Sand core repair paste, preparation method thereof and sand core

A repair paste and sand core technology, which is applied in the field of foundry core making, can solve the problems of sand sticking and other pores, reduce the gas production of sand cores, increase the gas production of sand cores, etc., achieve moderate viscosity, and improve sticky sand and pores. , The effect of improving the overall quality of the sand core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

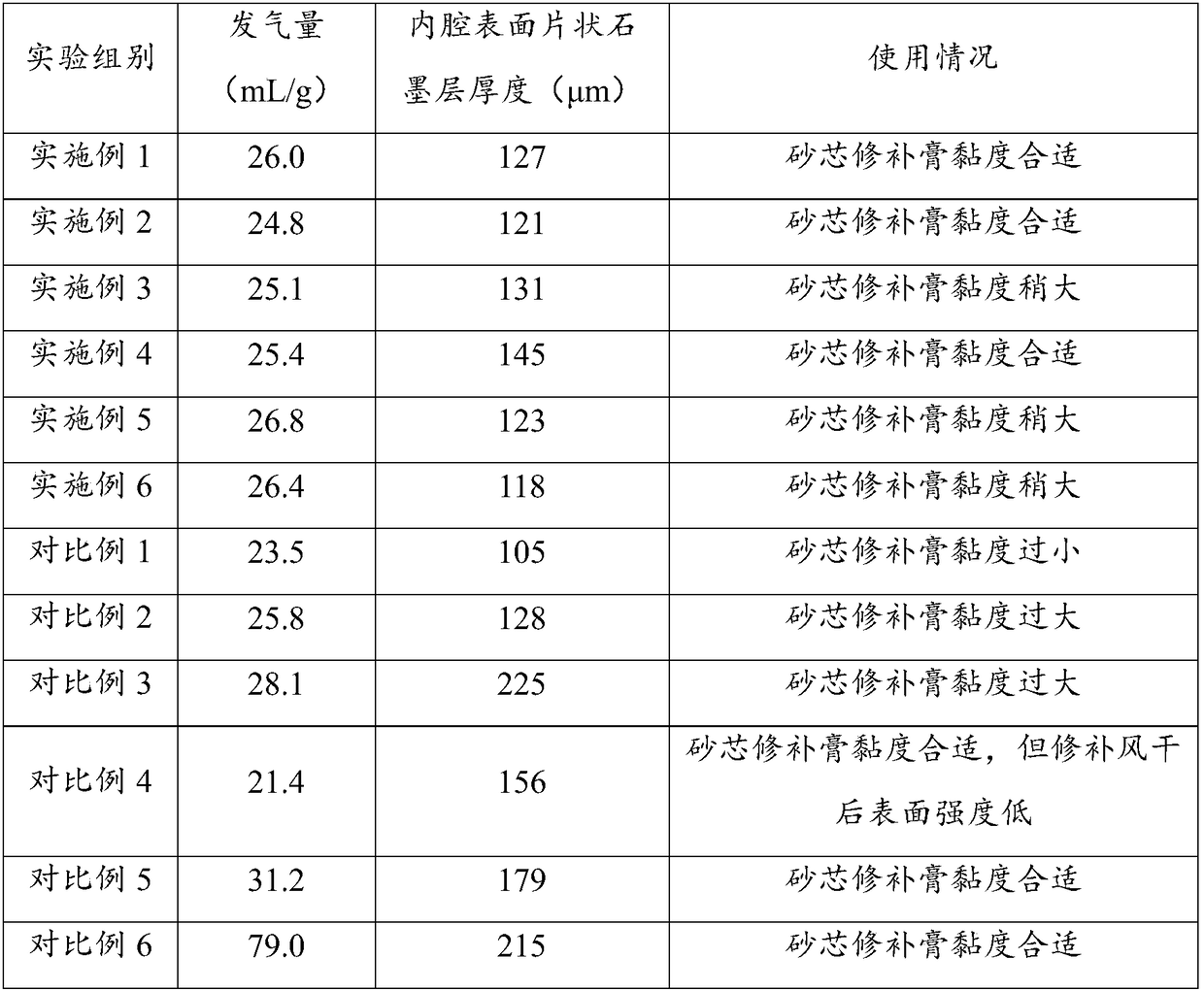

Examples

Embodiment approach

[0046]As a preferred embodiment of the present invention, the sand core repair paste includes the following raw materials in parts by weight: 45-60 parts of the first coating, 30-50 parts of the second coating and 3.5-8 parts of bentonite.

[0047] Preferably, the sand core repair paste includes the following raw materials in parts by weight: 45-55 parts of the first paint, 35-50 parts of the second paint and 4-7 parts of bentonite.

[0048] By further limiting the amount of each raw material, the prepared sand core repair paste has a lower gas generation and a more suitable viscosity, which is beneficial to the application in the subsequent sand core repair process.

[0049] As a preferred embodiment of the present invention, the first paint is the paint of Sanmenxia Sunshine YG-104, and the second paint is the paint of Shanghai Niujie HQ208.

[0050] The synergistic effect between the first paint, the second paint and the bentonite is more remarkable by specifying the grades...

Embodiment 1

[0073] A kind of sand core repair paste provided by the present embodiment comprises the following raw materials in parts by weight: 45 parts of the first coating, 50 parts of the second coating and 5 parts of bentonite;

[0074] Among them, the first paint is Sanmenxia Yangguang YG-104 water-based aluminum-silicon composite paint, the second paint is Shanghai Nujie HQ208 water-based paint, and the bentonite is Liaoning Jianping Keli PNa-12-35 bentonite, with a swelling value of 97.

[0075] The preparation method of this sand core repair paste comprises the following steps:

[0076] Mix and stir the first paint, the second paint and bentonite in the formulated amount for 20 minutes until they are uniform, and obtain the sand core repair paste.

Embodiment 2

[0078] A kind of sand core repair paste provided by the present embodiment comprises the following raw materials in parts by weight: 50 parts of the first coating, 47 parts of the second coating and 3 parts of bentonite;

[0079] Among them, the first paint is Sanmenxia Yangguang YG-104 water-based aluminum-silicon composite paint, the second paint is Shanghai Nujie HQ208 water-based paint, and the bentonite is Liaoning Jianping Keli PNa-12-35 bentonite, with a swelling value of 97.

[0080] The preparation method of the sand core repair paste provided in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com