Method for processing large-diameter figure-eight-shaped hole series

A processing method and figure-eight technology, applied in the field of machining, can solve the problems of sag deformation of the tool bar, overcutting, long processing path, etc., so as to improve the dimensional accuracy and shape and position accuracy, reduce the radial cutting force, The effect of easy control of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments, and all equivalent changes and modifications made according to the contents of this description belong to the patent application of the present invention scope of protection.

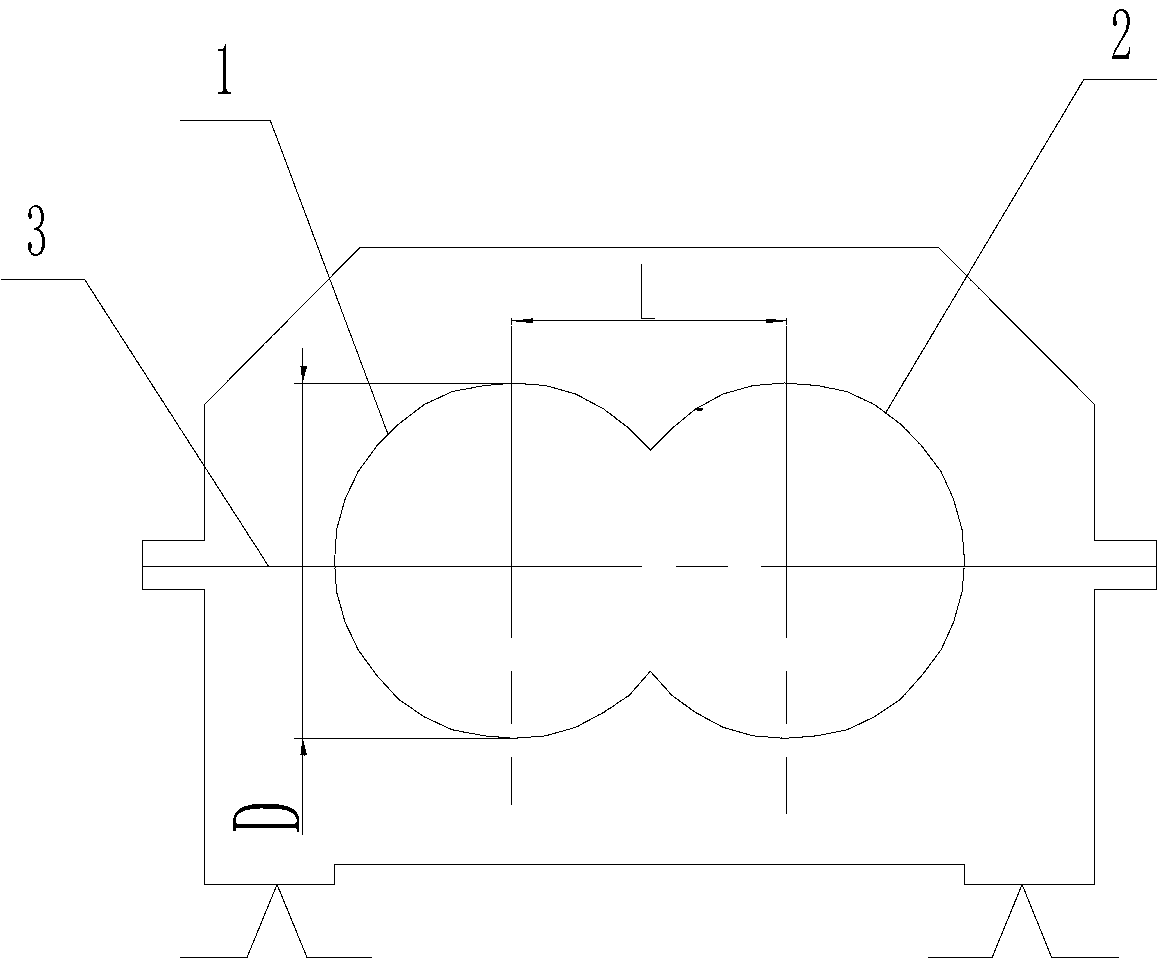

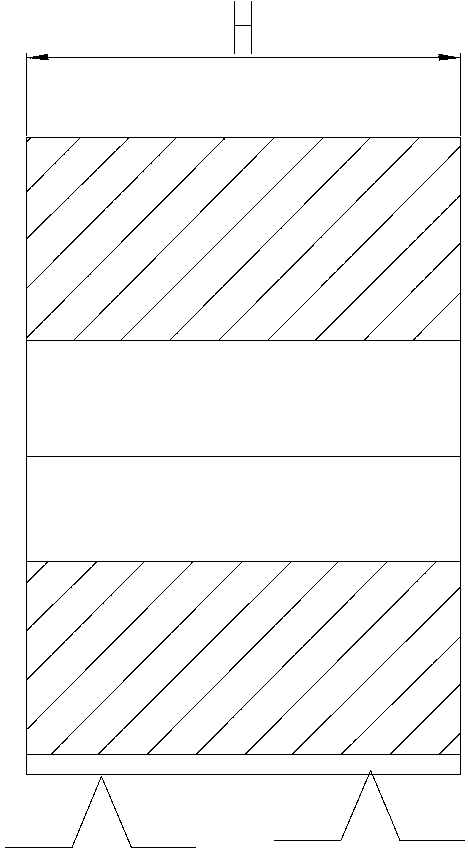

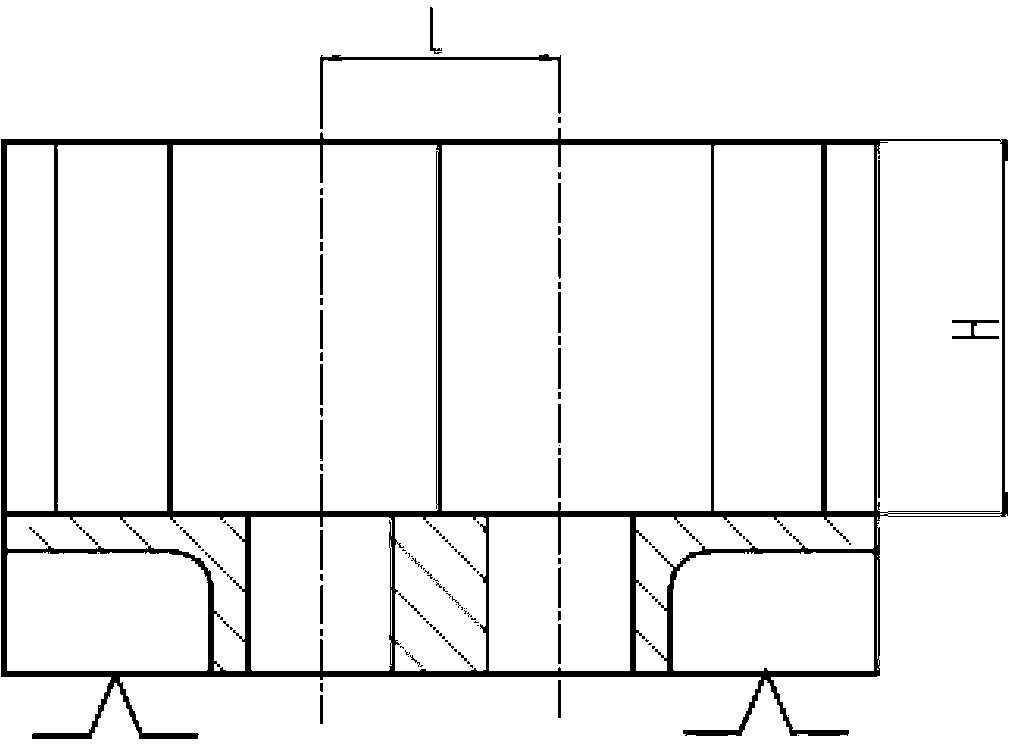

[0026] see image 3 , this embodiment takes the processing of the largest large-scale rotary screw machine casing in China as an example to illustrate the content of the present invention. The casing has a figure-eight hole system formed by the parallel intersection of the first hole 1 and the second hole 2. The diameter D of the hole 1 and the second hole 2 and its dimensional accuracy are Φ816.7H9 mm, the roughness of the hole wall is Ra1.6, the center distance L between the two holes and its precision are 640 +0.03 mm, the hole depth H is 1000 mm, and the cylindricity accuracy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com