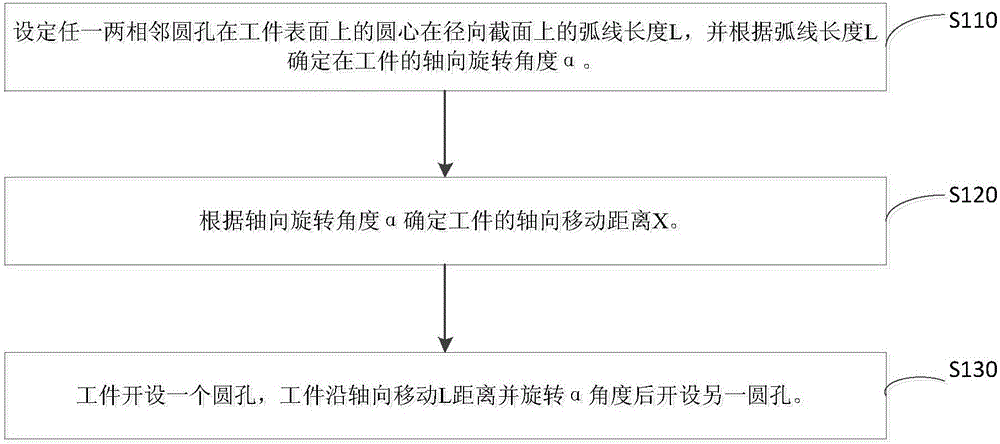

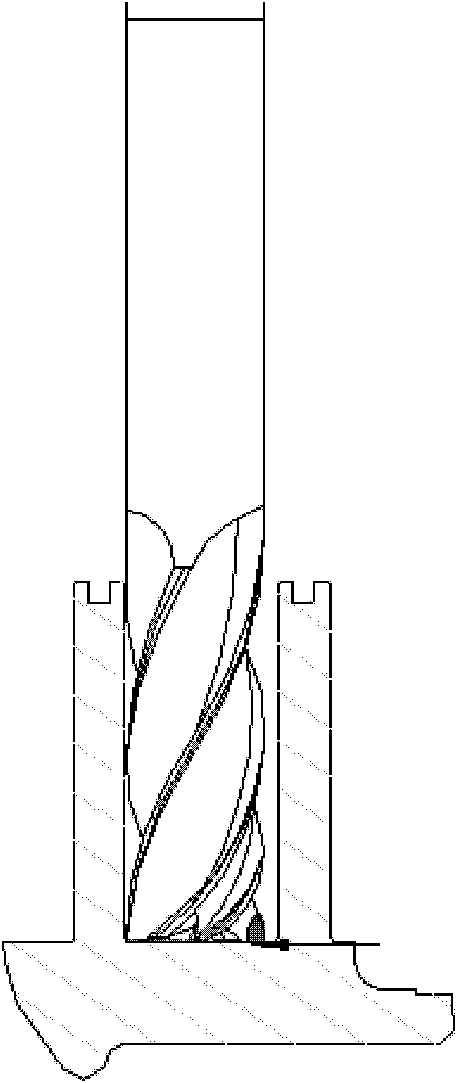

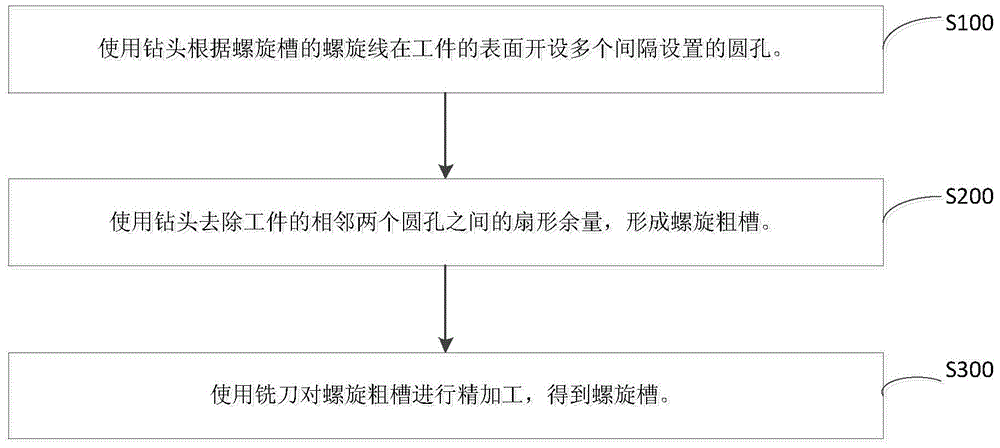

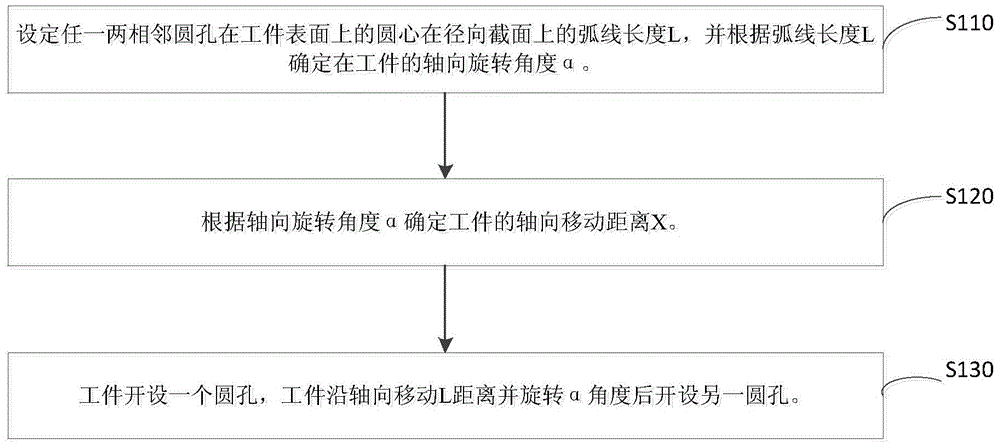

Method for machining spiral groove

The invention discloses a method for machining a spiral groove. The method includes the following steps that (1) a plurality of round holes arranged at intervals are formed in the surface of a workpiece by means of a drill according to the spiral line of the spiral groove; (2) the sector allowance between every two adjacent round holes of the workpiece is removed by means of the drill, so that a rough spiral groove is formed; (3) finish machining is conducted on the rough spiral groove by means of a milling cutter, so that the spiral groove is obtained. After most allowance is removed by means of the drill, the milling cutter is used for finish machining. The speed of the drill for machining the round holes to remove the allowance is higher than that of the milling cutter for grinding the allowance, and thus the machining speed can be increased. Besides, most allowance of the spiral groove is removed in the machining process of the rough spiral groove, and thus machining can be conducted through the milling cuter at a high speed and the machining speed of the spiral groove is further increased. The portion ground by the milling cutter is small, and therefore the abrasion loss is small, the machined spiral groove is protected against a slotting phenomenon, and the requirement for the roughness can be met. Polishing and repairing are not needed, so that the number of working procedures is reduced, and the machining speed is further increased.

Owner:AVIC POWER ZHUZHOU AVIATION PARTS MFG

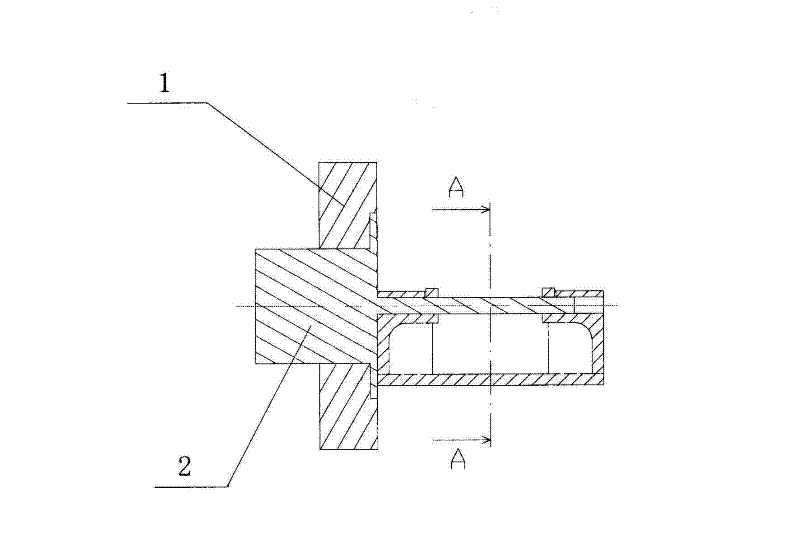

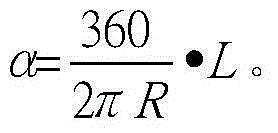

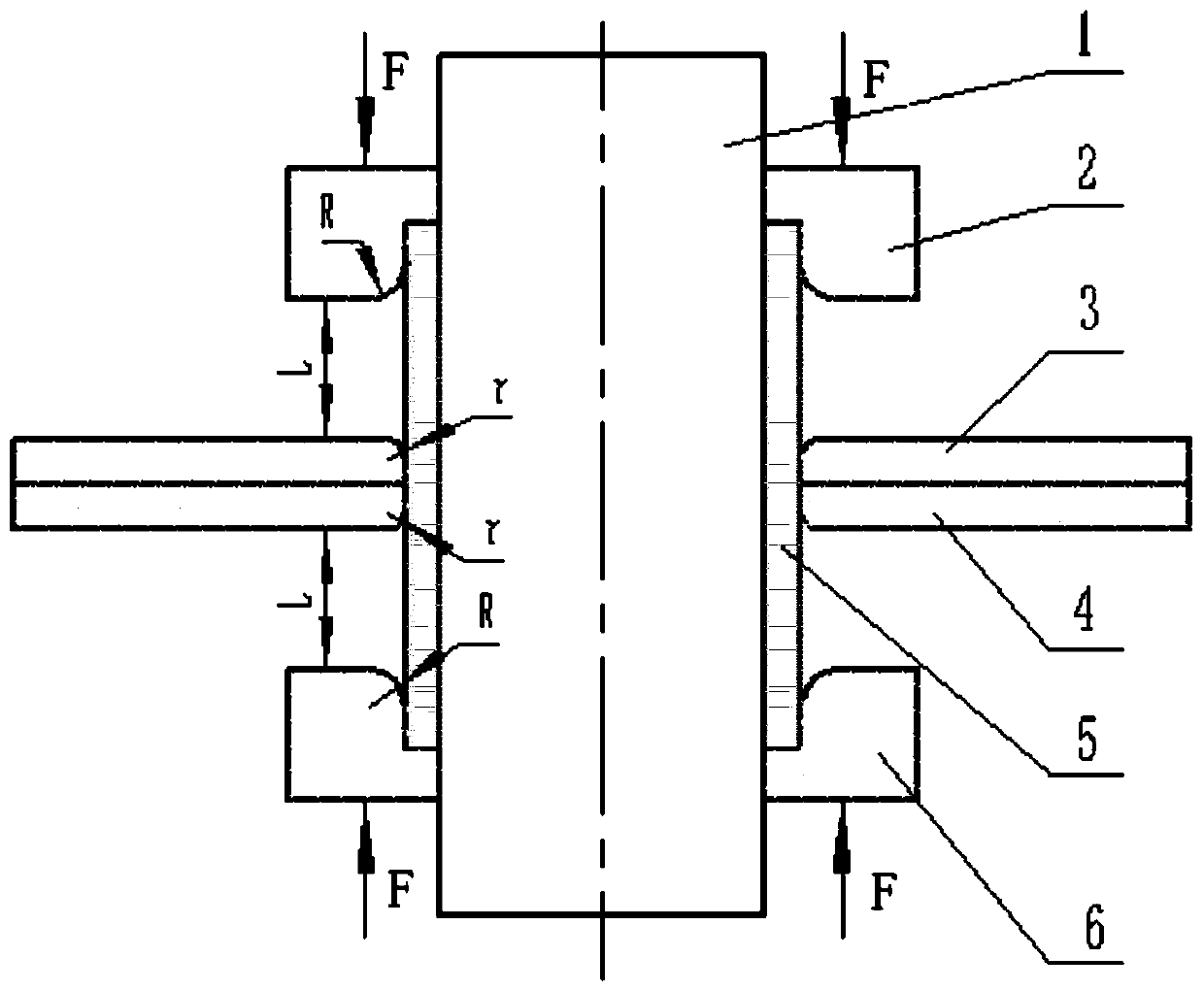

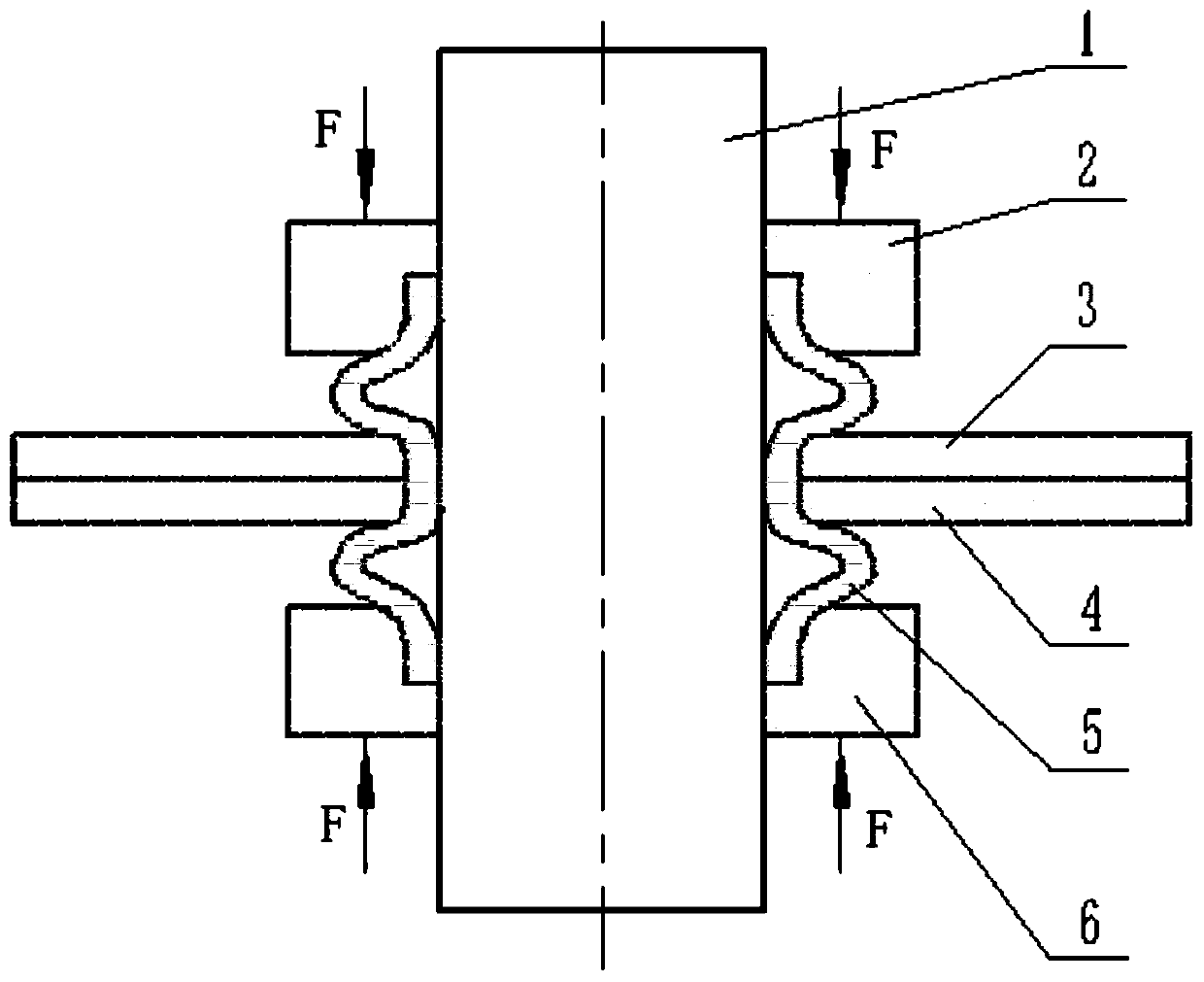

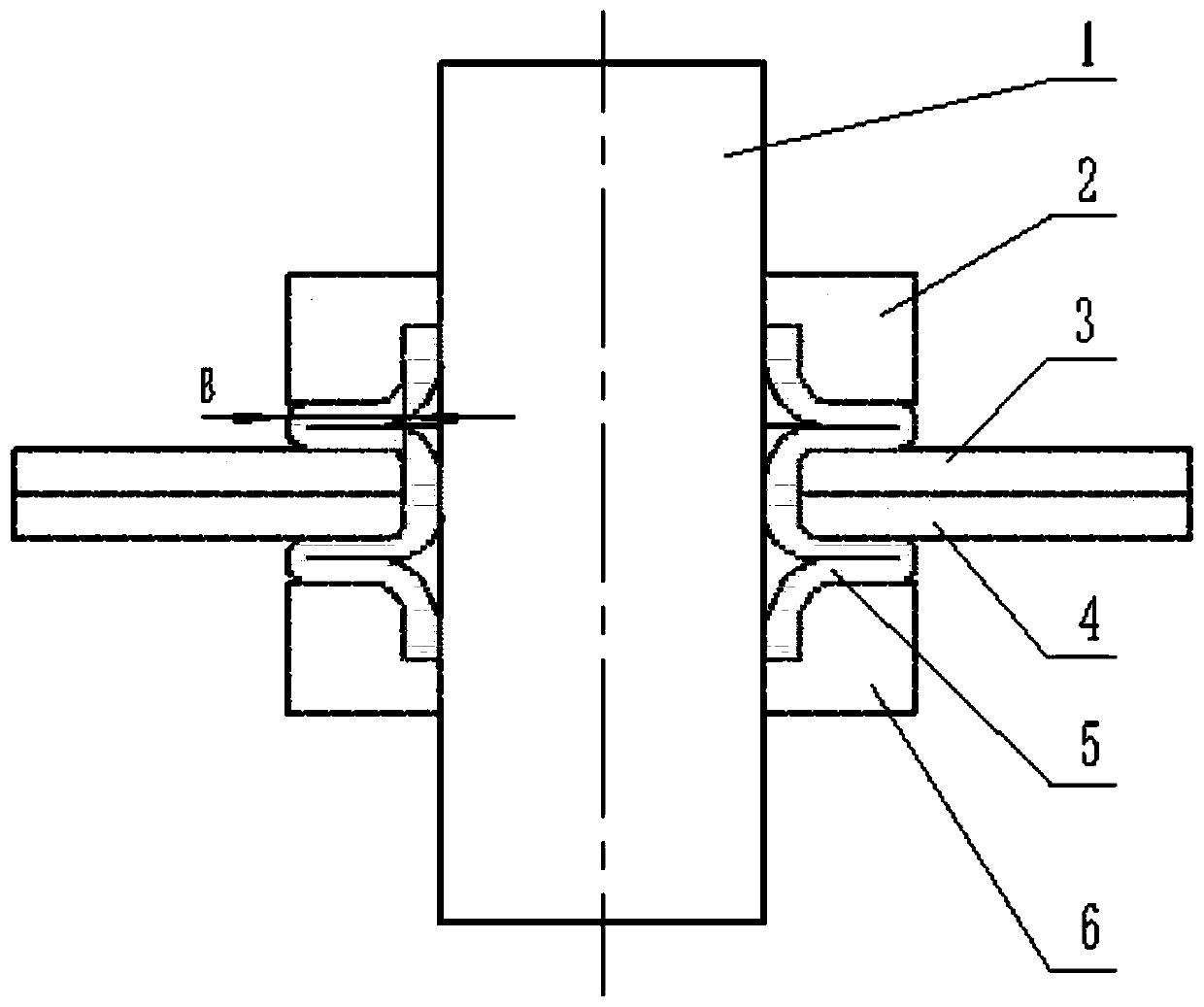

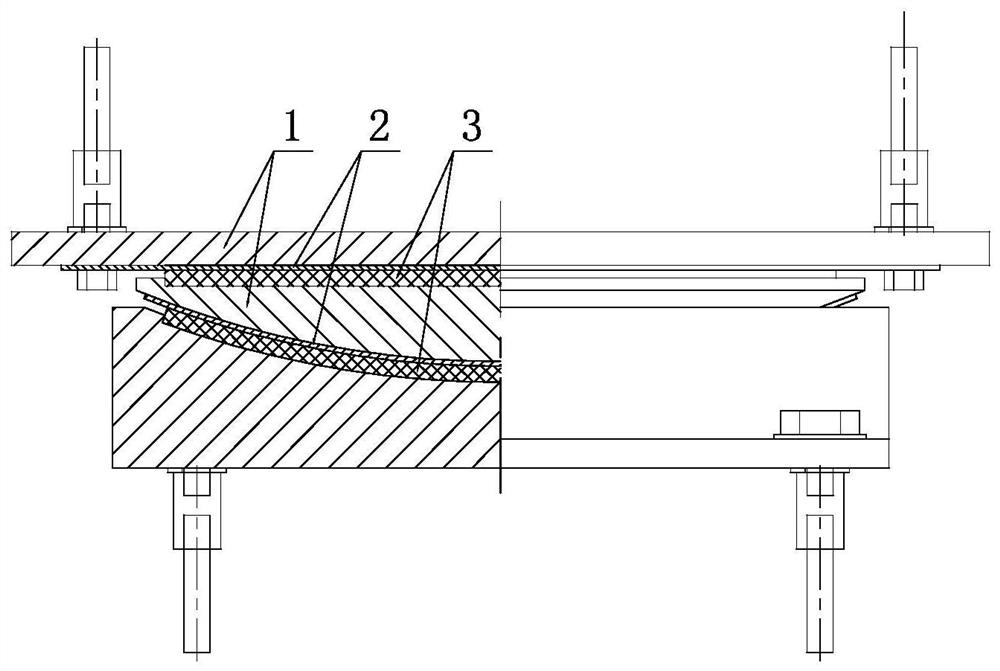

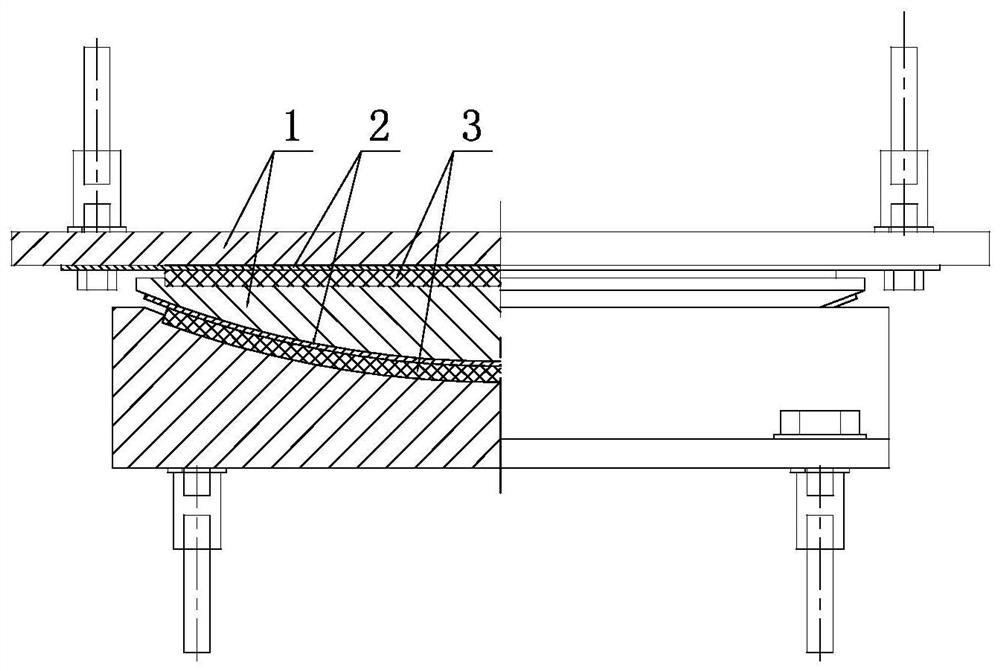

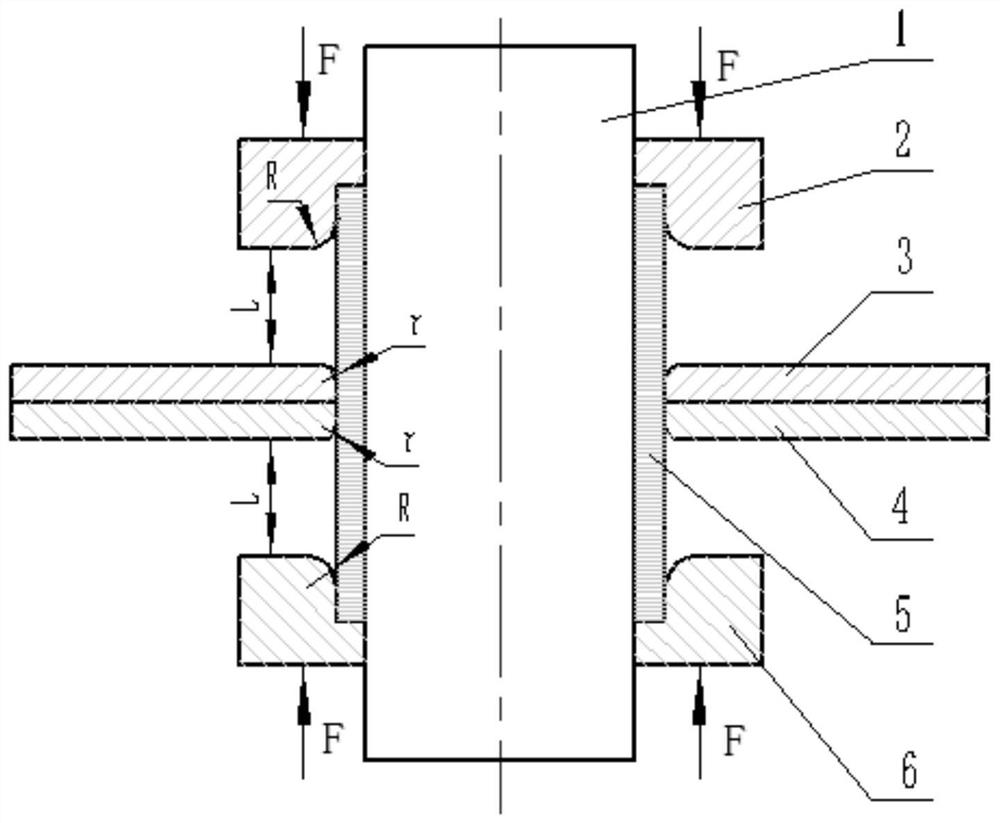

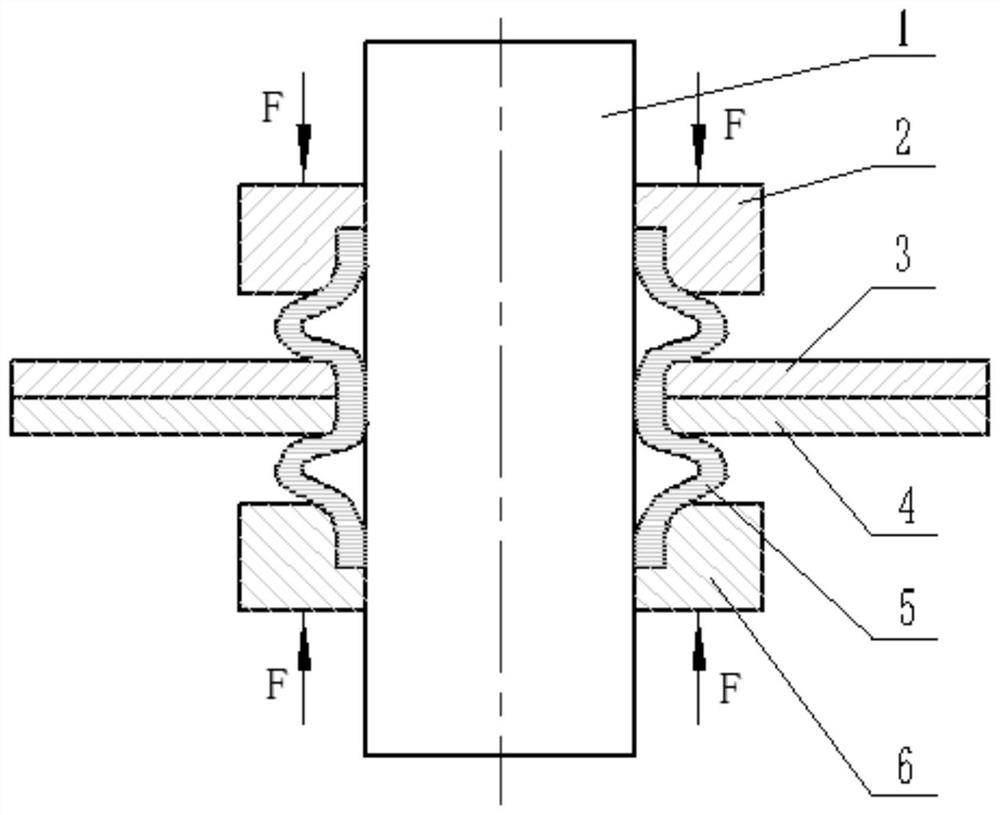

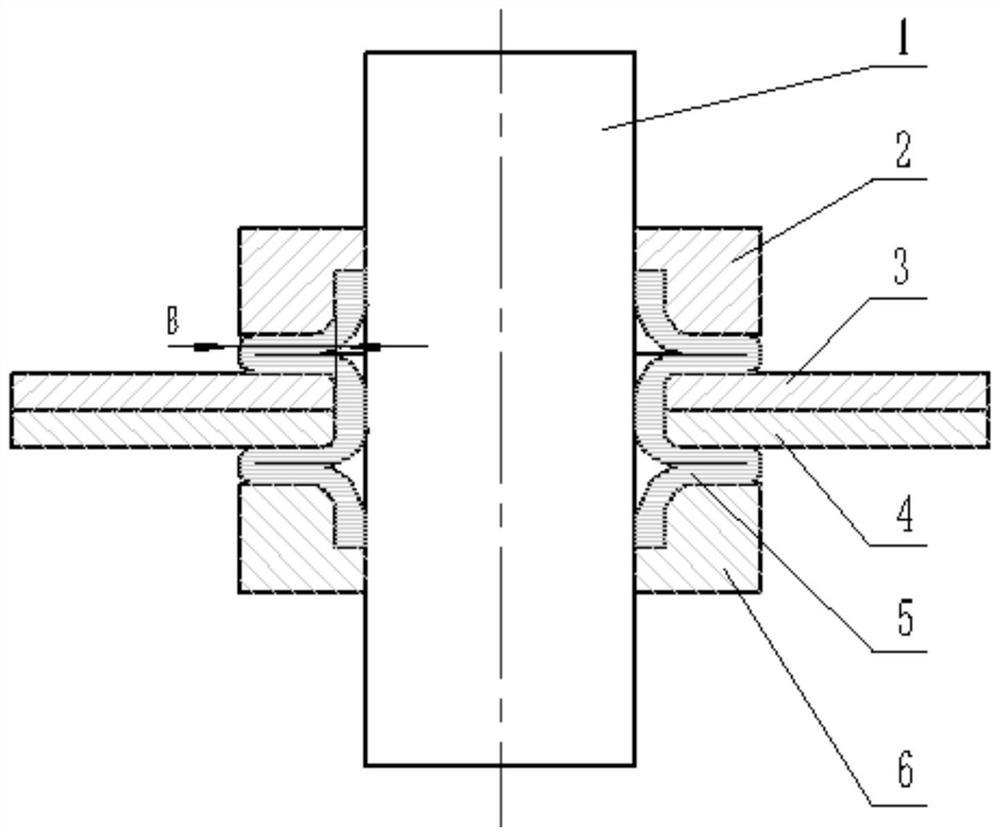

Method for achieving circular ring connection by utilizing wrinkling of metal pipes

ActiveCN110538931AHigh strengthSafe and reliable connectionShaping toolsEngineeringMechanical engineering

The invention discloses a method for achieving circular ring connection by utilizing wrinkling of metal pipes, and belongs to the technical field of material connection. The phenomenon that a connecting pipe deforms plastically under the action of force is utilized, so that the connecting pipe is wrinkled in a non-constraint area, the wrinkles are further compacted so as to achieve the plastic connection between two metal rings. After plastic deformation of the connecting pipe, the strength of the connection part can be enhanced due to deformation strengthening, so that the connection is safeand reliable; and the number of preparatory steps is few, the operation is simple and convenient, the whole connecting process is green and pollution-free, and the operation is simple, convenient andefficient.

Owner:SHAANXI UNIV OF SCI & TECH

End mill and method for milling compressor scroll by using the same

InactiveCN102837053AImprove quality requirementsAvoid problemsMilling cuttersMilling equipment detailsHexagonal boron nitrideMilling cutter

The present invention relates to an end mill, which comprises a cutter body and cutter teeth, and is characterized in that the cutter teeth are multiple blade helix blade, and the hard alloy blade and the polycrystalline hexagonal boron nitride blade are arranged at intervals, such that a side wall and a bottom surface of a workpiece can be simultaneously milled. During a production process, with the end mill of the present invention, production cost can be reduced, and products with excellent quality can be obtained. The present invention further provides a method for milling a compressor scroll part by using the end mill. The method mainly comprises the following steps: adopting a corrugated rough milling cutter to carry out semi-finish milling on a machined compressor scroll part; adopting the end mill to carry out finish milling on the semi-finish milled compressor scroll part; and completing a milling process of the compressor scroll part.

Owner:DANFOSS (TIANJIN) CO LTD

Turning method of titanium target assembly

InactiveCN112404461AReduce abnormal discharge phenomenonReduce wearWorkpiecesTurning toolsTitaniumIngot

The invention relates to a turning method of a titanium target assembly. The turning method comprises the following steps of cutting off a titanium ingot for plastic deformation; welding an obtained titanium target material blank with a back plate to obtain a titanium target material assembly crude product; then, sequentially performing rough turning and fine turning on a sputtering surface of thetitanium target blank in the obtained titanium target assembly crude product to obtain a titanium target material assembly; and wherein the to-be-machined allowance of the finish turning is 0.4-0.6mm, and the finish turning is divided into at least two times of turning. According to the turning method of the invention, a machining mode of sequentially carrying out rough turning and finish turningis adopted, the to-be-machined allowance of the finish turning is further limited, and turning is carried out in at least two times, so that the sputtering surface of the titanium target assembly canmeet the roughness requirement, the planeness can be guaranteed to be smaller than 0.1mm, surface stress is prevented from remaining, and the abrasion speed of a blade can be reduced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

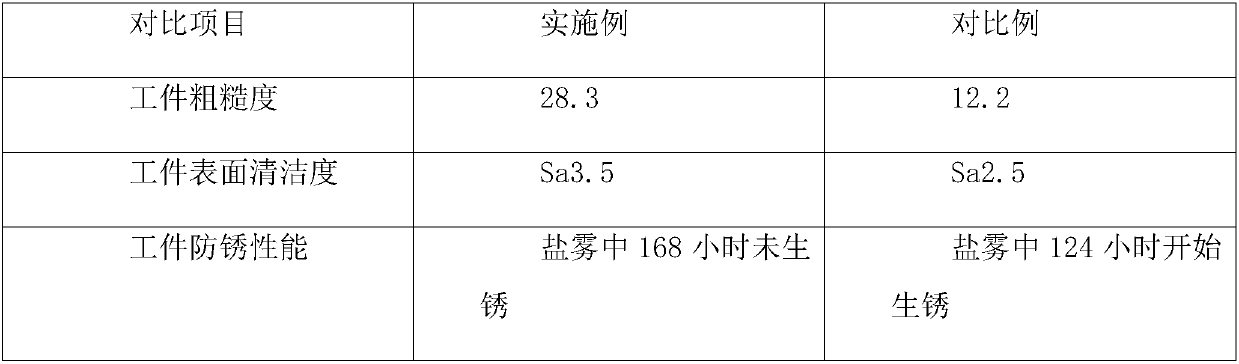

Shot blasting treatment method for rust removal and rust prevention of steel plate

InactiveCN107791156AGuaranteed costGuaranteed shot blasting effectPretreated surfacesAbrasive machine appurtenancesSheet steelTime control

The invention discloses a shot blasting treatment method for rust removal and rust prevention of a steel plate, and relates to the field of shot blasting. The shot blasting treatment method comprisesthe steps of S1, measuring the thickness of the steel plate; S2, carrying out degreasing treatment; S3, carrying out water washing, draining and drying; S4, carrying out shot blasting on the steel plate, adjusting cooperation of a current of a shot blasting machine and time according to the thickness, measured in the S1, of the steel plate, if the thickness of the steel plate is smaller than 3 mm,prohibiting treatment; if the thickness of the steel plate is 3 mm to 3.5 mm, controlling the current to be 15 A to 20 A, and controlling the shot blasting time to be 60 s to 70 s; if the thickness of the steel plate is 3.5 mm to 4 mm, controlling the current to be 15 A to 20 A, and controlling the shot blasting time to be 70 s to 90 s; and if the thickness of the steel plate is larger than 4 mm,controlling the current to be 20 A to 30 A, and controlling the shot blasting time to be 80 s to 100 s; S5, cleaning shots on the surface of a workpiece through a rolling brush or scraper; S6, checking the workpiece; and S7, spraying antirust paint to the surface of the qualified steel plate. According to the shot blasting treatment method, the current and time during shot blasting treatment areadjusted according to the thickness of the steel plate, resources are saved while the shot blasting effect is guaranteed, and cost is reduced.

Owner:江苏飞腾铸造机械有限公司

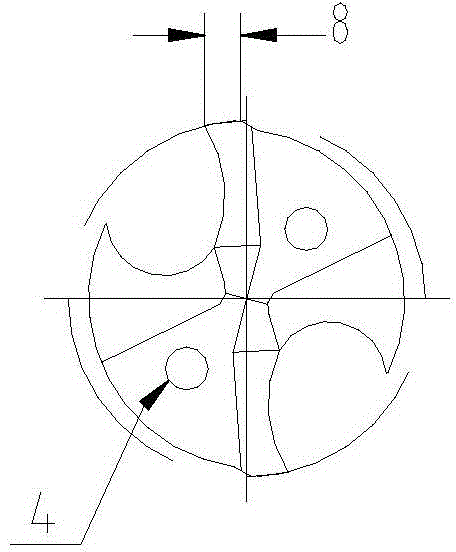

Solid carbide self-centering inner-cooling deep-hole twist drill for ABS valve body

InactiveCN104690342ACompatible with crumbsTaking into account the ability of chip removalTransportation and packagingTwist drillsCarbideEngineering

The invention relates to a solid carbide self-centering inner-cooling deep-hole twist drill for an ABS valve body. A cutter body and a handle part are coaxial cylinders of which the same central axis serves as the center; a spiral chip groove is formed in the cutter body; a solid part except the chip groove is a cutter back; two spiral edge strips are arranged on the cutter back; an inner-cooling hole which spirally penetrates through the cutter body is formed in the front end surface at the head of the cutter body; the intersection line of the chip groove and the cutter back in the radial direction forms an end edge; the end edge is in a double-vertex-angle double-flank-face form; the center position at the 1 / 4-1 / 3 effective edge diameter of the cutter body is a central vertex angle, and the rest are cutting vertex angles; a spiral face of the chip groove, formed by using a cutting edge as a generatrix, is a rake face; the ratio of the axial groove length of the chip groove to the radial effective edge diameter of the cutter body is 10-20; a circular arc of the chip groove is formed by smoothly connecting two circular arcs with different curvature radiuses. The efficient machining and the once feed competition are achieved, and peck drilling is eliminated; the solid carbide self-centering inner-cooling deep-hole twist drill has self-centering capacity, and the requirement on the roughness of an oil way hole of the ABS valve body is met.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

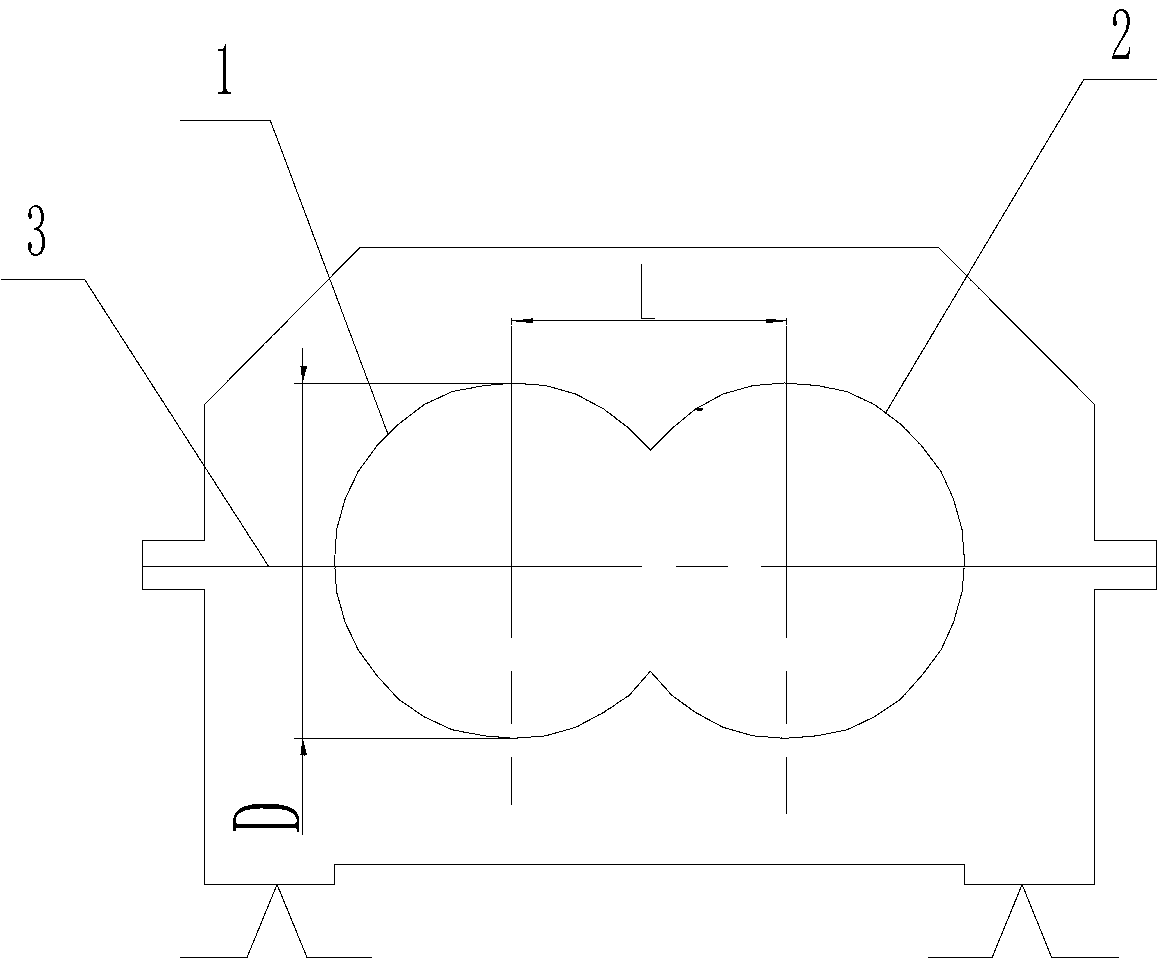

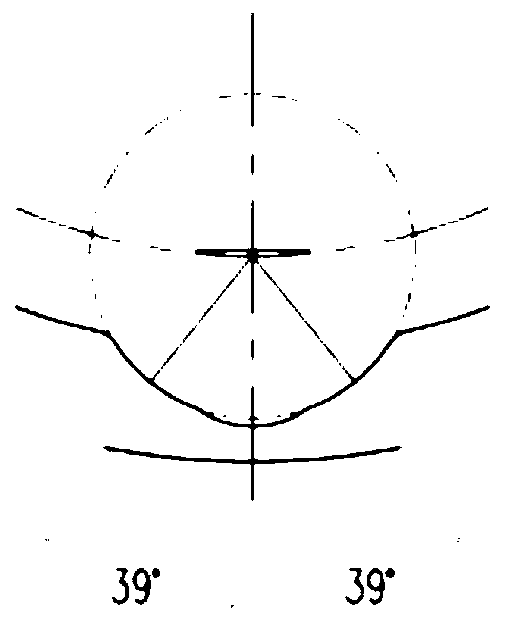

Method for processing large-diameter figure-eight-shaped hole series

InactiveCN102794472AHigh dimensional accuracyImprove shape and position accuracyEngineeringPerpendicular direction

The invention discloses a method for processing a large-diameter figure-eight-shaped hole series. The hole series comprises a first hole and a second hole which are crossed in parallel to form a figure-eight shape and are cut by a boring tool in a vertical boring way, and the range of a cutting edge angle Alpha of the boring tool is not less than 72 DEG and not more than 90 DEG; and the method comprises the steps as follows: 1), placing workpieces onto a vertical boring worktable and enabling the front end surfaces of the workpieces to face up, and enabling the shaft lines of the first hole and the second hole to be in the perpendicular direction and parallel to a vertical boring spindle; 2), aligning the shaft center of the first hole by a dial indicator and enabling the front end surfaces of the workpieces to be perpendicular to the vertical boring spindle, clamping and fixing the workpieces; 3), carrying out pre-boring, semi-fine boring and fine boring on the first hole in sequence, and blowing away cuttings by compressed air; 4), aligning the shaft center of the second hole on the basis of the shaft center of the first hole; 5), carrying out pre-boring, semi-fine boring and fine boring on the second hole in sequence, and blowing away the cuttings by the compressed air; and 6), deburring, chamfering, and finishing the workpieces. According to the method, the processing precision and the working efficiency are improved; and the method is suitable for cutting the large-diameter figure-eight-shaped hole series in large rotary screw rods or other large workpieces.

Owner:CSSC MES DIESEL

Forming method for precast concrete member bonding surface

InactiveCN108638300ALow priceWide range of specificationsMouldsMould auxillary partsPrecast concreteAir bubble

The invention relates to a forming method for a precast concrete member bonding surface. The method comprises the following steps that a concrete member is precast; an air bubble film is attached, specifically, the air bubble film is mounted on the inner surface, corresponding to the bonding surface of the precast concrete member, of a template; and the air bubble film is peeled off, specifically,after the template is dismounted, the air bubble film is peeled off, and concave pits which are consistent with the air bubble film in size and arrangement rule are formed in the precast concrete member bonding surface. According to the technical scheme, through the forming method for the precast concrete member bonding surface, the roughness requirement for the precast concrete member bonding surface is met through the air bubble film, the construction process is simple and convenient, the surface quality is good, in addition, materials of the air bubble film are easy to take, the price is low, and the advantages of customization and easy demolding are achieved.

Owner:NANJING UNIV OF TECH

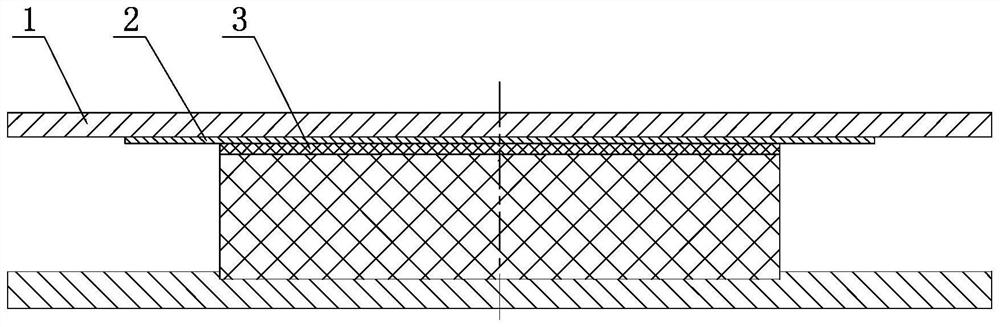

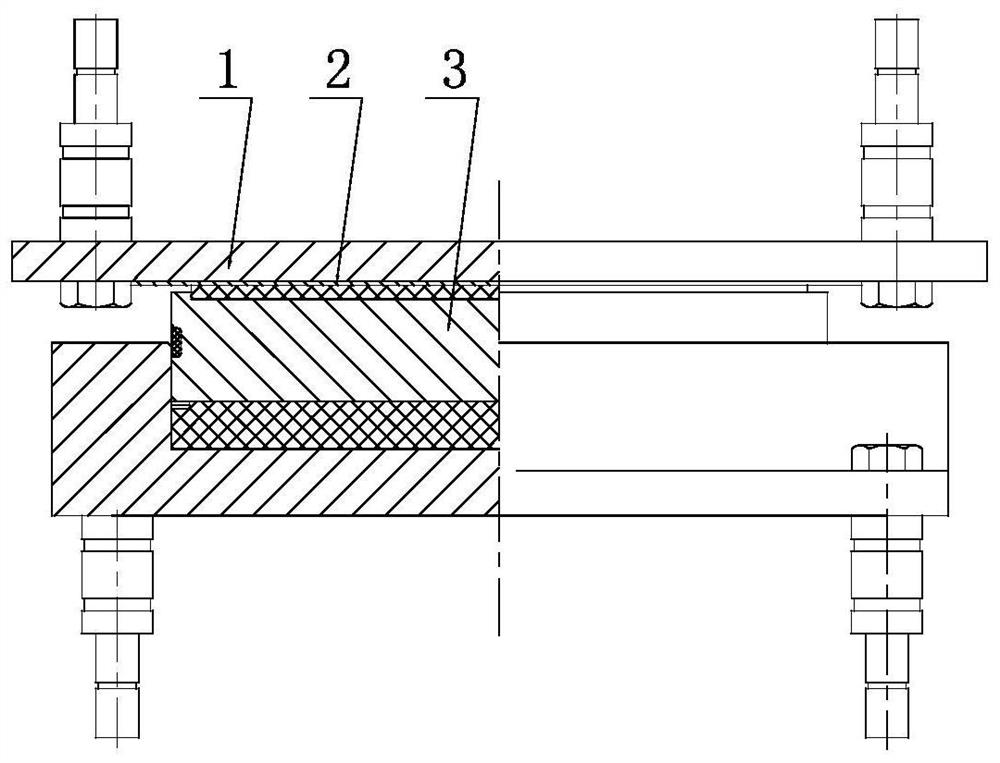

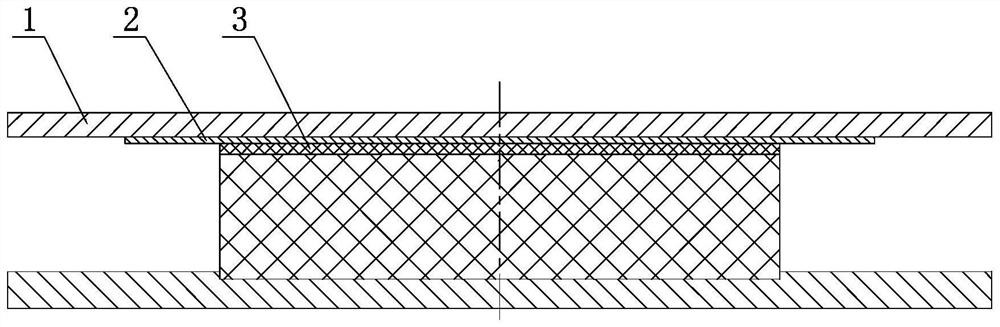

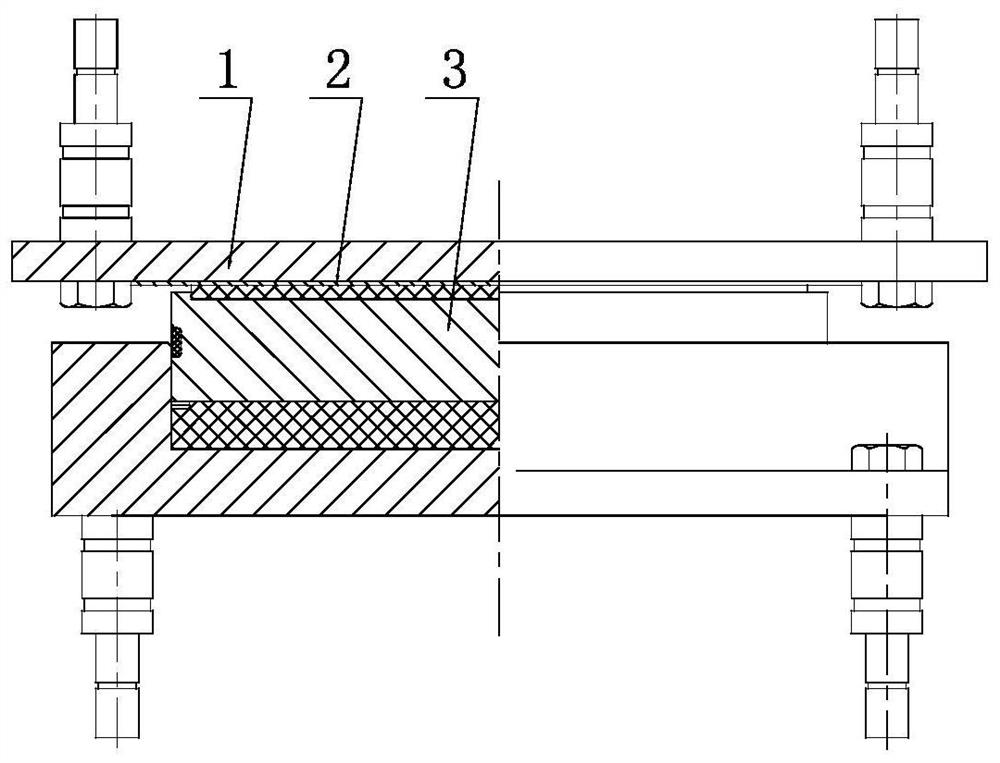

Bridge or house building support friction part convenient to rotate or slide and preparation method of bridge or house building support friction part

PendingCN113279327AReduce pollutionImprove processing efficiencyBridge structural detailsMetallic material coating processesArchitectural engineeringHouse building

The invention belongs to manufacturing of bridges or building supports, and particularly relates to a bridge or house building support friction part convenient to rotate or slide and a preparation method of the bridge or house building support friction part. The bridge or house building support friction part comprises an organic material sliding plate and a friction surface opposite to the organic material sliding plate; the friction surface comprises a base body and an anti-rust wear-resistant layer, and the anti-rust wear-resistant layer is arranged on the outer surface of the base body in a cladding mode. The problems that in the prior art, adjacent structural layers are not tightly matched, and the manufacturing cost is high are solved, and the beneficial effects that the adjacent structural layers are tightly matched, environmental pollution is reduced, and the machining efficiency is improved are achieved.

Owner:HENGSHUI ZHONGJIAO XINDE ENG RUBBLE & PLASTIC

Leather substance making-replica retro process

InactiveCN108531669AStrong penetrating powerTo achieve the old effectSpecial leather manufactureLeather surface mechanical treatmentSaline waterRoom temperature

The invention discloses a leather substance making-replica retro process. The leather substance making-replica retro process comprises the following steps that firstly, a leather substance purchased from the market is soaked in saline water with the mass fraction of 20-30% for 1-2h; the leather substance is taken out and subjected to liquid dropping for 5-10min; then the surface of the leather substance is rinsed with a low-concentration ethanol solution and subjected to liquid dropping after rinsing; a grinding machine is used for grinding the leather substance, and a retro agent with the temperature of 40-50 DEG C is sprayed on the surface of the leather substance while grinding; after grinding, the leather substance is air-dried at room temperature; then the leather substance is coloredas needed; and finally the leather substance is ground and polished. The leather substance making-replica retro process is simple and easy to operate, and treating fluid used is safe and environmentally friendly and is suitable for industrial production.

Owner:郭小仙

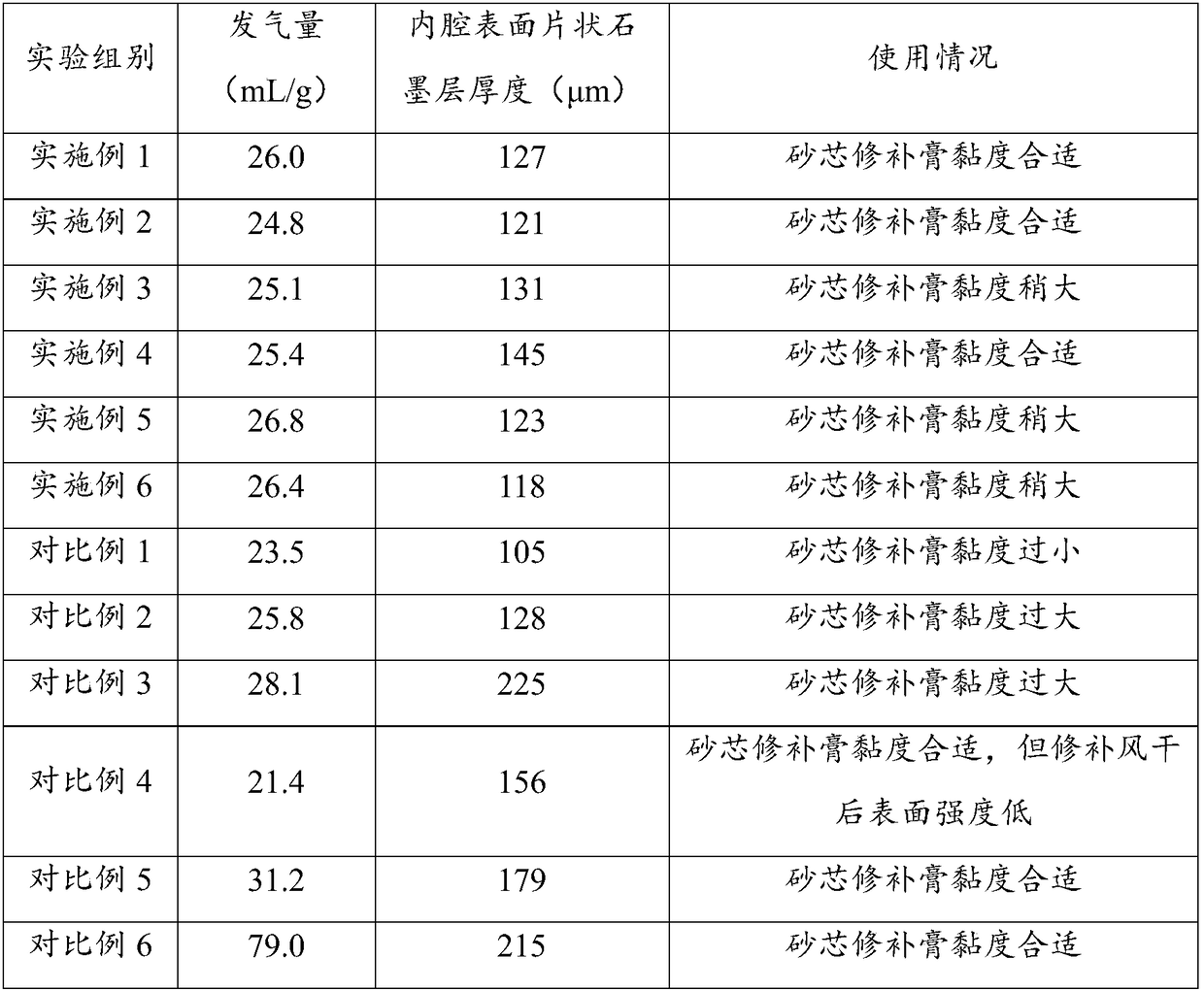

Sand core repair paste, preparation method thereof and sand core

PendingCN109014062ALow gas productionModerate viscosityFoundry mouldsFoundry coresViscosityMaterials science

The invention provides sand core repair paste, a preparation method thereof and a sand core, and relates to the technical field of casting core manufacture. The sand core repair paste includes first paint, second paint, bentonite and other raw materials. By means of synergetic cooperation of the raw materials mentioned above, the prepared sand core repair paste can have a low gas evolution amountand is moderate in viscosity and convenient to operate; and by using the sand core repair paste mentioned above for sand core repair, the defects of pasted sand, pores and the like in inner cavities of castings can be effectively overcome, and the problems that due to existing sand core repair paste, the gas evolution amount of the sand core is prone to be increased and the pasted sand, the poresand the other defects are caused to the inner cavities of the castings are solved. The invention further provides the preparation method of the sand core repair paste mentioned above. The preparationmethod is simple in process, easy to operate and suitable for industrial production. The invention further provides the sand core. The sand core is repaired through the sand core repair paste mentioned above. An inner cavity of the obtained sand core is smooth, the requirement of manufacturers for roughness of the inner cavity is met, the defects of the pasted sand and the pores in the inner cavities of the castings are overcome, and the overall quality of the sand core is improved.

Owner:西峡县众德汽车部件有限公司

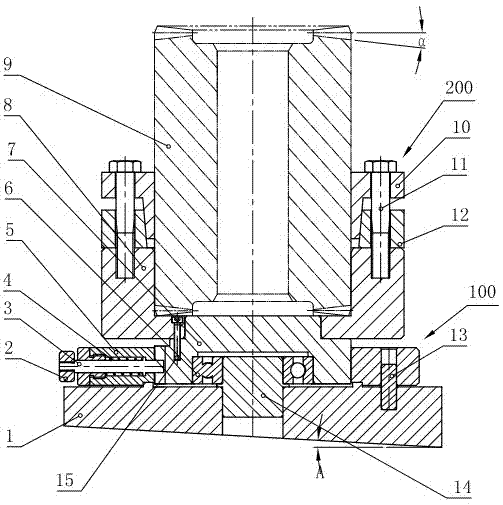

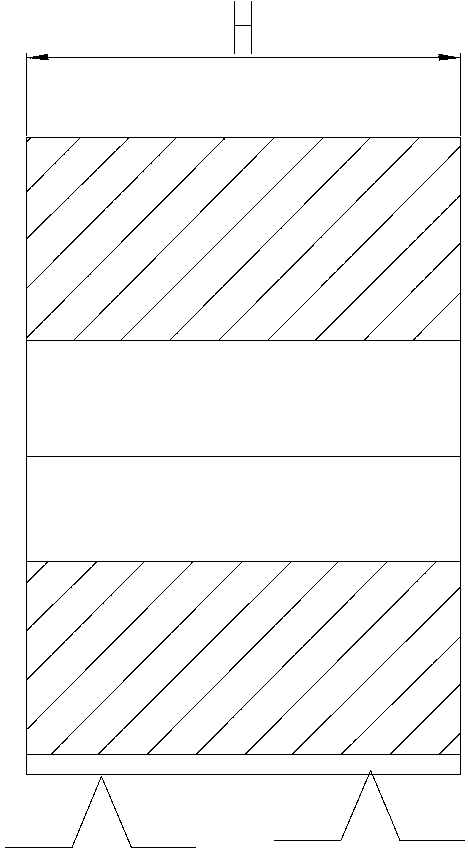

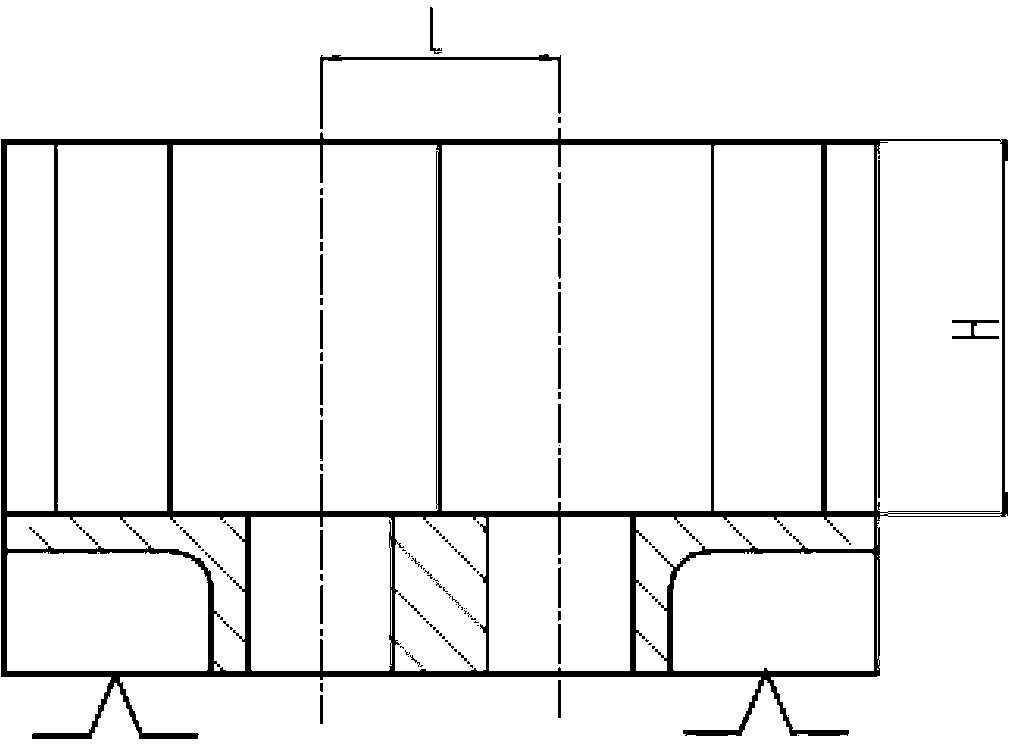

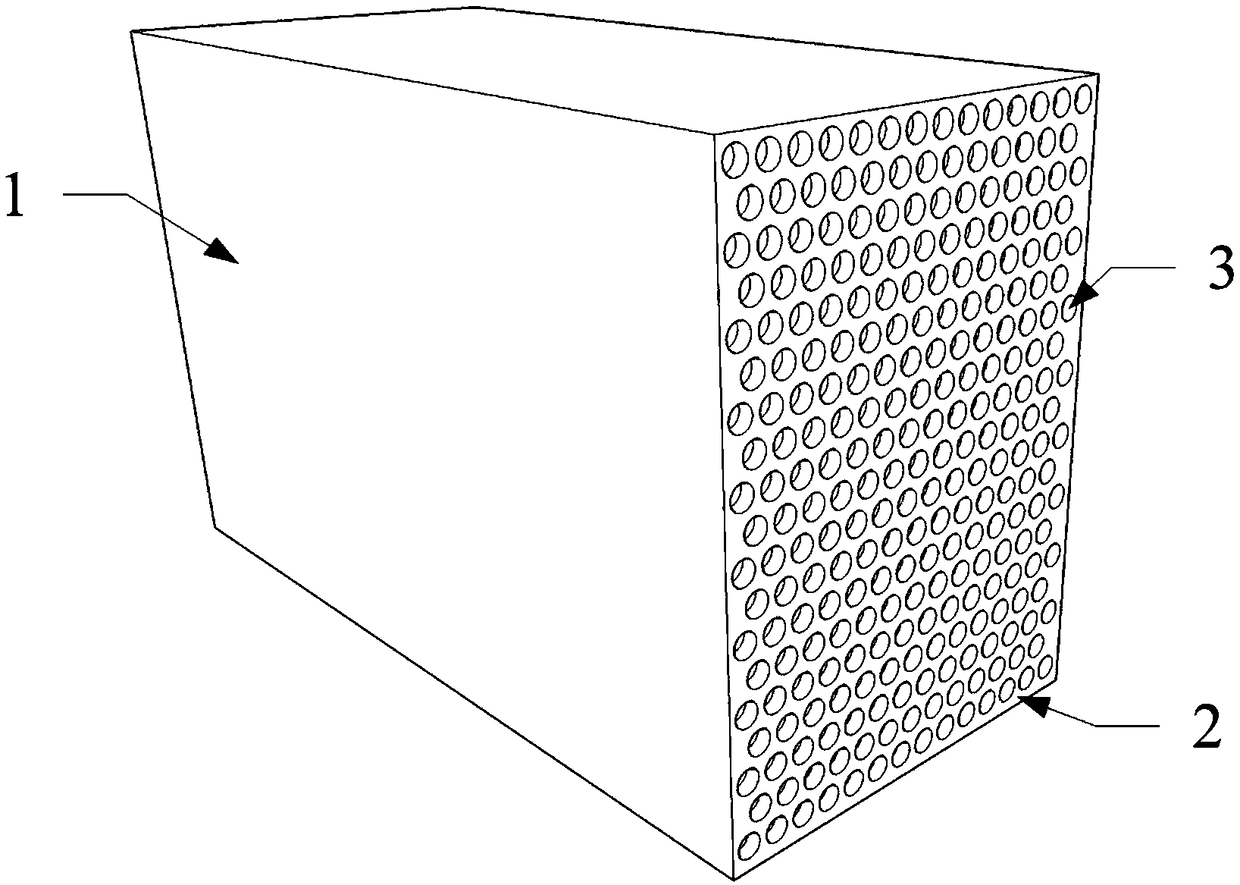

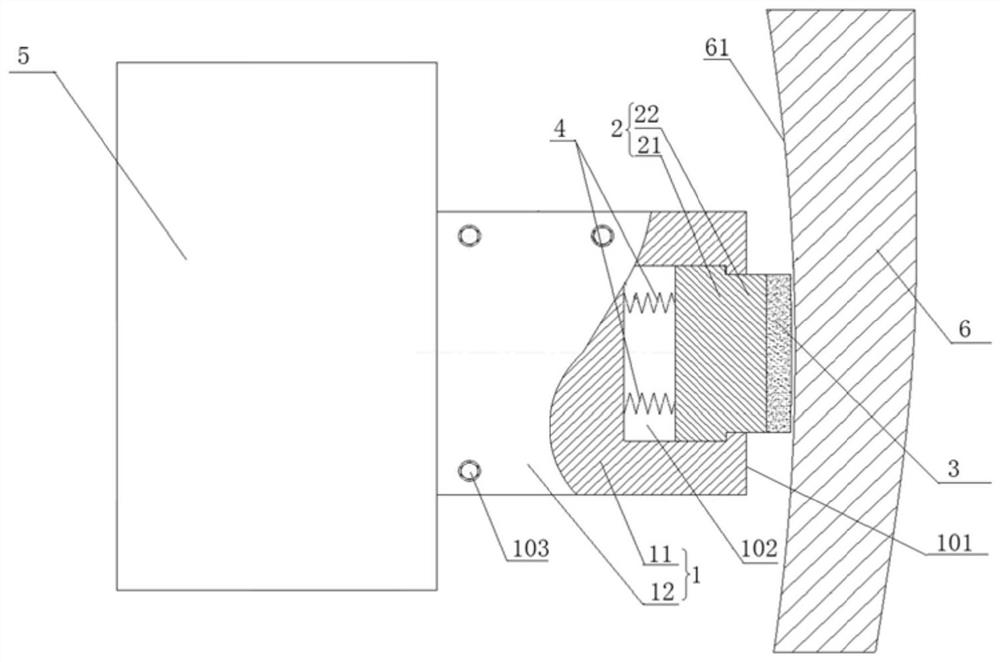

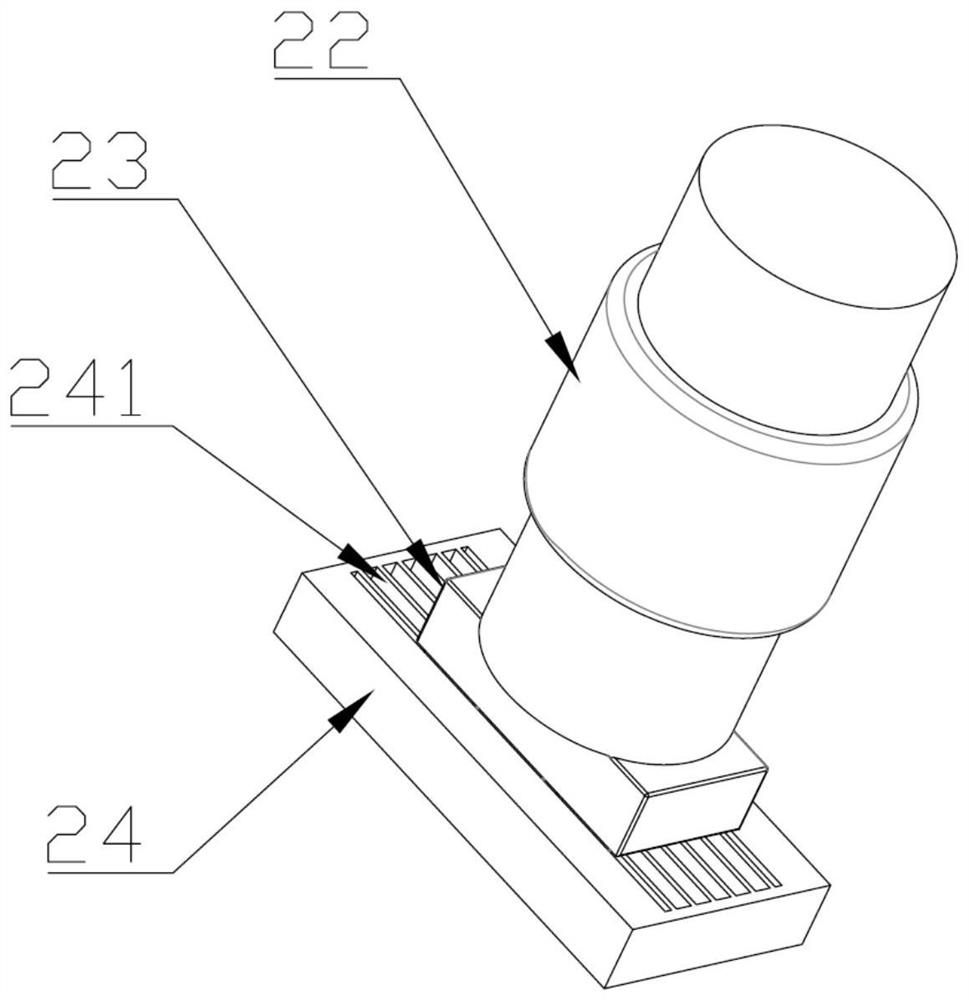

Vertical-lathe polishing tool and integrated machining method for improving roughness for large-diameter inner hole

The invention relates to a vertical-lathe polishing tool and an integrated machining method for improving roughness for a large-diameter inner hole. The tool comprises a main body block, a connectingplate, a honing abrasive strip and an elastic element, wherein the main body block is used for being connected to a vertical-lathe tool rest and is provided with a working end used for pointing to theside wall of an inner hole of a workpiece fixed to a vertical-lathe rotary workbench, and a mounting groove is formed in the working end of the main body block; the connecting plate is embedded in the mounting groove and provided with an extending part protruding out of an opening of the mounting groove, and the connecting plate can slide on a straight line where the pointing direction of the working end is located relative to the mounting groove; the honing abrasive strip is arranged at the tail end of the extending part of the connecting plate; and the elastic element is arranged in the mounting groove, acts on the connecting plate and applies elastic force pointing to the direction outside the mounting groove to the connecting plate. Compared with the prior art, the tool and the methodare simple and efficient, low in cost and capable of adapting to large-diameter inner hole machining with the high roughness requirement, the workpiece can be clamped on a vertical lathe at a time, machining is completed, and the form and location tolerance is guaranteed.

Owner:SHANGHAI DALONG MACHINE FACTORY CO LTD

Production method of automobile steering pipe column seamless steel pipe

InactiveCN111283011AMeet roughness requirementsGuarantee the requirements of the inner and outer diameter of the productMetallic material coating processesIndustrial engineeringHeat treating

The invention provides a production method of an automobile steering pipe column seamless steel pipe. The production method includes the following steps of laying off of a sawing machine, and punchingof a center hole; heating of a pipe blank, hot rolling hole punching and producing a steel billet into a tubular billet; cutting of chamfers at the head end and the tail end; preliminary acid pickling and grinding and modifying, acid pickling, phosphorizing and saponifying; two-roller cold rolling and oil removal heat treatment of the pipe blank; dog hammering treatment of the pipe blank after heat treatment is completed; acid pickling, phosphorizing, saponifying and lubricating treatment of a middle pipe; cold drawing treatment; and following treatment and storage. The traditional machiningcost is greatly reduced, and the purposes that the procedures are simplified, the process is optimized, the production efficiency is improved, and the cost is reduced are achieved.

Owner:HEBEI PROVINCE GOLD MYSTERIOUS PIPE CO LTD

Bridge or house building support friction part convenient to rotate or slide and preparation method thereof

InactiveCN113136795AAdaptableLow production costBridge structural detailsMetallic material coating processesHouse buildingSlide plate

The invention belongs to manufacturing of bridge supports, and particularly relates to a bridge or house building support friction part convenient to rotate or slide and a preparation method thereof. The friction part comprises an organic material sliding plate and a friction surface opposite to the organic material sliding plate, the friction surface comprises a base body and an anti-rust wear-resistant layer, and the anti-rust wear-resistant layer is arranged on the outer surface of the base body in a laser cladding mode. The problems that in the prior art, adjacent structural layers are not tightly matched, and the manufacturing cost is high are solved, and the beneficial effects that the adjacent structural layers are tightly matched, environmental pollution is reduced, and the machining efficiency is improved are achieved.

Owner:HENGSHUI ZHONGJIAO XINDE ENG RUBBLE & PLASTIC

Surface treatment process of pot

PendingCN114472113AMeet the requirements of surface roughnessMeet roughness requirementsCooking-vessel materialsPretreated surfacesChemical solutionSurface roughness

The surface treatment process of the pot comprises the following steps: S1, oil removal: carrying out oil removal treatment on the inner surface of a pot body needing to be treated by using a degreasing agent in a spraying state; s2, chemical solution spraying, wherein the chemical solution is atomized and coated on the inner surface of the pot body needing to be treated through a spray gun; s3, inner spraying, wherein PTFE or water-based ceramic is sprayed to the inner surface of the pot body needing to be treated through an air spray gun; and S4, high-temperature curing: after the pot body sprayed with the PTFE or the water-based ceramic is heated, the PTFE or the water-based ceramic is cured to form a non-stick coating film. The surface of a base material can be uniformly covered with the coating through chemical solution spraying, the coating and the base material form certain roughness through chemical bonds, and then the requirement of water-based ceramic spraying construction or PTFE spraying construction for the surface roughness of the base material is met. The process has the following two advantages: firstly, the sand blowing procedure is reduced, and the process cost is saved; and secondly, the phenomenon that the staff work in a dust environment to cause the lung silicon disease is avoided.

Owner:ZHEJIANG SANHO KITCHENWARE

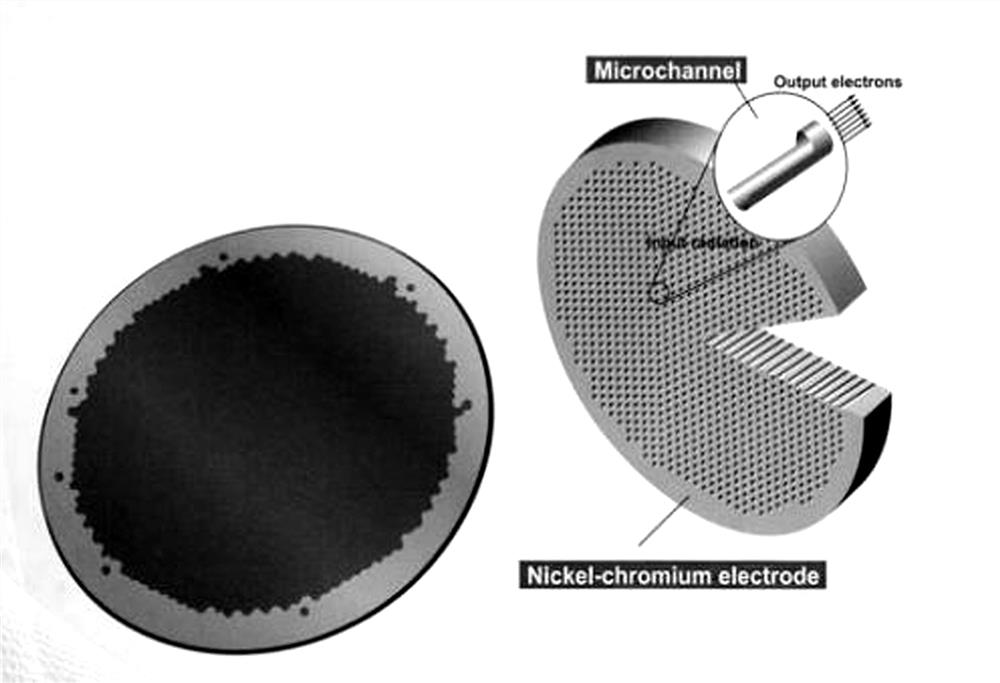

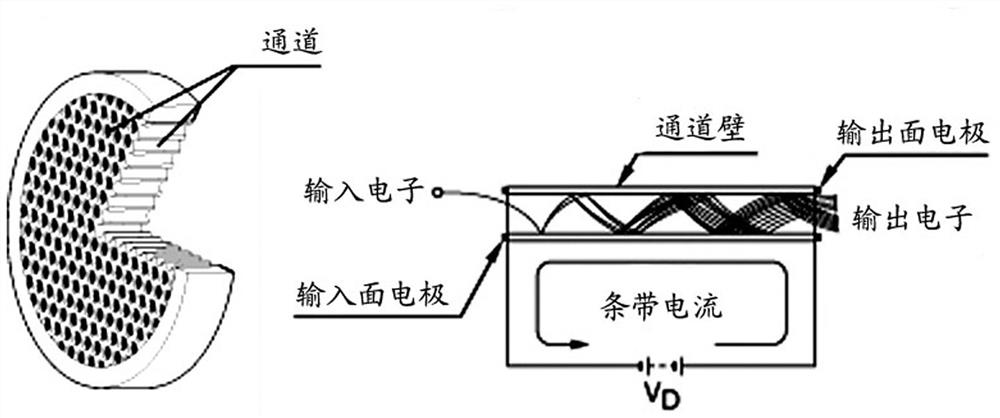

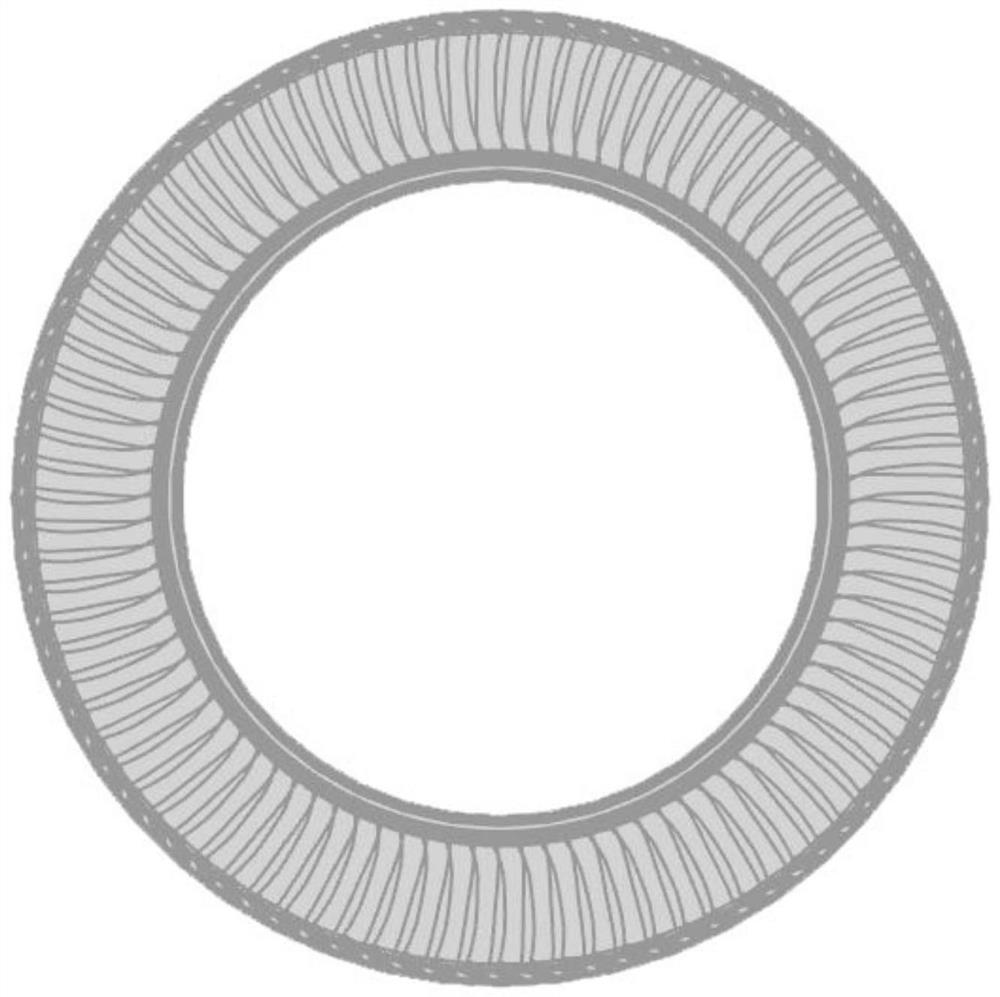

In-channel polishing method of microchannel plate

ActiveCN111029230BMeet roughness requirementsReduce roughnessMutiple dynode arrangementsCold cathode manufactureElectron multiplierMaterials science

The invention discloses a polishing method in the channel of a micro-channel plate, which relates to the field of manufacturing optimization of an electron multiplier micro-channel plate. Aiming at the micro-hole array glass blank that has been manufactured by using the traditional process, firstly, the nitric acid-hydrofluoric acid mixed solution is used for polishing. Ultrasonic vibration, and then replace the new nitric acid hydrofluoric acid mixture with a magnetic stirrer for a certain period of time, and use pure water to perform multiple water changes for cleaning; secondly, use a magnetic stirrer for a certain period of time in the hydrofluoric acid + sulfuric acid mixture. Then use pure water for multiple water changes and cleaning; then mix hydrofluoric acid + sulfuric acid + ammonium fluoride, stir in a magnetic stirrer, then use pure water for multiple water changes and cleaning; finally use ethanol solution to clean and put After roasting in a vacuum oven for a certain period of time, the internal polishing of the microchannel is achieved. The internal polishing method provided by the present invention meets the purpose of the ALD process for the roughness of the channel wall. This process avoids damage to the channel wall caused by traditional acid corrosion. Causes issues with launch points.

Owner:山西长城微光器材股份有限公司

A Method of Using Metal Pipe Wrinkles to Realize Circular Connection

Owner:SHAANXI UNIV OF SCI & TECH

Spiral groove processing method

The invention discloses a method for machining a spiral groove. The method includes the following steps that (1) a plurality of round holes arranged at intervals are formed in the surface of a workpiece by means of a drill according to the spiral line of the spiral groove; (2) the sector allowance between every two adjacent round holes of the workpiece is removed by means of the drill, so that a rough spiral groove is formed; (3) finish machining is conducted on the rough spiral groove by means of a milling cutter, so that the spiral groove is obtained. After most allowance is removed by means of the drill, the milling cutter is used for finish machining. The speed of the drill for machining the round holes to remove the allowance is higher than that of the milling cutter for grinding the allowance, and thus the machining speed can be increased. Besides, most allowance of the spiral groove is removed in the machining process of the rough spiral groove, and thus machining can be conducted through the milling cuter at a high speed and the machining speed of the spiral groove is further increased. The portion ground by the milling cutter is small, and therefore the abrasion loss is small, the machined spiral groove is protected against a slotting phenomenon, and the requirement for the roughness can be met. Polishing and repairing are not needed, so that the number of working procedures is reduced, and the machining speed is further increased.

Owner:AVIC POWER ZHUZHOU AVIATION PARTS MFG

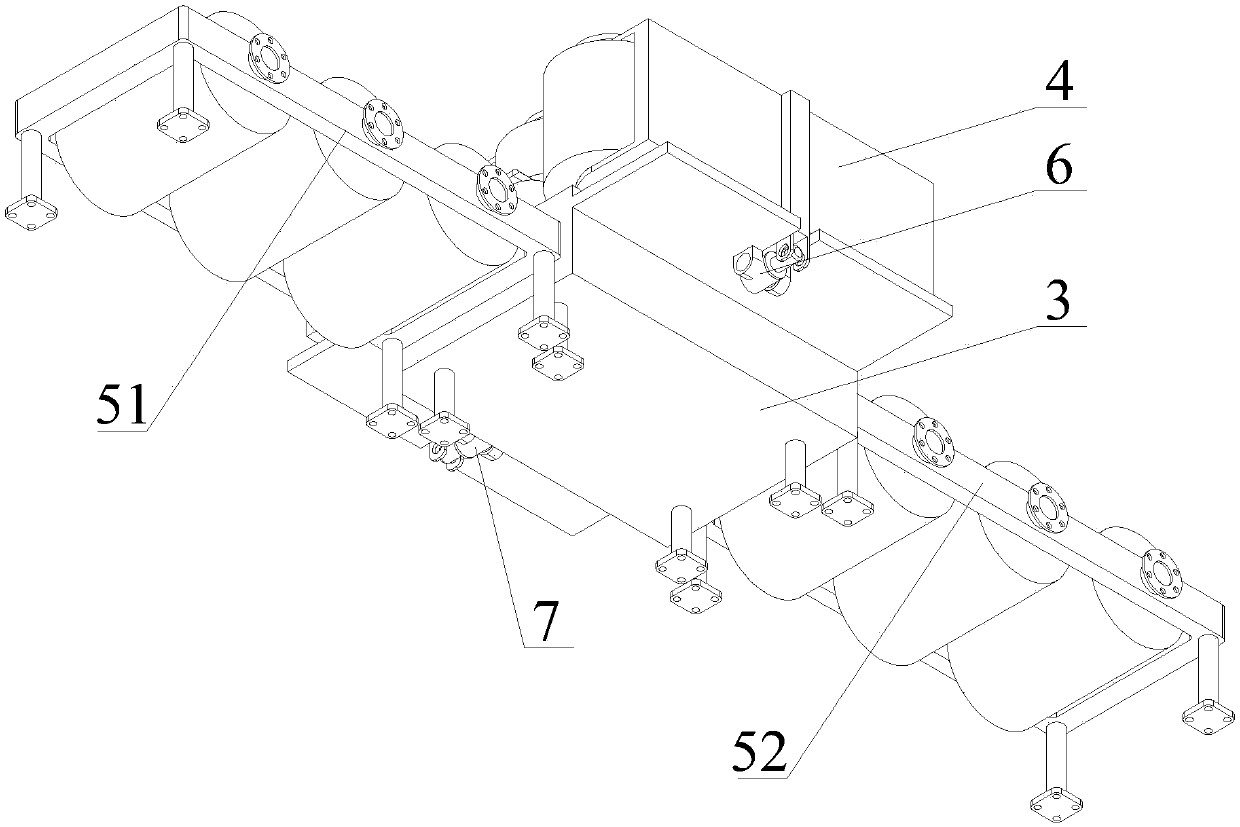

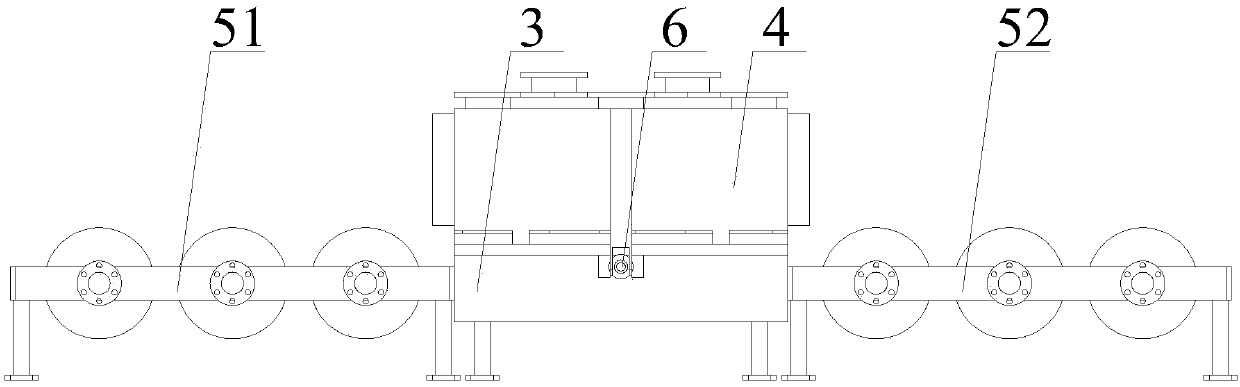

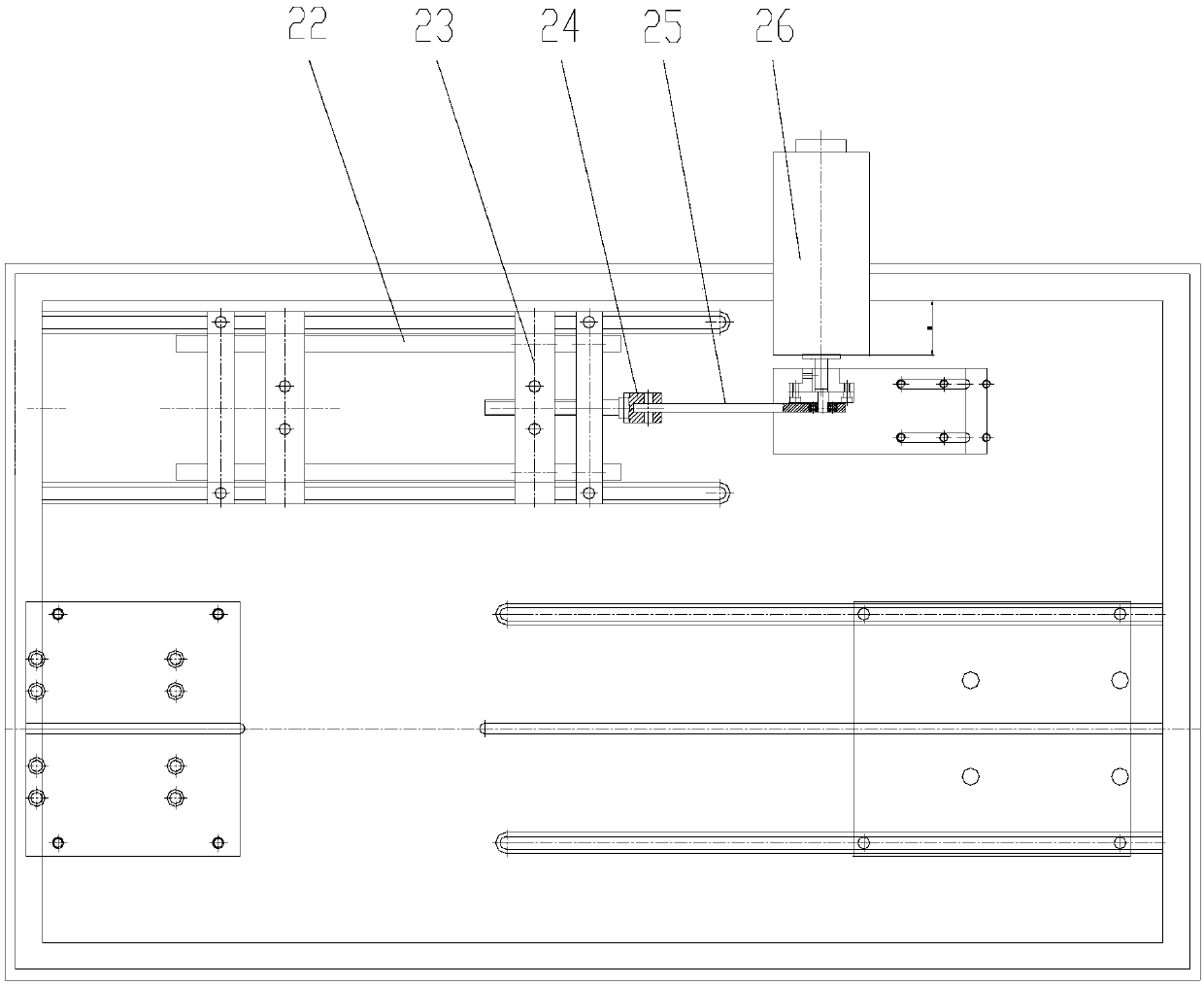

Rolling-type portal groove steel low-temperature correction device

ActiveCN109622671ASolve the deformationMeet size requirementsArchitectural engineeringDeep processing

The invention belongs to the technical field of steel deep processing, and particularly relates to a rolling-type portal groove steel low-temperature correction device. The rolling-type portal groovesteel low-temperature correction device comprises a workbench used for transporting portal groove steel and providing a mounting position, an inner side correction roller assembly mounted on the workbench and used for correcting inner side leg flanges of the portal groove steel, a side edge correction roller assembly mounted on the workbench and used for correcting an outer side leg flange on oneside of the portal groove steel and a unilateral flange on one side of the portal groove steel, and a combined correction roller assembly mounted on the workbench and used for correcting an outer sideleg flange on the other side of the portal groove steel and a unilateral flange on the other side of the portal groove steel. The problem of finished steel product deformation can be solved, use performance of the portal groove steel is guaranteed, it is guaranteed that the steel meets the requirements of size and surface flatness and roughness, and the characteristics of high correction efficiency and high shaping precision are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

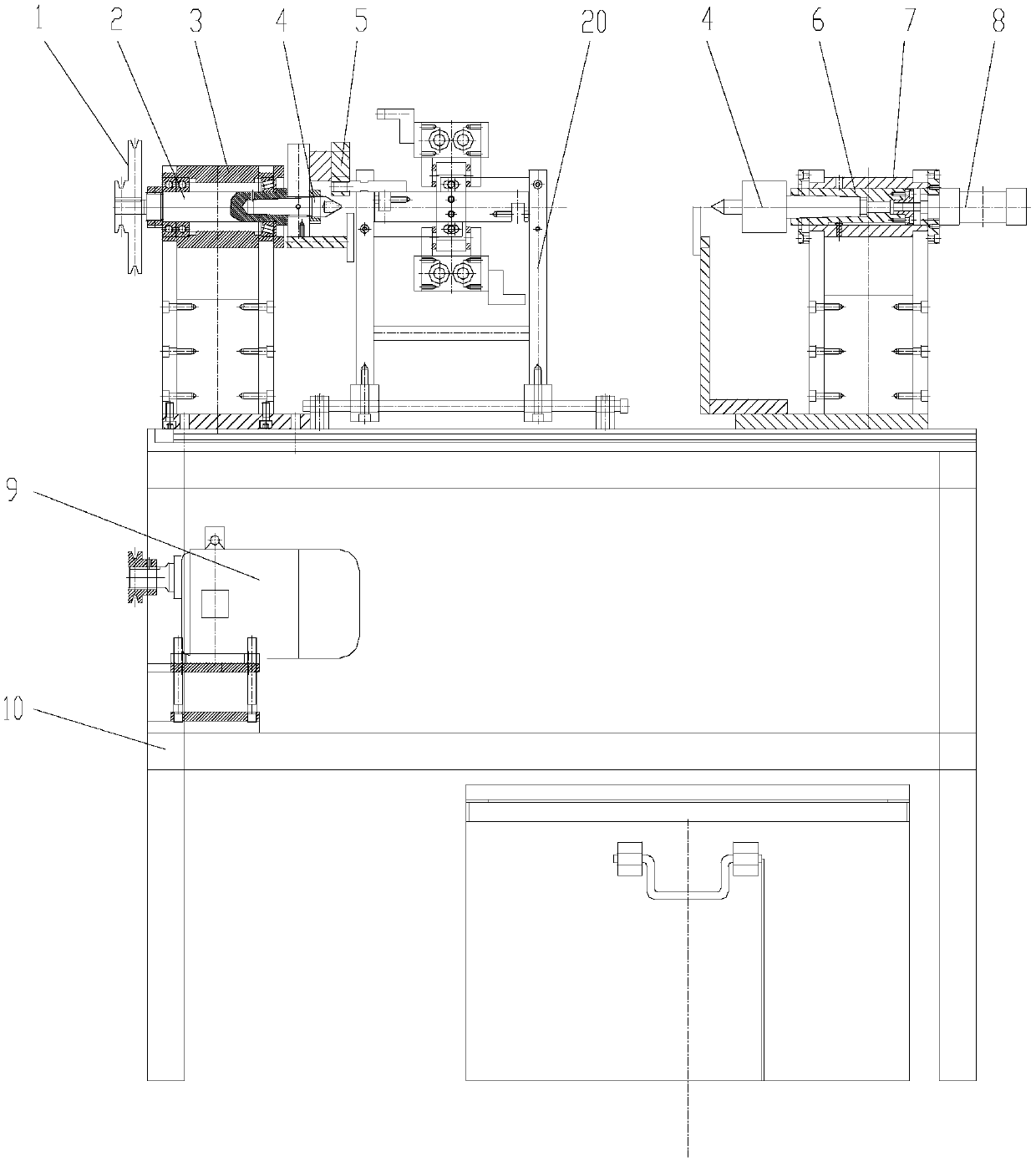

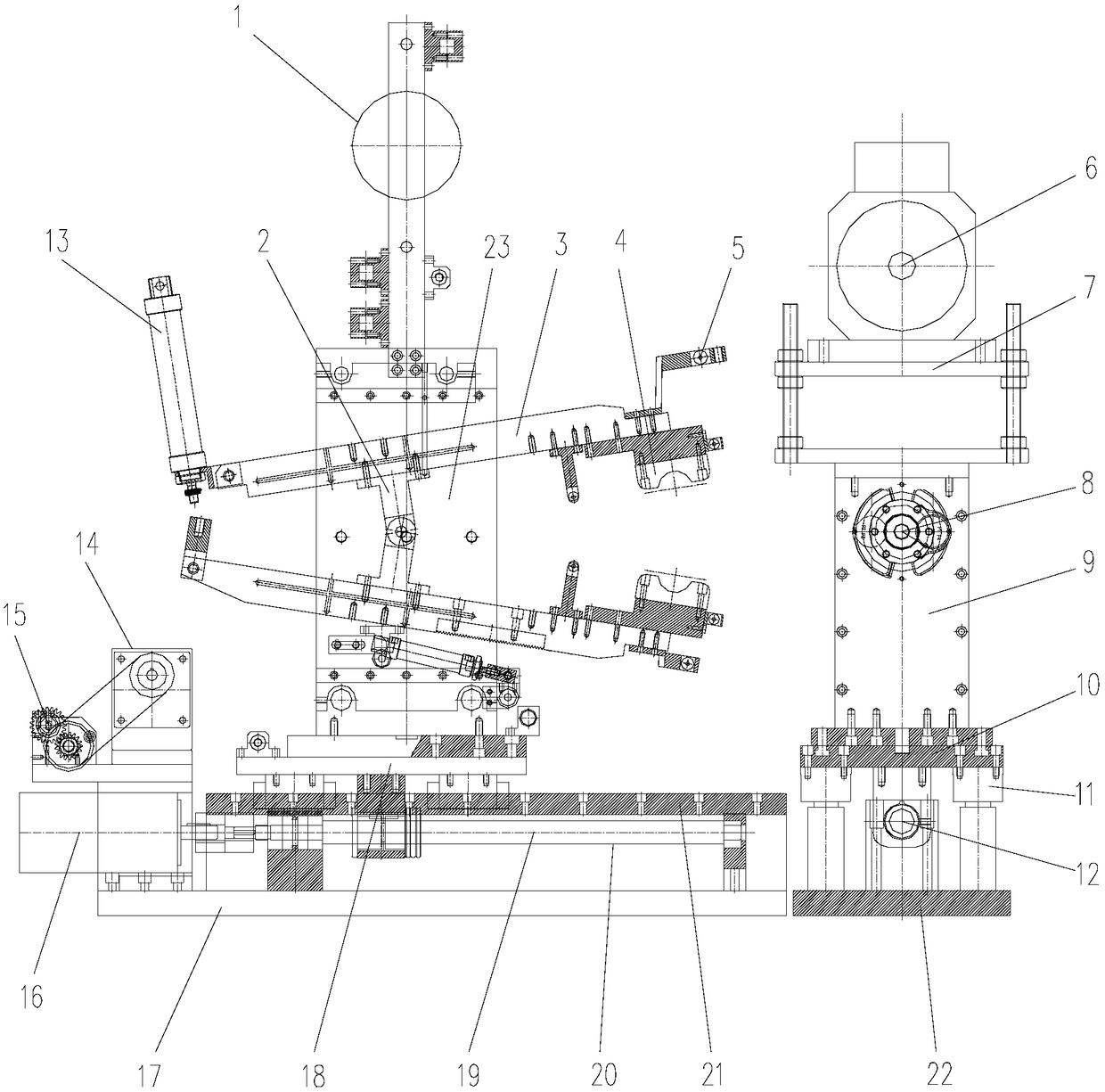

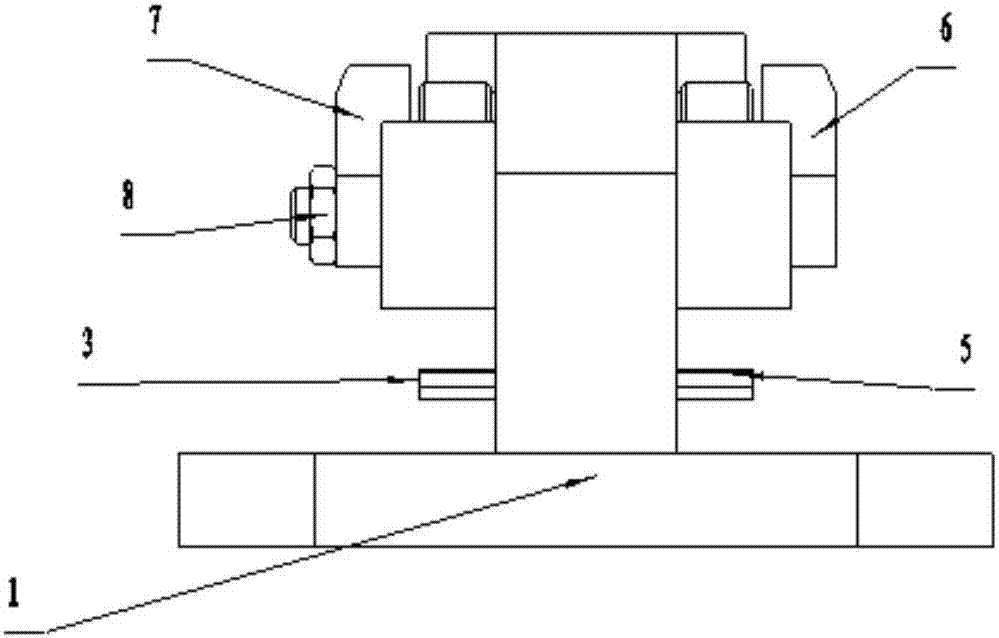

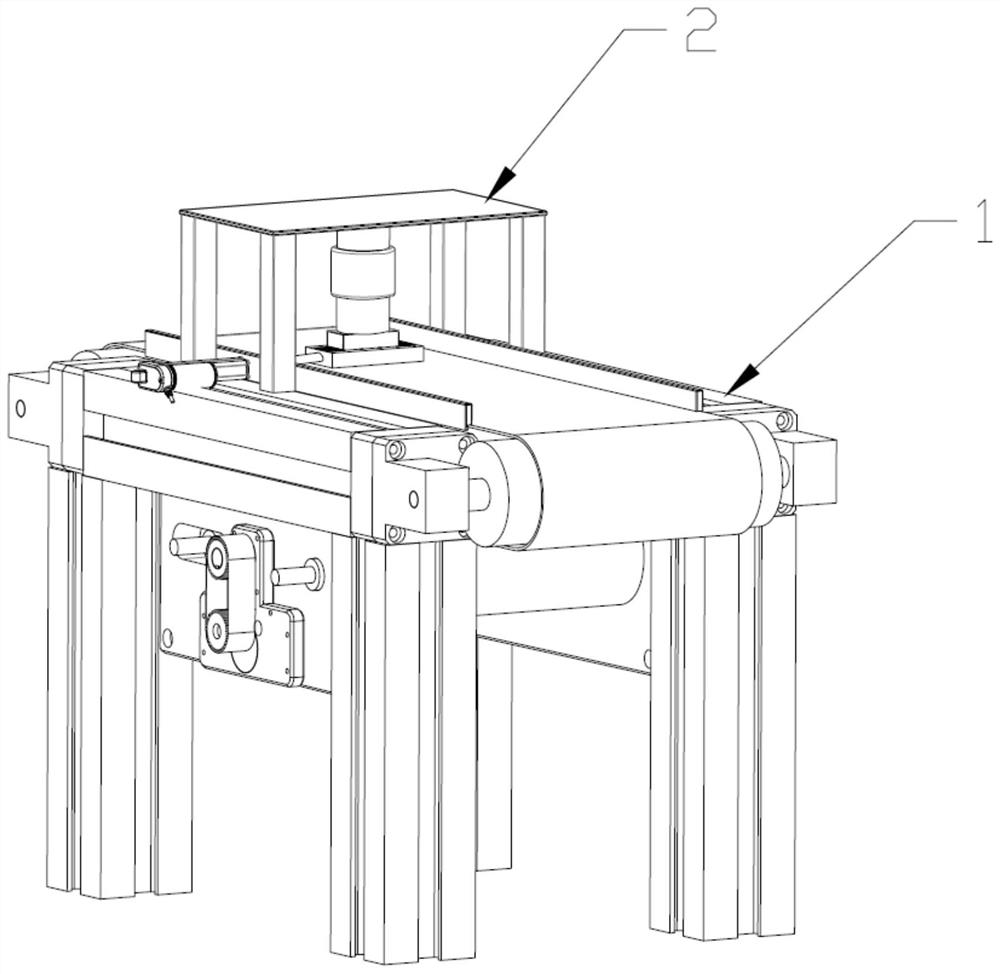

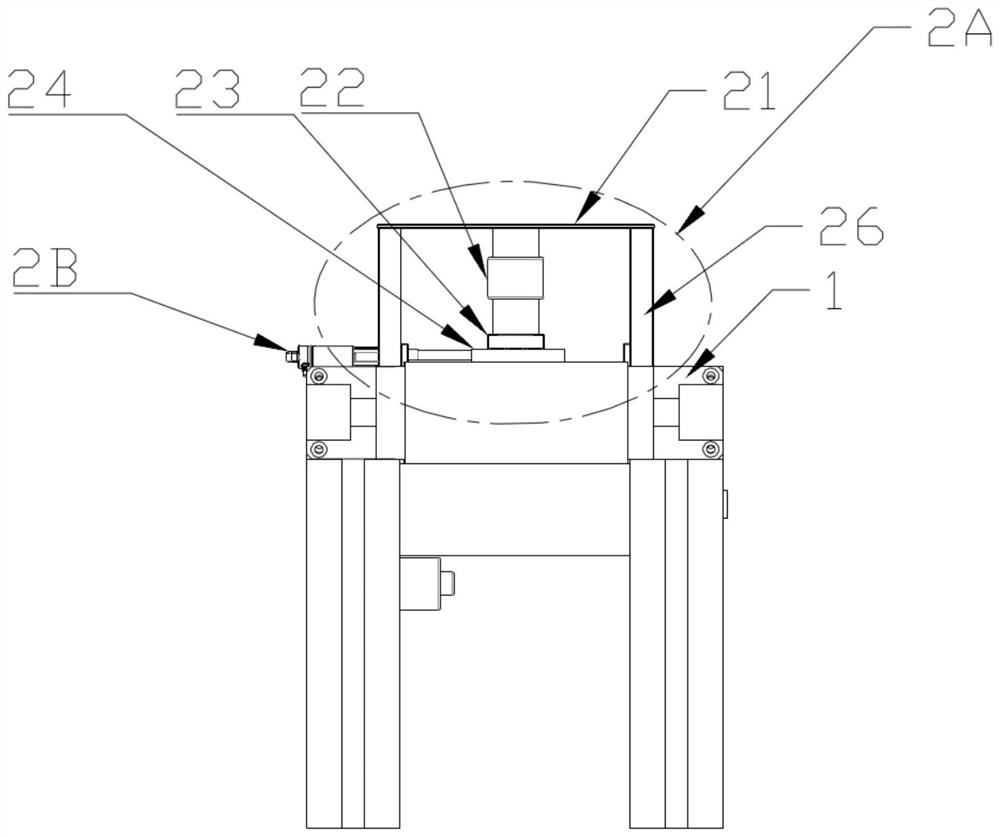

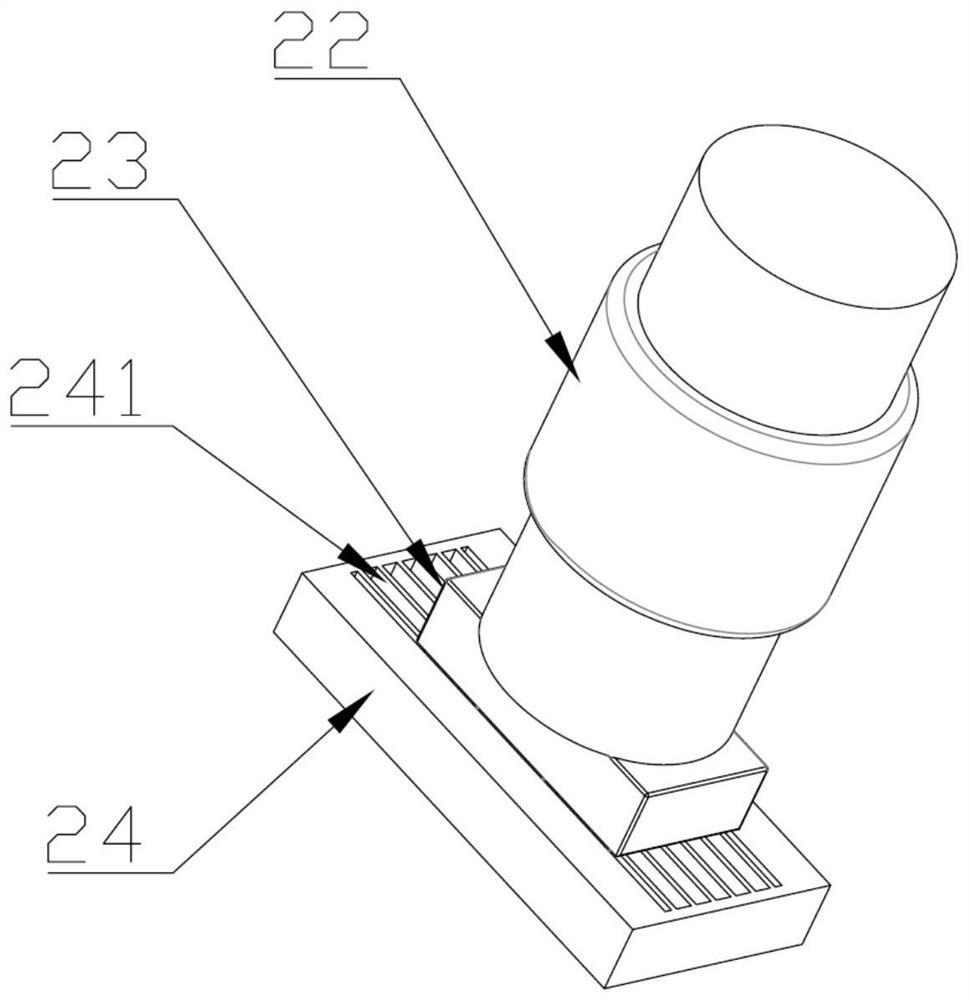

General machine crankshaft crank polishing machine

InactiveCN109531373AMeet roughness requirementsImprove the lubrication effectPolishing machinesGrinding drivesSurface roughnessEngineering

The invention discloses a general machine crankshaft crank polishing machine which comprises a machine frame, a swing speed regulating motor, a head frame motor, a crankshaft clamping device, a swingdevice, a polishing device and a tape winding device. The motor is installed on the machine frame through a motor fixing plate, the crankshaft clamping device, the swing device and the tape winding device are installed and fixed to the machine frame, and the polishing device is installed on the swing device. According to the general machine crankshaft crank polishing machine, a general machine crankshaft crank can be polished to obtain overlapping curves, a good lubricating effect is achieved, the surface roughness of a general machine crankshaft crank shaft neck can reach Ra0.1, and the requirement for cam surface roughness is met.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low-roughness processing method and equipment for zirconia ceramic structural parts

ActiveCN108067943BEnsure Surface Roughness VerificationImprove stabilityStone-like material working toolsMilling cutterGrinding wheel

The invention provides a low-roughness processing method for zirconia ceramic structural parts. The low-roughness processing method comprises the following steps that first, a grinding wheel rod I isused for initial repairing; second, a grinding wheel rod II is used for middle repairing; and third, a milling cutter is used for lateral layering processing, and the product is obtained; and the calculating mode of the layer number of layering processing comprises the formula that the layer number M = the required processed balance P on the zirconia ceramic structural parts after middle repairingis finished / the amount of feed N of a single milling cutter. By applying the technical scheme, the processing method comprises the steps of initial repairing, middle repairing and lateral layeringprocessing through the milling cutter, the technology steps are simplified, technology requirements are easily controlled, the required roughness requirements can be met, and it can be ensured that the qualified rate of the product is 98% or above. The invention further provides equipment adopted by low-roughness processing of the zirconia ceramic structural parts. The equipment comprises the milling cutter and a CNC machine tool. Assembling of the equipment is convenient, the CNC machine tool is adopted to control the processing parameters, and it is ensured that the qualified rates of the one-time size and the roughness are 98% or above.

Owner:LENS TECH CHANGSHA

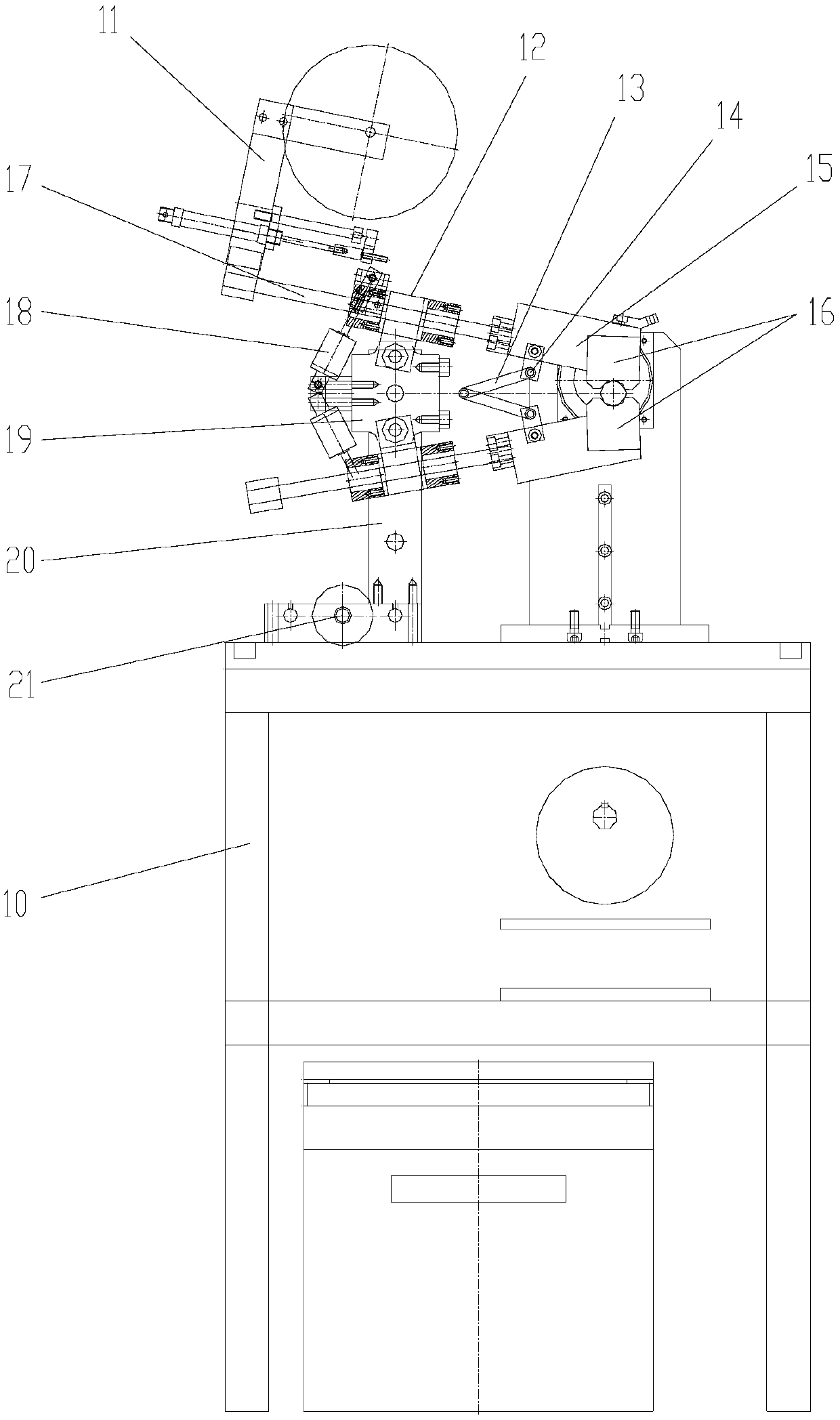

Automatic abrasive band polishing special machine of general machine crankshaft

The invention discloses an automatic abrasive band polishing special machine of a general machine crankshaft. The automatic abrasive band polishing special machine comprises a workpiece clamping partand a polishing machining part. The workpiece clamping part comprises a first base, a workpiece sliding table, a headstock and a headstock motor. The headstock is fixedly mounted on the workpiece sliding table. The polishing machining part comprises a second base, a polishing frame sliding table, a polishing frame vertical plate, polishing arms, polishing heads, a polishing clamping air cylinder,an abrasive band wheel, an abrasive band guide wheel and an abrasive band winding assembly. The middles of the two polishing arms are rotationally mounted on the polishing frame vertical plate througha transverse rotating shaft. The ends, close to the headstock, of the two polishing arms are each fixedly provided with the corresponding polishing head. A polishing mechanism swings along with rotary motion of a connecting rod bent neck, relative sliding is generated between the polishing heads and a connecting rod journal, polishing is carried out through relative sliding between the polishingheads and the rod journal, the surface roughness of a main journal and the connecting rod journal reaches Ra0.1 through the polishing effect, and any requirement for crankshaft surface roughness can be met basically; and the machine already becomes the leading product of the company for several years.

Owner:重庆希泽机械设备制造有限公司

Lock hook grinding notch clamp and using method thereof

PendingCN107263313AGuaranteed machining accuracyGuaranteed processing progressGrinding work supportsGrinding wheelScrew thread

The invention discloses a lock hook grinding notch clamp and a using method thereof, and belongs to the technical field of machining. A main body is of an inverted-T-shaped structure and is installed on the surface of a machine tool. Locating pin holes and threaded holes are symmetrically formed in the two sides of the main body. To-be-ground notches of two lock hooks are of a notch structure at the upper end of the main body so that the lock hooks at the two sides of the clamp can be ground at the same time. The two lock hooks are installed at the two sides of the main body through locating pins, and the effect that the notches of the lock hooks face upwards is guaranteed so that a grinding wheel on the machine tool can be matched for grinding. The two lock hooks are clamped through pressing plates separately and are further fixedly installed through matching of bolts and nuts. Two parts can be machined by means of one-time operation. By the adoption of the lock hook grinding notch clamp, time consumption in clamp splicing is reduced, the time is short and efficiency is high. The structure is simple, operation is convenient, two-hole location is utilized so that stability and reliability can be achieved, and product quality is improved. The lock hook grinding notch clamp is convenient to manufacture, capable of being used for a long time and economic. The clamp is small in size, high in precision, capable of being carried and used conveniently and further capable of guaranteeing part machining accuracy and meeting the working schedule needs.

Owner:SHENYANG AIRCRAFT CORP

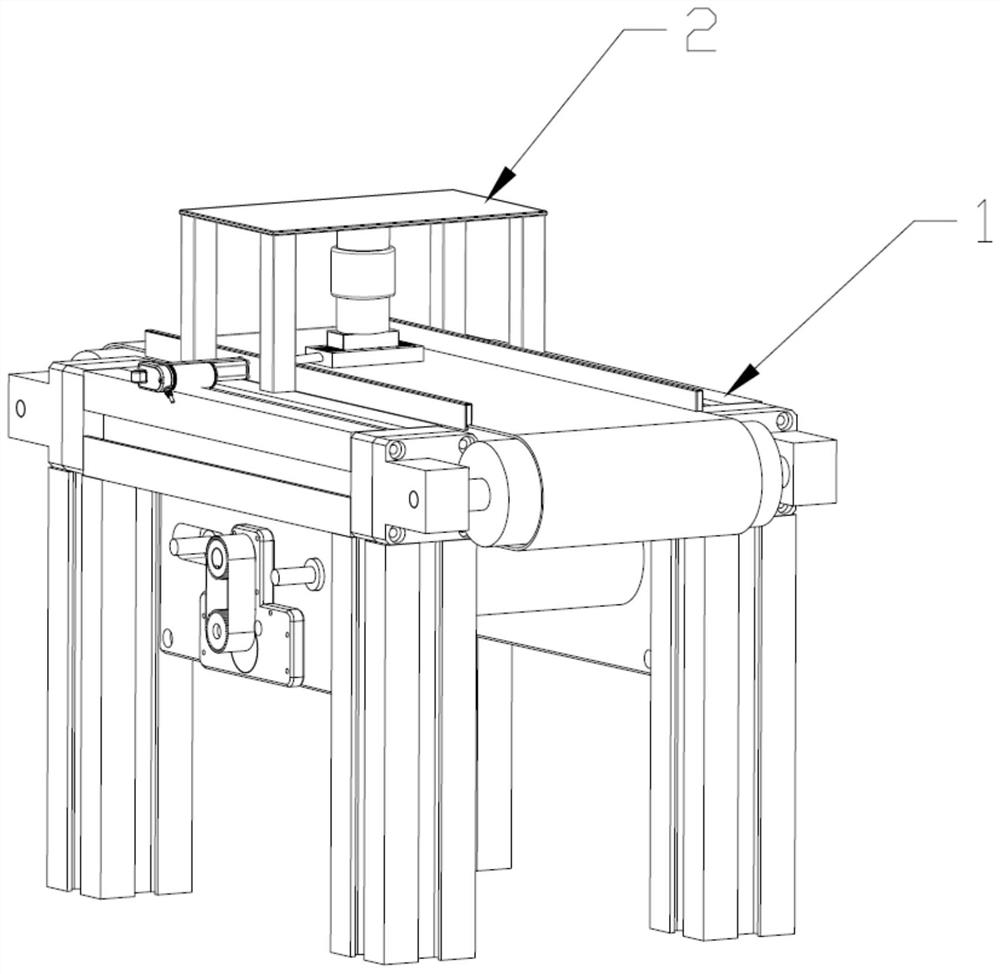

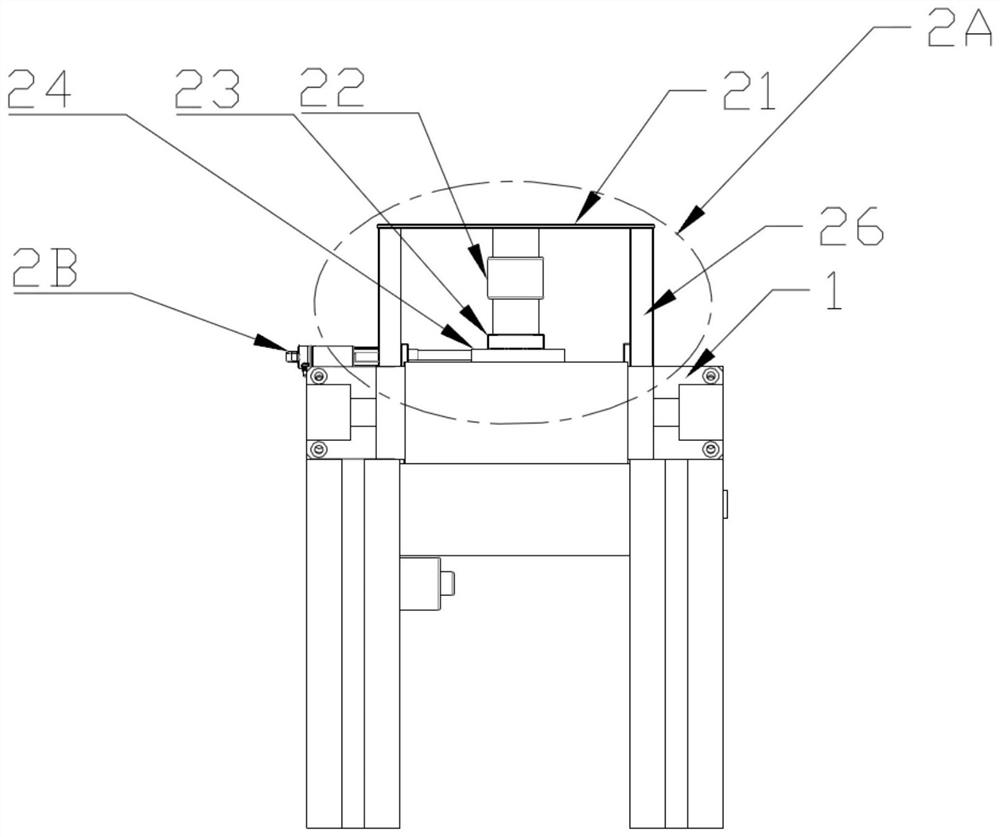

Grinding machine applied to magnesium alloy diaphragm

ActiveCN113043132AMeet roughness requirementsSimple structureGrinding drivesBelt grinding machinesMetallurgyEmery paper

The invention discloses a grinding machine applied to a magnesium alloy diaphragm. The grinding machine comprises a conveying mechanism and a grinding mechanism, the conveying mechanism is used for conveying abrasive paper, and the grinding mechanism is installed on the conveying mechanism and makes contact with the conveying mechanism. According to the grinding machine applied to the magnesium alloy diaphragm, the conveying device is adopted for conveying abrasive paper of different mesh numbers, so that the magnesium alloy diaphragm meets the requirement for roughness, the magnesium alloy diaphragm is automatically ground through the design of a grinding tool, and the grinding tool is designed to meet the requirement for the grinding thickness.

Owner:浙江沣沅生物科技有限公司

A grinding machine applied to magnesium alloy diaphragms

ActiveCN113043132BMeet roughness requirementsSimple structureGrinding drivesBelt grinding machinesSandpaperMagnesium alloy

The invention discloses a grinding machine applied to a magnesium alloy diaphragm, comprising a transmission mechanism and a grinding mechanism. The transmission mechanism is used for transmitting sandpaper, and the grinding mechanism is arranged on the transmission mechanism and is in contact with the transmission mechanism. The grinding machine applied to the magnesium alloy diaphragm of the present invention adopts a transmission device to transmit sandpapers of different meshes, so that the magnesium alloy diaphragm can meet the roughness requirements, and realizes automatic grinding of the magnesium alloy diaphragm through the design of the grinding tool, and realizes automatic grinding of the magnesium alloy diaphragm. The abrasive tool is designed to meet the requirements of grinding thickness.

Owner:浙江沣沅生物科技有限公司

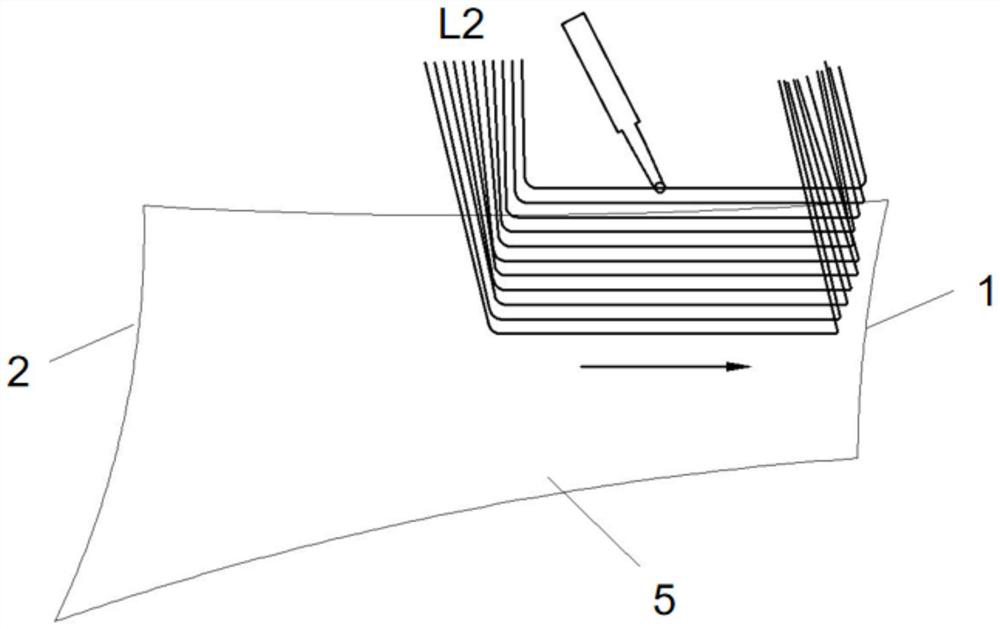

Five-axis numerical control milling method for integral blade ring

PendingCN114871481AAppropriate rake angleReduce overhang lengthEfficient propulsion technologiesMilling equipment detailsNumerical controlMilling cutter

The invention provides an integral blade ring five-axis numerical control milling method, and belongs to the technical field of integral blade ring machining, and the integral blade ring five-axis numerical control milling method comprises the steps that an exhaust end upper flow channel area, an exhaust end lower flow channel area, an air inlet end upper flow channel area and an air inlet end lower flow channel area are divided by taking the middle position as a boundary; designing a layer milling cutter rail of each area; the layer milling cutter rails of the exhaust end upper flow channel area and the layer milling cutter rails of the exhaust end lower flow channel area are combined according to a certain proportion, the middle position of the grooving area serves as a lower cutter point, a cutter is at a negative angle, a layer is milled in the direction of the upper flow channel firstly, then a layer is milled in the direction of the lower flow channel, and the steps are repeated, so that grooving and milling of the exhaust end are completed; and combining the layer milling cutter rails in the upper runner area of the air inlet end and the layer milling cutter rails in the lower runner area of the air inlet end according to a certain proportion, and completing the slotting and milling of the air inlet end by the same steps as the slotting and milling steps of the air outlet end. The blade profile surface allowance is uniform, and cutter shaft vector milling does not need to be selected for many times.

Owner:AECC AERO SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com